hydraulic safety valve manufacturer

Hydraulic relief valves are used to limit the pressure in a hydraulic system. They achieve this result by allowing the pressurized hydraulic fluid to flow out of the system into an auxiliary passage.

In hydraulic control systems, the relief valve acts as a check valve, with a ball and an adjustable spring. When a relief valve opens to divert fluid into an auxiliary passage, the pressure inside the hydraulic cylinder drops and allows the valve to close. A hydraulic system will often employ several types of valves, although the hydraulic relief valve is usually the first encountered in the circuit. Hydraulic relief valves can be found in almost any mechanism that runs on hydraulic power, such as automobile transmissions, brakes, power steering, aviation and in industrial and construction machinery.

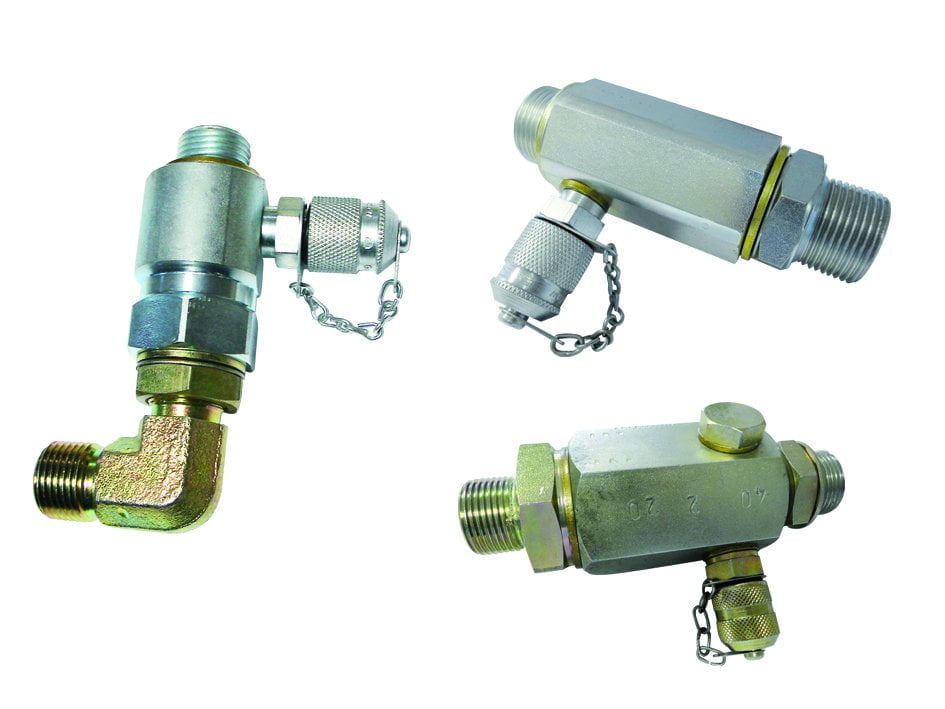

Relief valves are built from the same basic materials that most hydraulic valves are made from. The strong and corrosion resistant metals that are most common are stainless steel, aluminum, iron, brass and copper. Aluminum and stainless steel are thin, lightweight and flexible, while still retaining the strength necessary to control the flow of liquid. Usually when a heavy metal like iron is used for the body of a valve, one of those two lighter metals is still used for the disc or plunger. Plastic is also used, particularly thermoplastics that are developed specifically to be used as valve material. Although they are not as resistant to corrosion as metal, they are cheaper. It’s all about options.

Hydraulic relief valves protect hydraulic systems from being exposed to high pressures that exceed the mechanism"s specified limits. A relief valve is placed at the entrance to a separate tube and is set to only open when a certain amount of pressure is applied, which can only be applied if there is too much liquid or gas in the chamber or pipe. An auxiliary passage, which is where the relief valve sends the extra liquid or gas to relieve the pressure in a mechanism, is usually just an extra pipe that leads to a chamber where most likely the fluid is burned and the gas left over is released into the atmosphere.

This is a particular necessity in the chemical and petrochemical manufacturing industry, as well as in petroleum refining plants, natural gas processing and power generation industries. If the pressure in a hydraulic pump exceeds its designed pressure limit, internal leakage or damage to the pump components can occur. Depending on what the liquid is, such leaks could also cause serious damage to individuals in the vicinity and the environment.

