boiler safety valve discharge piping made in china

A fire-tube boiler can be fitted with one or more safety valves on the top of its shell, with each set to open when the boiler reaches its design pressure. Noisolation valvesor restrictions should be integrated between the safety valve(s) and boiler. If the valves are not installed directly onto the boiler shell, the pipework connecting the valves to the boiler must be kept clear of blockagesand water, and this must be confirmed by periodic testing.

Once a safety valve opens, steam is discharged via the exhaust pipe. Exhaust pipes must be designed to encounter as few bends as possible, be as short as possible, to have no reduction in pipe section (no internal pipe diameter reduction), and should lead to asafe point of discharge(typically outside the boiler house).

Water must be drained from the safety valve or exhaust pipework via a drainpipe. Drainpipes may be connected to holes drilled into the lowest section of the exhaust pipework, or, directly to drain holes in the safety valve body; these drains are not to be confused with the blowdown ring locking bolt, if one is fitted.

Where two safety valves are fitted, it is common that one is set just belowthe boiler’s design pressure. It is vital that each safety valve permits the full flow of steam produced when the boiler is operating at maximum capacity i.e. when the boiler is producing the maximum amount of steam it can possibly produce. If safety valves are sized correctly, a boiler can be firing at full capacity without the steam pressure exceeding design limits (because the safety valve(s) relieves pressure at a faster rate than it is accumulated).

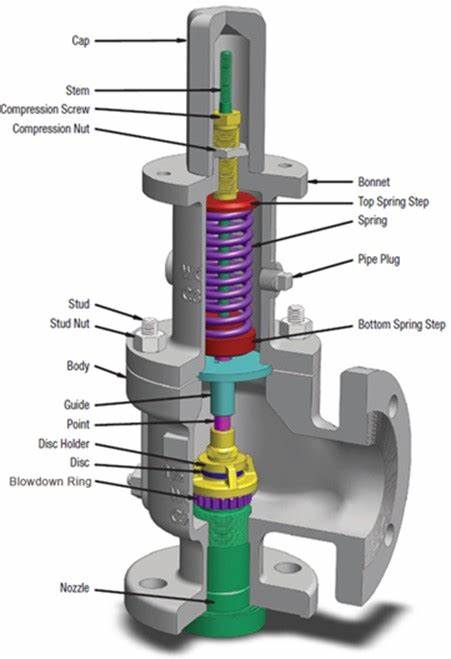

There are various types of safety valve, including high lift and improved high lift valves, which use the force of escaping steam to open a winged valve plug to achieve greater steam flow rates. In addition to this, some valves integrate a pistonat the bottom of the spring chamber. The piston has a larger surface area than the valve plug, which leads to the valve opening with a definitive ‘pop’ sound.

Some boiler safety valves include a blowdown ring. The blowdown ring can raise or lower the valve seat ring and is used to control the amount of blowdown through the valve. This ring is locked by a bolt that protrudes through the valve and into the adjusting ring segments.

Boiler safety valves should be fitted with an easing gear (looks like a handle), used, when necessary, to rapidly release boiler pressure. Easing gears can also be used for testing a safety valve, ensuring the spindle has freedom of movement and that the valve operating mechanism functions as intended. Easing gear testing is often not conducted due to operators having difficulty with the valves resealing, but this is generally only the case with valves that are not tested often enough. Actuating the easing gear several times is often all it takes to dislodge debris from the sealing area and allow the valve to seal again. For safe operation, the easing gear handle is usually connected via steel cables to an area neighbouring the boiler.

Like pressure gauges, all safety valves should be stripped, inspected, and calibrated, at least once a year; maintenance usually occurs during statutory inspections. Calibration of each valve should be conducted by a competent person, and any valve adjustment (including the blowdown ring) should be approved and sealed by the authorised inspector. After testing and calibration, all valves should be correctly marked, suitable certificates issued, and accurate records maintained.

An accumulation test can be conducted to ensure a safety valve can relieve over-pressure steam when the boiler burner is operating at maximum capacity. Accumulation testing of safety valves must be repeated after any alterations are made to the boiler e.g. replacement of a safety valve, fuel change, or changes to the control system. If, during an accumulation test, boiler pressure rises by more than 10% of its design pressure, the test must be aborted. Before the boiler is re-tested, amendments must be made to either the safety valve relieving capacity, thesafety valve exhaust pipework, or the boiler’s steaming capacity, to ensure the 10% limit is never exceeded.

Reliefand safetyvalves prevent equipment damage by relieving over-pressurisation of fluid systems. The main difference between a relief valve and a safety valve is the extent of opening at the set-point pressure.

