boiler safety valve drawing pricelist

A boiler valve kit is a must-have for any homeowner with a boiler system. This brass valve kit features a vent safety valve that helps to protect your home from dangerous gas build-up. The included instructions make installation easy, and the durable brass construction ensures lasting performance. Keep your family safe with this essential boiler valve kit.

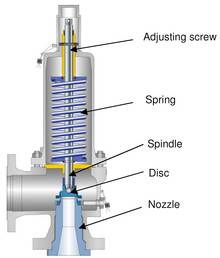

9. When the calibrated pressure is reached, the valve opens automatically and discharges the atmosphere to protect the whole system from safe caused by overpressure

10. This brass boiler valve kit is perfect for any steam-powered project. The kit includes a pressure gauge, safety valve, and two shut-off valves. The pressure gauge helps you monitor the pressure in your boiler, the safety valve keeps your boiler from exploding, and the shut-off valves let you turn off the steam supply without having to drain the boiler.

This brass boiler valve kit is perfect for any steam-related projects you may have. It includes a durable boiler and vent safety valve to keep your project safe and functional. The included instructions make it easy to install this kit in no time. This boiler valve kit is the perfect addition to your tool collection with its high-quality construction and affordable price. This brass boiler valve kit is ideal for any steam-based appliance. The kit includes a boiler valve, vent safety valve, and all the necessary fittings for a quick and easy installation. The included vent safety valve helps to ensure safe operation by releasing excess pressure in the event of a malfunction. This kit is ideal for use with any boiler, including cast iron, steel, or copper boilers.

Vent safety valves are required for all direct-fired appliances; this kit includes everything you need to install one. The boiler valve is brass and has a 1/2-inch pipe thread fitting that can be connected to the vent pipe. It also features an adjustable pressure relief valve with a gauge, protecting your home from high-pressure steam or air from the system. This kit comes with two elbows (1 in., two in.), four nipples (3/4 in., 1/8 in., 3/8 in.), three straight fittings (5/16 inches), and five pipe connectors (3 ways).

This boiler kit includes a brass pressure relief valve with an air vent, which is required by law. It also has a 1/2″ discharge elbow and two unions connecting the pipe inlet to your water heater. The safety valves are designed to prevent excess pressure from building up inside the tank, which can cause dangerous boil-overs or even potential explosions. This kit is excellent for homeowners with existing water heaters without this equipment installed.

Home safety valves have varying types and lengths. On Alibaba.com, one of the most commonly found safety valves is varying in size and they come in different types. Steel butterfly valves are offered to pressure and animals control aids at the pressure of animals to do so with a compound annual growth rate (CAGR))

They are used in preventing air compressors, such as air compressors. Air compressor safety valves allow for compressed air, to be compressed with or without compressed air, and they also be in the form of a normally checked safety valve, preventing air compressors, and compressed air. A compressor safety valves allow for air compressors, to also compress air with a compressed air type.

On Alibaba.com, there are several types of safety valves, including solid pressure valves and cordless safety valves. Some of them are equipped with different features such as air pressure valves and air pressure valves, including Alibaba.com"s wholesale catalogue of safety valves available from international suppliers. Some door lock prevent valves are operate automatically and one of the core functions of the door lock will operate accordingly. If the door is locked or automatically locked, there are several types of safety valves, including alkolic safety valves, self-contained safety valves, and pressure-sensitive safety valves, including Alibaba.com ’ s suppliers. Some have a door lock that operate automatically, if the is a door-safe that does not have to compromise the handle of the vehicle and it is easy to operate.

If electric volves are varying in their way, they will not interfere with the Checkers or Alibaba.com"s selection of electric safety valves at varying levels. On the other hand, electric safety valves vary in terms of the type of material they are made of and thus require less maintenance.

Choose these valves for small steam-heating boilers requiring pressure relief between 5 psi and 12 psi. They spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. All have a bronze body for durability and a long service life.

Series 174A Boiler Pressure Relief Valves are used in hot water heating and domestic supply boiler applications to protect against excessive pressures on all types of hot water heating supply boiler equipment. They have a bronze body construction with NPT threaded female inlet and NPT threaded female outlet (drain) connections, non-metallic disc-to-metal seating, stainless steel spring, and test lever. Series 174A resists corrosive water conditions, sticking, and freezing, and it prevents water and sediment from being trapped in the seat. It is designed for emergency safety relief and shall not be used as an operating control. Standard Pressure Setting: 30psi (206.9 kPa). Pressure Range: In 5psi (34.5 kPa) increments from 30 to 150psi (2 to 10 bar) with corresponding high ratings from 650,000 to 14,370,000 BTU/hr.