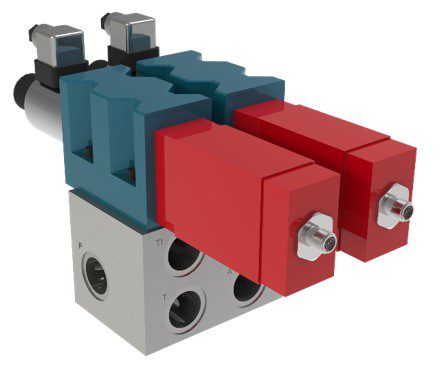

The HBH Series valves are redundant blocking valve systems designed for critical applications where safe load holding is required for hydraulically controlled cylinders. These valve systems are equipped with position sensors for external monitoring by an electrical safety control system.

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 ...

... base of an hydraulic cylinder, while the hose can be applied on the valve without any other components needed. The safety valves VUBA-DIN avoid an uncontrolled lowering ...

Hydraulic safety valves are made according to API 6A. When oil and gas leaking or firing, used for security protect on well site, the control system includes low pressure ...

Jereh Safety Valve is equipped with pneumatic, hydraulic or electric actuator, widely used in Christmas tree and surface manifold. In case of any emergency ...

The purpose of the valve is to, when energized, provide a flow path for a flow of hydraulic fluid from its source to the hydraulic system. When de-energized, the valve blocks flow from the hydraulic energy source and vents the hydraulic system to tank.

Q: What is Control Reliablitiy?A: Control Reliability essentially states that the safety system be designed, constructed and installed such that the failure of a single component within the device or system should not prevent normal machine stopping action from taking place, but shall prevent a successive machine cycle from being initiated until the failure is corrected. To achieve “Control Reliability”, a device should feature both redundancy and fault detection.

A: A safety valve, as it pertains to fluid power, is a component that, when properly applied, can allow access to an otherwise hazardous area. This is achieved by isolating the hydraulic source away from the system and venting any residual system pressure, downstream from the valve, to tank.

A: During normal operation, the valve operates like a traditional 3-way. If either of the redundant elements malfunction, the safety PLC or safety relay, monitoring the state of the redundant switches, will command the valve to its safe condition.

A: The three different configurations of Control Reliable Safety Valves are 2-way for blocking applications, 3-way for block and bleed applications, and LOTO or Lockout/Tagout.

A: A relief valve is a device that limits the maximum pressure in a system. It does help to keep a system and its surrounding environment safe from catastrophic failures due to over-pressurization but it is not a true safety product. The safety valves that we refer to are redundantly monitored devices that meet the rigorous requirements of safety standards organizations such as ANSI and ISO.

A: A blocking valve, as it pertains to fluid power, is a component that, when properly applied, can allow access to an otherwise hazardous area. This is achieved by isolating the hydraulic source away from the system.

A: During normal operation, the valve operates like a traditional 2-way. If either of the redundant elements malfunction, the safety PLC or safety relay monitoring the state of the redundant switches will command the valve to its safe condition.

Hydraulic relief valves are used to limit the pressure in a hydraulic system. They achieve this result by allowing the pressurized hydraulic fluid to flow out of the system into an auxiliary passage.

In hydraulic control systems, the relief valve acts as a check valve, with a ball and an adjustable spring. When a relief valve opens to divert fluid into an auxiliary passage, the pressure inside the hydraulic cylinder drops and allows the valve to close. A hydraulic system will often employ several types of valves, although the hydraulic relief valve is usually the first encountered in the circuit. Hydraulic relief valves can be found in almost any mechanism that runs on hydraulic power, such as automobile transmissions, brakes, power steering, aviation and in industrial and construction machinery.

Relief valves are built from the same basic materials that most hydraulic valves are made from. The strong and corrosion resistant metals that are most common are stainless steel, aluminum, iron, brass and copper. Aluminum and stainless steel are thin, lightweight and flexible, while still retaining the strength necessary to control the flow of liquid. Usually when a heavy metal like iron is used for the body of a valve, one of those two lighter metals is still used for the disc or plunger. Plastic is also used, particularly thermoplastics that are developed specifically to be used as valve material. Although they are not as resistant to corrosion as metal, they are cheaper. It’s all about options.

Hydraulic relief valves protect hydraulic systems from being exposed to high pressures that exceed the mechanism"s specified limits. A relief valve is placed at the entrance to a separate tube and is set to only open when a certain amount of pressure is applied, which can only be applied if there is too much liquid or gas in the chamber or pipe. An auxiliary passage, which is where the relief valve sends the extra liquid or gas to relieve the pressure in a mechanism, is usually just an extra pipe that leads to a chamber where most likely the fluid is burned and the gas left over is released into the atmosphere.

