asme safety valve code manufacturer

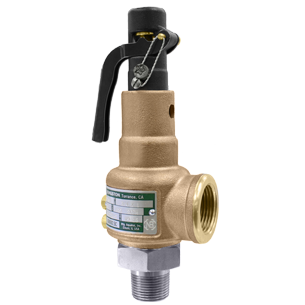

The Kingston Model 110C High Pressure Safety Valve is an ASME Code Certified, precision machined valve with a hard seat. This valve features support for high pressure applications up to 600 psi. It comes equipped with manual test lever and is construction is of cast brass alloy body, machined brass stem with stainless steel ball, seated on a stainless steel base. The Kingston Model 110C High Pressure Safety Valve approved in Massachusetts and Washington DC and is stamped with UV and NB symbols. Registered in all Canadian provinces and territories.

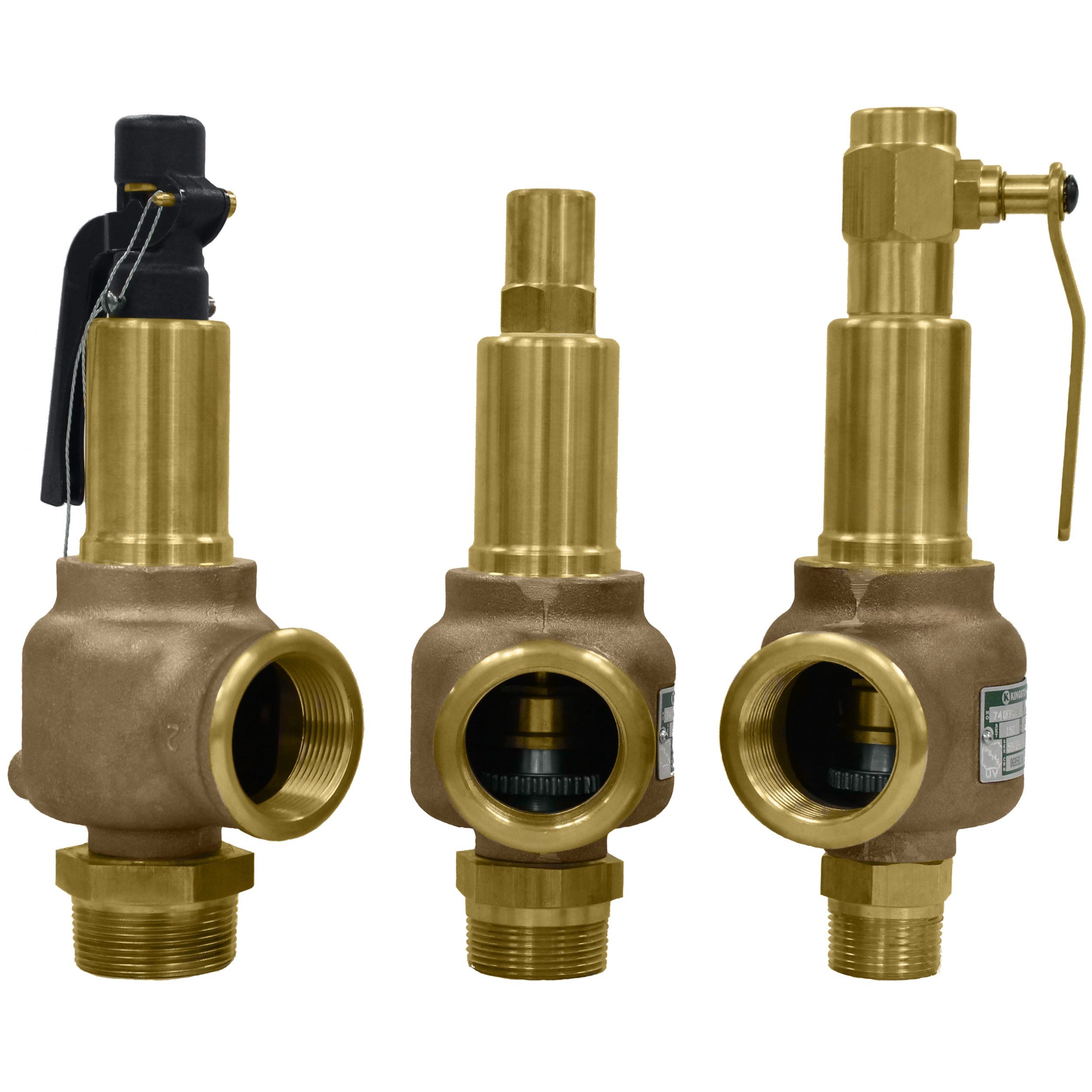

Kingston Model 115 ASME Code Soft Seat Safety Valves are constructed of brass with a Viton seal and positive stop for a bubble-tight seal. This valve is equipped with a pull ring for manual testing. Internal construction and performance are the same as Model 114 differing only by the pull ring. The Kingston Model 115 ASME Code Soft Seat Safety Valve, like every Kingston Safety Valve, is set and tested at factory for quality and dependability. The Kingston Model 115 ASME Code Soft Seat Safety Valve is approved in Massachusetts and Washington DC and is stamped with UV & NB symbols. Registered in all Canadian provinces and territories.

Disclaimer: This Code of Ordinances and/or any other documents that appear on this site may not reflect the most current legislation adopted by the Municipality. American Legal Publishing Corporation provides these documents for informational purposes only. These documents should not be relied upon as the definitive authority for local legislation. Additionally, the formatting and pagination of the posted documents varies from the formatting and pagination of the official copy. The official printed copy of a Code of Ordinances should be consulted prior to any action being taken.

For further information regarding the official version of any of this Code of Ordinances or other documents posted on this site, please contact the Municipality directly or contact American Legal Publishing toll-free at 800-445-5588.

