pilot safety valve factory

Consolidated Pilot Operated Safety Relief Valves (POSRVs) offer the safety you expect, the dependability you require, and the efficiency you need to keep your operations running smoothly. These valves offer a premium performance and numerous technical benefits and operating advantages over traditional Pressure Relief Devices.

Pilot Operated Safety Relief Valves are designed with several features that differentiate it from traditional spring loaded safety relief valves with superior performance, and with a compact design are lighter weight and easier to install in most applications.

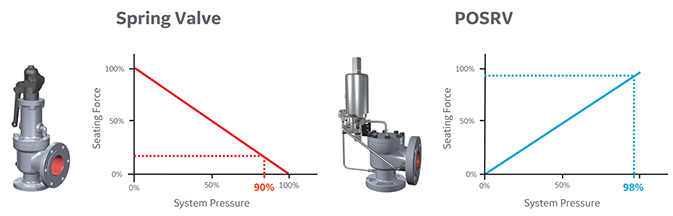

Consolidated Pilot Valves offer industry leading performance with both main valve and pilot seat tightness up to 98% of set pressure. This advanced design ensures zero-leakage during normal operating conditions for even the most demanding high-pressure applications.

Remote sense configuration eliminates rapid cycling valve chatter in applications with >3% inlet line loss, enabling Consolidated POSRVs to open and relieve pressure in a stable and efficient manner. The modulating style opens proportionally to your overpressure pilot, ensuring a smooth opening cycle and relieving only required capacity, keeping your operation safe, efficient and reliable.

Certified on gas, liquid and steam, and configured to suit your application with flexible features including an adjustable blowdown, bolt-on modulator, pilot line pressure surge snubber and dozens of optional accessories, ConsolidatedPOSRVs can be configured for any service.

No need to shut down your process to send your PRV to a service shop, conduct a standard set pressure test in the field while your process is running with theConsolidated Field Test Connection accessory. It comes standard with every Consolidated Pilot Valve, and allows you to conduct your set pressure test while the valve is live in service and continuously protecting your pressure vessel.

In comparison to a Direct Spring PRV, the Consolidated Pilot Valve offers significant size & weight advantages for a more compact installation. As the main valve size increases, the Pilot Valve remains the same, which further amplifies this benefit as pipe sizes increase.

For corrosive service applications, the Consolidated 2900 Series Gen II provides a full-nozzle Pilot Valve design option. With a full-nozzle, the media is isolated from the inlet neck area of the main valve body, allowing you to avoid costly exotic material upgrades in some corrosive service applications.

If you have an existing installation of a Direct Spring PRV that is oversized, improperly specified, or could benefit from the features and benefits a high performance Pilot Valve has to offer, the solution is the Consolidated 2900 Series Gen II Pilot Valve. This is the only Pilot Valve solution in the market that is able to replace any manufacturer’s API 526 Direct Spring PRV without piping modification caused by center-to-face dimensional differences. Click Here to learn more about the unique Consolidated drop in replacement Pilot Valve.

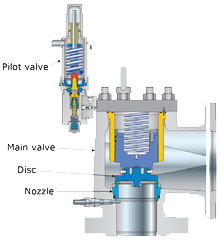

Pilot operated pressure relief valves (POSV = “pilot operated safety valves”)are controlled by the process medium in which they operate. To achieve this, system pressure is fed to the pilot valve (= control component for the main valve) via the pressure tapping line. To enable this, the system pressure is transferred to the pilot valve via the pressure tapping line. The pilot valve uses the space in the dome above the main valve piston to open and close the main valve.

The pilot operated safety relief valve is used for safety purpose in Oil and Gas industries. The pilot operation make these valves ideal for industrial applications in Oil and Gas.

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

The pilot is designed to open gradually, so that less of the system fluid is lost during each relief event. The piston lifts in proportion to the overpressure.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

The F7000/F8000 series POSRV’s features the first direct mount pilot valve with integral porting. Design provides for easy conversion of orifice sizes through addition of annular flow plug (F8000 series), interchangeable pilot mounting (F100/F200/F300/F500), and field adjustability. Other features include a low profiles, inline repair, and minimal connections.

We are a leading Manufacturer of pilot operated valves, pilot operated safety relief valves and safety relief valve pilot operated from Ahmedabad, India.

PilotOperatedReliefValves are used for emergency relief during over pressure events (e.g., a tank gets too hot and the expanding fluid increases the pressure to dangerous levels). As safe protected devices, it is to be used in equipment and pipeline systems of air and petroleum gas that which operation temperature is no higher than 420℃. When the pressure in equipment or pipeline exceeds allowed value, the valve will be opened automatically and fully discharge, then closed again when the pressure reduced to the regulated value so as to ensure the safe operation of the equipment or pipeline.

The SVP-7200 pilot operated pressure relief valves are able to operate at considerably higher set pressure than is possible with spring loaded safety relief valves, the valve operation and lift are unaffected by back-pressure.

The AST pilot operated safety relief valves are designed and manufactured according to 97/23/CE P.E.D. and ASME VIII, API527 requirement. They have passed several laboratories tests to obtain the conformance to the Pressure Equipment Directive, PED 97/23CE, accordingly to the product regulation EN ISO 4126-4 for use with gas, vapour and liquid. Many other homologations and approvals are available like ATEX, GOST R for Russia and others.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

8613371530291

8613371530291