boiler safety valve leaking for sale

The bleeder valve will get a steam leak when corrosion results from purified waters, formulated waters, and hard waters. The valve gets stuck open and has a steam leak. Pinching the hsoe atatched to the bleeder valve after the machine is fully heated will confirm a steam leak once released after several seconds of holding.

The safety valve will also get corrosion to cause a steam leak OR the boiler is running hotter because the PID sensor has corrosion from the same aforementioned waters.

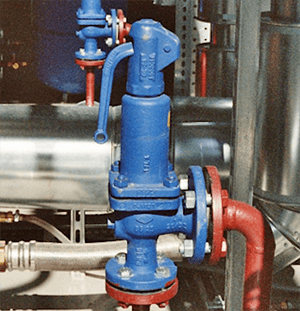

A common sight in a hydronic boiler room is water dripping from the discharge pipe of the boiler relief valve. While it may appear to be inconsequential, it could cause extensive damage to the heating system.

Some boiler rooms have a bucket under the relief valve discharge pipe to mask the problem. The following are some suggestions if you would like to resolve the problem.

Leaking water from a sealed hydronic system can reduce the life of the system by introducing untreated makeup water containing oxygen and solids to the system. The oxygen can attack and pit the boiler and piping, causing corrosion and leaks.

The solids can affect the efficiency and safety of the system. Solids form scale on the hottest surfaces in the boiler lowering the heat transfer ability and efficiency of the system. A leaking relief valve can allow solids to form on the seat of the relief valve increasing the rate of the leak.

A worse situation occurs when the solids form on the spring side of the relief valve as it could alter the opening pressure. A relief valve was a contributing factor in a fatal boiler accident as scale formed on the relief valve, prohibiting it from opening properly.

The relief valve, rated for 30 psig, was tested after the accident and did not open until the pressure reached 1,500 psig. Diagnosing the cause of the leaking relief valve is time-consuming and sometimes frustrating. I like to explain this to the customer to prepare them when the diagnosis and repair may take more than one visit.

The first thing I check is the system pressure. Most hydronic boilers have a gauge called a tridicator, or PTA (pressure, temperature, altitude) gauge. How much pressure do we need for the system? Each pound of system pressure will raise water 2.3 feet. The way to calculate how much pressure you need is to determine the height of the tallest radiator and divide the height by 2.3.

The next step is to verify the pressure rating of the relief valve. The pressure rating of the relief valve should be at least 10 psig higher than the operating pressure of the system but less than the maximum allowable working pressure (MAWP) of the boiler. Many hydronic boilers are shipped with a 30 psig relief valve from the factory. In this example, the relief valve should be at 40 psig or higher. If the system pressure is 30 psig and the relief valve, rated for 40 psig, is leaking, the relief valve is most likely defective.

Another troubleshooting task I perform is watching the tridicator (or PTA gauge) while the boiler is firing and heating the water. When water is heated from 65° F to 180°, the water volume expands by 3%. If the pressure gauge starts creeping up as the water heats, I would suspect a flooded compression tank or plugged piping to the compression tank.

In some instances, it may take several days for the pressure to build and open the relief valve and these are the most difficult to troubleshoot. The first place I would look is the compression tank. If the tank is flooded, there are a couple of reasons.

The most common causes are leaking gauge glass fittings above the water line of the tank, excessive system pressure, undersized tank, or the tank has a leak above the water line. If the system has been operating correctly for years, I would be hesitant to believe the tank is undersized.

A pinhole leak on top of the tank may be impossible to find and one of the ways to test the integrity of the tank is to valve off the water feeder to the system and check the tank in a few days to see if it flooded. If the tank is flooded, you might have to replace the tank.

Another culprit that can cause the pressure to rise and open the relief valve is if the boiler has an indirect water which uses the boiler water to heat the domestic water using a water to water heat exchanger. A leaking heat exchanger could allow the higher city water pressure to enter the space heating side and increase the system pressure. To test this idea, shut the valves from the domestic water side and see if the pressure still rises.

The last item to check is the pressure-reducing valve (PRV). This is a brass valve with an adjustment screw. Some models have a quick-fill feature, which allows you to pull a lever and quickly fill the system. A stethoscope is sometimes used to trouble shoot the PRV to detect if water is leaking through the valve.