Pressure Safety and Relief Valves (PSV) are totally directed by codes and regulations. The four most important codes and standards for PSVs (safety valve standards) are ASME (USA), API (USA),ISO (international) and PED (Europe).

ISO 4126-6.Safety devices for protection against excessive pressure — Part 6: Application, selection and installation of bursting disc safety devices.

ISO 4126-9.Safety devices for protection against excessive pressure — Part 9: Application and installation of safety devices excluding stand-alone bursting disc safety devices.

ISO 4126-10.Safety devices for protection against excessive pressure — Part 10: Sizing of safety valves for gas/liquid two-phase flow.ISO Pressure relief code

Austria.SAA AS 1271.Safety valves, other valves, liquid level gauges and other fittings for boilers and unfired pressure vessels.Other Countries Pressure Relief International ISO Codes

Safety and Relief Valves are completely governed by codes and regulations. The two major codes are ASME (USA) and PED (Europe), and both are laws and failure to comply is a criminal offence. As you would imagine, they are both very similar but also do have some distinct differences. Because the codes are law, they must be adhered to when equipment is installed in a specific region. Most manufacturers therefore have both approvals. When installing a safety valve however, to be compliant with these codes you not only need to use an approved supplier, but you also need to select settings, and install them in accordance with the codes.

The governing standards and recommended practises are API 520 (USA) and EN4126 (Europe). API 520 incorporates more detail on correction factors (more conservative) for back pressure and viscosity, hence is the most widely used for valve sizing.

The European PED, from a legal perspective replaces the very many local codes in all European member states such as BS (UK), TUV (Germany), AFNOR NFE (France), Stoomwezen (The Netherlands), ISPESL (Italy).

Some European users may also stipulate their local code however in addition to the PED. Local codes have different ways of presenting things but often the results are the same.

ASME B16.34 - Applies to valves with flanged, threaded, and welding ends: This standard covers pressure/temperature ratings, dimensions, tolerances, materials, non-destructive examination requirements, testing and marking. This standard is not specifically applicable to Safety Relief Valves but is often used by manufacturers as good engineering practice.

ASME B16.5 - Applies to pipe flanges and flange fittings: Provides allowable materials, pressure / temperature limits and flange dimensions for standard ANSI flanges.

ASME itself does not certify the valves. This is done by a National Board (NB) and they certify the valves capacity and the valves complaince with the ASME code. It is then published in the "Red Book" - NB18, along with the true flow co-efficients as measured and approved by them. A copy can be found at www.nationalboard.org

ASME safety valves are used across several applications including low-pressure and high-pressure boilers, process equipment, and air, gas, and vapor equipment. We have multiple products in a range of configurations and material construction that meet ASME Class I, IV, and VIII.

Boiler explosions have been responsible for widespread damage to companies throughout the years, and that’s why today’s boilers are equipped with safety valves and/or relief valves. Boiler safety valves are designed to prevent excess pressure, which is usually responsible for those devastating explosions. That said, to ensure that boiler safety valves are working properly and providing adequate protection, they must meet regulatory specifications and require ongoing maintenance and periodic testing. Without these precautions, malfunctioning safety valves may fail, resulting in potentially disastrous consequences.

Boiler safety valves are activated by upstream pressure. If the pressure exceeds a defined threshold, the valve activates and automatically releases pressure. Typically used for gas or vapor service, boiler safety valves pop fully open once a pressure threshold is reached and remain open until the boiler pressure reaches a pre-defined, safe lower pressure.

Boiler relief valves serve the same purpose – automatically lowering boiler pressure – but they function a bit differently than safety valves. A relief valve doesn’t open fully when pressure exceeds a defined threshold; instead, it opens gradually when the pressure threshold is exceeded and closes gradually until the lower, safe threshold is reached. Boiler relief valves are typically used for liquid service.

There are also devices known as “safety relief valves” which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service.

Nameplates must be fastened securely and permanently to the safety valve and remain readable throughout the lifespan of the valve, so durability is key.

The National Board of Boiler and Pressure Vessel Inspectors offers guidance and recommendations on boiler and pressure vessel safety rules and regulations. However, most individual states set forth their own rules and regulations, and while they may be similar across states, it’s important to ensure that your boiler safety valves meet all state and local regulatory requirements.

The National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation, and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulationsin order to provide guidance and encourage the development of crucial safety laws in jurisdictions that currently have no laws in place for the “proper construction, installation, inspection, operation, maintenance, alterations, and repairs” necessary to protect workers and the public from dangerous boiler and pressure vessel explosions that may occur without these safeguards in place.

The American Society of Mechanical Engineers (ASME) governs the code that establishes guidelines and requirements for safety valves. Note that it’s up to plant personnel to familiarize themselves with the requirements and understand which parts of the code apply to specific parts of the plant’s steam systems.

High steam capacity requirements, physical or economic constraints may make the use of a single safety valve impossible. In these cases, using multiple safety valves on the same system is considered an acceptable practice, provided that proper sizing and installation requirements are met – including an appropriately sized vent pipe that accounts for the total steam venting capacity of all valves when open at the same time.

The lowest rating (MAWP or maximum allowable working pressure) should always be used among all safety devices within a system, including boilers, pressure vessels, and equipment piping systems, to determine the safety valve set pressure.

Avoid isolating safety valves from the system, such as by installing intervening shut-off valves located between the steam component or system and the inlet.

Contact the valve supplier immediately for any safety valve with a broken wire seal, as this indicates that the valve is unsafe for use. Safety valves are sealed and certified in order to prevent tampering that can prevent proper function.

Avoid attaching vent discharge piping directly to a safety valve, which may place unnecessary weight and additional stress on the valve, altering the set pressure.

8613371530291

8613371530291