psv pressure safety valve in stock

USA Industries" Pressure Safety Value Racks allow a standard, quick transportation rack for pressure safety valves of all sizes, while keeping them in an upright position. Store up to 12 units on our large rack and up to 14 units on our small rack (depending on the size of your valves). Further, with quicker and easier loading of your PSVs, you can rent cranes, trucks and other equipment for shorter durations, which help lower project costs. In addition, you also save time & labor by purchasing uniform racks instead of having skilled laborers build them out of miscellaneous materials.

Our in-house engineering and fabrication teams will customize a Pressure Safety Valve Rack to your exact needs. Call us today and see how we can help you at (713) 941-3797!

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale pressure safety valve psv on Alibaba.com. When you search for pressure safety valve psv and related items, you will be able to find many types of pressure safety valve psv varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of pressure safety valve psv that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

Adjustable high pressure relief valves are offered in pressure ranges 1000 psi to 20000 psi in two models. PSV pressure safety valve suitable for use with hydraulic, water, gases, oils and more in many applications such hydrostatic, hydraulics and instrumentation control systems in all industries.

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

Curtiss-Wright"s selection of Pressure Relief Valves comes from its outstanding product brands Farris and Target Rock. We endeavor to support the whole life cycle of a facility and continuously provide custom products and technologies. Boasting a reputation for producing high quality, durable products, our collection of Pressure Relief Valves is guaranteed to provide effective and reliable pressure relief.

While some basic components and activations in relieving pressure may differ between the specific types of relief valves, each aims to be 100% effective in keeping your equipment running safely. Our current range includes numerous valve types, from flanged to spring-loaded, threaded to wireless, pilot operated, and much more.

A pressure relief valve is a type of safety valve designed to control the pressure in a vessel. It protects the system and keeps the people operating the device safely in an overpressure event or equipment failure.

A pressure relief valve is designed to withstand a maximum allowable working pressure (MAWP). Once an overpressure event occurs in the system, the pressure relief valve detects pressure beyond its design"s specified capability. The pressure relief valve would then discharge the pressurized fluid or gas to flow from an auxiliary passage out of the system.

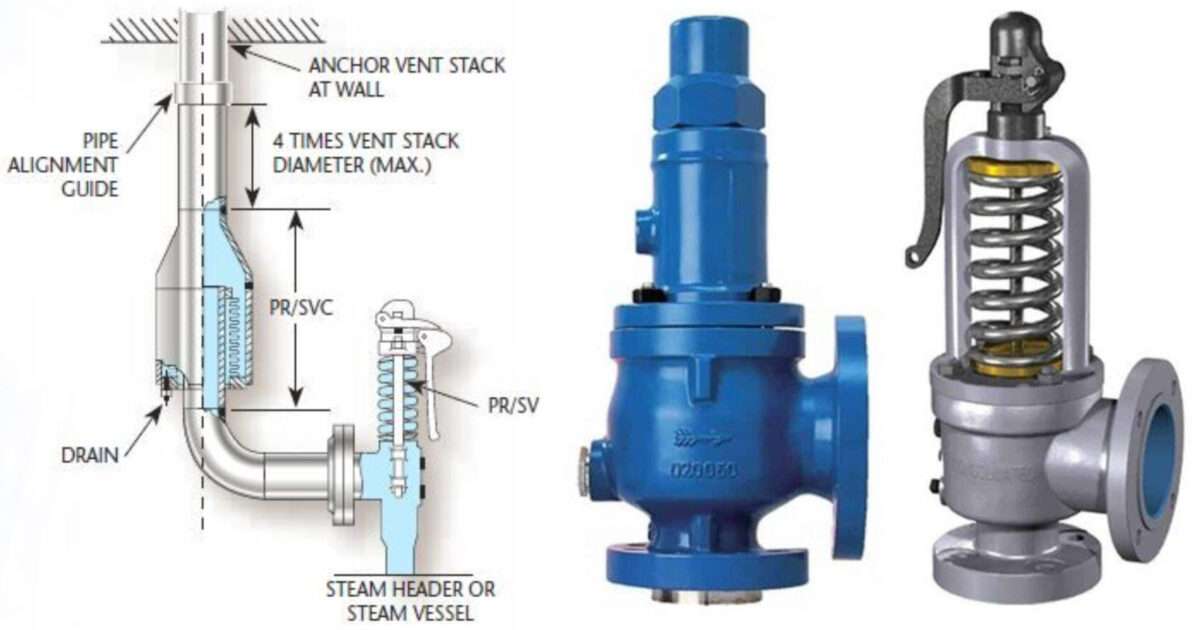

Below is an example of one of our pilot operated pressure relief valves in action; the cutaway demonstrates when high pressure is released from the system.

Air pressure relief valves can be applied to a variety of environments and equipment. Pressure relief valves are a safety valve used to keep equipment and the operators safe too. They"re instrumental in applications where proper pressure levels are vital for correct and safe operation. Such as oil and gas, power generation like central heating systems, and multi-phase applications in refining and chemical processing.

