boiler safety valve leaking quotation

This article describes the causes of leaks, drips, or discharges from pressure relief valves, temperature/pressure relief valves, or TP valves found on heating boilers, water heaters, or the simpler pressure relief valves found on water pressure tanks.

We list the wide variety of possible TP Valve leaks and how to find and fix each of those problems, including how to fix a leaky pressure relief valve or leaky TP valve on a boiler, water heater, or water tank - what are the possible causes of leaks at these safety devices. Safety Hazard Warnings About Dripping or Leaking Pressure Relief Valves.

How to use an expansion tank to relieve high water pressure. T&P Valves Installed on Gas Sidearm Heaters: special problems. Closed Hot Water System & Thermal Expansion Problems.

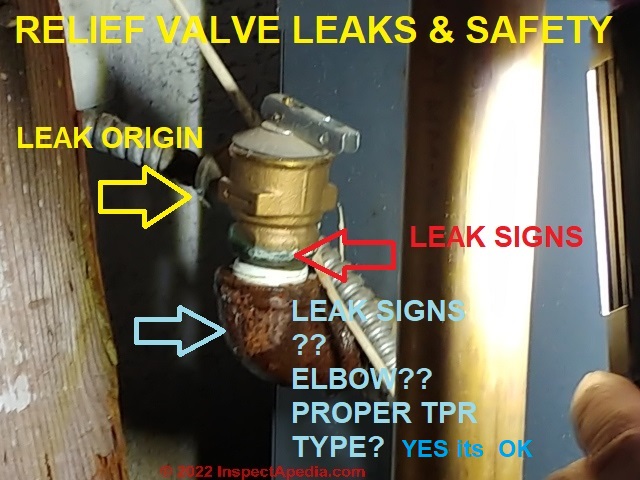

So if you see water actually spilling or even if it"s just dripping at the temperature/pressure relief valve on your heating boiler or water heater, the cause needs to be found and fixed promptly, and it may be appropriate to install a new T&P valve (also called TPR valve) after those repairs are complete.

Boiler limit control problems: On a heating boiler, the boiler temperatures are excessive, possibly due to an improperly set limit control, lack of contact between the limit switch sensor and its mounting well, or a defective control.

Gas sidearm heater TP valves: The T&P valve is installed on a sidearm gas heater that is causing an overheat condition at the sensor point of the valve (This thermal expansion is discussed

Expansion tank defects or problems: if the expansion tank or compression tank on a hydronic heating system boiler or on other thermal expansion systems is itself defective (waterlogged, leaky, damaged internal bladder) system pressures will be excessive due to otherwise normal pressure & temperature variations during system operation, resulting in spillage at the relief valve.

Leaks into the heating boiler or water heater: leaks into a heating of water from a higher pressure building source can cause recurrent TP valve leaking. For example, if the tankless coil in a heating boiler is leaky, higher pressure water inside the tankless coil may leak out of the coil into the heating boiler.

Similarly, an internal leak in the heat exchanger coil of an indirect water heater can send water from the water heater"s potable water into the coil and thence into the heating boiler.

This same leak problem can cause high water pressure in a heating boiler that is used to heat water in an indirect-fired water heater. In that case, a coil containing boiler water (typically at 12-29 psi) that develops a leak may accept higher building pressure water from the building water supply to the indirect water eater tank (or cylinder) that is typically between 20 psi and 70 psi.

Diagnose this problem by observing that when the boiler is left OFF and its own water feeder is left OFF but building water supply is left ON into the tankless coil on the boiler or ON into the indirect water heater, boiler pressure will creep up several hours. With a reader we discuss this possible TP valve leak cause in the FAQs section of this article.

Watch out: under normal conditions, because building water supply pressures are above boiler pressures, an internal leak in the tankless coil or indirect water heater"s heat exchanger coil will cause boiler pressures to rise. But there can be exceptions in the direction of water leakage, as we explain

A deteriorated gasket inside the relief valve or corrosion on the valve seat can cause leaking at the valve; we find this mess occurring when someone lifts the "test lever" on a older P/T valve that has not been tested or operated for some time. A brittle piece of gasket can be spit out of the valve and it will then keep leaking.

The wrong T&P valve has been installed or set to too-low a working pressure. (Proper set pressure is at least 20-30 psi above the working pressure of the equipment to be protected).

Thermal expansion problems: A closed water system with thermal expansion and no means of relief can cause leaks at the pressure/temperature relief valve, such as

Can occur on a hot water heater (hot water cylinder, calorifier, hot water tank) with some building piping arrangements, particularly where a check valve or pressure reducing valve are used.

See THERMAL EXPANSION TPR VALVE LEAKS for an explanation of why thermal expansion leaks occur at the relief valve on hot water systems & what to do about it

Can occur also a hot water heating boiler (used for building heating) at which the boiler"s thermal expansion tank has become waterlogged or has a ruptured internal bladder.

Water expansion pressure (thermal expansion) increases in any closed plumbing system, particularly where a check valve installed close to the water heater.

Watts suggests installing a bypass model water pressure regulator that lets the excessive pressure head back to the street main or building water supply system - a solution that only works if the supply pressure is lower than the T&P relief valve spill pressure - which it usually is.

