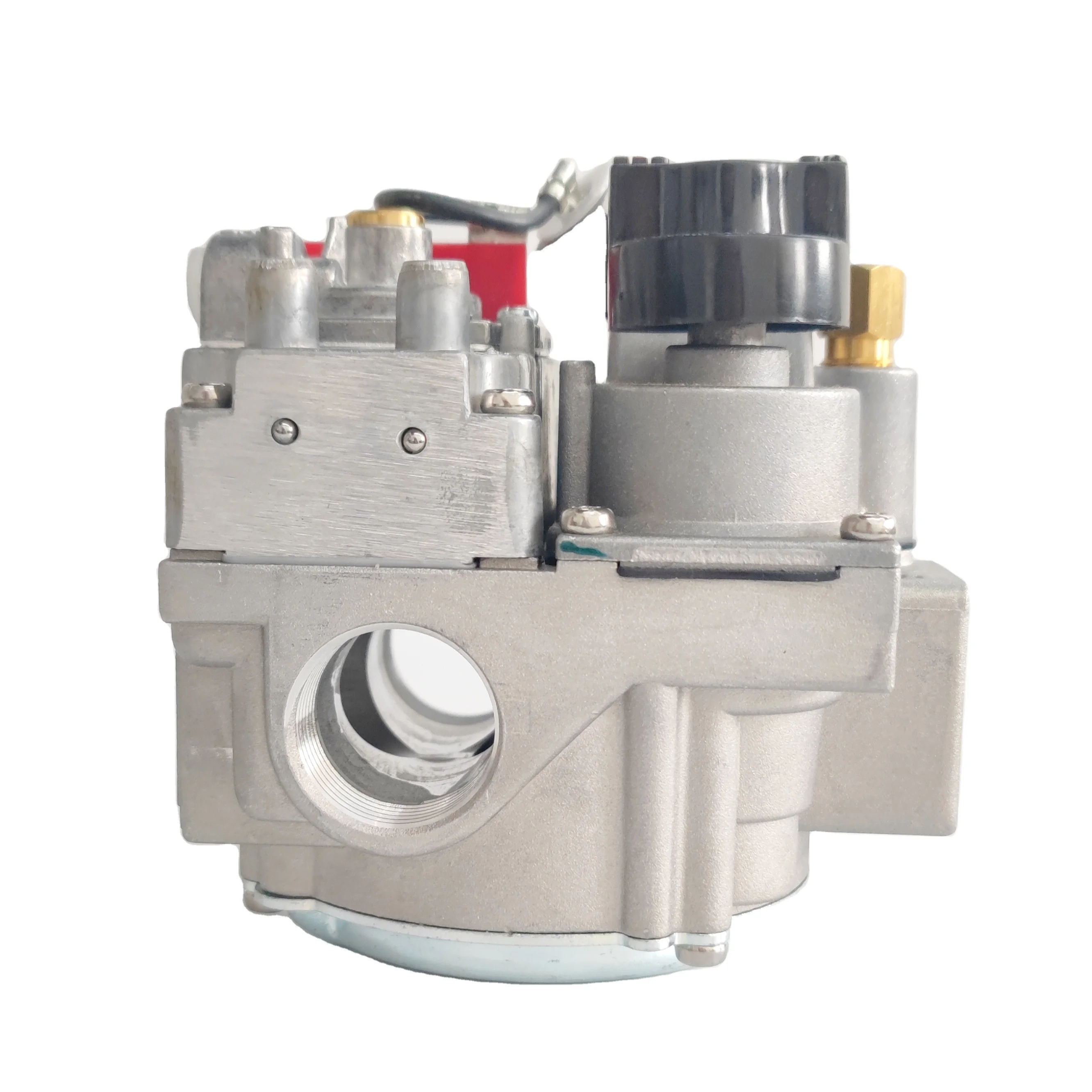

robertshaw safety valve free sample

The Robertshaw® TS Series Thermomagnetic Safety Valve is a control used to cut off the flow of gas to the burner in the event of a pilot outage. The magnet assembly is energized by voltage generated by a thermocouple that is heated by the pilot flame. When this flame is extinguished, the thermocouple voltage decreases until a spring overcomes the magnetic force and closes off both the pilot and main gas. This control can be used for commercial and residential ovens, infrared heaters, chicken and pig brooders, recreational vehicle gas appliances and many more applications requiring automatic safety valves.

Robertshaw® has been creating and implementing innovative solutions throughout its history. Robertshaw continues to develop ground-breaking solutions that make products more effective, more efficient, and more attainable.

Abstract: A variable flow rate gas control valve for use in consumer and commercial appliances is presented. The valve utilizes two or more solenoids to control the operating position of two different valve members whose orifices are sized in an exponential relationship with one another. By opening one or more of the valving members in various combinations, a variable flow rate of gaseous fuel may be controlled in integer multiple steps from full off to full on. The solenoid configurations may be in line, opposing, or symmetrical about an axis of the valve. The number of unique flow rates (F) is related to the number of solenoids (N) as F=2N. The relationship between the size (S) of the individual gas control orifices for each of the solenoids is related to N by the relationship S=2n?1 for each individual gas control orifice (n) numbered 1 to N.

