avk safety valve testing pricelist

ABBEY ROGERS offers a lift assist device that allows for the testing of safety relief valves while still in line, and operational. The AVK is an electro-hydraulic computerized testing unit that when connected to the valve records the pressure at which the valve lifts. The AVK connects to the stem of the safety valve and measures the vertical forces exerted by the spring and load train of the valve. These tests are preformed while your system is under pressure, therefore no loss of production due to removing safety relief valves. The documentation provided will satisfy ASME & Insurance inspectors.

Valve requirements for the AVK are the following: pressure under the valve, must be flanged, must be at least a 21" clearance above the valve, service must be non-liquid, and non-hazardous vapors. The AVK is ideal for testing valves in place which will determine which valves need to be pulled out of service for repair, and which can remain inline through another cycle. The AVK will reduce manpower and downtime expenses.

relief valve industry. This vast knowledge, coupled with continuous customer input, allows AVK to provide the first in-line pressure relief valve testing devices designed specifically with you in

with your specific application, and make the testing of pressure relief valves a cost effective way of ensuring plant safety with the utmost in flexibility.

A very critical aspect of inline testing is the accuracy of effective seat areas that are used in calculating set point, our products have been proven by comparative live testing and empirical

analysis through many years. Our Nuclear software has passed V & V certification. Our products have been independently verified for accuracy by major valve manufacturers and

One-Piece BallAVK’s unique one-piece Ductile Iron EPDM rubber encapsulated ball offers superior flow with head loss less than 2.5psi at 1000 gallons per minute.

Dual PurposeThe AVK FlowGuard dual purpose design offers protection in both directions. During normal operation the FlowGuard is designed to prevent backflow and cross-contamination.

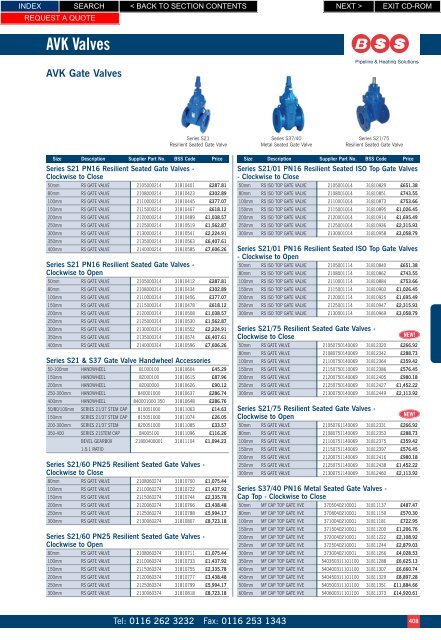

AVK gate valves are designed with built-in safety in every detail. The wedge is fully vulcanized with AVK’s own EPDM rubber compound with NSF drinking water approval. It features an outstanding durability due to the ability of the rubber to regain its original shape, the double bonding vulcanization process and the sturdy wedge design. The triple stem seal system, the high strength stem and the thorough corrosion protection safeguard the unmatched reliability

Safety valves are used in a variety of industrial applications to include air/gas, vapor, steam, and liquid service, among many more. These pressure relief valves are critical to the safe operation of our customer’s equipment and provide—as their name implies—a safety measure that can reduce the number of risks that can threaten both your personnel and facilities.

Millennium Power Services’ safety valve technicians will get your valves tested, repaired, and quickly set to the exact specifications. We serve as your knowledge partner and will also evaluate the repair condition of every valve and make recommendations as needed to help you make the best decisions.

AVK series 851 double orifice, triple action air valves are designed to allow air to rapidly either escape or enter the pipe system when filling or draining, as well as for automatic discharge of accumulated air during normal working conditions. The unique ‘Aerokinetic’ design allows air to rush out of the system at great speed without forcing the float upwards and closing it prematurely. This makes sure that the valve closes only after all air has left the system and water has entered the chamber.

Using the data acquired through system transducers, the AVK consistently and accurately verifies valve set pressure. The portable device includes a small actuator assembly that is mounted to the valve. A custom-designed adapter with sensor applies force to the valve spindle to determine set pressure. The test results can then be printed or downloaded to other applications.

PRICE LIST VALVES, HYDRANTS & FITTINGS OCT 2020 MYREXPECTSUPREME PRODUCTS

AVK is a global leader within valves, hydrants, fittings and accessories for water supply, gas supply, wastewater treatment and fire protection.

AVK benefits from modern production faciliites and a large distribution center which enable us to deliver within a short period of time.

A complete product range, fast delivery, superior quality products, competive prices and top service are some of the benefits to expect when dealing with AVK.