Water hammer: The building plumbing system suffers from water hammer. Water hammer in buildings causes surging in the water piping that in turn can cause leaks at pressure/temperature or other pressure relief valves, particularly at the pressure safety valve found at water pressure tanks.

Water pressure too high: The building water supply pressure is too high or periodically water pressure fluctuates and is too high at times. Pressures over 70 psi in a typical building tend to cause leaks at plumbing fixtures and higher pressures are likely to cause or contribute to leaks at TPR valves.

Water pressure reducing valve / water feed valve problems: On a hot water hydronic heating system, if the water pressure reducer/feeder valve is not working properly it may over-feed water into the heating system causing overpressure.

Combinations of factors causing TP Valve Leaks: OK so this is more than 12 causes of TPR valve leaks, but keep in mind that the temperature/pressure relief valve leak causes listed above can also occur in combination. For example high incoming water pressure alone may not cause a TPR valve to leak but if we add water hammer then the valve may be leaky.

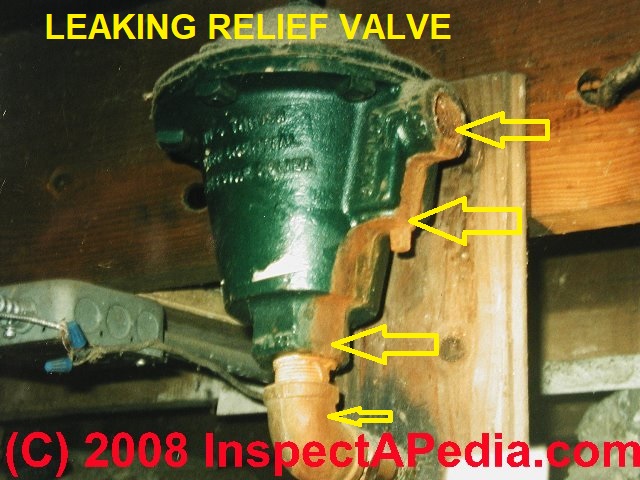

As our photo shows (above left), mineral salts left behind as hot water evaporates from the mouth of a pressure or temperature relief valve can completely clog the spring that is intended to allow the relief valve to open under excess (unsafe) pressure.

The impaction of the relief valve spring with copper and calcium salts in this photo means that the valve is almost certainly not going to open should the heater"s internal pressure become unsafe.

The drip shown at the mouth of this relief valve demonstrates that a relief valve can drip and leak for a long time without anyone observing this dangerous condition.

Technical note: why must the TP Valve point "down"? Take a look at the photo above. If a relief valve is dripping the deposit of minerals inside the valve will accumulate still more rapidly if the valve points to the side or upwards. The result is a clogged valve as we explain above - a dangerous situation that risks an explosion.

Watch out, serious safety hazards can be caused by dripping at the TP discharge line: often the dripping is caused by thermal expansion of hot water.

For details please see THERMAL EXPANSION TPR VALVE LEAKS - an explanation of why thermal expansion leaks occur on hot water systems & what to do about it

Also see HOT WATER PRESSURE EXPANSION RATE - for an explanation of just how much pressure increase to expect when heating water. In explaining why the relief valve on a water heater may be dripping

With a sidearm gas heater a common problem is frequent T&P valve opening even though there is very little hot water in the hot water storage tank. That"s because an overheated condition exists right at the sensor point of the T&P valve - most of the overheated water is "congested" at the top of the tank.

In turn this congestion (think of it as a hot water traffic jam) causes overheating right where the T&P valve sensor is located, thus causing the valve to spill hot water repeatedly.

Because there is just a small volume of "too hot" water where the valve is located, the valve opens, spills the small amount of hot water, then is cooled and closes after just a short interval.

RELIEF VALVE LEAKS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

[6] A.O. Smith"s Form No. 4778* All about Deliming Coil-Type/Tube-Type Commercial Water Heaters and Hydronic Boilers *Normally supplied when ordering Part No. 4930 Motorized Deliming Pump Kit

[7] "Building Owner Water Heater Safety Notice", Building Department, City of Colleyville TX, web search 09/24/2010, original source: http://www.colleyville.com/dmdocuments/Building%20

Water heater safety is imperative to the occupants of a building or structure. If improperly installed, water heaters can be detrimental to the structure, as well as being potentially fatal to its occupants. The proper installation of a water heater is so important that according to Texas State Law all water heater installations must be inspected by a state licensed plumbing inspector.

[9] Watts, 815 Chestnut Street, North Andover, MA, USA 01845-6098, web search 09/18/2010 original source: http://www.watts.com/pages/learnAbout/reducingValves.asp?catId=64

In small scale testing, the Mythbusters started with a small six gallon water heater and disabled all of its safety features under the theory of poor installation or neglect. While the water heater eventually ruptured, it did not explode like a rocket. The Mythbusters then upgraded to larger thirty gallon water heater which exploded with significantly greater force, sending the water heater several hundred feet into the air. In order to confirm the stated myth, the Mythbusters obtained a full size fifty two gallon water heater and built a shack around it with a roof that followed standard California building codes. The water heater eventually exploded, shooting through the roof five hundred feet into the air and disintegrating the shack. In light of these results, and the fact that there is documented evidence corroborating the myth, the Mythbusters deemed it confirmed.

