the safety valve discharges automatically at the pressure of pricelist

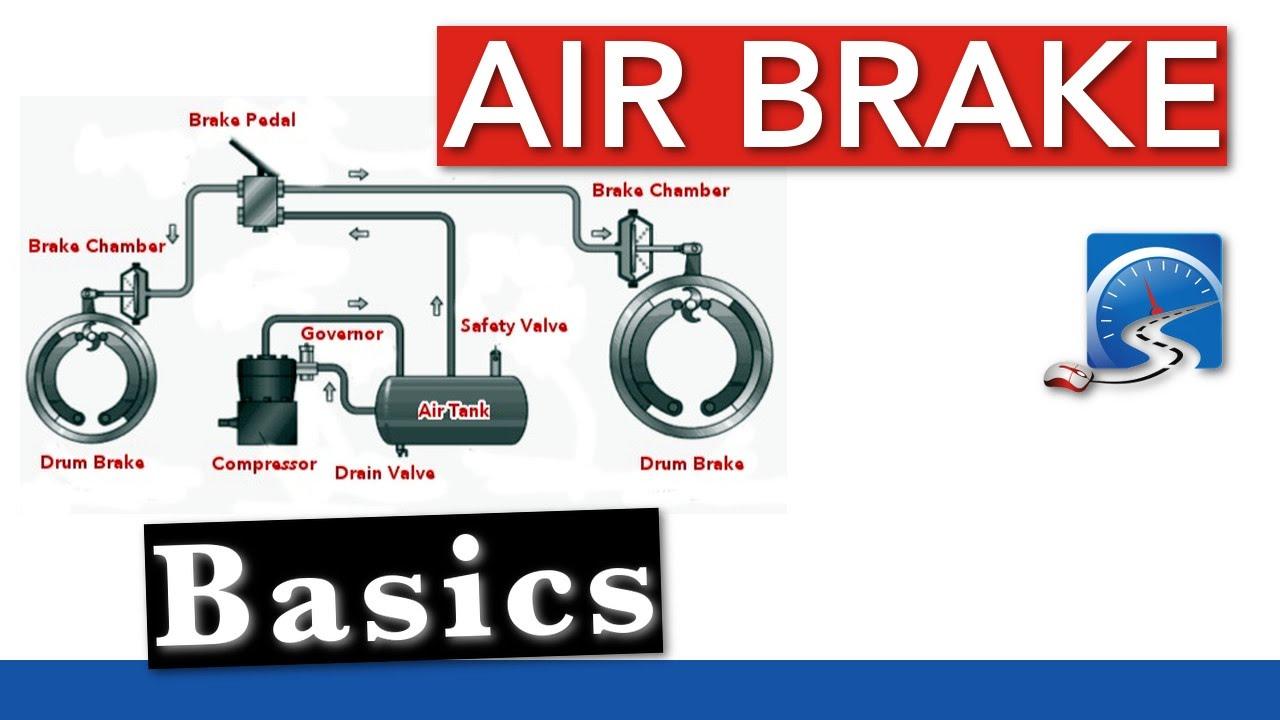

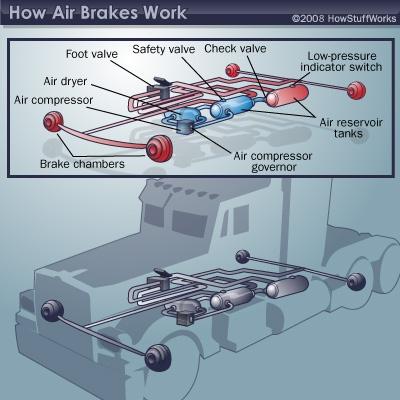

With a basically fully-charged air system (within the effective operating range for the compressor), turn off the engine, release all brakes, and let the system settle (air gauge needle stops moving). Time for 1 minute. The air pressure should not drop more than:

Finding a quality driving school in can be a difficult and time consuming task. driving-schools.com comprehensive database of driving schools helps you pick one that’s right for you.

Safety valves Air compressor is a device used in compressed air systems, this is a small but very important device in the compressed air system. Air compressor safety valves are used in air compressor systems for the purpose of controlling the pressure of compressed air and limiting pressure buildup in the system.