Inhouse R&D handled through a global network of sales By obtaining and maintaining the most widelyIn our Development Department in Denmark, companies and dealers. This network services accepted certification, we show ourideas and suggestions for new products are the enduser, allowing AVK to monitor market customers that AVK valves always meet thegathered, and existing products are updated changes and keep abreast of customer highest quality and safety standards.continuously. requirements. AVK focuses on the environmentWe use FEA (Finite Element Analysis) to Quality certifications AVK products are part of vital infrastructures,optimise the strength and geometry of our AVK’s quality management system is certified which play an important role for the localcomponents and CFD Computational Fluid according to ISO 9001, and in 2018, we also environment all over the world. AVK alsoDynamics) analyses to validate different obtained the ISO/TS 9001 certification. focuses on the environment in all its internalproduct designs prior to creating physical processes. The AVK Group has outlined aprototypes, enabling us to predict ISO/TS 29001 is an industry-specific number of strict objectives for itsconsequences in cases where it is impossible standard for the oil and gas industry based on manufacturing companies regarding energyto create full scale tests on physical products. ISO 9001, but with stricter requirements for and water consumption. Our suppliers also control measures and risk management, in need to comply with a number of standards inWe make our own test and production that key issues such as staff training, order to be a certified supplier of the AVKequipment, and in our flow lab, we conduct traceability of materials and obtained test Group, as it is vital for AVK to achievethorough prototype and life cycle tests prior to results must be documented. sustainability throughout the supply chain.release for production. New product types aregenerally field tested in co-operation with end Moreover, we are certified to ISO 14001, theusers before final launch. international standard for environmental management, and OHSAS 8001, theProduction international Occupational Health and SafetyProduction takes place in several countries in Standard.Europe and Asia as well as in the US andSaudi Arabia. AVK manufactures valves and Third party certificationaccessories for water, gas and wastewater Authorities such as DVGW (Germany), KIWAapplications as well as valves and hydrants (Netherlands) and UL & FM (the US) offerfor fire protection - all according to the DIN certification of finished valves, and these arestandard. also recognized and accepted by other countries that do not have their ownStock control and distribution to end users are certification schemes. AVK’s four main segments: Water supply Gas supply Gate valves and accessories, butterfly valves, swing Gate valves and accessories, ball valves, couplings and check valves, air valves, control valves, hydrants, repair clamps. couplings, fittings, etc.

Wastewater treatment Fire protection Gate valves, knife gate valves, ball and swing check Fire hydrants, monitors, gate valves, post indicators, valves, butterfly valves, air valves, penstocks etc. butterfly valves etc.TABLE OF CONTENTS

21/36-101 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith stem capFace-to-face dimension 21-050-36-21420641 50 PN10/16 14 A 899.35according to EN 558 Table 2 21-065-36-21420641 65 PN10/16 16 C 946.20Basic Series 3 21-080-36-21420641 80 PN10/16 17 A 968.01Ductile Iron 21-100-36-21420641 100 PN10/16 19 A 1,075.67EPDM rubber, WRAS appr.Fusion bonded epoxy coating 21-150-36-21420641 150 PN10/16 34 A 1,832.88to DIN 3476-1 and EN 21-200-36-21420641 200 PN16 52 A 2,727.2114901, GSK approved 21-300-36-21420641 300 PN16 116 A 6,121.67Clockwise to Close 21-350-36-21420641 350 PN16 212 C 12,410.38 21-400-36-21420641 400 PN16 217 C 12,748.94PN10 available upon request.

21/36-104 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith handwheelFace-to-face dimension 21-050-36-41420641 50 PN10/16 14 C 913.41according to EN 558 Table 2 21-065-36-41420641 65 PN10/16 16 C 960.26Basic Series 3 21-080-36-41420641 80 PN10/16 17 C 982.08Ductile Iron 21-100-36-41420641 100 PN10/16 19 C 1,089.74EPDM rubber, WRAS appr.Fusion bonded epoxy coating 21-150-36-41420641 150 PN10/16 33 C 1,882.88to DIN 3476-1 and EN 21-200-36-41420641 200 PN16 52 C 2,777.2214901, GSK approved 21-250-36-41420641 250 PN16 85 A 4,893.77Clockwise to Close 21-300-36-41420641 300 PN16 117 A 6,446.72 21-350-36-41420641 350 PN16 189 C 12,891.08PN10 available upon request. 21-400-36-41420641 400 PN16 212 C 13,229.64