Because of built in safety devices most water heaters safely operate day in, day out without any major problems. But don"t let the excellent safety record of water heaters lull you into forgetting about the explosive potential of these marvels of convenience. When a water heater explodes, it releases a tremendous blast force which can easily demolish a building.

Randall Hilton and crew, with help from the Service Roundtable has prepared this video of a water heater explosion as a demonstration of the explosive power of a simple water heater. The hot water tank explodes using the steam pressure that any water heater can generate when the thermostat and temperature pressure relief valve (T&P valve or PT valve) malfunction. We were impressed by how far the tank flew after the water heater exploded. Click on the links below to view the video. Then, visit the Q&A page for warning signs as well as simple steps which can help you prevent your own water heater from exploding.

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

You may have a defective boiler feed water pressure regulator. (Looks like this.) This device takes water from your plumbing system and feeds it into the boiler until the pressure in the boiler reaches a certain level, typically 12 PSI. Then it stops adding water unless the pressure again drops below 12 PSI for any reason, such as a leak or the intentionally draining of some water. When the boiler heats up, expansion takes place and the water pressure rises a bit above 12 PSI. This excess pressure is absorbed by the expansion tank so the final pressure of the hot boiler may go up to 15-20 PSI typically, which is below the usual 30 PSI setpoint of the pressure relief valve.

Some regulators include a backflow preventer and some use a separate backflow preventer that is installed between the regulator and the boiler. The backflow preventer prevents boiler water from backing up into your household plumbing and potentially poisoning you.

If the regulator is faulty, it may be allowing water to continue to flow slowly into your boiler, raising the boiler pressure until it reaches 30-40 psi. At that point, the pressure relief valve would start dripping.

Boiler explosions have been responsible for widespread damage to companies throughout the years, and that’s why today’s boilers are equipped with safety valves and/or relief valves. Boiler safety valves are designed to prevent excess pressure, which is usually responsible for those devastating explosions. That said, to ensure that boiler safety valves are working properly and providing adequate protection, they must meet regulatory specifications and require ongoing maintenance and periodic testing. Without these precautions, malfunctioning safety valves may fail, resulting in potentially disastrous consequences.

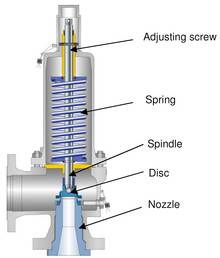

Boiler safety valves are activated by upstream pressure. If the pressure exceeds a defined threshold, the valve activates and automatically releases pressure. Typically used for gas or vapor service, boiler safety valves pop fully open once a pressure threshold is reached and remain open until the boiler pressure reaches a pre-defined, safe lower pressure.

Boiler relief valves serve the same purpose – automatically lowering boiler pressure – but they function a bit differently than safety valves. A relief valve doesn’t open fully when pressure exceeds a defined threshold; instead, it opens gradually when the pressure threshold is exceeded and closes gradually until the lower, safe threshold is reached. Boiler relief valves are typically used for liquid service.

There are also devices known as “safety relief valves” which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service.

Nameplates must be fastened securely and permanently to the safety valve and remain readable throughout the lifespan of the valve, so durability is key.

The National Board of Boiler and Pressure Vessel Inspectors offers guidance and recommendations on boiler and pressure vessel safety rules and regulations. However, most individual states set forth their own rules and regulations, and while they may be similar across states, it’s important to ensure that your boiler safety valves meet all state and local regulatory requirements.

The National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation, and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulationsin order to provide guidance and encourage the development of crucial safety laws in jurisdictions that currently have no laws in place for the “proper construction, installation, inspection, operation, maintenance, alterations, and repairs” necessary to protect workers and the public from dangerous boiler and pressure vessel explosions that may occur without these safeguards in place.

The American Society of Mechanical Engineers (ASME) governs the code that establishes guidelines and requirements for safety valves. Note that it’s up to plant personnel to familiarize themselves with the requirements and understand which parts of the code apply to specific parts of the plant’s steam systems.

High steam capacity requirements, physical or economic constraints may make the use of a single safety valve impossible. In these cases, using multiple safety valves on the same system is considered an acceptable practice, provided that proper sizing and installation requirements are met – including an appropriately sized vent pipe that accounts for the total steam venting capacity of all valves when open at the same time.

The lowest rating (MAWP or maximum allowable working pressure) should always be used among all safety devices within a system, including boilers, pressure vessels, and equipment piping systems, to determine the safety valve set pressure.

Avoid isolating safety valves from the system, such as by installing intervening shut-off valves located between the steam component or system and the inlet.

Contact the valve supplier immediately for any safety valve with a broken wire seal, as this indicates that the valve is unsafe for use. Safety valves are sealed and certified in order to prevent tampering that can prevent proper function.

Avoid attaching vent discharge piping directly to a safety valve, which may place unnecessary weight and additional stress on the valve, altering the set pressure.

A boiler leaking water is usually a sign that a seal or a valve has developed a fault. However, if the problem is left untreated, a leaking boiler can cause other components to erode as well as cause damage to the electrical components within the boiler. Your best option when you notice a leak is to fix the problem quickly to prevent further damage.