Abstract: Presented are embodiments of pressure relief valves for use in water supply systems to prevent damage thereto caused by over pressure resulting from freezing of the water therein. In one embodiment the pressure relief valve is included in an electromechanical solenoid controlled water valve particularly useful in appliances such as washing machines, water heaters, refrigerators, etc. Prior to the main valving member, a spring loaded pressure relief valving member is included. Once the pressure within the valve exceeds the spring force, which is set below the failure pressure of the water supply system and the valve, the pressure relief valving member opens to allow a flow of water therethrough. Alternatively or additionally, a temperature active device such as a bi-metal disc is interposed between the spring and the pressure relief valving member to provide actuation thereof below a predetermined temperature.

Abstract: A system to reduce standby losses in a hot water heater is presented. The system utilizes a dual safety relay valve between the combination gas controller and the burner. The dual safety relay valve bypasses gas to a rotary damper actuator valve to position a damper flapper valve located over/inside the flue pipe. Once the flapper valve has opened to ensure combustion, the gas is allowed to flow back to the dual safety relay valve. Some of the bypass gas may be diverted to boost the pilot or to supply a booster. The dual safety relay valve is then opened to allow the gas supply to the burner. Once the burner is turned off, bypass gas bleeds out of the rotary damper actuator valve to close the damper flapper valve to reduce standby losses through the flue pipe, and to allow the dual safety relay valve to close tightly.

Abstract: A valve includes a valve housing with a valve inlet and valve outlet. A valve member is disposed between the valve inlet and valve outlet. The valve member is movable between an open and closed position. The valve has one or more electronic sensors disposed in the valve housing. The one or more electronic sensors may include an electronic flow meter, a temperature sensor, pressure sensor, and/or a position sensor. A wireless RF transmitter is electrically coupled to the one or more electronic sensors. The wireless RF transmitter is configured to wirelessly communicate information from the one or more electronic sensors.

Abstract: An unregulated gas valve for a water heater that includes an inlet configured to receive a gas flow into the gas valve, an outlet configured to direct a portion of the gas flow to a combustion chamber, a pilot line configured to direct a portion of the gas flow to a pilot flame, and a dial configured to regulate the flow of gas into the gas valve, and further configured to select a water temperature setting.

Abstract: A water tight valve with sealed flying leads is presented. The sealing is provided by an adhesive heat shrink collar that is affixed to the insulation of the flying leads. An overmolding is used to provide further protection of the terminal/wire contact interface and to seal against the exterior surface of the collar. The profile of the collar also provides a tortuous path that further prevents the ingress of any conductive fluid to the wire/terminal contact area.

Abstract: A gas valve assembly with integrated pressure regulator is provided. The gas valve assembly includes a pressure regulator and a gas valve module. The pressure regulator and gas valve modules each include cast housing bodies. The cast housing bodies have cast in mounting holes and assembly features that allow for the assembly of the gas valve assembly without secondary machining operations.

Abstract: A flow control valve includes a housing forming internal passages in fluid communication with a port of the valve, and an internal cavity. A flow direction block is disposed in the internal cavity and forms at least one flow passage extending through a portion thereof. The flow direction block is moveable within the internal cavity such that the free ends of the least one flow passage can be selectively aligned with a respective internal passage along an interface as the flow direction block is moved from a first, closed position to a second, open position. A seal is disposed around each interface and includes an internal face, which presses against an outer surface of the flow direction block, and an external face, which presses against the housing. Sealing function is improved, at least in part, by a differential fluid pressure that acts on the seal.

Abstract: A shank mount assembly for a water heater that includes an annular nipple having an opening, the nipple configured to removably attach to an opening in a water heater tank. The shank mount assembly further includes an annular shank mount having an opening, the shank mount configured to removably attach to the nipple, wherein the shank mount is further configured to attach to a gas valve assembly.

Abstract: A solenoid operated pilot valve utilizes an offset pilot opening and a lever arm to provide a mechanical advantage to multiply the opening force of the solenoid, thereby allowing the solenoid size to be reduced. The lever arm used to position the pilot valving member is mechanically positioned via a solenoid driven plunger in one embodiment, and is positioned by magnetic force alone in an alternative, plungerless embodiment. The lever arm pivots via a fixed fulcrum point, a profiled fulcrum providing continuously variable mechanical advantage, or a stepped fulcrum providing discreet different mechanical advantages as the pilot valving member is moved from its fully closed to its fully opened position.