Basically, the air compressor safety valve will work by automatically opening when the pressure in the system exceeds the allowable level of the pressure reducing valve, the valve will release compressed air to reduce pressure, the valve is discharged until system pressure drops.

This air compressor safety valve with the most popular production is from the brass material line, for this type of product, the application is in the pneumatic system, brass material is a very suitable material for application.

Air compressor safety valve product line is installed in the air compressor system to release compressed air to help reduce pressure when the pressure in the system is too high.

The main function of the air compressor safety valve is to discharge compressed air in the system with excess pressure, which helps to ensure the safety of the system.

Safety valve products help to discharge compressed air completely automatically, when the rated pressure is exceeded, the safety valve will automatically discharge compressed air.

The air compressor safety valve is a normally closed valve, the air compressor safety valve product line will always be in a closed state, when the pressure level rises above the set level, the air compressor safety valve will open to discharge. pressure, which is also characteristic of this air compressor safety valve operation.

Air compressor safety valve is used in air compressor system. In the compressed air system, if the pressure is too high, it may cause some parts to explode, the air compressor safety valve is installed in the air compressor system to help prevent overpressure and detonation occurs, helping to keep the operator safe.

The rated pressure of the safety valve must not exceed the maximum allowable working pressure of the pneumatic accumulator. This helps to ensure that the compressor safety valve will always open before the tank reaches its maximum pressure capacity.

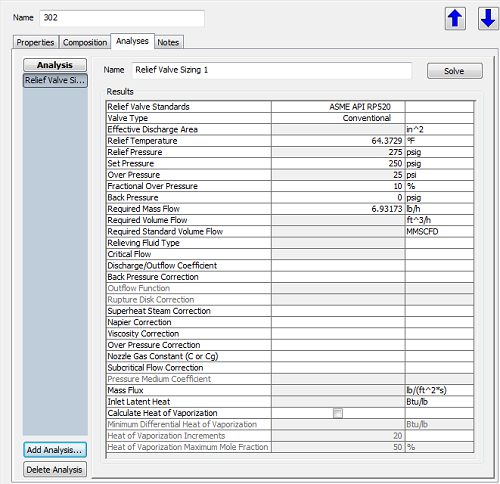

It is also important to note the minimum working capacity of the safety valve, which must meet the requirements of the American Society of Mechanical Engineers Code.

Air compressor safety valves classified by pressure drop will be classified based on the maximum pressure that this safety valve can reduce in the system.

When the inlet pressure of the relief valve is greater than the load of the spring, the valve will open to release air. The load force of this spring can be set to the desired level.

The pneumatic safety valve works directly, it will automatically react when the pressure in the system is too high, in general the operation of the pneumatic safety valve.

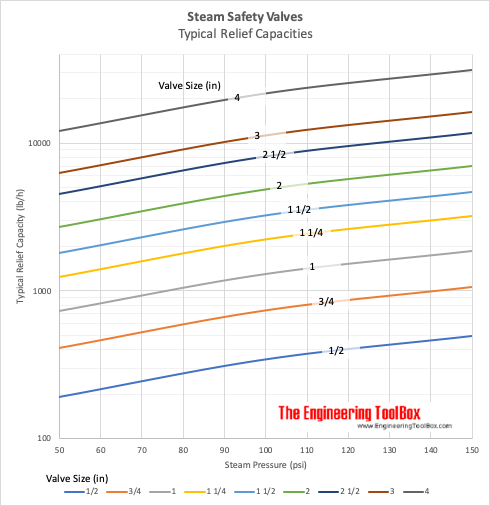

Regarding the discharge capacity of the safety valve, the safety valve will reach the maximum discharge capacity when the system pressure level will be 10% higher than the set pressure of the pressure relief valve and the safety valve will close completely when The system pressure drops below the valve set pressure, which is usually set at 90%.

Why is it necessary to check the air compressor safety valve, the air compressor safety valve is installed in the air compressor system, after a period of use, the air compressor safety valve may be worn or wrong number.

The air compressor safety valve inspection needs to be done at least once a year, to ensure the quality and operation of the air compressor safety valve remains stable.