Before you can do anything with your boiler, you need to find out why it’s leaking, but this isn’t always easy. The first thing to do is find where the water is coming from, as this will give you a better idea of why. Below, we’ve listed some of the main causes of a leaking boiler.

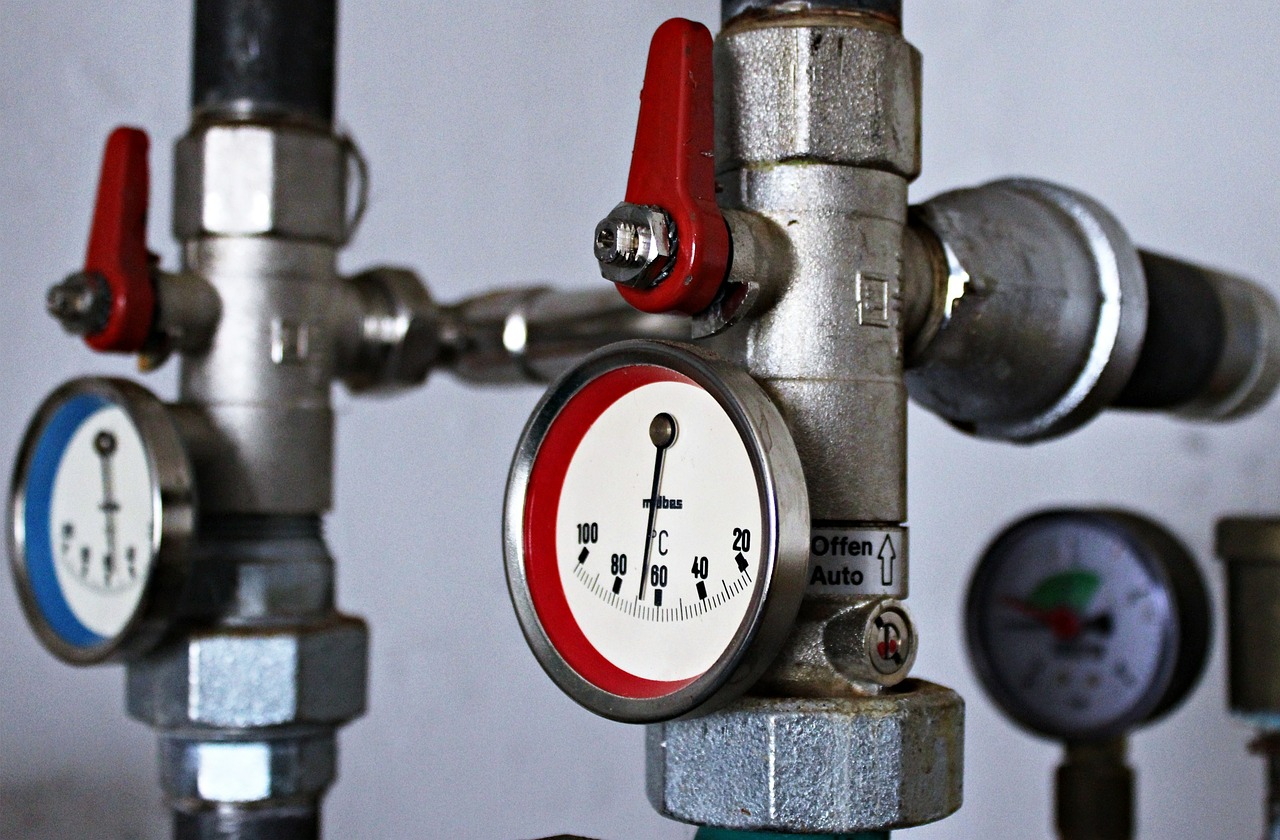

Have you ever noticed the gauge on the front of your boiler? This is important as it tells you how much water pressure there is in the system. Too little or too much pressure can cause a problem, so you should check the valve regularly and add or remove water as required.

If your boiler is leaking, you should check the pressure gauge to see if the pressure is too high. If this is the case, it’s likely that the pressure relief valve is trying to release some of the water in the system to bring the pressure back down to a comfortable level, which can lead to your boiler dripping water. The valve needle should be between 1 and 1.5 bar (usually shown on the gauge as a green zone). If the needle is higher than this, or in the red zone, you may need to bleed the radiators to release extra water.

Corrosion can be a problem in older boiler systems as it can cause rust and other debris to build up within your radiators and pipework. As the water runs around the system, it can pick up this debris and return it to your boiler. The older the system, the more likely you are to have issues with corrosion, which in turn can lead to your boiler leaking water from the bottom. Unfortunately, many people don’t know corrosion is there as it can’t be seen.

Corrosion can break the rubber seals around the joints of pipes, so water may be leaking through here. If the corrosion is on an individual component, an experienced contractor will be able to replace this with ease. However, if the corrosion is widespread, then you may need to replace the boiler completely.

A contractor will be able to advise you if a new system is required or if a new boiler and a flush of the system would be adequate. If you have an old boiler, replacing it with a newer model could make your home more efficient and could save money on your gas bills, too.