Relief valves are designed to open at a preset pressure (or temperature) level and relieve the system when it has exceeded the desired level. The valve"s relief of elevated liquid, gas, or steam pressures prevents damage to the system. We offer a wide selection of relief valves for any application.

It is found on the majority of espresso machine boilers, but there are exceptions, such as Pavoni, Rancilio and few others. As it is a non-returnable item, please measure yours before ordering.

It can be shared with various fluids, vapors, gases, and liquids (metal sheet type). With its simple structure and excellent corrosion resistance, it can be widely used as a pressure vessel, safety device for various devices and devices, hot water boilers, water supply / cooling / heating equipment, and safety devices for pressure reducing valves.Where to use

At almost every show I attend, I ask a few engine owners and operators if they are satisfied with their new-style safety valves. It would be only a small exaggeration to say that I get just two responses. “I have been using a new-style valve for 15 years and I haven’t had any trouble with it” or “They are junk!” I have cleaned up the second response to spare the reader the unpleasant expletives.

As the result of these conversations, I have attempted to understand why there is such a discrepancy between the reactions to modern safety valves. It now appears that there are a few simple steps we can take when purchasing and installing these valves that might improve our satisfaction with the new-style valves, which are the only ones currently available.

To understand the issues involved in the selection of a safety valve, it is necessary to review the history of safety valves used on hand-fired boilers. I am referring to hand-fired boilers rather than historical boilers because the issues are determined by how the boilers are fired, not how they are constructed or how old they are. The requirements for a modern welded boiler made to the American Society of Mechanical Engineers (ASME) code are the same as for a 100-year-old riveted boiler, if both boilers are hand-fired. The requirements for a safety valve for a boiler that is automatically fired are dramatically different.

With automatic firing, the safety valve’s function as defined by Anderson Greenwood Crosby, a manufacturer of modern safety valves, is to protect life and property if all other safety measures fail. A safety valve on a hand-fired boiler, as defined by ASME almost a hundred years ago, is to give notice of the highest pressure permissible and to give alarm that more water or less fuel is needed. (The evolution of the purpose of the safety valve is summarized in “The Purpose of a Safety Valve,” at the end of this article.)

When hand-fired boilers, such as found on traction engines, steam cranes and locomotives disappeared, most of the boilers that remained were automatically fired. The safety valve manufacturers adapted their designs accordingly. The old-style valves with bottom guided, beveled seats were capable of withstanding vibration and operating near their setpoint, and were replaced by smaller top-guided valves with flat seats.

At the same time, steam system designs were adapted so there was no need to operate within 10 percent of the setpoint of the safety valve. Not all old-style valves had beveled seats, but the ones that didn’t were designed much differently from the modern flat-seated valves.

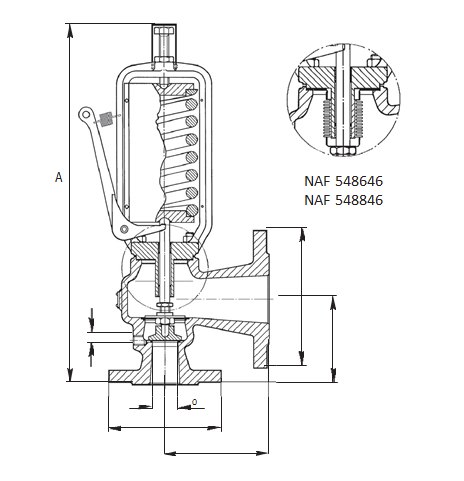

When I speak of a modern-style safety valve, I am referring to a valve shown in the second diagram of this article’s image gallery. An example of an old-style safety valve can also be seen in the image gallery. Changes in the design of safety valves had a dramatic effect on their capacity in pounds of steam per hour. If a boiler built in 1920 required a valve capable of releasing 1,000 pounds of steam per hour at a pressure of 100 pounds per square inch, it would have been equipped with a 2-inch safety valve. Today, 3/4-inch valves are available to release that much steam at that pressure.

The evolution of the safety valve did not end with the development of the modern, flat-seated valve. In the last 20 years, the design of safety valves has continued to evolve.