21/38-004 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve,with ISO mounting flange mm drilling weight/kg pallet code MYRFace-to-face dimension 21-050-38-0142064 50 PN10/16 14 C 1,252.12according to EN 558 Table 2 21-065-38-0142064 65 PN10/16 16 C 1,310.44Basic Series 3 21-080-38-0142064 80 PN10/16 17 C 1,349.22Ductile Iron 21-100-38-0142064 100 PN10/16 19 C 1,488.53EPDM rubber, WRAS appr. 21-150-38-0142064 150 PN10/16 35 C 2,477.60Fusion bonded epoxy coating 21-200-38-0142064 200 PN16 53 C 3,677.97to DIN 3476-1 and EN 6,584.79 21-250-38-0142064 250 PN16 85 C14901, GSK approved 21-300-38-0142064 300 PN16 117 C 8,015.21Clockwise to Close 21-350-38-0142064 350 PN16 211 C 18,116.68PN10 available upon request. 21-400-38-0142064 400 PN16 217 C 18,612.72

21/46-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve,rising stem, mm drilling weight/kg pallet code MYRwith handwheel 21-050-46-014 50 PN10/16 19 C 1,965.88Face-to-face dimension 21-065-46-014 65 PN10/16 23 C 2,102.90according to EN 558 Table 21-080-46-014 80 PN10/16 25 C 2,101.362 Basic Series 3 21-100-46-014 100 PN10/16 39 C 2,700.59Ductile iron 21-125-46-014 125 PN10/16 45 C 4,445.06EPDM rubber, WRAS, W270 21-150-46-014 150 PN10/16 63 C 4,449.82appr.AVK coating standard 21-200-46-014 200 PN16 97 C 6,250.80Clockwise to Close 21-250-46-014 250 PN16 157 C 9,587.19 21-300-46-014 300 PN16 238 C 13,088.57PN10 available upon request 21-350-46-014 350 PN16 320 C 25,971.88 21-400-46-014 400 PN16 360 C 27,684.45

21/60-007 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve,PN25 mm drilling weight/kg pallet code MYRFace-to-face dimension 21-050-60-0742064 50 PN25 17 C 1,415.39according to EN 558 Table 21-080-60-0742064 80 PN25 - C 1,551.852 Basic Series 3 21-200-60-0742064 200 PN25 - C 5,538.58Ductile iron 21-300-60-0742064 300 PN25 - C 17,550.98EPDM rubber, WRAS, W270 21-400-60-0742064 400 PN25 - C 26,618.90appr.Epoxy CoatingClockwise to Close

Products for Water Supply and Wastewater 9 Resilient Seated Gate Valves

02/20-021 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve,Type A mm drilling weight/kg pallet code MYRFace-to-face dimension 02-050-20-014649 50 PN10/16 10 C 824.90according to EN 558 Table 2 02-080-20-014649 80 PN10/16 15 C 1,117.60Basic Series 3 02-100-20-014649 100 PN10/16 17 C 1,278.80Ductile iron 02-150-20-014649 150 PN10/16 32 C 2,291.40EPDM rubber, WRAS, W270 02-200-20-014649 200 PN16 51 C 3,443.00appr.Fusion bonded epoxy coating 02-250-20-014649 250 PN16 82 C 5,653.90to DIN 3476-1 and EN 02-300-20-014647 300 PN16 128 C 7,619.7014901, GSK approved 02-350-20-014647 350 PN16 214 C 17,131.30Clockwise to Close 02-400-20-014647 400 PN16 221 C 17,563.10

55/66-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve,Face-to-face dimension mm drilling weight/kg pallet code MYRaccording to EN 558 Table 2 55-450-66-014 450 PN16 496 A 33,500.31Basic Series 3 55-500-66-014 500 PN16 531 C 34,985.14Ductile Iron 55-600-66-014 600 PN16 757 A 42,675.21EPDM rubber, WRAS appr.Epoxy coating to DIN30677-2 GSK approvedClockwise to Close

55/66-002 AVK ref. no. DN Flange Theoretical Deliv. Gross PriceResilient seated gate valve,with bypass mm drilling weight/kg code MYRFace-to-face dimension 55-450-66-01400H 450 PN16 512 A 35,175.32according to EN 558 Table 2 55-500-66-01400H 500 PN16 545 C 36,734.40Basic Series 3 55-600-66-01400H 600 PN16 771 C 44,808.97Ductile IronEPDM rubber, WRAS appr.Epoxy coating to DIN30677-2 GSK approvedClockwise to Close

55/66-101 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith stem capFace-to-face dimension 55-450-66-01400010001 450 PN16 450 C 33,596.58according to EN 558 Table 2 55-500-66-01400010001 500 PN16 531 C 33,048.33Basic Series 3 55-600-66-01400010001 600 PN16 757 C 42,766.79Ductile IronEPDM rubber, WRAS appr.Epoxy coating to DIN 30677-2GSK approved Clockwise toClose