Also because the air compressor safety valve helps to protect human safety. If the pressure relief valve fails, it can lead to overpressure of the air compressor system, which can lead to a breakdown or rupture or explosion of the system.

To check the air compressor safety valve first need to turn on the system and bring it to the operating pressure level. Pull the ring on the top of the safety valve to drain all the compressed air in the tank. Turn off the system and ensure that the system returns to normal pressure when the system is restarted.

Non-discharge safety valve: Non-flush safety valve refers to the condition that the safety valve does not release air when in an overpressure condition, which will endanger the whole system.

This failure of the safety valve does not discharge is usually a safety valve fault, because the safety valve has a certain error in operation. The easiest way to deal with this error is to change the product to a new one.

Or maybe the pressure switch device in the system is damaged, the pressure switch device does not turn off the tank motor, this time it is necessary to replace the new pressure switch.

Safety valves or pressure relief valves are pressure regulating devices that are responsible for expelling excess pressure from the system when the maximum pressure levels for which they have been designed are exceeded, usually due to a

Safety valves perform their function when the pressure of the system where the fluid is contained, becomes higher than the maximum set pressure of the valve previously adjusted. When the system pressure is higher than the valve’s set

pressure, this opens, releasing the excess pressure to the atmosphere or to containment tanks, depending on the toxicity of the fluid. After releasing the excess, the valve closes again and the system pressure returns to normal.

To ensure total safety of personnel and installation, make sure that the valves have passed all safety tests and meet the requirements of the system where they are to be installed. All our valves are supplied with certificates of materials, cas-

What is the difference between the instantaneous full opening safety valve AIT (PSV) and the normal opening relief valve AN or progressive opening relief valve AP (PRV)?

The Pressure Safety Valve (PSV) opens instantaneously and fully upon reaching the set pressure for which it is designed, expelling the excess pressure from the system immediately. They are optimised for use with steam or gases.

In contrast, the normally or progressively opening Pressure Relief Valve (PRV) opens gradually as the system pressure rises above the set pressure of the valve above its setting. They are optimised to work with liquids.

At VYC Industrial we are specialists in the design and manufacture of all types of safety valves. We have a wide range of safety valves to cover all the needs of the sector.

The Mod. 496 EN safety valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The Mod. 495 EN pressure relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

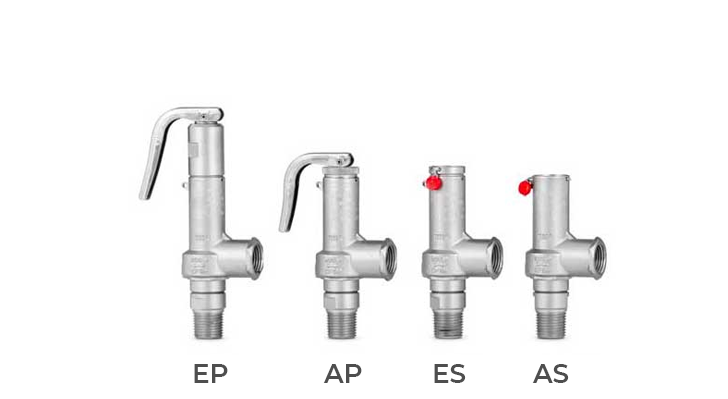

Fabrication program Catalogues by product Operating principles AP CP EP ES Assembly and disassembly instructions AP CP EP ESComplementary technical instructions

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

They are used in places such as power, chemical and petrochemical plants to discharge safety valves, control valves, etc. in pressure lines and equipment that convey compressible substances such as steam, air, carbon dioxide, helium, methane, nitrogen, oxygen and other gases.

Test bench for regular inspections and setting and resetting safety valves. Ideal for distributors, maintenance companies or with in-house maintenance. It allows safety valves to be adjusted, tested and/or checked to the test pressure (setting) Pe wile cold (simulating service conditions), matching the opening pressure Ps and the closing pressure Pc, in accordance with the standard regulations.

Controlled safety pressure relief system CSPRS valves are mainly used where conventional direct-loaded spring action valves cannot guarantee the opening and closing margins that certain specifi c conditions of service demand.

