ari safety valve catalogue quotation

ARI-SAFE Safety valve Full lift safety valve / Standard safety valve ARI-SAFE Full lift safety valve D/G Standard safety valve F • Type-test approved acc. to DIN EN ISO 4126 / AD2000-A2 • TÜV · SV · . . -663 · D/G Figure 901-912 • TÜV · SV · . . -663 · F Figure 901/911 • Further approvals: see inside ARI-SAFE Standard safety valve for the heating technology • Type-test approved acc. to TRD 721 • TÜV · SV · . . -688 · D/G/H Figure 903 • TÜV · SV · . . -688 · D Figure 904 ARI-SAFE-P Standard safety valve D/G/F • Type-test approved acc. to DIN EN ISO 4126 / AD2000-A2 • TÜV · SV · . . -811 · D/G Figure 921-924 • TÜV · SV · . . -811 · F Figure 921/923 ARI-SAFE-TC Full lift safety valve D/G Standard safety valve F • Type-test approved acc. to DIN EN ISO 4126 / AD2000-A2 • TÜV · SV · . . -995 · D/G Figure 941-943 • TÜV · SV · . . -995 · F Figure 941/943 ARI-SAFE-TC Standard safety valve for the heating technology • Type-test approved acc. to TRD 721 • TÜV · SV · . . -997 · D/G/H Figure 945 • TÜV · SV · . . -997 · D Figure 946 ARI-SAFE-TCP Standard safety valve D/G/F • Type-test approved acc. to DIN EN ISO 4126 / AD2000-A2 • TÜV · SV · . . -1041 · D/G Figure 961-963 • TÜV · SV · . . -1041 · F Figure 961/963 ARI-SAFE-TCS Standard safety valve D/G/F • Type-test approved acc. to DIN EN ISO 4126 / AD2000-A2 • TÜV · SV · . . -1041 · D/G Figure 951-953 • TÜV · SV · . . -1041 · F Figure 951/953 FOR HORIZONTAL APPLICATION Edition 11/12 - Data subject to alteration Features: • Direct loaded with spring • Wear resistant seat/disc • Precision disc alignment and guide • Possible with soft seal disc • Possible with EPDM bellow 953 • Possible with stainless steel bellow Page 28 • ARI-SAFE-TC/TCP/TCS: All common thread types Data sheet 900001 englisch (english)

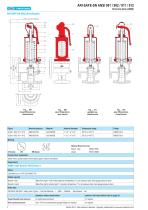

Fig. 901 / 902 / 911 / 912 ARI-SAFE - Full lift safety valve D/G, Standard safety valve F Figure Nominal pressure Nominal diameter Temperature range Flange holes/thickness tolerances DIN 2533/2533 DIN 28607/28605 DIN 2545/2543 DIN 2545/2543 Type-test approval Full lift safety valve: TÜV · SV · . . -663 · D/G (Fig. 901/902/911/912) Standard safety valve: TÜV · SV · . . -663 · F (Fig. 901/911) Set gauge pressure refer to „Capacity“. Requirement Acc. to EN ISO 4126-1, VdTÜV-leaflet 100, AD2000-A2, TRD 421, material selection observe TRB 801 No. 45!! Construction Safety valve, spring loaded,...

Fig. 901 / 902 / 911 / 912 Dimensions and weights DN1/DN2 (mm) 20/32 18 d0 (mm) 254 A0 (mm2) 85 l (mm) 95 l1 (mm) 270 H (mm) 310 H (Bellow design) (mm) 150 X (mm) G 1/4“ Drainhole with plug 1) (inch) 8,5 Weight (kg) 9,5 Weight (Bellow design) (kg) Standard-flange dimensions refer to page 34. 1) Spring ranges: Standard design (barg) DN20 DN25 - 50 DN65 DN80 Spring ranges: Bellow design (barg) DN20 DN25 DN32 DN40 Design with bellow as standard valve (only Fig. 901/911) Description Body Seat Studs Spindle guide Hexagon nut Bonnet, closed 12 Disc unit 14 Spindle * 17 Adjusting screw 28 Cap,...

Capacity Fig. 901 / 911 Capacity water incl. 10% overpressure Gauge press. ← max. set pressure stainless steel version Certified coefficient of discharge Kdr (Values for D/G variable: DN20-100 < 3,5 bar, DN125-150 < 4,0 bar) Kdr D/G Edition 11/12 - Data subject to alteration

ARI-SAFE - Heating-safety valve Figure Nominal pressure Nominal diameter Temperature range Flange holes/thickness tolerances DIN 2533/2533 Type-test approval spring loaded: TÜV · SV · . . -688 · D/G/H Set gauge pressure refer to „Capacity“. Requirement Acc. to TRD 721 Part 6, material selection observe TRD! (EN-JL1040 max. 10 bar; >10 bar 25.903 EN-JS1049 or 35.903 1.0619+N) Application Acc. to DIN EN 12828 Heating systems in buildings Constructions Standard safety valve, spring loaded, direct loaded metal seat with EPDM insert, EPDM-bellow, closed spring bonnet with control hole, open...