10 Products for Water Supply and WastewaterResilient Seated Gate Valves

55/66-105 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith bypass and stem capFace-to-face dimension 55-450-66-01400H10001 450 PN16 512 C 35,271.59according to EN 558 Table 2 55-500-66-01400H10001 500 PN16 545 C 36,830.67Basic Series 3 55-600-66-01400H10001 600 PN16 771 C 44,900.55Ductile IronEPDM rubber, WRAS appr.Epoxy coating to DIN 30677-2GSK approved Clockwise toClose

55/66-104 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith handwheelFace-to-face dimension 55-450-66-014000C0001 450 PN16 505 C 34,001.98according to EN 558 Table 2 55-500-66-014000C0001 500 PN16 540 C 35,486.81Basic Series 3 55-600-66-014000C0001 600 PN16 773 C 43,408.79Ductile IronEPDM rubber, WRAS appr.Epoxy coating to DIN 30677-2GSK approved Clockwise toClose

55/66-106 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith bypass and handwheelFace-to-face dimension 55-450-66-01400HC0001 450 PN16 521 C 35,676.99according to EN 558 Table 2 55-500-66-01400HC0001 500 PN16 554 C 37,236.07Basic Series 3 55-600-66-01400HC0001 600 PN16 787 C 45,542.55Ductile IronEPDM rubber, WRAS appr.Epoxy coating to DIN30677-2 GSK approvedClockwise to Close

55/30-021 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve,Face-to-face dimension mm drilling weight/kg pallet code MYRaccording to EN 558 Table 2 55-800-30-01464 800 PN16 2460 C 187,952.67Basic Series 15Ductile IronEPDM rubber, WRAS appr.Fusion bonded epoxycoating to DIN 3476-1 andEN 14901, GSK approvedClockwise to Close

Products for Water Supply and Wastewater 11 Resilient Seated Gate Valves

55/30-022 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith bypassFace-to-face dimension 55-800-30-01464F001 800 PN16 2513 C 195,625.00according to EN 558 Table 2Basic Series 15Ductile IronEPDM rubber, WRAS appr.Fusion bonded epoxy coatingto DIN 3476-1 and EN14901, GSK approvedClockwise to Close

55/67-004 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve,Face-to-face dimension mm drilling weight/kg pallet code MYRaccording to EN 558 Table 2 55-900-67-0146400001 900 PN16 3342 C 257,149.69Basic Series 3 55-1000-67-014464 1000 PN16 3412 C 269,599.66Ductile IronEPDM rubber, WRAS appr.Fusion bonded epoxy coatingto DIN 3476-1 and EN14901, GSK approvedClockwise to Close

55/67-003 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated gate valve, mm drilling weight/kg pallet code MYRwith bypassFace-to-face dimension 55-900-67-01464M0011 900 PN16 3362 C 261,688.40according to EN 558 Table 2 55-1000-67-0144643001 1000 PN16 3432 C 272,076.48Basic Series 3Ductile IronEPDM rubber, WRAS appr.Fusion bonded epoxy coatingto DIN 3476-1 and EN14901, GSK approvedClockwise to Close

12 Products for Water Supply and WastewaterAccessories for Resilient Seated Gate Valves

04/22-001 AVK ref. no. DN/DN F1 Theoretical Units/ Deliv. Gross PriceStem cap for Series 02 mm weight/kg pallet code MYRDuctile ironAVK coating standard 08-040-61-000 (1) 40 - 50 14 0.2 C 22.54 08-065-61-000 (1) 65 - 80 17 1.0 C 37.07 08-100-61-000 (1) 100 - 150 19 0.6 C 37.78 08-200-61-000 (1) 200 - 200 24 0.7 C 68.49 08-250-61-000 (1) 250 - 300 27 1.1 C 68.94 08-400-61-000 (1) 350 - 500 32 1.1 C 102.61 55-500-22-000 (2) 450 - 600 Ø31 3.0 C 96.28 (1) With bolt in stainless steel, A2 for standard gate valves (2) For series 06, 46 and 55/35 gate valves, ø30 mm

08/D-001 AVK ref. no. DN/DN Theoretical Units/ Deliv. Gross PriceStem cap for Series 21 weight/kg pallet code MYRDuctile ironAVK coating standard 08-100-51-000 50-100 0.6 A 48.20 08-200-51-000 200-300 1.4 A 80.30 08-400-51-000 350-400 3.1 A 161.30

08/A-014 AVK ref. no. DN/DN D F Theoretical Units/ Deliv. Gross PriceHandwheel assembled with mm mm weight/kg pallet code MYRbolt and washer for the newgeneration of gate valves 08-080-66-00000 65 - 80 160 17 1.0 C 53.28Cast Iron 08-100-66-00000 100 200 19 1.3 C 62.24AVK coating standard 08-150-66-00000 125 - 150 240 19 1.9 C 98.18 08-200-66-00000 200 280 24 2.2 C 119.86