This is a particular necessity in the chemical and petrochemical manufacturing industry, as well as in petroleum refining plants, natural gas processing and power generation industries. If the pressure in a hydraulic pump exceeds its designed pressure limit, internal leakage or damage to the pump components can occur. Depending on what the liquid is, such leaks could also cause serious damage to individuals in the vicinity and the environment.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

Youli supplies various pressure control valves types, for instance pilot operated relief valve, reducing pressure valve, unloading relief valve and counter relief valves, etc. Youli is a well-known and professional

Located in Taiwan since 1989, SEVEN OCEAN HYDRAULIC INDUSTRIAL CO., LTD. has been a hydraulic valves, power units and accessories manufacturer. Their main products, include Pilot Operated Check Valve, Solenoid Operated Directional Control Valves, Pilot Operated Directional Control Valves, 4/2 Directional Control Valves, 4/3 Directional Control Valves, Variable Volume Vane Motor Pumps, Modular Stack Valves, Sandwich Valves, Hydraulic Power Units, Hydraulic Pressure Control Valves and Flow Control Valves, which are suitable for forklift, machine tool, plastic injection and recycling electrical machinery industries .

SEVEN OCEAN HYDRAULICS"s Pilot Operated Check Valve are reliable, sustainable, and cost effective, bringing you long-term value at an affordable price-point. With over 31 years of experience in manufacturing hydraulic systems, valves and components, Seven Ocean Hydraulics is able to streamline production time and has a greater control over product quality with in-house manufacturing of core components. We have gained trust from world- renowned brands for OEM projects, providing essential components for hydraulic products that are seen and used all over the world.

SEVEN OCEAN HYDRAULICS has been offering customers high-quality hydraulic valves, both with advanced technology and 31 years of experience, SEVEN OCEAN HYDRAULICS ensures each customer"s demands are met.

Located in Taiwan since 1989, SEVEN OCEAN HYDRAULIC INDUSTRIAL CO., LTD. has been a hydraulic valves, power units and accessories manufacturer. Their main products, include Pilot Operated Check Valve, Solenoid Operated Directional Control Valves, Pilot Operated Directional Control Valves, 4/2 Directional Control Valves, 4/3 Directional Control Valves, Variable Volume Vane Motor Pumps, Modular Stack Valves, Sandwich Valves, Hydraulic Power Units, Hydraulic Pressure Control Valves and Flow Control Valves, which are suitable for forklift, machine tool, plastic injection and recycling electrical machinery industries .

SEVEN OCEAN HYDRAULICS"s Pilot Operated Check Valve are reliable, sustainable, and cost effective, bringing you long-term value at an affordable price-point. With over 31 years of experience in manufacturing hydraulic systems, valves and components, Seven Ocean Hydraulics is able to streamline production time and has a greater control over product quality with in-house manufacturing of core components. We have gained trust from world- renowned brands for OEM projects, providing essential components for hydraulic products that are seen and used all over the world.

SEVEN OCEAN HYDRAULICS has been offering customers high-quality hydraulic valves, both with advanced technology and 31 years of experience, SEVEN OCEAN HYDRAULICS ensures each customer"s demands are met.

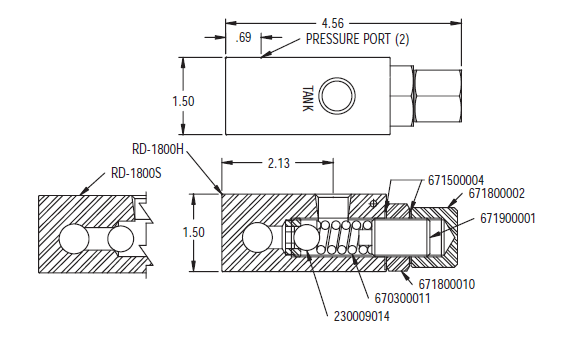

Valve manufacturers today are able to inspect parts during assembly rather than after to produce near-perfect fluid pressure relief valves. The Promess Electro-Mechanical Assembly Press (EMAP) uses no pneumatics or hydraulics; instead, press motion is initiated by a servomotor and ball screw. A computer monitors the press ram’s position and pressing force, and accepts data from additional external sensors. To make the pressure relief valve, the EMAP is fitted with an attachment that pumps fluid through the valve at 1.2 liters/min while it is in the press.

Sensors provide information on fluid flow and pressure to the EMAP’s controller. While the valve is assembled, the system monitors the valve release pressure. The EMAP compensates for variations in the valve components that affect release pressure by compressing the spring inside the valve to increase its resistance. The EMAP presses the valve seat into the valve body until the target release pressure of 1,000 psi is reached.

8613371530291

8613371530291