Pressure relief valves ensure efficiency and safety in many chemical, oil, and gas plants, but they’re susceptible to leaks. If a pressure relief valve is leaking, systems can become overpressurized and even fail, especially if the valve isn’t addressed or repaired quickly.

When you shut down the system, carefully examine the pipelines and the valve itself to determine the cause of the leak. This will help you figure out exactly what you need to do to repair it.

Pressure relief valve leaks usually occur when the valve isn’t properly seated or when the seal is broken or damaged. Leaks can also happen when the pressure relief valve is operating too closely to the set point.

If the valve isn’t completely repaired after your first attempt, you have up to 15 days to perform any additional repairs according to the EPA. If the valve still isn’t fixed, then you can either replace the pressure relief valve or wait until the next shutdown cycle to do more repairs.

When the pressure relief valve has been fixed or replaced, it’s important to take the necessary steps to avoid leaks in the future. To do that, consider implementing a leak detection and repair (LDAR) program for your company.

An LDAR program will help to train workers on everything they need to know about detecting and repairing a leak before system damage can occur. It will also help you monitor valves more efficiently so you can spot leaks faster and spend less money on overall valve repair and maintenance costs.

The dip tube carries cold water to the bottom of the tank for heating. If the dip tube is corroded, blocked, or leaking, water heating won’t occur as efficiently.

The pressure relief valve makes sure your water tank pressure remains at safe levels. If pressure builds up too much, this valve opens to relieve some of that pressure.

If you notice that the valve is consistently leaking, it may mean that the tank’s pressure is too high, or you might simply have a faulty/clogged valve.

A leak from your water heater’s pressure relief valve is a major concern, especially if it’s the first time dealing with this problem. While some people tend to panic and get help immediately, others may just shrug their shoulders and assume that the leak is a common occurrence. However, there are many causes of leaks in water pressure relief valves. And all these must be addressed immediately given the high risks of property damage and hazards that can occur if the issue is ignored.

The pressure relief valve gives steam and water a chance to escape when either the pressure or temperature in the water tank gets too high. A malfunctioning valve can cause the water heater to explode and is the major cause of water heater explosions. In water heater pressure relief valves, the valve is set to open when the pressure exceeds 150 psi.

A leaking valve is not always a broken valve. In some cases, a water heater’s pressure relief valve may leak because it is functioning as intended. As excess pressure is relieved out of your water heater system, some water may leak. This necessitates the need to test the pressure in your water heater.

If you get a high-pressure reading, then you could be dealing with a closed plumbing system issue. This means that when the water is heated, the pressure increases as it should. But with nowhere to go, the valves open to relieve the pressure. Luckily, this can be solved by installing an expansion tank that gives the pressure an outlet other than a pressure relief valve.

Although rare, your water heater’s pressure relief valve could be leaking as a result of excessively high temperatures. However, the water has to be near the boiling point. To check the water temperature, ensure you turn on the hot water faucet. Run the water for one minute and use a meat thermometer to take the temperature reading. The temperature should be around 120 degrees. If more than this, then you need to have the water heater checked. The water temperature would need to be close to 212 degrees to set off the relief valve.

While this is an uncommon occurrence, it is not far-fetched. Your technician could have used a pressure valve for another appliance since they have the same function. However, these other pressure relief valves are set to go off at a lower psi. For instance, boiler pressure valves go off at 30 psi. If installed in a water heater, you are likely to get leaks immediately after installation. As such, if you have had your water heater for years and only experienced the leaks after a long period, then this is an unlikely cause of the leak.

A slight leak may occur if your water heater’s pressure relief valve has not been opened for a while, say a few years. While this leak is normal and may not be an indicator of a problem with the water heater system, you may need to replace the valve if the leak becomes more serious. It is cheaper to replace the entire valve than to repair it and have to deal with the same problem later on.

A leak in your water heater’s pressure relief valve could also be caused by a faulty pressure relief valve. While pressure relief valves barely break down, excessive wear and improper installation can cause extensive damage. Unfortunately, a faulty pressure valve can not be repaired and must be replaced. However, the cost of pressure valves is affordable and ranges around $30.

Know your water heater and how it functions– Water heaters can be intimidating, especially for people with less technical know-how. Understand what every part of the system plays in heating water such as the water shutoff valve, drain valve, thermostat, and pressure relief valve. This eases the maintenance routine and ensures you have a fair understanding of any malfunctions.

Carry out regular maintenance– Inspect your water heater monthly, ensuring that all valves and pipes are in good shape. This also helps you catch corrosion and leaks early enough before they turn out to be bigger problems. And every year, carry out a water heater flush. Given that you cannot pinpoint all problems, have a qualified technician inspect the system annually.

Regardless of the possible cause of a leak in your water heater’s pressure relief valve, please contact a qualified plumber as soon as possible. And if you think it’s a problem that you can solve without getting help, ensure you have a qualified plumber confirm that the system is performing optimally after. Water heater issues should not be taken lightly as they can cause more issues, even explosions.

Boilers are wonderful home heating systems that have stood the test of time. Instead of heating air like furnaces do, boilers heat water and turn it into steam. Because boilers contain a lot of water, what should you do when you notice the system leaking?

Depending on where the leak is and how much water is coming out of the boiler can determine your state of panic. Theboiler experts at Poston Brothers are here to help you troubleshoot your leaking boiler and let you know when to call us for boiler services.