08/A-004 AVK ref. no. DN/DN D F Theoretical Units/ Deliv. Gross PriceHandwheel assembled with mm mm weight/kg pallet code MYRbolt and washerCast Iron 08-250-02-000 250 - 300 500 27 8.6 A 405.40AVK coating standard 08-400-01-000 (1) 350 - 500 640 32 15 B 642.00 (1) Square stem

04/15-002 AVK ref. no. Valve Theoretical Units/ Deliv. Gross PriceT-key for gate valves DN mm weight/kg pallet code MYR 04-300-49-94100 50 - 300 7.0 C 878.00 04-300-49-94150 50 - 300 8.9 C 957.70 04-300-49-94200 50 - 300 11 C 1,046.00 04-300-49-94250 50 - 300 13 C 1,127.20 04-300-49-94300 50 - 300 15 C 1,208.40 04-400-50-94100 350 - 400 7.4 C 920.20 04-400-50-94150 350 - 400 9.3 C 997.90 04-400-50-94200 350 - 400 11 C 1,088.60 04-400-50-94250 350 - 400 13 C 1,171.40 04-400-50-94300 350 - 400 15 C 1,254.60

Products for Water Supply and Wastewater 13 Accessories for Resilient Seated Gate Valves

04/Z-001 AVK ref. no. A D Theoretical Units/ Deliv. Gross PricePedestal for gate valves. mm mm weight/kg pallet code MYR 04-89-01-01-000004 25.4 90 32 C 3,364.70 04-89-01-02-000004 25.4 165 22 C 3,380.00 04-89-01-03-000004 25.4 165 22 C 3,394.60 04-89-01-04-000004 25.4 175 23 C 3,411.60 04-89-01-05-000004 25.4 210 25 C 3,436.00 04-89-01-06-000004 25.4 300 34 C 3,451.40 04-89-01-07-000004 38.1 90 43 C 3,714.00 04-89-01-08-000004 38.1 165 27 C 3,729.40 04-89-01-09-000004 38.1 165 27 C 3,743.90 04-89-01-10-000004 38.1 175 28 C 3,760.90 04-89-01-11-000004 38.1 210 30 C 3,785.30 04-89-01-12-000004 38.1 300 39 C 3,800.70

04/Z-002 AVK ref. no. Valve Connection Theoretical Units/ Deliv. Gross PriceExtension spindle for gate DN mm weight/kg pallet code MYRvalves 04-89-03-01-000001 - 1 4.2 C 1,043.60 04-89-03-01-000002 50 - 300 2 4.9 C 976.60 04-89-03-01-000003 350 - 400 2 5.1 C 1,010.50 04-89-03-02-000001 - 1 5.0 C 1,090.50 04-89-03-02-000002 50 - 300 2 5.7 C 1,023.50 04-89-03-02-000003 350 - 400 2 5.9 C 1,057.40 04-89-03-03-000001 - 1 6.2 C 1,161.50 04-89-03-03-000002 50 - 300 2 6.8 C 1,094.50 04-89-03-03-000003 350 - 400 2 7.1 C 1,128.40 04-89-03-04-000001 - 1 8.1 C 1,279.00 04-89-03-04-000002 50 - 300 2 8.8 C 1,212.00 04-89-03-04-000003 350 - 400 2 9.0 C 1,245.90 04-89-03-05-000001 - 1 10 C 1,396.90 04-89-03-05-000002 50 - 300 2 11 C 1,329.90 04-89-03-05-000003 350 - 400 2 11 C 1,363.80 04-89-03-06-000001 - 1 12 C 1,514.40 04-89-03-06-000002 50 - 300 2 13 C 1,447.30 04-89-03-06-000003 350 - 400 2 13 C 1,481.30 04-89-03-07-000001 - 1 9.3 C 1,392.90 04-89-03-07-000002 50 - 300 2 9.9 C 1,207.60 04-89-03-07-000003 350 - 400 2 10 C 1,241.50 04-89-03-08-000001 - 1 11 C 1,486.40 04-89-03-08-000002 50 - 300 2 12 C 1,301.10 04-89-03-08-000003 350 - 400 2 12 C 1,335.00 04-89-03-09-000001 - 1 14 C 1,626.30 04-89-03-09-000002 50 - 300 2 14 C 1,441.00 04-89-03-09-000003 350 - 400 2 15 C 1,474.90 04-89-03-10-000001 - 1 19 C 1,859.40 04-89-03-10-000002 50 - 300 2 19 C 1,674.10 04-89-03-10-000003 350 - 400 2 19 C 1,708.00 04-89-03-11-000001 - 1 23 C 2,092.80 04-89-03-11-000002 50 - 300 2 23 C 1,907.50 04-89-03-11-000003 350 - 400 2 24 C 1,941.40 04-89-03-12-000001 - 1 27 C 2,325.80 04-89-03-12-000002 50 - 300 2 28 C 2,140.50 04-89-03-12-000003 350 - 400 2 28 C 2,174.40