RICHMOND, Va. - Robertshaw Controls Co. has announced a voluntary recall, in cooperation with the U.S. Consumer Product Safety Commission (CPSC), of certain models of the Robertshaw 7000 Series gas control valve. Under certain circumstances, some valves have failed to halt the flow of gas when pilot lights go out, posing a risk of gas explosion and fire, which could potentially result in severe personal injury and/or property damage.

"We instituted this voluntary recall because safety is our highest priority," stated Rick Johnson, Robertshaw spokesperson. "We take every complaint seriously and when we found out there might be a problem with some of our valves, we looked into it and performed extensive testing on the 7000 Series valves. We determined that during a recent 18-month period, we made a modification in our processing which led to the potential for some valves to stick in the open position, permitting some gas to continue to flow if the pilot light has gone out. This is unacceptable to us and our customers; therefore we instituted the 7000 Series recall. In addition, we have adjusted our manufacturing process to resolve the issue."

The voluntary recall applies to specific 7000 Series models produced between February 2003 and September 2004 that have production dates beginning with code 0306 and ending with 0436. The 7000 Series gas valves that are being recalled are installed in gas appliances including residential space heaters, wall heaters, boilers, fireplaces, pool heaters, infrared heaters and furnaces, and commercial heating applications such as commercial cooking appliances, fryers, commercial water heaters, and poultry brooders.

Not all 7000 Series valves manufactured during the indicated timeframe are being recalled. Of particular note are model numbers containing the letters "MV." Recalled gas valves include "MV" models that also include the letters "LP" and model numbers 7000AMV; 7000BMV; 7000BMV-S7CL; 7000MVLC; and 7000MVRCLC. All "MV" valves with the indicated date codes that have been converted to liquid propane (LP) gas use are also included in the recall. Not included in the recall are model numbers 7010 and above; model numbers containing the letters "D" or "BV;" and model numbers containing the letters "MV" except for the ones listed above.

A full listing of recalled model numbers is available at www.robertshaw.com or can be obtained by calling 800-232-9389. The recall applies to about 425,000 Robertshaw 7000 Series gas control valves.

The valves, assembled in Mexico, are sold through gas appliance retailers and distributors; food service equipment manufacturers and dealers; specialty retailers, such as fireplace, pool, and spa dealers; and poultry equipment manufacturers. The gas control valves and components were also sold separately through gas appliance service providers.

The company is recommending that owners of appliances with the recalled products in the United States and Canada should immediately arrange for free repair or, if necessary, replacement through Robertshaw Controls Co. Consumers should visit Robertshaw"s Web site or call the company"s toll free number (both noted above) to determine if their product is involved in the recall and to register to obtain a free repair or, if necessary, replacement.

The company says the vast majority of the valves were sold in the United States and Canada. However, a number of them were also sold in over two dozen countries around the world. Robertshaw is partnering with local equipment manufacturers and subsidiaries in each country to process the recall, and consumers will be informed via these local partners. More information again is available at the company"s Web site in Spanish, French, and English.

The Supreme Court has reinforced the theory of the First Amendment as a "safety valve," reasoning that citizens who are free to to express displeasure against government through peaceful protest will be deterred from undertaking violent means. The boundary between what is peaceful and what is violent is not always clear. For example, in this 1965 photo, Alabama State College students participated in a non-violent protest for voter rights when deputies confronted them anyway, breaking up the gathering. (AP Photo/Perry Aycock, used with permission from the Associated Press)

Under the safety valve rationale, citizens are free to make statements concerning controversial societal issues to express their displeasure against government and its policies. In assuming this right, citizens will be deterred from undertaking violent means to draw attention to their causes.

The First Amendment, in safeguarding freedom of speech, religion, peaceable assembly, and a right to petition government, embodies the safety valve theory.

These and other decisions rest on the idea that it is better to allow members of the public to judge ideas for themselves and act accordingly than to have the government act as a censure. The Court has even shown support in cases concerning obscenity or speech that incites violent action. The safety valve theory suggests that such a policy is more likely to lead to civil peace than to civil disruption.

Justice Louis D. Brandeis recognized the potential for the First Amendment to serve as a safety valve in his concurring opinion in Whitney v. California (1927) when he wrote: “fear breeds repression; . . . repression breeds hate; . . . hate menaces stable government; . . . the path of safety lies in the opportunity to discuss freely supposed grievances and proposed remedies; and the fitting remedy for evil counsels is good ones.”

ROBERTSHAW FMDA COMMERCIAL GAS SAFETY VALVES• Capillary length18"• Inlet outlet 3/8" NPT• Button length 3/16 "• Valve provides positive shut off of gas when pilot is out• 1/4" O.D. tubing inlet and outlet for pilot• For Wolf models CH, CHSS (1979 and before)• Wolf no. 19312picture is not of actual valve. actual valve has a thicker capillaryNew (old stock)Valves are tested before they ship. Returns accepted as exchange only for defective valve up to 2 weeks from date of sale.

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

8613371530291

8613371530291