boiler safety valve gagging tool pricelist

Before attempting to adjust the safety valves of any boiler,its essential to verify the accuracy of the boiler pressure gauge,safety valves must be set at a pressure not exceeding 3% above the approved working pressure each safety valve is adjusted independently.

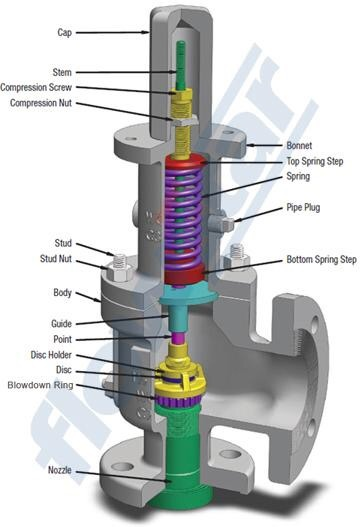

You will hear a hissing sound, this is the floating condition of the valve and subsequently the valve will lift. if the valve lifts before the set pressure is achieved tighten the compression nut. if the valve fails to lift at the set pressure loosen the compression nut, maintain the boiler pressure constant while adjusting, reduce boiler pressure, remove gagging tool and fit to other valve for setting.

After both valves are set, remove the gagging tool and fire the boiler to maximum capacity. note full flow of waste steam from waste steam pipe. note pressure on gauge, the pressure should not exceed 10% of set pressure. after completion refit caps, cotter, locks and easing gear.

IMO your question is more suitable for PSV forum http://www.eng-tips.com/threadminder.cfm?pid=1203 . Of course some of us in this forum have experiences in safety valve.

See some hint from some expert whom have done this http://www.eng-tips.com/viewthread.cfm?qid=180240 . Moral of the story, this is a risky job with some uncertainties, be cautious for operator to position themselves when performing this. If your safety valve is open loop, do not position any parts of someones" body in front or near the outlet

Be cautious that you or the commissioning personnel should correspond both safety valves" setting pressure vs the testing pressure. If its gagged (set the screw to prevent it from opening)at X Psi, then the testing pressure is not advisable to exceed 5% of X. this potentially bent the spindle. And if this happened, as per safety regulation the damage parts shall be renewed with UV stamped (read: original) manufacturer parts (if your safety valve manufacturer and your boiler are referring to ASME).

Boiler safety valve setting procedure is given in this article. To make the content easier to understand and also to make reader to understand as how this important activity is done.

As an engineer onboard you will be required to set the safety valve after each boiler survey. It is a process which needs precision and skill also. Let’s check the stepwise details of the procedure you need to follow while setting the valve.

2) Boiler is ready to be fired. Make sure that the steam blow off line after the safety valve, have a drain and it should be unclogged and should have free passage.

7) Screw down the compression nut little bit more than the previous distance. If you don’t have previous reading, then it will require little bit more attempts before you can actually set the valve.

8) Now let’s say you have to set valve at 9 bar. So, raise the pressure slowly. Just before the 9 bar, like 8.8 or 8.9, you will start seeing little bit of steam coming out of the safety valve.

Note: If you safety valve lifts at 10 bar instead of 9, then don’t try to set it down at the same time. Lower the pressure to 7 bar or something and then adjust the compression nut and then again raise the pressure to 9 bar. Otherwise you get all the wrong adjustment.

14) After both valves are set, they usually have some difference like 0.3 bar. This is not intentional and comes due to the fact that precise and similar adjust of both the valves is not same.

DEAR FRNDS, IF WE DO GAGING AT ANY PRESSURE IT IS WRONG. I HAVE RECENTLY GONE THROUGH A TRAINING PROGRAM ON SAFETY VALVE .IT RECOMMENDS THAT GAGING TO BE DONE AT 70% PRESSURE.

Never, ever gage a safety valve while under any pressure. Serious injury can occur. The safeties are gaged only if you are doing a hydro over the set pressures on the valves. This is only accomplished after major repairs. The NBIC recommends going to 80% of the lowest safety valve setting for a tightness hydro or after the completion of routine repairs.

I"m not sure precisely what the API has to do with boiler operation but whatever. You only gag a safety if you"r squeezing the vessel to 1 1/2 times the working pressure. This is only done after construction or major repair. The rest of the time you squeeze the boiler to working pressure and if you"r careful not to go over that you don"t need to gag the safety valves. You most certainly would never operate the boiler with gags on the safety valves.

Test Gag is a bolt used for the spindle block of the pressure relief valve (PRV) to allow the PRV to be closed during the pressure test. The bolt should be tightened when the system has 80% of the pressure used. test (test pressure) to ensure that the PRV is closed at the test Pressure:

8613371530291

8613371530291