The objective is to help the closure by means of pressure so that the valve remains completely watertight until reaching the set pressure and/or to activate the opening with pressure.

Once evacuated and in keeping with a previous adjustment, to assist with closing pressure, to once again achieve closure with the desired watertightness.

Increase the operating pressure of the system up to 99.9% of the set pressure.The control safety pressure relief system CSPRS device can be used with any safety valve available in the market and in particular, with models VYC Mod. 485, 486, 494, 495 and 496.

of valve types has been developed. Examples of the common types are the ball valve, butterfly valve, globe valve, gate valve, plug valve, diaphragm valve, reducing valve, needle valve, check valve, and safety/relief valve. Each type

Series LFF113FP Flood Protection Shutdown Control Valves help protect against catastrophic property damage due to excessive RPZ backflow relief valve discharge by continuously monitoring for excess discharge, and closing the water supply during potentially catastrophic flood conditions.

This Series features a time delay to prevent false alarms, a control valve switch to provide an indication of valve closure, as well as an option to integrate with SentryPlus Alert™ technology to provide multi-channel alerts to notify you in real time if there is an issue so you can take action. Alerts can be a text, email, or phone call.

A Pop-Up Water Relief Valve (also commonly known as a Pop-Up Drainage Emitter) that is normally closed except when there is a build up of hydrostatic pressure. As the drainage pipes fill and build up slight pressure, the cover rises to allow the excess water to escape. Once the water is discharged the pressure drops and a stainless steel spring automatically retracts the cover to its closed flush position. The flush design of the product ensures that it blends well into the surrounding area. The Pop-Up body is manufactured from structurally foamed High Density Polyethylene (HDPE) with a UV inhibitor to reduce sun damage, while the Elbow (which comes with a pre-drilled hole to drain excess water) is manufactured from PVC and the Adapter from High Impact Polystyrene (HIPS). Typical application for this product is at the discharge end of the drainage pipe. Can be installed in either a vertical or horizontal position. Connects to 3″ & 4″ Sewer & Drain Pipe (ASTM D2729), 3″ & 4″ Corrugated Pipe and 3″ & 4″ Triple Wall Pipe.

Series LFF113FP Flood Protection Shutdown Control Valves help protect against catastrophic property damage due to excessive RPZ backflow relief valve discharge by continuously monitoring for excess discharge, and closing the water supply during potentially catastrophic flood conditions.

This Series features a time delay to prevent false alarms, a control valve switch to provide an indication of valve closure, as well as an option to integrate with SentryPlus Alert™ technology to provide multi-channel alerts to notify you in real time if there is an issue so you can take action. Alerts can be a text, email, or phone call.

A safety valve is a device designed to automatically release excess pressure. It works by opening immediately in order to prevent overpressure conditions. It releases pressure without the operator’s assistance so it takes less effort and works efficiently. The brass safety valve is also a kind of safety valve, except it is made of brass. The material of the safety valve differs as they’re made for different purposes so that they accommodate well. These safety valves work when the other relief valves fail to control the pressure release in a system.

The safety valves have a specific function which is a constant in every industry they’re used in. It is said that the main purpose of safety valves such as Brass safety relief valves, is to prevent the occurrence of a catastrophe due to a sudden pressure release. These Brass alloys air safety valves are not meant to control the pressure, rather they are designed to immediately release pressure. They are made to protect property, people and processes. The setpoint of a safety valve is usually set 3 points above the working pressure limit. These safety valves are divided into a wide range of types that are used in various industries accordingly.

Boulder safety valves are used extensively in steam systems. They are used widely and strictly in such industries and their work is to protect property, people, and produce. Alloy cw617n boiler safety valves are typically used for boiler overpressure protection. These are also used in applications such as downstream pressure-reducing controls. The primary role of such Brass cz108 boiler safety valve is providing safety. They are made up of valves and it prevents damage caused due to excess pressure. These valves open when the pressure reaches above the set limit.