As soon as you notice your boiler leaking water, clean up the water to prevent water damage. Then, monitor the leak to see how fast it is leaking water. See if you can identify where the leak is coming from. A leaking boiler will need to be fixed by an HVAC technician, but doing some troubleshooting yourself can help save time. Not every leaking boiler needs to be replaced, but having the professional team at Poston Brothers look at your boiler is the only way to be sure.

Leaks are never a good sign, but there are a few steps you can take to stop them. Boilers use both gas and very hot water to supply heat to your home. If you are not comfortable being around these elements, call Poston Brothers right away.

The pressure relief valve on your boiler can get clogged with sediment and cause leaks. Boilers need to release pressure regularly, and if it cannot release steam, it will release water instead. Turn off your boiler and let it cool. Then open the pressure relief valve to release the water for 3-4 seconds. The water should come out clean. If you shut the valve and it continues to leak, that means there’s more sediment inside. Repeat this process until the boiler leaks stop. If they don’t stop, then call Poston Brothers.

Corroded pipes and tanks are a common reason your boiler is leaking water. Corrosion is a problem, and you’ll need to consult with a technician to see how bad the corrosion is and what repairs you’ll need.

If your boiler was recently installed and you’re noticing leaks, then there’s a good chance that the installation was done incorrectly. Occasionally, some joints and pipe fittings aren’t installed correctly, and that can cause a leaking boiler. Poston Brothers is always happy to provide a second opinion on boiler installation.

Just like pipes, seals and parts can break down over time. A broken seal will spray a lot of water, so you’ll notice it right away. It’s important to turn off your boiler if the leaking water is constant to prevent water damage.

The temperature control valve regulates the temperature of the water in the boiler. If your temperature valve is malfunctioning and setting your boiler temperature too high, it could be causing boiler issues like leaks.

Boilers, like any central heating system, need to be maintained on an annual basis. If it’s been a long time since you’ve had a reputable HVAC company like Poston Brothers look at your boiler, now is the time. If it’s hard to remember to schedule your yearly maintenance, then join our Poston Club maintenance plan.

When you’re a member, we’ll remind you when your boiler is due for service and then we’ll schedule your appointment around your schedule. Member benefits also include a discount on all repairs, replacement credits, and discounts on service calls. Call Poston Brothers today for boiler repairs, and ask your technician about joining the Poston Club maintenance program.

The boiler safety valve is one of the most important safety accessories to ensure the safe operation of the boiler. Whether it can be opened accurately and reliably is of great significance for maintaining the safe operation of the boiler.

As a valve with important protection functions, safety valves are widely used in various pressure vessels and piping systems. When the pressure vessel (system) reaches the upper limit of the specified pressure tolerance, it can automatically open Discharge the excess medium out of the pressure vessel (system) and close it automatically after the discharge, to ensure that the pressure vessel can operate within a safe and reliable pressure allowable range and avoid major safety accidents. The normal operation of the safety valve is not only related to the normal safe use of pressure vessels such as boilers, but also directly related to the safety of the people"s lives and property. Therefore, we must pay high attention to the common failures of boiler safety valves and resolve them in a timely manner.

Valve leakage is one of the most common faults in boiler safety valve failures. It mainly refers to the leakage of the valve flap and valve seat seal that exceeds the allowable level under normal working pressure of the boiler.

① Dirt falls on the sealing surface. You can use a lift wrench to open the valve several times to wash away the dirt; ② The sealing surface is damaged. It should be repaired by grinding or turning after grinding according to the degree of damage. After repair, the flatness of the sealing surface should be ensured, and its smoothness should not be less than 10; ③ Due to improper assembly or pipeline load, the concentricity of the parts is destroyed. The additional load of the pipeline should be reassembled or removed; ④ The opening pressure of the valve is too close to the normal pressure of the equipment, so that the sealing surface is lower than the specific pressure. When the valve is subject to vibration or medium pressure fluctuations, leakage is more likely to occur. The cracking pressure should be properly adjusted according to the strength of the equipment; ⑤ The relaxation of the spring reduces the set pressure and causes valve leakage. It may be caused by high temperature or corrosion. Measures such as spring replacement or even valve replacement should be taken. If it is caused by improper adjustment, just tighten the adjustment screw properly.

Low reseating pressure will cause a large amount of medium to be discharged over time and cause unnecessary energy loss. The reason is that the steam discharge on the spring pulse safety valve is large. After this type of impulse safety valve is opened, the medium is continuously discharged and vibrates The front and back forces of the safety valve body or impulse safety valve continue to increase due to insufficient medium discharge of the main safety valve, so the steam in the pulse tube continues to flow to the impulse safety valve along the gas collecting header in the steam drum to maintain the action of the impulse safety valve. On the other hand, due to the action of this type of impulse safety valve, the sealing surface of the impulse safety valve. After its reorganization forms a kinetic energy pressure area, the valve core is raised, so that the impulse safety valve continues to discharge, the greater the steam discharge, the greater the safe upward thrust acting on the valve core, the smaller the impulse safety valve is, and the easier it is to seat. . At this time, the way to eliminate this fault is to close the throttle valve to reduce the flow of medium flowing out of the impulse safety valve and reduce the pressure in the kinetic energy pressure zone, so that the impulse safety valve is seated. The second factor that causes the low seating pressure is that the cooperation clearance between the valve core and the guide sleeve is not suitable, and the cooperation clearance is too small. After the impulse safety valve is opened, the throttle is instantaneously throttled at this location to form a higher kinetic energy pressure area. The method of lifting and delaying the reseating time is to carefully check the size of each part of the valve core and the guide sleeve. If the clearance is too small, reduce the diameter of the valve flap cover or the diameter of the valve flap steam cap or increase the valve flap and guide. The radial gap between the sleeves increases the flow area of this part, so that the steam flow path does not divide, and the local pressure forms a high kinetic energy pressure zone.