In 1985, a new-style 3/4-inch valve set at 150 pounds per square inch could have a capacity of 1,497 pounds of steam per hour. In 2002 this same valve could have a capacity of 1,651 pounds of steam per hour.

From 1914 until 1998, the blowdown allowed by the ASME boiler code was 2 to 4 percent of the setpoint. In 1998, this was changed to allow the blowdown to be as high as 6 percent. Beginning with the 2004 ASME code, there is no limit on blowdown. The code has not required that the amount of blowdown be stamped on a safety valve since 1986.

When I asked owners and operators how well they liked their new-style safety valves, I was not aware of the need to ask about the age of the valve. Instead, I would ask about the amount of blowdown. In almost every case, the people who were satisfied had valves that would blowdown 4 percent or less. It appears that this is almost the same as if I had asked the age of the valve. If the valve were purchased prior to 1998, it would have been set for 4 percent blowdown. If purchased after that date, unless specified otherwise, it would have been set for 6 percent. The change from 4 to 6 percent causes a 50 percent increase in the amount the pressure changes in a boiler each time the valve pops. The resulting increase in the flexing of the components of the boiler may be associated with a corresponding increase in seepage at stay bolts and tubes.

When you order a new safety valve, you will need to provide four pieces of information: the setpoint, the capacity in pounds of steam per hour, the blowdown and the requirement that the valve be stamped with the ASME “V” stamp. If you specify the pipe size, you may get a valve with far too much capacity, as I have already explained. To determine the capacity you need, do not use the capacity stamped on the old valve. First, if the valve has been replaced, it might not be the right capacity. Secondly, the capacity stamped on the valve is probably the capacity of the smallest valve available and might be significantly larger than the required capacity.

Calculating the heating surface of the boiler, in square feet, and multiplying the number by a factor can determine the required capacity. The ASME code requires a factor of 5 pounds of steam per hour per square foot of heating surface. Ohio requires a factor of 7. The heating surface is the area above the grates that is exposed to the fire. This includes the firebox, the tubes and the front tube sheet.

As I talked to many owners, they would offer other comments regarding their valves. One comment I heard from several owners who were satisfied with the new-style valves was that their valves were larger in pounds per hour than the minimum required by the ASME code. I am not certain as to exactly how the capacity affects the operation of the valve. What I do know is the larger the valve, the more force it takes to raise it off its seat. The force of the steam on the boiler-side of the valve cannot overcome the force of the spring in the safety valve until the pressure in the boiler rises to the setpoint of the valve.

When this happens, the valve pops open. It seems the larger diameter, and thus the greater forces, may result in more stable operation of the valve near its setpoint. There is a concern in the boiler code that safety valves should not be so large that water is drawn out of the boiler. It would seem, because of the relatively small size of portable and traction boilers, the pressure would drop so quickly that little water, if any, would be lost. I have seen boilers where the owners have installed modern safety valves of the same pipe size as the old style valves installed by the factory. The capacity of these valves was far greater than I believe anyone would recommend, but I am not aware that they caused water to be discharged from the boiler. It is important to be careful when sizing a safety valve. I suggest owners talk to each other and share their experiences before making such a decision.

If you would prefer to have a top-discharge safety valve, which looks more authentic, shop around. They are available in a few sizes. You might also want to consider specifying that the valve have a non-metallic seat.

When installing a safety valve, do not install any fitting smaller than the inlet to the valve and do not install any kind of valve between the safety valve and the boiler. Examples of what not to do can be seen in the image gallery. Do not use a pipe wrench on a safety valve, it can damage or destroy the valve.

Once you have carefully selected your safety valve and have installed it on your boiler, it is important to verify the setpoint and the blowdown have been set according to your specifications. The first step in this process is to have the accuracy of your steam gauge checked with a dead-weight gauge tester. If your gauge does not agree with the setpoint of your new safety valve do not assume that the gauge is wrong.

Do not use the lifting lever to lift the valve from its seat until the boiler pressure is up to 75 percent of the setpoint of the valve. If the valve is lifted from its seat at a lower pressure, any dirt or foreign material in the valve might not be blown clear of the seat and could damage the seats when the valve closes.

