api safety valve brands

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

This page lists the ApprovedPressure and Safety Relief ValveManufacturers (vendors), also provides inspection and test advice to thePressure and Safety Relief Valvepurchasers buying from vendors, suppliers and distributors.

Nivz Valves & Automation manufacturing range all Pressure Safety Relief Valves are designed as per API 526. They also conform to ASME Section – VIII. Dimensions of valves meet to API 521/521. Metal seated Safety Valves Testing is carried our as per API 527 for Set Pressure & Leakages.

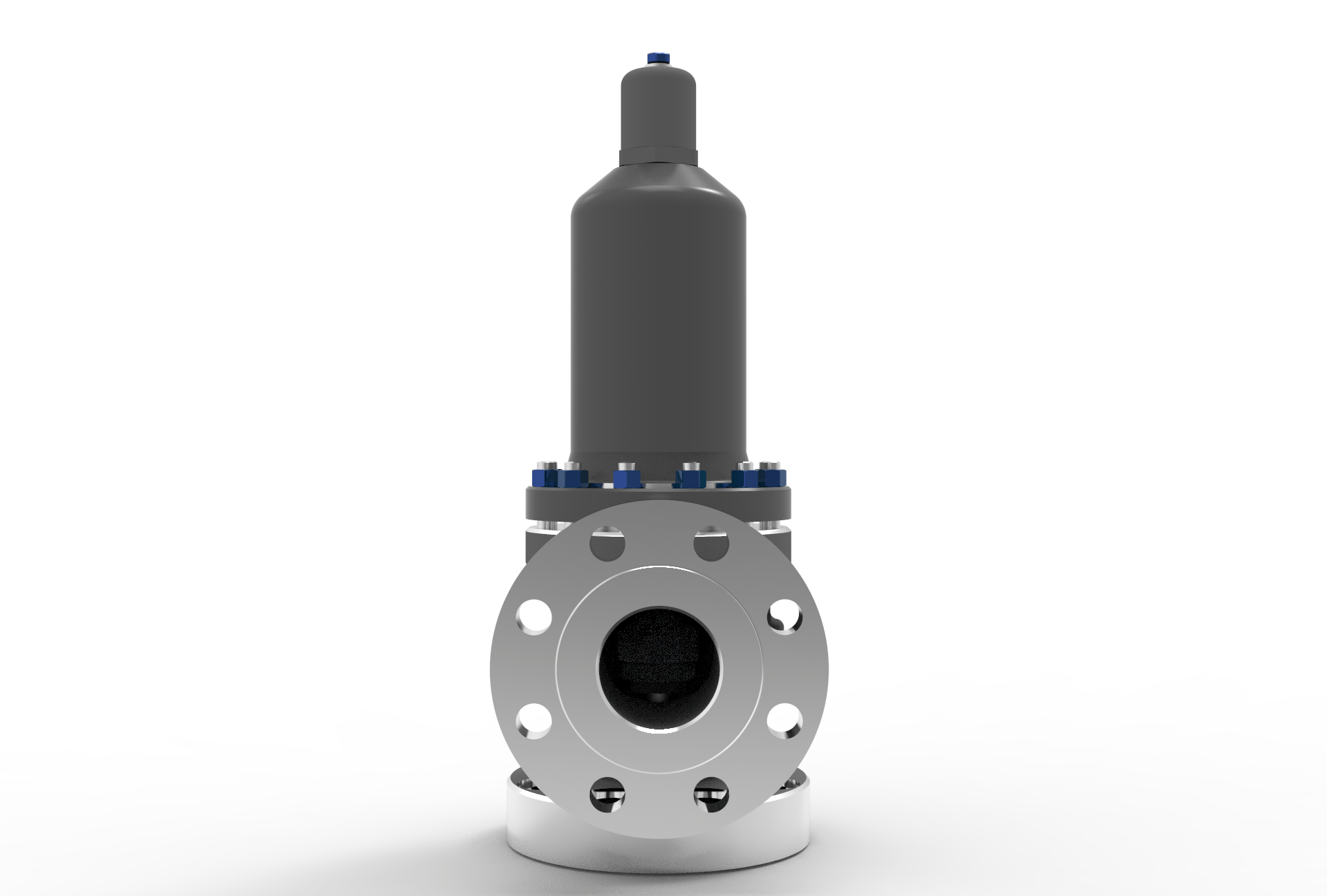

A Safety Relief Valve is a mechanical, self actuating, pop design, spring loaded angle type valve, which is being used for the automatic release (on a set pressure) of a substance from a Pressure Vessel, Boiler, Overpressure of Pipeline or any Industrial System when the Pressure or Temperature exceeds required limits.