37/50-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceMetal seat gate valve,with stem cap mm drilling weight/kg pallet code MYRFace-to-face dimension 37-050-50-210001 50 PN16 11 C 1,706.15according to EN 558 Table 2 37-080-50-210001 80 PN16 21 C 2,022.97Basic Series 3 37-100-50-210001 100 PN16 27 C 2,384.84Blue epoxy RAL 5017 250 37-150-50-210001 150 PN16 43 C 3,883.39micron. 37-200-50-210001 200 PN16 76 C 6,413.24Clockwise to Close 37-250-50-210001 250 PN16 105 C 9,368.94 37-300-50-210001 300 PN16 159 C 12,812.21

37/51-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceMetal seat gate valve,with ISO mounting flange mm drilling weight/kg pallet code MYRFace-to-face dimension 37-050-51-010001 50 PN16 17 C 1,792.72according to EN 558 Table 2 37-080-51-010001 80 PN16 21 C 2,200.11Basic Series 3 37-100-51-010001 100 PN16 26 C 2,466.81Blue epoxy RAL 5017 250 37-150-51-010001 150 PN16 43 C 4,011.43micron. 37-200-51-010001 200 PN16 76 C 6,687.28Clockwise to Close 37-250-51-010001 250 PN16 107 C 9,545.23Gearbox / Actuator available 37-300-51-010001 300 PN16 164 C 12,981.51upon request.

54/3132-001 AVK ref. no. DN Flange Actuator Theoretical Units/ Deliv. Gross PriceMetal seat gate valve, mm drilling flange weight/kg pallet code MYRFace-to-face dimensionaccording to EN 558 Table 2 54-0350-31-1101100 350 PN16 14 291 C 23,081.17Basic Series 3 54-0400-31-1101100 400 PN16 14 359 C 26,424.25Ductile Iron 54-0450-31-1101100 450 PN16 14 437 C 31,256.45SS431 Shaft 54-0500-31-1101100 500 PN16 14 538 C 37,679.70Alu-bronze seatA4/galv. 8.8 bolts 54-0600-31-1101100 600 PN16 14 708 C 47,101.69Epoxy coated, WRAS 54-0700-31-1102100 700 PN16 16 1416 C 103,030.04approved. 54-0800-31-1103100 800 PN16 25 1766 C 126,271.39Clockwise to Close 54-0900-31-1103100 900 PN16 25 2317 C 159,876.15 54-1000-31-1103100 1000 PN16 25 3059 C 205,855.24PN10 / CTO / gearbox /actuator available upon 54-1100-31-1303100 1100 PN16 25 4000 C 314,874.96request. 54-1200-31-1304100 1200 PN16 30 4691 C 386,084.23 54-1400-31-1304100 1400 PN16 30 7500 C 737,713.51 54-1600-31-1304100 1600 PN16 30 12100 C 1,022,803.55 54-1800-31-1304100 1800 PN16 30 14800 C 1,456,141.23

54/3334-001 AVK ref. no. DN Flange Actuator Theoretical Units/ Deliv. Gross PriceMetal seat gate valve, mm drilling flange weight/kg pallet code MYRwith bypassFace-to-face dimension 54-0350-33-1101100 350 PN16 14 304 C 24,206.42according to EN 558 Table 2 54-0400-33-1101100 400 PN16 14 372 C 27,643.15Basic Series 3 54-0450-33-1101100 450 PN16 14 452 C 32,672.09Ductile Iron 54-0500-33-1101100 500 PN16 14 553 C 38,301.21SS431 ShaftAlu-bronze seat 54-0600-33-1101100 600 PN16 14 723 C 48,253.42A4/galv. 8.8 bolts 54-0700-33-1102100 700 PN16 16 1440 C 107,953.76Epoxy coated, WRAS 54-0800-33-1103100 800 PN16 25 1789 C 128,851.63approved. 54-0900-33-1103100 900 PN16 25 2341 C 162,557.27Clockwise to Close 54-1000-33-1103100 1000 PN16 25 3083 C 207,010.47PN10 / CTO / gearbox / 54-1100-33-1303100 1100 PN16 25 4078 C 391,291.52actuator available upon 54-1200-33-1304100 1200 PN16 30 4730 C 359,894.44request. 54-1400-33-1303100 1400 PN16 25 7600 C 686,403.19 54-1600-33-1304100 1600 PN16 30 12200 C 1,029,607.62 54-1800-33-1304100 1800 PN16 30 14900 C 1,335,542.97