A relief valve gradually opens as the inlet pressure increases above the set-point. A relief valve opens only as necessary to relieve the over-pressure condition. Relief valves are typically used for liquid systems.

A safety valve rapidly‘pops’ fully openas soon as the pressure setting is reached and will stay fully open until the pressure drops below the reset pressure. The reset pressure is lower than the actuating set-point pressure. The difference between the actuating pressure set-point, and the pressure at which the safety valve resets, is called blowdown. Safety valves are typically used for gas or vapour systems.

A safety relief valve may open fully, or proportionally, once the pressure setting is reached. SRVs may be used for any fluid system (gas, liquid, or vapour).

The water heater is known for its high heat and high pressure. The water heater temperature-pressure relief valve (TPR Valve), protects us from this high heat and pressure. So what is the TPR valve, why does it leak, and what should you do about it?

The TPR valve, also called, a pressure relief valve is a specialized valve at your water heater. This valve is typically on the top or side of your water heater.

The valve functions by releasing water if your water heater becomes too pressurized. Since heated water expands, the water heater can become a ticking time bomb if we were to continually build pressure in your water heater.

As seen in the featured image, a TPR valve is required to have a discharge pipe/tube. This tube should be aimed straight to the ground and never go up. This is because hot water will come out of the TPR valve as it releases water. Therefore, extremely hot water should discharge to the ground for safety.

Additionally, if a pipe were to go up, water will have to work against gravity to empty. So, it is possible a slow drip of the TPR valve will collect water in the tubing and ultimately rust out the valve rather than empty it to the floor.

Terminate not more than 6 inches (152 mm) above and not less than two times the discharge pipe diameter above the floor or flood level rim of the waste receptor.

Be one nominal size larger than the size of the relief valve outlet, where the relief valve discharge piping is installed with insert fittings. The outlet end of such tubing shall be fastened in place.

However, if you find the relief valve to continue to leak even after replacement, you should contact a plumber for assistance. A licensed plumber will be able to evaluate your system and decide on installing an expansion tank or other solutions.

D&R Metal Industry is China’s no.1 manufacturer and source of high-quality brass pressure relief valves. We have served thousands of plumbing industries and clients internationally. We maintain our good reputation by satisfying customers’ needs and exceeding their expectations.

Since its establishment, D&R Metal Industry is serving customers with the best quality brass pressure relief valves. We manufacture products using our advanced equipment and state-of-the-art production facilities.

Our complete set of forging machines and CNC machines assure you full capabilities in providing your brass pressure relief valve needs. D&R Metal Industry has been continuously improving the quality of products to ensure enhanced and up-to-date features.

Through constant innovation, D&R Metal Industry can provide you the best design and superior quality of brass pressure relief valves. We always make sure to produce products that will meet your requirements. Thus, we offer custom services according to your exact specifications.

As the best manufacturer in China, we only used superior quality raw materials for your brass pressure relief valves. Our engineers carefully selected solid and 100% tested brass materials. With its excellent properties, you can assure high-quality.

We manufacture brass pressure relief valves that are widely used for limiting or controlling surges of pressure in a pipeline. It can protect your system against equipment or instrument failure. D&R Metal Industry manufactures different types of brass pressure relief valves such as spring-loaded relief valves.

Other than that, we designed brass pressure relief with different pressure ratings based on applications. It also comes in unlimited sizes and designs. With their compact structure and design, D&R brass pressure relief valves will meet various space requirements.

D&R Metal Industry always makes sure that your brass pressure relief valves are tested rigorously to ensure higher quality. We also thoroughly inspected your products before shipment for their safety during delivery.

If you have inquiries or questions about our brass pressure relief valves, message us immediately. We have 24/7 assistance to support you. Our highly knowledgeable sales team will always accommodate your needs.

Water Pressure Relief ValvesWater Pressure Relief Valves: Water pressure relief valves, alternatively referred to as water pressure-lowering valves, are frequently employed by private and municipal water delivery organizations.

Available in various lengths, widths, and pipe sizes to fit different machines.Hydronic Pressure Valves: Hydronic pressure relief valves are a category of pressure relief valves designed specifically for hydronic applications.

Hydronic pressure valves give relief by assuring that these systems are pressurized to a safe working pressure of roughly 4-5 pounds per square inch gauge.

Consider the following additional characteristics of water hydronic pressure valves:Cast iron, forged brass, and stainless steel are all available in a range of models, sizes, and metals.

Here are a few additional properties of back pressure valves:Available in brass, cast iron, bronze, and other metals, these valves frequently feature many functions.

8613371530291

8613371530291