Pressure Relief valves also being used to Control the Pressure in an Industrial System, Process Pipeline or Pressure Vessel which can develop by a failure of equipment, instrument or process upset.

Safety Valve also known by the name of Pressure Relief Valve (PRV) and Pressure Safety Valve (PSV). Other names of Safety Valves are Safety Relief Valve, Thermal Relief Valve, Relief Valve, Spring Loaded Safety Valve, Angle Type Safety Valve, Pilot Operated Safety Relief Valve and Low Pressure Safety Relief Valves.

The difference in between Pressure Safety Valve (PSV) and Pressure Relief Valve is Pressure Safety Relief Valve have provided a manual lever with a cap to relieve the pressure in case of emergency.

Mostly two types of protection encountered in Industries which are Flow Protection & Thermal Protection. Flow protection is done by the using of Safety Relief Valves and Thermal Protection by Thermal Relief Valve.

The pilot operated safety relief valve is used for safety purpose in Oil and Gas industries. The pilot operation make these valves ideal for industrial applications in Oil and Gas.

ASME section VIII “UV” stamp | PED “CE” mark | DOT, API | Marine IGC, ABS, BV, DNV-GL, LR | ISO 9001:2015 | Canadian CRN Approval (all provinces/territories)

Safety valves from the API product group meet all the requirements of API 526 such as standardized capacity, nominal diameter, and center to face dimensions which offers 100% compatibility. Because of their robust construction, they are especially suitable for being constructed from special materials such as Duplex, Monel, and Hastelloy.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