Products for Water Supply and Wastewater 15 Butterfly Valves

756/218-002 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceDouble eccentric butterfly mm drilling weight/kg pallet code MYRvalve to EN 593with integral seat and IP67 756-0200-2-14018 200 PN16 47 A 5,438.97gearbox w. handwheel 756-0250-2-14018 250 PN16 64 A 6,322.02Face-to-face dimension 756-0300-2-14018 300 PN16 97 A 8,540.72according to EN 558 Table 2 756-0350-2-14018 350 PN16 121 A 10,645.77Basic Series 13 756-0400-2-14018 400 PN16 153 A 11,796.18EPDM rubber WRAS 756-0450-2-14018 450 PN16 201 A 15,547.37Ductile iron | SS431 Shaft |SS304 Seal retainer ring 756-0500-2-14018 500 PN16 256 A 18,242.45Fusion bonded epoxy to DIN 756-0600-2-14018 600 PN16 394 A 25,733.903476-1 and EN 14901Clockwise to Close

756/218 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceDouble eccentric butterflyvalve to EN 593 mm drilling weight/kg pallet code MYRwith integral seat and IP67 756-0700-2-14018018 700 PN16 477 C 43,982.79gearbox w. handwheel Face- 756-0800-2-14018018 800 PN16 659 C 52,828.58to-face dimension according 756-0900-2-14018018 900 PN16 797 C 66,065.02to EN 558 Table 2 Basic 1000 PN16 1095 C 80,369.10 756-1000-2-14018018Series 13 756-1200-2-14018018 1200 PN16 1642 C 125,748.12EPDM rubber WRAS Ductileiron | SS420 Shaft | SS304Seal retainer ring Fusionbonded epoxy to DIN 3476-1and EN 14901 Clockwise toClose

756/218-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceDouble eccentric butterflyvalve to EN 593 mm drilling weight/kg pallet code MYRwith integral seat and IP67 756-1400-2-14018018 1400 PN16 2323 C 167,050.94gearbox w. handwheel Face- 756-1500-2-14018018 1500 PN16 2863 C 191,662.87to-face dimension according 756-1600-2-14018018 1600 PN16 3273 C 222,565.92to EN 558 Table 2 Basic 756-1800-2-14018018 1800 PN16 3969 C 323,898.85Series 13 756-2000-2-14018018 2000 PN16 5573 C 428,613.09EPDM rubber WRAS Ductileiron | SS420 Shaft | SS304Seal retainer ring Fusionbonded epoxy to DIN 3476-1and EN 14901 Clockwise toClose

756/218-021 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceDouble eccentric butterflyvalve to EN 593 mm drilling weight/kg pallet code MYRwith stainless steel seat and 756-0150-2-1401809 150 PN16 36 C 5,939.11IP67 gearbox w. handwheel 756-0200-2-1401809 200 PN16 47 C 6,376.73Face-to-face dimension 756-0250-2-1401809 250 PN16 64 C 7,705.21according to EN 558 Table 2 756-0300-2-1401809 300 PN16 97 C 10,510.66Basic Series 13 756-0350-2-1401809 350 PN16 121 C 13,042.59EPDM rubber WRAS 756-0400-2-1401809 400 PN16 153 C 14,222.60Ductile iron | SS431 Shaft 756-0450-2-1401809 450 PN16 201 C 17,278.11SS304 Seat ring | SS304 756-0500-2-1401809 500 PN16 256 C 20,880.65Seal retainer ring Fusionbonded epoxy to DIN 3476-1 756-0600-2-1401809 600 PN16 394 C 28,083.60and EN 14901 Clockwise to 756-0700-2-1401809 700 PN16 483 C 50,559.22Close 756-0800-2-1401809 800 PN16 665 C 60,906.54Sizes available up to 756-0900-2-1401809 900 PN16 804 C 75,339.82DN2000 756-1000-2-1401809 1000 PN16 1105 C 91,285.18 756-1200-2-1401809 1200 PN16 1652 C 140,447.06

76/70-005 AVK ref. no. DN Product Theoretical Units/ Deliv. Gross PriceConcentric butterfly valve with mm PN Class weight/kg pallet code MYRloose linerSemi-lug 76-0050-70-817402690205 50 PN16 2.7 C 413.93Face-to-face dimension 76-0065-70-817402690205 65 PN16 3.4 C 468.50according to EN 558 Table 2 76-0080-70-817402690205 80 PN16 4.0 C 547.79Basic Series 20 76-0100-70-817402690205 100 PN16 6.0 C 737.16Ductile iron 76-0125-70-817402690205 125 PN16 7.7 C 1,020.58SS316 Disc 76-0150-70-817402690205 150 PN16 8.3 C 1,224.64EPDM rubber EP - 80µm (tbs) 76-0200-70-817402690205 200 PN16 14 C 1,861.39Clockwise to Close 76-0250-70-817402690203 (1) 250 PN16 23 C 3,607.28 76-0300-70-817402690203 (1) 300 PN16 31 C 4,921.78 (1) With wormgear