At Curtiss-Wright, we provide a range of different pressure relief valves based on two primary operations – spring-loaded and pilot operated. Spring-loaded valves can either be conventional spring-loaded or balanced spring-loaded.

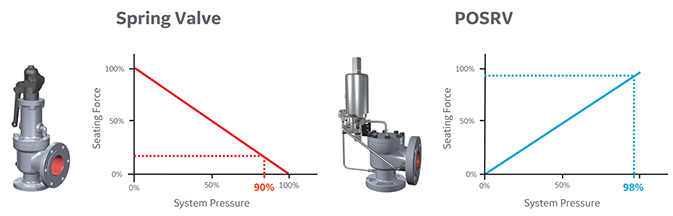

Spring-loaded valves are programmed to open and close via a spring mechanism. They open when the pressure reaches an unacceptable level to release the material inside the vessel. It closes automatically when the pressure is released, and it returns to an average operating level. Spring-loaded safety valves rely on the closing force applied by a spring onto the main seating area. They can also be controlled in numerous ways, such as a remote, control panel, and computer program.

Pilot-operated relief valves operate by combining the primary relieving device (main valve) with self-actuated auxiliary pressure relief valves, also known as the pilot control. This pilot control dictates the opening and closing of the main valve and responds to system pressure. System pressure is fed from the inlet into and through the pilot control and ultimately into the main valve"s dome. In normal operating conditions, system pressure will prevent the main valve from opening.

The valves allow media to flow from an auxiliary passage and out of the system once absolute pressure is reached, whether it is a maximum or minimum level.

When the pressure is below the maximum amount, the pressure differential is slightly positive on the piston"s dome size, which keeps the main valve in the closed position. When system pressure rises and reaches the set point, the pilot will cut off flow to the dome, causing depressurization in the piston"s dome side. The pressure differential has reversed, and the piston will rise, opening the main valve, relieving pressure.

When the process pressure decreases to a specific pressure, the pilot closes, the dome is repressurized, and the main valve closes. The main difference between spring-loaded PRVs and pilot-operated is that a pilot-operated safety valve uses pressure to keep the valve closed.

Pilot-operated relief valves are controlled by hand and are typically opened often through a wheel or similar component. The user opens the valve when the gauge signifies that the system pressure is at an unsafe level; once the valve has opened and the pressure has been released, the operator can shut it by hand again.

Increasing pressure helps to maintain the pilot"s seal. Once the setpoint has been reached, the valve opens. This reduces leakage and fugitive emissions.

At set pressure the valve snaps to full lift. This can be quite violent on large pipes with significant pressure. The pressure has to drop below the set pressure in order for the piston to reseat.

The pilot is designed to open gradually, so that less of the system fluid is lost during each relief event. The piston lifts in proportion to the overpressure.

At Curtiss-Wright we also provide solutions for pressure relief valve monitoring. Historically, pressure relief valves have been difficult or impossible to monitor. Our SmartPRV features a 2600 Series pressure relief valve accessorized with a wireless position monitor that alerts plant operators during an overpressure event, including the time and duration.

There are many causes of overpressure, but the most common ones are typically blocked discharge in the system, gas blowby, and fire. Even proper inspection and maintenance will not eliminate the occurrence of leakages. An air pressure relief valve is the only way to ensure a safe environment for the device, its surroundings, and operators.

A PRV and PSV are interchangeable, but there is a difference between the two valves. A pressure release valve gradually opens when experiencing pressure, whereas a pressure safety valve opens suddenly when the pressure hits a certain level of over pressurization. Safety valves can be used manually and are typically used for a permanent shutdown. Air pressure relief valves are used for operational requirements, and they gently release the pressure before it hits the maximum high-pressure point and circulates it back into the system.

Pressure relief valves should be subject to an annual test, one per year. The operator is responsible for carrying out the test, which should be done using an air compressor. It’s imperative to ensure pressure relief valves maintain their effectiveness over time and are checked for signs of corrosion and loss of functionality. Air pressure relief valves should also be checked before their installation, after each fire event, and regularly as decided by the operators.

Direct-acting solenoid valves have a direct connection with the opening and closing armature, whereas pilot-operated valves use of the process fluid to assist in piloting the operation of the valve.

A control valve works by varying the rate of fluid passing through the valve itself. As the valve stem moves, it alters the size of the passage and increases, decreases or holds steady the flow. The opening and closing of the valve is altered whenever the controlled process parameter does not reach the set point.

Control valves are usually at floor level or easily accessible via platforms. They are also located on the same equipment or pipeline as the measurement and downstream or flow measurements.

An industrial relief valve is designed to control or limit surges of pressure in a system, most often in fluid or compressed air system valves. It does so as a form of protection for the system and defending against instrument or equipment failure. They are usually present in clean water industries.