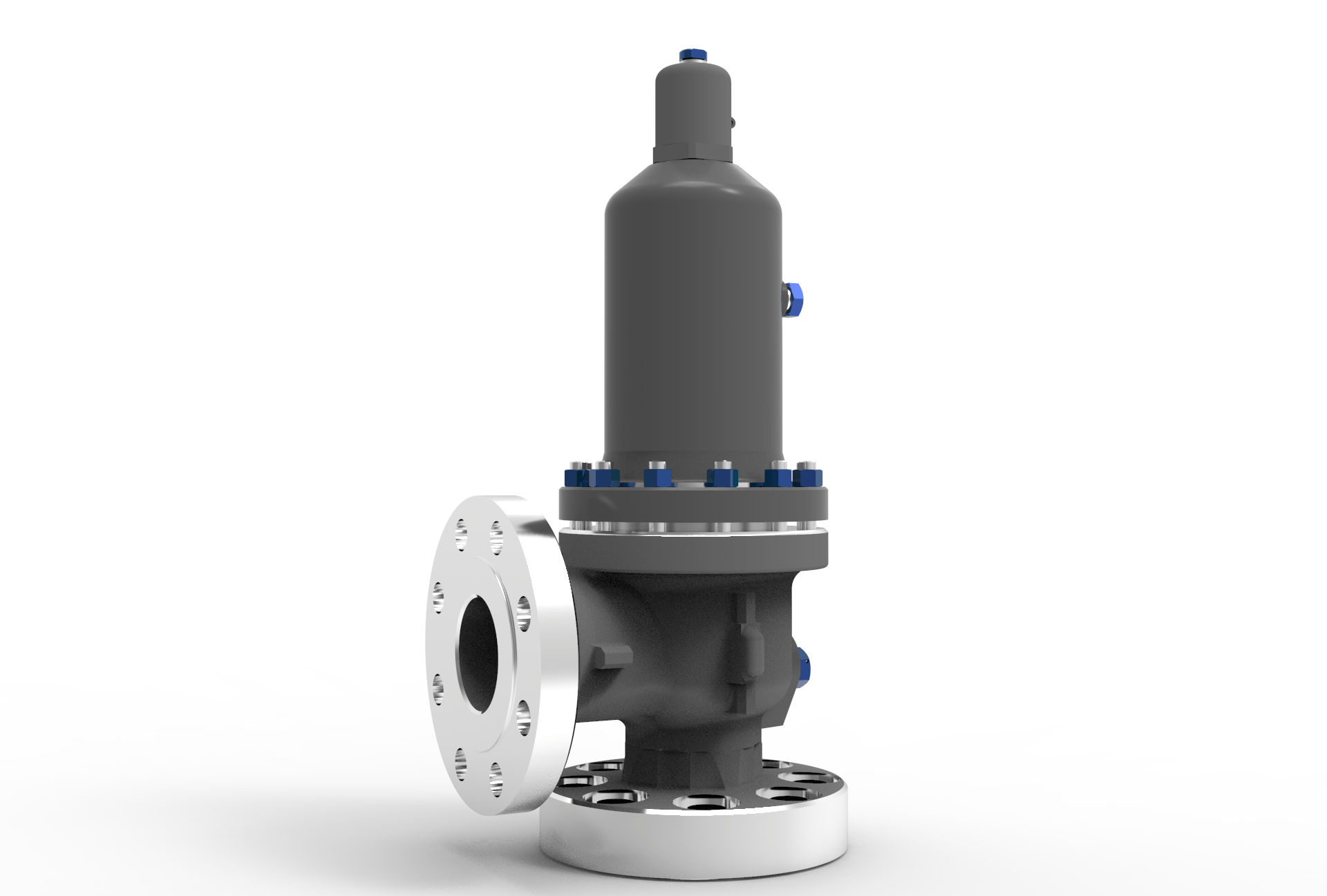

The Trillium Flow Technologies™ Sarasin-RSBD® brand offers a comprehensive range of safety valves for use in the oil & gas, petrochemical, fossil, and nuclear power industries.

Under our PRODIM program, our team of dedicated experts will assist you throughout your entire project, from product selection through the commissioning of all safety related devices. Together with the experience and expertise of all of our facilities, PRODIM can provide essential advice and support for all safety related questions.

For safety valves that provide optimum performance, safety, and reliability – turn to Sarasin-RSBD®. We’re singularly focused on manufacturing the top safety valves and backup devices for your industry.

Air,API,ASME,ATEX,Food & Beverage,Gas,General Industry,Industries,ISO,Liquid,LNG,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Steam,Traditional Power,Water & Wastewater

Air,API,ASME,ATEX,Food & Beverage,Gas,General Industry,Industries,ISO,LNG,Media,Nonrenewable Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Steam,Traditional Power,Water & Wastewater

Air,API,ATEX,Fertilizer,Food & Beverage,Gas,General Industry,Industries,ISO,LNG,Media,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Steam,Traditional Power,Water & Wastewater

Air,ANSI,API,Fertilizer,Food & Beverage,Gas,General Industry,Industries,Liquid,LNG,Media,Nonrenewable Power,Nuclear Power,Oil & Gas,Oil & Gas - Downstream,Oil & Gas - Midstream,Oil & Gas - Upstream,Renewable Power,Standard,Steam,Traditional Power,Water & Wastewater

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

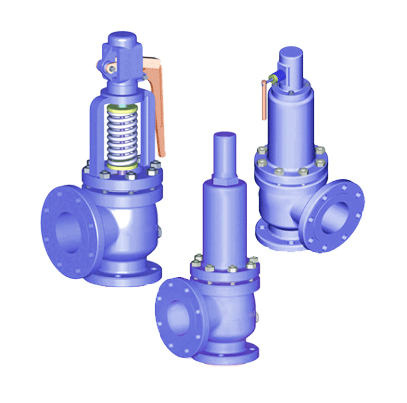

The safety valves / pressure relief valves provided by Weldon mainly include spring-loaded safety valve, pilot-operated safety valve, bellow balanced safety valve and changeover valve (switch device). The calculation sheet could be provided for all projetc and all the safety valves are designed and manufactured according to API 2000, API PR520 and API 526.

Safety valve is the safe guard in the pressure vessels such as chemical plants, eletcric power boilers and gas storage tanks, acting as a protetcion equipment from exploding or damaging. The safety relief valve is opened automatically to relief when the system pressure exceeds the set pressure, and resumes closed when the system pressure bellow the set pressure.

The Spring-loaded safety valves is the most conventional safety valve, the spring load is preset to equal the force the inlet fluid exerts on the closed disk when the system pressure is at the set pressure of the valve. As the pressure exceeds a set value, the spring opens releasing the disc and the fluid flowing through the valve.

The Pilot-operated safety valves are composed of a "pilot valve" and a "main valve", differently from spring-loaded safety valves, the pressure is monitored and adjusted by the pilot valve, not the main valve. Pilot-operated safety valves are widely used for large size valve and high-pressure applications, which need lager torque and high reliability.