76/70-003 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceConcentric butterfly valve withloose liner mm drilling weight/kg pallet code MYRSemi-lug 76-0350-70-817702690213 350 PN16 50 C 9,685.02Face-to-face dimension 76-0400-70-817702690213 400 PN16 83 C 13,546.24according to EN 558 Table 2Basic Series 20Ductile ironSS316 DiscEPDM rubber EP - 80µm (tbs)Clockwise to Close

76/71-012 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceConcentric butterfly valve withloose liner mm drilling weight/kg pallet code MYRFull-lug 76-0050-71-837402690205 50 PN16 3.3 C 482.28Face-to-face dimension 76-0065-71-837402690205 65 PN16 4.1 C 520.80according to EN 558 Table 2 76-0080-71-837402690205 80 PN16 5.4 C 628.99Basic Series 20 76-0100-71-837402690205 100 PN16 8.0 C 827.79Ductile iron 76-0125-71-837402690205 125 PN16 11 C 1,190.47SS316 Disc 76-0150-71-837402690205 150 PN16 12 C 1,414.26EPDM rubber EP - 80µm (tbs) 76-0200-71-837402690205 200 PN16 19 C 2,218.25Clockwise to Close 76-0250-71-837402690203 (1) 250 PN16 32 C 4,138.70 76-0300-71-837402690203 (1) 300 PN16 45 C 5,696.97 (1) With wormgear

76/71-005 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceConcentric butterfly valve with mm drilling weight/kg pallet code MYRloose linerFull-lug 76-0350-71-837702690213 350 PN16 55 C 10,528.00Face-to-face dimension 76-0400-71-837702690213 400 PN16 99 C 14,981.57according to EN 558 Table 2Basic Series 20Ductile ironSS316 DiscEPDM rubber EP - 80µm (tbs)Clockwise to Close

76/74-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceConcentric butterfly valve withloose liner mm drilling weight/kg pallet code MYRDouble flanged 76-0050-74-867402690205 50 PN10/16 6.0 C 811.01Face-to-face dimension 76-0065-74-867402690205 65 PN10/16 7.0 C 949.61according to EN 558 Table 2 76-0080-74-867402690205 80 PN10/16 8.5 C 1,144.66Basic Series 20 76-0100-74-867402690205 100 PN10/16 11 C 1,421.84Ductile iron 76-0150-74-867402690205 150 PN10/16 18 C 2,227.72SS316 DiscEPDM rubber EP - 80µm (tbs)Clockwise to Close

Products for Water Supply and Wastewater 17 Check Valves

41/20-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated swing check mm drilling weight/kg pallet code MYRvalvewith free shaft end 41-050-20-018 50 PN10/16 14 C 2,012.42Face-to-face dimension 41-080-20-018 80 PN10/16 17 C 1,559.03according to EN 558 Table 2 41-100-20-018 100 PN10/16 22 A 1,864.24Basic Series 10Ductile iron 41-150-20-018 150 PN10/16 42 A 3,216.25EPDM rubber wedge, WRAS 41-200-20-018 200 PN16 67 A 4,939.66appr. 41-250-20-018 250 PN16 161 A 11,495.45Blue epoxy RAL 5017 250µm 41-300-20-018 300 PN16 238 C 13,241.10

41/22-001 AVK ref. no. DN Flange Theoretical Units/ Deliv. Gross PriceResilient seated swing checkvalve mm drilling weight/kg pallet code MYRwith lever and weight 41-050-22-0180106 50 PN10/16 14 C 2,169.05Face-to-face dimension 41-080-22-0180106 80 PN10/16 17 C 1,679.59according to EN 558 Table 2Basic Series 10 41-100-22-0180106 100 PN10/16 22 C 2,103.17Ductile iron 41-150-22-0180106 150 PN10/16 42 C 3,650.05EPDM rubber wedge, WRAS 41-200-22-0180106 200 PN16 67 C 5,187.39appr. 41-250-22-0180106 250 PN16 161 C 12,536.06Blue epoxy RAL 5017 250µm 41-300-22-0180106 300 PN16 238 C 14,189.33PN10 available upon request.

41/39-004 AVK ref. no. DN

8613371530291

8613371530291