Another way to test for leaking is to feel the downstream pipe and see if it is cold. In many instances, the water is fed slowly and difficult to detect. Another way to test to see if the PRV is leaking through is to shut off the valves on the feed water pipe and see if the pressure still rises. If it does, I will suspect the piping to the compression tank is restricted or the tank is flooded. If the pressure does not rise, it could be the pressure reducing valve.

A pressure relief valve (prv), also called a safety relief valve, is one of the most important types of safety valves. This type of valve sets a limit on the rise of pressure in a boiler. In normal operation, the valve is closed and no water passes through.

But if the pressure in the system exceeds the limit – normally 3 bar, the valve opens to relieve the pressure. It sends system water into the overflow pipe outside until pressure has gone down. This protects the expensive parts of the boiler from damage due to high pressure.

Without a relief valve, the pressure can continue to grow until another component fails in the boiler and pressure is released. You can find a prv anywhere on a system but with a combi, it’s mostly inside the casing.

When working correctly, the prv should not leak. Pressure relief valves are connected to an outlet pipe outside. If the prv leaks constantly and the pressure in the boiler drops regularly, this normally means the valve is not fully closing.

This is most likely due to dirt and debris stopping it from sealing closed after it has opened up. If the valve is more than 5 years old, it can also become faulty from wear and tear.

PRV’s are almost always inside the a combi boiler casing and a gas engineer will need to investigate. If the cause of the leak is debris on the seal, a simple clean will get it working again. PRV’s are not an expensive part to buy if it does need replacing.

If the PRV is leaking after replacement, it may be working normally by releasing extra pressure that has built up in the system. It is a safety device and a brand new component is unlikely to be faulty. Before looking to replace it again, look for pressure issues in the system. Call out an engineer to find and fix any defects.

If you are looking for quality service, Hometree is well worth a look. It covers all aspects of home care including your boiler. Click here to see why they are recommended.

It is important that the prv is tested during a boiler service, especially if there has been no need to repressurise the system in the last 12 months. If the prv leaks after a test, you may need to replace it if there are no other issues with the boiler.

If the prv is leaking and you can see corrosion on the threads, the whole component will need to be replaced. It is not a good idea to try to fix rust or another defect on the prv or seal it another way. PRV’s are a relatively inexpensive part that can be exchanged quickly.

A boiler prv that keeps going off and there is water discharge indicates some sort of boiler problem. Apart from a faulty prv itself with dirt, sludge or seating of the valve, it can also indicate a faulty pressure gauge, expansion vessel out of charge or excessive pressure in the system.

High pressure in a boiler and central heating is usually caused by either having too much water in the system by overfilling it or leaving the filling valves on; or there is not enough air in the expansion vessel. Too much pressure can lead to symptoms such as an increased risk of leaks. You can relieve some of the pressure by bleeding the radiators in your home.

You may have a defective boiler feed water pressure regulator. (Looks like this.) This device takes water from your plumbing system and feeds it into the boiler until the pressure in the boiler reaches a certain level, typically 12 PSI. Then it stops adding water unless the pressure again drops below 12 PSI for any reason, such as a leak or the intentionally draining of some water. When the boiler heats up, expansion takes place and the water pressure rises a bit above 12 PSI. This excess pressure is absorbed by the expansion tank so the final pressure of the hot boiler may go up to 15-20 PSI typically, which is below the usual 30 PSI setpoint of the pressure relief valve.

Some regulators include a backflow preventer and some use a separate backflow preventer that is installed between the regulator and the boiler. The backflow preventer prevents boiler water from backing up into your household plumbing and potentially poisoning you.

If the regulator is faulty, it may be allowing water to continue to flow slowly into your boiler, raising the boiler pressure until it reaches 30-40 psi. At that point, the pressure relief valve would start dripping.

after reading and scanning literally hundreds of threads here and at CG, knowing this question is answered somewhere, i have to just ask: how many times can a safety valve blow due to over pressure before its kaput? mine popped for the first time this morning (i bet its because i"ve been toying with the idea of replacing the livia with a cremina, and now i have to keep it around to fix it).

i"m confused because i"ve read threads that talk about them blowing everyday (?!) before they were replaced, and others that blew once and were replaced. some threads say the spring can wear out, some say it won"t. of course i"d like to err on the side of safety, but if there"s no need to spend $50 on a new one, i"d like to go that route.