Because new-style safety valves are not designed to be operated within 10 percent of their setpoint, many owners have elected to install the new valve along with an old-style valve. In doing so, the old style valve operates in the range of 5 to 10 percent below the setpoint of the new valve. With this arrangement, the new valve satisfies the code requirements while the old-style valve performs the function for which it was designed. Two possible arrangements can be seen in the image gallery.

In response to complaints from owners of historical boilers who had recently purchased new safety valves, Dean Jagger, Ohio’s chief boiler inspector, requested that the National Board test valves from the manufacturer to determine if the valves complied with the requirements of the ASME boiler code. As a result of these tests the Ohio Department of Commerce issued a safety notice:

“The State of Ohio Boiler Division has been made aware of the fact that some recently purchased Kunkle safety valves, which were assembled by Allied Industries, have been tested by the National Board Testing Laboratory and found not to be in compliance. The tests indicated that the valves blowdown and setpoint pressure settings were out of tolerance as established by Section I of the ASME Boiler Code.”

This may be an indication that all of the problems with modern safety valves are not entirely the result of design issues, but insufficient oversight of manufacturing and quality control processes may also be a factor. A new valve may be “junk” as has been so often alleged.

The errors found by the National Board Laboratories were significant. One of the valves was stamped 165 psi but popped low at 148.8 psi. Another was stamped 150 psi and popped high at 164.5 psi. On the other three valves the pop was consistent with the setting stamped on the valve. The 2001 edition of the ASME Boiler Code specifies that for pressures from 70 to 300 psi the tolerance, plus or minus from the set pressure, shall not exceed 3 percent of the set pressure. The 165 psi valve popped 9.6 percent below the set pressure stamped on the valve, and the 150 psi valve popped 9.7 percent above the set pressure stamped on the valve.

The blowdowns on all of the valves that were tested were out of tolerance. The 2001 edition of the ASME Boiler Code specifies that for pressures from 67 to 250 psi the blowdown shall not be greater than 6 percent of the set pressure. With such a wide range of variations in both setpoint and blowdown, in a sample of just five valves, it seems reasonable to suspect that even greater variations may exist. The results of the tests are shown in the image gallery.

Complaints about quality problems are not limited to the five valves recently tested by the National Board; for example, an engine owner told me of purchasing a new 1-1/4-inch valve stamped 175 psi. When installed on a traction engine, the valve consistently popped at 185 psi and blew down 15 psi. (A pressure of 11.1 psi equals the allowed 6 percent.) The manufacturer told the owner that the valve had been tested properly prior to shipment but accepted it back. The owner had verified the accuracy of the pressure gauge prior to contacting the manufacturer.

The ASME and National Board procedures for safety valves merely confirm the adequacy of the design of the valve and do not assure the adequacy of production and quality control practices. Each boiler owner and operator must carefully confirm the accuracy of the setpoint and blowdown on every safety valve and not rely on the ASME and National Board stamps as assurances of quality. At this time, I have no reason to believe the monitoring of the ASME and National Board requirements at other valve manufacturers and assemblers is any different than what existed at Kunkle and Allied.

One scenario that concerns me is the owner who installs a new safety valve on his boiler and, seeing that the pop does not coincide with the reading on his 80- or 100-year-old gauge, decides that obviously his gauge must be wrong. This is a conclusion I am sure I would have considered when I first began my study of safety valves.

Incorrect settings of safety valves are more likely to be detected when the valves are used on hand-fired boilers than when used on modern boilers. If the controls on a modern boiler are to limit the pressure to 10 percent or more below the setpoint of the safety valve, the valve can be set as much as 10 percent below its rating and the error might not be apparent. Errors above the setpoint also wouldn’t be obvious even if the boiler were operated up to the setpoint stamped on the valve. Also, incorrect setting of the blowdown would not be apparent until the valve had operated.

1909: “The function of the safety valve is two fold: (A) it gives notice of the highest pressure permissible; (B) it gives alarm that more water or less fuel is needed.”

Today: “A PRV (pressure relief valve) is a safety device intended to protect life and property if all other safety measures fail.” – Anderson Greenwood Crosby, 2001 (safety valve manufactuer)

Bob Ferrell, Bob Schuler and Fred Harrison of the National Board of Boiler and Pressure Vessel Inspectors were instrumental in helping to obtain the information from the old editions fo the ASME boiler codes. Their assistance is greatly appreciated.

A high pressure boiler is a type of boiler that operates at 80 bars or higher and is used in thermal power plants to generate power. Using water-filled tubes in a metal tank or enclosure, they create power by converting water into steam through thermal energy, which is used to power equipment.