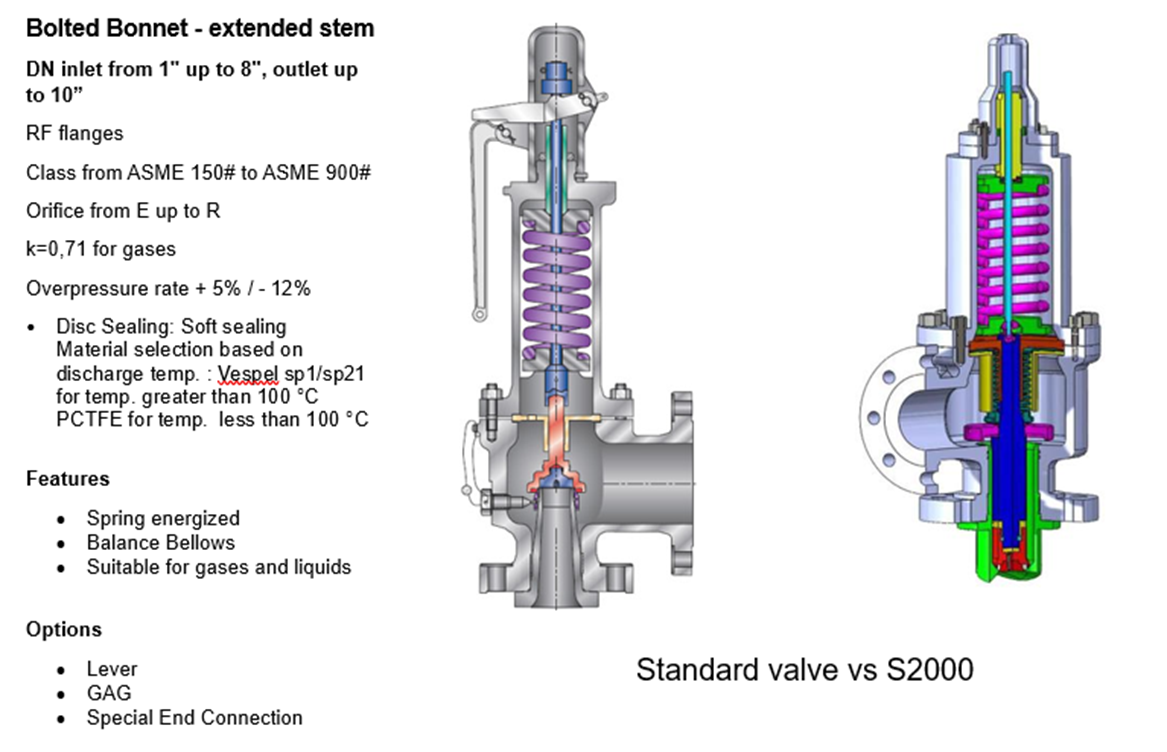

Bellow balanced safety valves are designed to reduce the effetc of back pressure accumulation, the "Bellows" located between the bonnet and the valve body, where maintained free from the effetc of back pressure, the opposing pressure on the inlet fluid is only generated by the spring without contribution from any sort of backpressure. The space enclosed by bellows is freely vented to air, the back pressure is expetced to be 10 - 50% of the set pressure. The Bellows can also protetc the spring and other trim components from corrosive media.

Breather Valves, also named Pressure/Vacuum Relief Valves, available with flanged outlets or vented to atmosphere, are special types of Relief Valves which are specifically designed for tank protetcion. Breather Valves are usually installed in the in-and out breathing lines of tanks, vessels and process equipment to prevent the of excessive pressure or vacuum which can unbalance the system or damage the storage vessels.

Changeover valves, also called Switch valves, are designed to connetc two safety valves to a single pressurized system, acting as the three ways devices for flow seletcion in a pipeline.

Through these Changeover valves, one of the two safety valves is in operation and ensures the protetcion of the system, the other safety valve is in "stand by" ready to come into operation if the first one must be changed or removed to maintenance. Changeover valves are often required for the continuous production.

The world is rapidly changing. As the industries we serve face increasing pressure to reduce their carbon footprint, digitally transform processes and optimize operations, the Valves team at Baker Hughes is ready to help our customers meet those challenges. Our culture of innovation and legacy of quality make us uniquely positioned to recognize and adapt to changing industry trends. From staying abreast of new manufacturing processes and materials sciences development, to converting our facilities and processes to reduce our own carbon footprint, we are creating solutions to help customers achieve their goals.

8613371530291

8613371530291