Dimensions and weights DN1/DN2 (mm) 20/32 18 d0 (mm) 254 A0 (mm2) 85 l (mm) 95 l1 (mm) 270 H (mm) 150 X (mm) G 1/4“ Drainhole with plug (optional) (inch) 8,5 Weight (kg) Standard-flange dimensions refer to page 34. Parts Pos. Description 1 Body 2 Seat 3 Studs 4 Spindle guide 8 Hexagon nut 11 Bonnet, closed 12 Disc unit 14 Spindle * 17 Adjusting screw 29 Cap, open 37 Spring * 41 Lever, open 43 Bellow * Spare parts Information / restriction of technical rules need to be observed! ARI-Valves of EN-JL1040 are not allowed to be operated in systems acc. to TRD 110. A production allowance acc. to...

Capacity Fig. 903 Capacity water Water 20°C (kg/h) ^ Sizing: 1 l/h = 1 kW Sizing safety valves for the volume flow of water expansion (DIN 4751 p2 - item 8.1) Edition 11/12 - Data subject to alteration

ARI-SAFE - Low pressure steam - safety valve Figure Nominal pressure Nominal diameter Temperature range Flange holes/thickness tolerances DIN 2533/2533 Type-test approval Low pressure steam - safety valve: TÜV · SV · . . -688 · D Set gauge pressure refer to „Capacity“. Requirement Acc. to TRD 721 Part 5 Application For low pressure steamgenerators up to 1 bar, DIN 4750 and DIN EN 12828 Heating systems in buildings Construction Standard safety valve, spring loaded, direct loaded, EPDM-bellow, closed bonnet with control hole, open lifting device, stainless steel seat and spindle Sizing refer...

The ARI-REYCO line from ARI Armaturen features a range of direct spring acting safety relief valves for gas, liquid, and steam service. As a distributor for ARI-Armaturen, Cross company offers a variety of options to keep your operation safe and our team of experts have worked with customers in a wide range of process applications across multiple industries.

With such a variety of options available, finding the right solution is important. We can work with your team to determine the best product for your operation. Learn more about ARI-REYCO series safety relief valves below and Start a conversation with a Cross expert today!

*ARI-REYCO brand valves (and/or valve parts) are fully interchangeable with, and replaceable for, Lonergan valves (and/or valve parts). Londergan is a trademark of Pentair Valves and Controls. ARI-Reyco is not licensed to use the Lonergan trademark.

We’ve got your back. Let us find the exact part you’re looking for in our 100,000 sq. ft. warehouse stocked with 35,000 ready-to-ship valves from the world’s most renowned brands. We’ll put our decades of experiencing cross-referencing valves to work fast. Just give us a call.

Kunkle Relief Valve OverviewWhen it comes to industrial and commercial safety and relief valve products, Kunkle’s valve’s catalog is second to none in steam, air, gas, and liquid applications.

Kunkle relief valves range in size from ¼” NPT to 6” flange and are suitable in cryogenic and high temperatures up to 800°F environments at vacuum to 7,500 psig pressure. Kunkle Valve’s code certifications meet several global and national board standards, including ASME Section I, Section IV, and Section VIII, PED, CRN, TU and Chinese, as well as non-code requirements.

Relief Valves for Steam ServiceSteam supplies heat for industrial and chemical processes and also is used to heat buildings, supply mechanical energy, and drive mechanical equipment. Steam moves from the boiler to the end point, then heats by direct heating or indirect heating through a heat exchanger. Kunkle steam relief valves are critical to protecting equipment such as boilers, steam lines, and pressure valves, from being over-pressurized.

Relief Valves for Air ServiceKunkle designs valves for air service, for example for air compressors in mechanical shops and small factories where either low-pressure or high-pressure air is required. NASVI stocks Kunkle relief valves for air service in iron, steel and bronze for a variety of uses.

Relief Valves for Liquid ServiceKunkle also makes valves for liquid service, which provide bypass relief in a variety of applications and liquid types.

More About KunkleKunkle Valve is a renowned pressure relief valve manufacturer. Erastus B. Kunkle invented the safety valve to prevent overpressure in locomotive engines. Kunkle patented it in 1875. Since that time, Kunkle has earned its reputation for high-quality valves, and other equipment manufacturers ship their products with Kunkle’s valves pre-installed.

NASVI has stocked Kunkle safety relief valves since we opened in 1975, so we are confident when we call ourselves Kunkle safety valve experts. Every day we fulfill orders for our customers looking for Kunkle relief valves for steam, air, gas, and liquid applications.

Forged from heavy-duty cast steel with a stainless steel nozzle, these safety valves are certified for air, gas and steam. Used in steam boilers, steam generators, air compressors, gas compressors, pressure tanks, pressure receivers, intercoolers, and oil/gas separators, these sturdy valves contain a bolted yoke design for easy maintenance.

A relieving regulator releases excess pressure through a relief valve, a hole in the middle of the diaphragm. When air pressure exceeds the acceptable limit of a system, the relieving regulator opens a vent to allow the air to escape. A hissing sound usually indicates the release of air. There is no need to add an extra relief valve to the flow system since the relieving regulator performs this function on its own.

A non-relieving regulator restricts airflow once it exceeds the setpoint. There’s no vent path in a non-relieving regulator so the gas stays in the system. These regulators require extra care because they can become dangerous if excess pressure builds up without being released. In a closed system, it is important to have a relief valve downstream. Alternatively, an open system design should be implemented downstream of the regulator to prevent the build-up of excessive pressure.

Non-relieving regulators are most beneficial when dealing with hazardous or expensive gases. By trapping these gases for safe or controlled release, operators ensure the safety and efficiency of the entire facility.

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

8613371530291

8613371530291