The key to a high pressure boiler is the amount of pressure it creates, which differentiates it from other boiler types. Pressure and steam are created by burning a fuel, such as coal, natural gas, or petroleum. The heated gasses, are circulated by natural convection or forced by a pump. Forced circulation is produced by a centrifugal pump to increase the evaporation rate to 210 k of force per square centimeter. Natural force is incapable of generating the necessary force of a high pressure boiler.

The different forms of high pressure boilers include steam generators, electrical boilers, vertical, horizontal, gas, water tube, and fire tube, to name a few. A key feature of most high pressure boilers is the use of small diameter tubes that increases the heating area between surface area and volume ratio, which improves the rate of heat transfer.

In a fire tube boiler, hot gas is pushed through tubes that are immersed in water, which heat the water to create steam as can be seen in the image below.

The majority of boilers work using the same principle of heated water producing steam. The variations between the different types are their geometric orientation, external or internal fire, pressure, water circulation, number of tubes, and the circulation of gasses.

The geometric orientation of a boiler can be horizontal, or inclined with fire on the outside or on the inside, depending on the boiler‘s design. The division of megapascal pressure (MPa) determines whether a boiler is low and high pressure. Boilers that produce pressure above 80 MPa are considered to be high pressure. Low pressure boilers have a MPa below 80 MPa.

Tubing for a boiler can be either single or multiple. The traditional Cornish boiler is an example of a single tube boiler since it has only one fire tube. There is a long list of boilers that have multiple tubes, which is modern boiler design.

The Lamont boiler is a forced convection water tube boiler that uses a pump to circulate water. It has an economizer to save on energy and increase efficiency, a boiler drum, superheater, evaporator, and air preheater. The combustion chamber for a La Mont Boiler has water pumped through the economizer and preheater into the boiler drum.

The boiler drum serves as a steam separator. The pump pushes the water to a distributor header that has nozzles to send the feed water into the evaporator tubes located in the walls of the boiler to increase surface heating.

The water and steam go into the boiler drum, where the steam is separated and passed to the superheater and on to the turbine. The superheater increases the temperature of the saturated steam to prevent water droplets from entering the turbine.

The Benson boiler has some of the same features as the La Mont boiler without a steam separator and it works under critical pressure. It is a water tube, forced circulation boiler, where the feed water is compressed to supercritical pressure to prevent the formation of bubbles in the water tube. The compressed water feed increases the density of the water such that its density and that of the steam become the same, which reduces the latent heat in the water to zero making it easier to convert to steam.

The function of the air preheater, economizer, superheater, evaporator, and combustion chamber are the same. Unlike the La Mont boiler, the combustion chamber can be mounted horizontally.

The Loeffler boiler was developed to resolve a problem with the La Mont boiler, which was salt and sediment buildup on the surface of the water tube and reduced heat transfer. Like the Benson boiler, water is circulated under high pressure in the water tube.

The Loeffler boiler has radiant and convective superheaters that work together to distribute the steam to the turbine. The radiant superheater heats the saturated steam using radiant energy produced by the burning fuel and is where heat transfer takes place. The steam then passes through the convective superheater that is heated by the flue gases, which further heats the steam before it passes on to the turbine.

The Velox boiler is a forced circulation water tube boiler that uses high velocity to rapidly produce steam. The principle of the Velox boiler is built on the velocity of the gas, which moves faster than the speed of sound and increases the rate of heat transfer.

The Velox boiler has a gas turbine compressor that sends compressed air into the combustion chamber, where more heat is released. The increased rate of heat release enhances the flue gases velocity to the speed of sound. The flue gases pass from the fire tubes at the bottom of the combustion chamber and surround water filled tubes.

Water is forced from the economizer to the circulating pump at high speed causing the heat to transfer from the gases to the water very rapidly. The water and steam move to the water separator and on to the superheater. As with the Loeffler boiler, the flue gasses are used to heat the superheater.

The Cornish boiler is the simplest form of boiler. It is a fire tube boiler that has a long horizontal tube with a single flue that contains the fire. The cylindrical shell of a Cornish boiler is one to two meters in diameter and can be four to seven meters long.