The leakage of the joint surface of the valve body mainly refers to the leakage phenomenon at the joint surface between the upper and lower valve bodies.

One is that the bolts of the joint surface are not tight enough or tightly biased, resulting in a poor sealing of the joint surface. The elimination method is to adjust the bolt tightening force. When tightening the bolt, it must be tightened diagonally. It is best to measure the gap everywhere while tightening, tighten the bolt until it is not tight, and make the joint surface gap. Consistent. Second, the toothed gasket on the joint surface of the valve body does not meet the standard. For example, there are slight groove marks in the radial direction of the toothed gasket, poor parallelism, and defects such as over-sharpness or over-slope of the tooth shape, which can cause seal failure. So that the valve body joint surface leaks. The quality of spare parts should be checked during maintenance, and the use of standard tooth seals can avoid this phenomenon. The third is that the flatness of the joint surface of the valve body is too poor or it is cushioned by hard impurities, resulting in seal failure. If the flatness of the joint surface of the valve body is too poor to cause leakage of the joint surface of the valve body, the method of elimination is to disintegrate the valve and regrind the joint surface until it meets the quality standards. If the seal fails due to the padding of impurities, carefully clean the joint surface during the assembly of the valve to avoid the impurities falling into it.

The main reasons for this failure are the following two aspects. On the one hand, the amount of steam leakage in the piston chamber of the main safety valve, although the impulse safety valve is seated, the pressure of the steam in the pipeline and the piston chamber is still very high, and the force pushing the piston down is still very large. Therefore, the main safety valve is sluggish. The method to eliminate this fault is mainly solved by opening the throttle valve and increasing the throttle aperture. The opening of the throttle valve and the increase of the throttle hole make the steam remaining in the pulse tube quickly discharged , Thereby reducing the pressure in the piston, so that the thrust acting on the piston downward movement is rapidly reduced, and the valve core is quickly returned by the upward thrust of the steam medium in the header and the upward tension of the main safety valve’s spring seat. On the other hand, the reason is that the friction between the moving parts of the main safety valve and the fixed parts is too large, which will cause the main safety valve to return to the seat slowly. The solution to this problem is to match the clearance between the moving parts of the main safety valve and the fixed parts. The standard range of the console.

The chattering phenomenon of the safety valve during the discharge process is called chattering of the safety valve. The occurrence of chattering phenomenon is very likely to cause fatigue of the metal, reduce the mechanical performance of the safety valve, and cause serious hidden dangers to equipment.

The main causes of chattering are the following: on the one hand, the improper use of the valve, the discharge capacity of the selected valve is too large, and the method of elimination should be to make the rated displacement of the selected valve as close as possible to the necessary discharge of the equipment. On the other hand, because the diameter of the inlet pipe is too small, smaller than the inlet diameter of the valve, or the resistance of the inlet pipe is too high, the method of elimination is to make the inner diameter of the inlet pipe not less than the inlet diameter of the valve when the valve is installed, or reduce the inlet pipe diameter. Resistance, the resistance of the discharge pipe is too large, and excessive back pressure during discharge is also a factor that causes valve flutter, which can be solved by reducing the resistance of the discharge pipe.

In most instances, you’ll find that the pressure relief valve is located within the boiler itself. This is not something you should attempt to fix on your own as you are not Gas Safe registered, so you cannot legally take the case off the boiler. So if you do notice a drip coming from your pressure relief pipe, you should call an engineer right away.

So, in conclusion, it’s not really feasible for you to repair a leaking boiler pressure relief valve yourself and the job should be left to an engineer. These things do take time, by the way. So, if you’re curious about how long it takes to fix a boiler leak, then our blog will help you.

If your boiler"s leaking gas, you may be able to smell it. Other signs of a leak include black stains above or near the boiler. There may be excess condensation on your windows. Or the pilot light – the flame that indicates your boiler’s working – might be burning orange or yellow (rather than blue).

Boilers should never leak gas or oil. For safety, modern boilers burn gas or oil in a sealed combustion chamber. They bring in the oxygen needed to make the fuel burn and then release the exhaust fumes safely back outside. This sealed system keeps poisonous gases out of your home. But, very occasionally, things can go wrong.

We provide onsite safety relief valve diagnostic testing and repair services while helping you manage your overpressure protection assets for regulatory compliance.