Select from the list of audited brass safety valve suppliers in UAE, before ordering alloy cw602n air and steam safety valves compare response times and prices in Dubai

Air safety valves are pressure relief valves for air compressor systems. The mechanisms of such valves are simple and are mostly spring-loaded. When the inlet pressure force is greater than the spring load, the uns c37000 air safety valve opens in and releases the air as needed. When the pressure gets too high these valves for compressed air applications automatically react. They control and limit the pressure build-up in a system. In case excessive pressurization occurs, the compressed air force exceeds the force exerted by the spring. This results in the lifting of the valve disc of the valve seat, and the valve discharges the compressed air into the atmosphere. This happens when the system pressure climbs to more than 10% above the set pressure of the valve.

Meet verified suppliers of brass cz108 boiler safety valves who supply nationwide in a full range of standard and special sizes, must check uns c27200 steam safety valve price in the United Arab Emirates

CW617n safety valve is a cold working valve that is made up of various materials and is found in different dimensions and capacities. The sizes of such valves range from 1⁄2 inches to 2 inches. They are able to operate up to 10000 cycles and the working temperature ranges from -10 degrees to 110 degrees. The valves have 100% leak proof systems and can stand pressures of PN30 or 500 Psi. The maximum pressure these valves can sustain is 500 psi so these valves fly open at pressures above that limit. The spring-loaded or direct-acting safety valves are the most common safety valves. These types of valves are available for pressure ranges from approximately 1 to 1400 bar.

Quickly get pricing from genuine cw617n safety valves suppliers in the middle east and Africa, check alloy cw617n boiler safety valve prices in Sharjah

UNS C27200 steam safety valve runs according to the ASME Code. The code states that each steam heating boiler shall have more than one officially rated safety valve. The valves are adjusted and sealed to discharge at a maximum pressure of 103 kPa (15 psi). The safety valves that are required to protect piping and connected equipment in pulsating service are verified thoroughly before setting up at maximum pressure. For the Alloy cw602n steam safety valve, the steam pressure is set at a minimum of 70 kPa (ga) above the normal operating pressure of the system.

Each air tank shall be protected by 1 or more safety valves and other indicating and controlling devices that will insure safe operation of the tank. If the tank has a volumetric capacity in excess of 2,000 gallons, it shall be fitted with at least 2 safety valves, the smallest of which shall have a relieving capacity of at least 50 percent of the relieving capacity of the largest valve. These appliances shall be constructed, located, and installed so that they cannot be readily rendered inoperative. Safety valves shall be of the direct spring-loaded type, and for pressures of 2,000 psi or less shall be equipped with a substantial lifting device so that the disc can be easily lifted from its seat not less than 1/8 the diameter of the seat when the pressure in the tank is 75 percent of that at which the safety valve is set to open. For pressures in excess of 2,000 psi, the lifting device may be omitted providing the valve is removed for testing at least once each year and a record is kept of this test and made available to the qualified inspector. For pressures exceeding 2,000 psi acceptable rupture discs may be used in lieu of spring-loaded safety valves. All safety valves shall be ASME stamped and rated for air pressure service. The safety valves and rupture discs shall be set to open at not more than the allowable working pressure of the air tank, and the relieving capacity shall be sufficient to prevent a rise of pressure in the tank of more than 10 percent above the allowable working pressure when all connected compressors are operating with all unloading devices rendered inoperative. The opening or connection between the tank safety valves shall have a cross-sectional area at least equal to the combined areas of all attached safety valve inlets.

All safety valves shall be tested frequently and at regular intervals to determine whether they are in good operating condition. It is recommended that safety valves up to and including 200 psi setting shell be tested at least monthly. Discharge pipes from safety valves and rupture discs installed on air tanks shall have a cross-sectional area at least equal to the combined outlet areas of all valves discharging into them, and shall be designed and installed so that there will be no interference with the proper operation or discharge capacity of the safety valve or rupture disc. No valve of any description shall be permitted in these discharge pipes. All discharge pipes shall be fitted with open drains which will prevent the accumulation of liquid above the safety valve seat or rupture disc. Discharge pipes shall be installed and supported in a manner that will prevent undue stresses on the safety valve or rupture disc. The discharge from all safety valves and rupture discs shall be led to a safe place of discharge.

8613371530291

8613371530291