The Babcock and Wilcox boiler is a water tube horizontal boiler with natural draft circulation and multiple tubing. Water enters the tubes by a down take header, is heated by hot flue gases and moves in a zigzag fashion forced by baffle plates. The steam in the tubes moves to an uptake header, where it is collected in a boiler drum. An anti-priming pump filters the steam to remove any water droplets so that only steam is sent to the superheater, which increases the temperature of the steam. The steam from the superheater is collected or sent on to the turbine.

High pressure boilers have characteristics and features that make them the best choice for the creation of energy and power. The main factors that differentiates high pressure boilers from other methods of energy creation are fuel, emissions, and efficiency. Each of these have an influence on the equipment‘s performance and cost. The information below contains some of the important features of a high pressure boiler.

Water expands 1600 times to form steam, which can carry large amounts of heat. This makes water an economical and ideal raw material for generating heat and power. High pressure boilers heat water to create steam at over 15 psi and have water pressure over 160 psig.

Combustion efficiency is how well the fuel is being used in combustion, which is different from stack loss, the heat carried away by flue gasses and moisture. High pressure boilers are highly efficient and operate with 15 to 20% excess air. All of the fuel is converted into thermal energy.

Thermal efficiency is the heat exchanger"s ability to transfer heat from the heating process to water or steam, leaving out radiation and convection loss. In most cases, high pressure boilers have a 95% thermal efficiency.

Fuel-to-steam efficiency is measured by the ASME Power Test Code. It is the ratio of BTU output divided by the BTU input. The input is the amount of fuel used to power the boiler, while the output is the steam produced. The higher this ratio, the more efficient is the boiler. In the majority of cases, high pressure boilers have an 95% thermal efficiency.

An efficient boiler uses as much of the heat from the combustion as possible. A low stack loss temperature means effective heat transfer and less heat loss. To avoid stack loss, high pressure boilers control the amount of air to avoid excess air, which can cause stack loss. The amount of air needed depends on the type of fuel.

Burners normally require 15 to 20% excess air to burn properly. Keeping the amount of excess air to a minimum results in an efficiently operating high pressure boiler. The evidence of excess air can be found in the rise of the flue gas temperature. An economizer, installed in the flue, can recover some of the lost heat.

The amount of radiation and convection loss depends on the type, size, and pressure of the boiler. Radiation and convection losses happen because the boiler is far hotter than its surrounding environment. Though it is impossible to totally eliminate radiation and convection losses, they can be controlled by insulating the piping and boiler body.

The American Boiler Manufacturers Association (ABMA) has developed a standard radiation loss chart that can be used to measure radiation loss. The amount of radiation and convection loss is proportional to the surface area of the boiler.

The more heating surface a boiler has per horsepower, the more efficient it is. The normal design of a boiler is 5 to 7.5 lbm/hr of steam per square foot of heating surface. This varies between the different models.

The number of passes flue gas makes before leaving the boiler is a good method for examining boilers. As the gas moves around the boiler, it cools, which changes its volume. The more passes it makes increases the efficiency of the boiler and increases the gasses velocity.

The performance of a boiler depends a great deal on the burner, controller, and boiler working as an integrated system. For a boiler to be efficient, the burner must make optimum use of the air supply and eliminate excess air. The productivity of the burner is critical to the cost of the boiler"s operation. Air levels specifically are set to ensure proper combustion from the burner.

The different models of high pressure boilers are divided by their type of fuel, which is a major consideration since it substantially affects high pressure boiler operating costs. Depending on the regulations of the area where the boiler is used, there can be challenges in regard to the environmental impact of the choice of fuel. Having an understanding of the various fuels can be helpful in selecting the right high pressure boiler for its location and use.

A recent trend in high pressure boiler selection is choosing a boiler that can operate on more than one fuel, such as natural gas, propane, or #2 fuel oil. A major benefit of being able to use different fuels is the ability to adjust fuel consumption as fuel costs change.

Coal has been a fuel source for boilers for over a hundred years. For many modern boilers, it is pulverized into a powder. Anthracite coal is the hottest burning coal and is considered to be clean burning since it produces more heat and less smoke.

Wood chips are produced by putting wood through a wood chipper that converts them to the proper size to be used as fuel. Boilers that run on wood chips are referred to as multifuel boilers since they can run on pellets made from a variety of waste from crop production. Wood chip boilers have a feeding mechanism to continuously feed the boiler.