A PRV is often referred to as a pressure relief valve, which is also known as a PSV or pressure safety valve. They are used interchangeably throughout the industry depending on company standards.

A pressure safety valve actuated by inlet static pressure and characterized by rapid opening or rapid popping action. This safety valve is tight shut-off and is for safety only. Meets ASME SEC. VIII (Not a Fulflo valve)

A spring loaded pressure relief valve, actuated by the static pressure upstream of the valve. The valve opens normally in proportion to the increase in pressure over the set pressure. (Fulflo)

A pressure relief valve characterized by rapid opening or pop-action in direct proportion to the pressure increase, depending on the application. (Fulflo)

The pressure existing at the outlet of a pressure relief valve, due to the pressure in the discharge system. The pressure can be constant or variable. It is the sum of the superimposed and build-up pressure.

The pressure existing at the outlet of the relief device at the time the device is required to operate. It is a result of pressure in the discharge system coming from another source. This pressure may be constant or variable.

Fulflo was established in 1912 and is celebrating its 100th anniversary. Located in Blanchester, OH, Fulflo was incorporated in 1933 under its present name and trademark. Patents for the original guided piston, direct acting relief valve were obtained in 1935, coinciding with the onset of fluid power systems. The need for providing large flows without excessive bulk was met by the pilot-valve-control relief valve which was patented in 1943.

Fulflo parts and valves are used in oil and gas refineries, are essential to the military, including ships and aircraft carriers, and amusement roller coaster rides.

The primary purpose of a pressure relief valve is to protect life, property and the environment. Pressure relief valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of pressure relief valves differs depending on the main type or loading principle of the valve. The main types of pressure relief valves are spring-loaded, weight-loaded and controlled pressure relief valves.

Regardless of the type or load, pressure relief valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

Kings Energy Services provides service, repairs, and testing for a wide variety of safety/relief valves and devices. We will happily provide skilled valve servicing in-house or on-location (field servicing is only available for ANSI or API valves). To reduce downtime for producers, Kings Energy has an assortment of valves in stock for exchange and/or sale.We also carry stock inventory, enabling quicker turn-around times and reduced customer costs.

Our experienced and technically trained staff are knowledgeable about appropriate industry codes, regulations, and manufacturer guidelines. To maximize efficiency, we utilize an assembly-line operations system to service and repair relief valves. The process goes through several stages in order to maintain a high-quality assurance program, and valve data is entered into our database at every station.Receiving and Dismantling

Valves are given a visual inspection to record the received condition, identification numbers, make, model, and serial number, code stamps, set pressure, capacity, and any irregularities. After proper safety precautions are completed, a pre-test is performed and recorded. The valve is then dismantled in accordance with the manufacturer’s recommendations.

Special care is taken to properly assemble each valve using quality OEM manufactured parts. After assembly, each valve is tested to its appropriate PSI range; a final inspection is performed to re-confirm the valve data previously recorded, and the valve is sealed according to industry regulations.

Pressure Safety Valve (PSV) Repairs can be done on our in Red Deer, Drayton Valley, Provost, Grande Prairie, Dawson Creek and Cambridge, Ontario service facilities. We also have a fully mobile valve servicing unit that can come to your facility to provide servicing.

Both pressure relief valves (PRV) and pressure safety valves (PSV) are used for process safety to relieve excess pressure. Although they’re often used interchangeably, they do have different functions and it’s important to know the difference.

If the PRV fails to maintain optimal pressure, the PSV kicks in. This valve opens quickly to avoid overpressurization when a set pressure is reached, preventing a potential safety incident.

Industrial Valve offers new PSVs and PRVs from Farris. Our Farris Authorized Service Team (FAST) can conduct pre-installation testing, install your valve, and perform regularly scheduled maintenance to keep your workflow operating at peak efficiency. Should you ever need an emergency repair, just call us – our technicians are available 24 hours a day!

Pacific Controls is proud to represent Industry leading Brands offering the best a complete range of Pressure Management Solutions from Crosby, Anderson Greenwood, Varec and Enardo to name a few.

Our Pressure Management team is dedicated to providing pressure relief devices and life cycle services in Australia, PNG and New Caledonia. Our facility in Queensland. This support is supported by around-the-clock access to a large relief valve inventory facilitating our Quick-ship program through our Relief valve Authorised Centre.

Our Over-pressure protection specialists and factory authorised technicians provide you with the expertise you can depend on to protect your people, equipment and the environment.

Steven Barrow graduated from Brigham Young University with a B.S. in Chemical Engineering. He is a husband, father of 4, entrepreneur, and licensed professional engineer who is passionate about his family, leadership, and energy. He is an expert in chemical process safety and loves designing, building, and operating projects in the oil & gas industry. He is the Chief Executive Officer of Patronus Energy, an innovative engineering and technology firm. Steven sits on several different boards including the BYU Industrial Advisory Board and the board of directors for Rosedown Energy, a private midstream company.

8613371530291

8613371530291