However, what is even more surprising is that many of these people have been told by their plumber that this means the valve is faulty and should be replaced. In fact, we even had one customer who had been told this by their plumber, had followed their advice and replaced it only to find the same thing happened again. So they called the manufacturer and they advised the same thing, so they bought ANOTHER valve, and … you guessed it, the same thing happened yet again.

Now, we are not qualified plumbers but what we can tell you is that in the majority of cases, pressure relief valves do not fail. They work. And what this means is that water comes out of them when the pressure gets too high. That’s exactly what they are supposed to do when the pressure needs relieving.

Before I go any further, let’s clarify that I am talking about a pressure RELIEF valve, not a pressure REDUCING valve. These are often (but not always) built into the top of an electric water. Often they are combined with a temperature relief valve. Sometimes they are on the cold supply side of the water heater.

Pressure in an electric hot water system builds up primarily because when water is heated, it expands. If designed and installed properly, this is allowed for in the system – usually through the installation of an expansion vessel. If this fails, or if one was not installed in the first place, then there is nowhere for this pressure to go when the water is heating up, and it escapes through the Pressure Relief Valve.

So if you find the PRV is leaking water (particularly when the water is heating up) then the chances are that your expansion vessel is either inadequate, or it needs repressurising. (When it is working correctly, an expansion vessel lets water in as the pressure increases, and lets it out when the temperature - and therefore pressure - decreases). Any plumber would be able to do this, and they would know what pressure it should be pumped to.

A common sight in a hydronic boiler room is water dripping from the discharge pipe of the boiler relief valve. While it may appear to be inconsequential, it could cause extensive damage to the heating system.

Some boiler rooms have a bucket under the relief valve discharge pipe to mask the problem. The following are some suggestions if you would like to resolve the problem.

Leaking water from a sealed hydronic system can reduce the life of the system by introducing untreated makeup water containing oxygen and solids to the system. The oxygen can attack and pit the boiler and piping, causing corrosion and leaks.

The solids can affect the efficiency and safety of the system. Solids form scale on the hottest surfaces in the boiler lowering the heat transfer ability and efficiency of the system. A leaking relief valve can allow solids to form on the seat of the relief valve increasing the rate of the leak.

A worse situation occurs when the solids form on the spring side of the relief valve as it could alter the opening pressure. A relief valve was a contributing factor in a fatal boiler accident as scale formed on the relief valve, prohibiting it from opening properly.

The relief valve, rated for 30 psig, was tested after the accident and did not open until the pressure reached 1,500 psig. Diagnosing the cause of the leaking relief valve is time-consuming and sometimes frustrating. I like to explain this to the customer to prepare them when the diagnosis and repair may take more than one visit.

The first thing I check is the system pressure. Most hydronic boilers have a gauge called a tridicator, or PTA (pressure, temperature, altitude) gauge. How much pressure do we need for the system? Each pound of system pressure will raise water 2.3 feet. The way to calculate how much pressure you need is to determine the height of the tallest radiator and divide the height by 2.3.

The next step is to verify the pressure rating of the relief valve. The pressure rating of the relief valve should be at least 10 psig higher than the operating pressure of the system but less than the maximum allowable working pressure (MAWP) of the boiler. Many hydronic boilers are shipped with a 30 psig relief valve from the factory. In this example, the relief valve should be at 40 psig or higher. If the system pressure is 30 psig and the relief valve, rated for 40 psig, is leaking, the relief valve is most likely defective.

Another troubleshooting task I perform is watching the tridicator (or PTA gauge) while the boiler is firing and heating the water. When water is heated from 65° F to 180°, the water volume expands by 3%. If the pressure gauge starts creeping up as the water heats, I would suspect a flooded compression tank or plugged piping to the compression tank.

In some instances, it may take several days for the pressure to build and open the relief valve and these are the most difficult to troubleshoot. The first place I would look is the compression tank. If the tank is flooded, there are a couple of reasons.

The most common causes are leaking gauge glass fittings above the water line of the tank, excessive system pressure, undersized tank, or the tank has a leak above the water line. If the system has been operating correctly for years, I would be hesitant to believe the tank is undersized.

A pinhole leak on top of the tank may be impossible to find and one of the ways to test the integrity of the tank is to valve off the water feeder to the system and check the tank in a few days to see if it flooded. If the tank is flooded, you might have to replace the tank.

Another culprit that can cause the pressure to rise and open the relief valve is if the boiler has an indirect water which uses the boiler water to heat the domestic water using a water to water heat exchanger. A leaking heat exchanger could allow the higher city water pressure to enter the space heating side and increase the system pressure. To test this idea, shut the valves from the domestic water side and see if the pressure still rises.

The last item to check is the pressure-reducing valve (PRV). This is a brass valve with an adjustment screw. Some models have a quick-fill feature, which allows you to pull a lever and quickly fill the system. A stethoscope is sometimes used to trouble shoot the PRV to detect if water is leaking through the valve.

Another way to test for leaking is to feel the downstream pipe and see if it is cold. In many instances, the water is fed slowly and difficult to detect. Another way to test to see if the PRV is leaking through is to shut off the valves on the feed water pipe and see if the pressure still rises. If it does, I will suspect the piping to the compression tank is restricted or the tank is flooded. If the pressure does not rise, it could be the pressure reducing valve.

8613371530291

8613371530291