Gas boilers can use propane or natural gas. The gas is ignited in a combustion chamber and heats the heat exchanger. Gas type boilers are the most common form of boiler and inexpensive to install and operate.

Oil boilers have the same operating principle as a gas boiler. The fuel is ignited in a combustion chamber and heats the heat exchanger that heats the water. Oil boilers are not eco-friendly since oil burning produces CO2. Although there are problems with oil boilers, they can be more efficient, depending on their model and design. They are also more expensive to operate because of the changing prices of crude oil.

Electric boilers use electric heating elements to heat water directly. They are cleaner burning but not as efficient and far more expensive than any of the other boiler types. They are simple to operate and a good choice where there are strict emission standards.

Boiler construction requires an understanding of the purpose of a boiler, which is to generate steam from water. Though there are several purposes for the production of steam, the main purpose of an industrial high pressure boiler is to generate and produce energy and power to drive equipment and machinery.

Each type of boiler has a different design and geometric orientation. Despite their differences, there are common elements for most boilers, which are the burner, combustion chamber, and heat exchanger.

Accessories and mountings are necessary for the boiler to produce energy efficiently. Accessories include economizers, superheaters, feed pumps, controllers, and air preheaters. Mountings include feed check valves, steam stop valves, fusible plugs, blow off cocks, critical safety valves, and water level indicators.

The burner is the heat source for the boiler. It requires fuel to burn and is activated by the thermostat that tells it to produce heat. When liquid fuel is pumped into the boiler, it is changed to a vapor by a nozzle and is ignited. Solid fuels, like wood, coal, and biomass, are fed into a grate in the combustion chamber before being ignited.

The purpose of a heat exchanger is to transfer heat without making direct contact with the water. With a boiler, heat transfers from the heated gasses from the combustion chamber through piping, as can be seen in the image below. It is a central part of a boiler for the creation of steam.

The economizer is where the water enters the boiler, and flue gas increases its temperature. Economizers are energy improving devices that lower costs by saving fuel and making the system more efficient.

The steam produced in a boiler is wet or saturated water vapor. The water droplets it creates are harmful. The purpose of a superheater is to remove or evaporate the water droplets by further heating the steam.

Boiler controllers monitor the operation of a boiler and check for abnormalities or dysfunctions. The aquastat of the controller controls water temperature to prevent the boiler from firing too often. Controllers monitor water levels and the feed rate to prevent low water levels, which can cause a boiler to overheat and fire too often.

The air preheater (APH) heats the air using recovered flue gases. The heated air enters the boiler and increases its thermal efficiency. The recirculated flue gas cools after heating air, and before it enters the gas stack. Air preheaters are either recuperative or regenerative.

The water level indicator provides a reading of the level of the water in the boiler and is a safety device. Most boilers have two water level indicators. A water level indicator has three cocks and a glass tube. The first cock keeps the glass tube connected to the steam, while the second cock connects the glass tube to the water. The third cock indicates whether cocks one and two are clear.

All boilers are required to have a pressure gauge, which can be mounted on the front or side. A Bourdon pressure gauge is typically used on a high pressure boiler.

The safety valve protects the boiler against extreme high pressure inside the drum. It allows for blowoff when the working pressure gets too high. As an extra precaution, and as the steam is released, it makes a loud, uncomfortable noise to warn people in the area. The varieties of safety valves are lever, dead weight, high steam low water, and spring loaded (as seen in the image below).

A stop valve controls the flow of steam and can completely stop it. It manages the steam supply to use and can be operated manually or be part of the control system.

A fusible plug is found in a firetube boiler as a protection against the boiler overheating. During normal operation, the fusible plug is covered in water to keep it stable. When the water level falls, the plug is uncovered and its fusible metal melts, allowing water to enter and put out the fire in the boiler to protect the fire tubes.

The blow off cock is used to remove unwanted deposits in the bottom of the boiler or drain off water. When the cock is open, the deposited material leaves under pressure.

The feed check valve monitors the water supply as it enters the boiler and prevents water from escaping if the pump fails or has low pressure. It is also known as a no return valve and is placed just below the water level in the boiler.

Though high pressure boilers are essential to the production of energy and provide excellent power, they are a potentially dangerous piece of equipment and have to be monitored closely. Regardless of the many safety features on a high pressure boiler, if the pressure is not contained, the steam energy will cause the boiler to explode and release metal and superheated steam.

Melt down is when the metal of the boiler melts. It is usually the result of a low water supply. This condition will not result in an explosion but can severely damage the boiler. Though there may not be an immediate explosion, if the situation remains unresolved, an explosion will occur.

The purpose of a boiler is to create steam pressure, which has to be closely monitored. All boilers are required to have safety measures in place to prevent this from happening.

This is the most important part of boiler maintenance, since low or high water levels can lead to major problems. There are two methods for checking the water level. The first is the gauge glass, which is the easiest. The second method is checking the cocks when the gauge glass is not working.

During blowdown, the water in the gauge glass should fill quickly when the blowdown valve is closed. If it happens slowly, there may be a blockage in the water flow.

The capacity of a safety valve is measured in the pounds per hour that it can handle. Its capacity has to be the same or more than the boiler‘s pounds per hour rate. Safety valves are tested by activating the try lever. When the try lever is released, the disk of the safety valve should move to the closed position.

Modern boilers have a flame safeguard as part of their control systems. It is designed to monitor the burner and shut off fuel if fuel is not being supplied. A flame scanner measures the flicker of the flame and its intensity. It scans the visible, infrared, and ultraviolet light to determine the strength of the burning fuel.

One of the problems of working with water is rust and corrosion. For boilers, corrosion weakens the metal and causes pitting in the tubes, piping, and various components. Water treatment ensures the boiler‘s efficiency and lengthens its life span.

When doing a blowdown, the boiler should have a light load and be at a normal operation water level. Opening of the valve should happen slowly and with caution to avoid injury.

When opening a steam valve, safety glasses or shields should be worn as well as gloves. The valve should be opened very slowly to equalize the pressure and warm the downstream equipment. Traps should be drained as well.

The above listed measures are a few of the actions that need to be taken when dealing with a high pressure boiler. Each organization and manufacturer has their own safety standards that should be strictly followed.

The Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have strict guidelines and regulations for high pressure boiler safety.

The oversight groups for boiler standards and regulations include OSHA, NFPA, and the American Society of Mechanical Engineers (ASME). OSHA and NFPA have developed safety protocols and regulations regarding proper handling of high pressure boilers in specific situations.

OSHA‘s boiler regulations are designed to prevent serious injuries. The standards that have been established are designed to meet specific conditions for individual industries.

NFPA 85 specifies the operating safety and preventive measures for uncontrolled fires, explosions, and implosions as part of Section 1.1. It establishes the requirements for design, installation, operation, training, and maintenance of boilers and pressure devices.

The ASME Boiler Code is the national standard for public safety, product reliability, and industrial efficiency and has increased research efforts in industrial groups as well as provided stability to contractual relations and certification. It has become the international standard for accreditation programs.

A key component of high-performance high pressure boilers is their ability to produce superheated steam, which is not possible with all high pressure boilers.

The variations between the different types of boilers are their geometric orientation, external or internal fire, pressure, water circulation, number of tubes, and the circulation of gasses.

There are several oversight groups that have specific standards and regulations regarding high pressure boilers. The spectrum of control groups include international, national, state, and local organizations that provide regulations and stipulations.

Stainless Steel Safety Relief Valve is a safety mechanism deployed in applications to prevent them from bursting under pressure. Suraj Metal Corporationis a leading manufacturer and supplier of the different types such as the Brass Safety Valveand others in various sizes and dimensions. The valves are fitted with the pipelines in a way that when the pressure goes above the threshold level, the Stainless Steel Air Safety Valveopens up and relieves the system of pressure.

This is important to prevent the pipes from being damaged or bursting under high pressure. The Stainless Steel Safety Exhaust Ball Valveis used in the exhaust systems where the temperature plays major role. When the temperature exceeds certain point, it increases pressure and the safety valve opens and balances the pressure in the system. The spring loaded boiler safety valveis used in boilers and heat exchanger systems where steam and hot water are circulated through pipes. There are different gas safety valvetypes and each of these differ in their purpose and functions. Please feel free to contact us for more information on the different types of air compressor pressure relief valveand others with pricing.

We Keep Bulk Stock of CF8 stainless steel Pressure Safety Valve at our stockyard, contact us for Free Sample & stock list, View Brass Safety Valve Dimension chart

find Stainless Steel Safety Exhaust Ball Valve Dimensions, price list, size chart here, Buy ASTM A351 CF8M 316 temperature safety valve at best price in India

8613371530291

8613371530291