I don"t think the number of times it opens has anything to do with it needing replacement. The spring might get a little looser, making it open at lower pressure, but that is not a safety hazard. Eventually it would open below 1.5 bars, and then it would need to be replaced.

The opposite seems more dangerous. If the spring rusts, freezes, or otherwise gets stiff from non-use, that would raise the pressure at which it opens. Fortunately, pressure stats go bad often enough so that the safety valve gets a test and a workout every few years.

Thanks for the feedback. i pulled the valve off today, and checked that the spring would move freely under pressure, and added some teflon tape to the threads and reseated it.

REPLACE that pressurestat, it is supposed to keep your boiler at 1.5bar, if it let the OPV blow that would have been at least 10bar (you should have that specified in your instruction booklet). Do not worry for the OPV spring : they are normally stainless and do not rust and should they loosen a little bit it would open say at 9bar? so what"s the problem, and anyway most OPV are adjustable and you can always put that back to open at the original pressure: If your boiler had a resettable safety thermostat you could always make sure (it is actually the manufacturer who makes sure) that you do not even get close to that 10bar(?) limit ( you know, the higher the pressure the higher the temperature)...and the OPV would just sit there, just in case everything else goes bad. Also the OPV will not get clogged with lime scale since steam is scale free, having already deposited as water got heated....

I don"t recall exactlythe indicated pressure of my Brewtus when the P-Stat quit, but it was still indicating (i.e. not off-scale) and the scale for the steam boiler only goes up to 2.5 bar. It must have been around 2 bar when the relief valve kicked in.

acquavivaespresso wrote:REPLACE that pressurestat, it is supposed to keep your boiler at 1.5bar, if it let the OPV blow that would have been at least 10bar...

I think you misunderstand; the steam boiler pressure relief valve opened, not the hydraulics system, which is gated by the OPV (also referred to as an expansion valve).

A bit of background for those following this thread... Most espresso machines include a pressure test certification of the boiler from the factory. The steam boilers I"ve seen were tested at 2.0 bar and the pressure relief valve opens ~1.6 bar. The expansion valve on a rotary pump is typically regulated to 12 bar; it"s purpose is to (a) relieve pressure when the boiler heats the water in the (closed) hydraulics system and (b) relieve pressure if the pump bypass valve fails to open, preventing the system from pressurizing beyond 12 bar. For vibe pump machines, they"re typically regulated to 11 bar in conformance to ESE pod standards (or so I"ve been told, I don"t use pods).

As for the 10 bar ????? Do you know how much pressure is 10 bar. 140 psi, at 140 psi your boiler temperature would equal approx 170 Deg C your heat exchanger temp would exceed 200 Deg C, At this stage you and all around would be covered in boiling hot water.

Fortunately, by understanding how relief valves work, you can solve whatever problem you’re having with the one on your water heater. In this article, we’ll review everything you should know about this valve.

A water heater pressure relief valve, also referred to as a T&P valve, pressure relief valve, or water heater temperature valve is a safety feature that you can find on any water heater. The reason it’s there is to keep you safe in case the water pressure is too high.

Without this safety feature, your water heater could end up breaking. You could potentially end up with burns if the high water pressure is dangerously high.

This valve also ensures that there aren’t any leaks in your water heater, which would lead to low water pressure when you want to use it to wash the dishes or take a shower.

The water heater pressure relief valve is in place so that it can relieve excess pressure and temperature in a water heater if either of these is too high. Because this everyday appliance is a closed system, thermal expansion occurs in water heaters.

If your water heater pressure relief valve is working, this is when it will open. This releases steam and hot water from the discharge tube, making your water heater operate safely again.

On the micro-level, the functioning of this valve works like this. The relief valve itself has been set up by a professional or pre-designed to open when the temperature or pressure reaches a dangerous level.

This specific state that the water heater is in is called the “blowdown.” Usually, the “blowdown” is defined by professionals (and is used in the design or set up of the valve) as a specific pressure percentage.

The “blowdown” is usually somewhere between 2 and 20%. Once the pressure has reached the “blowdown” amount, the pressure relief valve will close again so that you can use the water heater as intended.

If you’ve been noticing any issues with your water heater pressure relief valve, then you need to know where it is on your water heater. Usually, you can find it on the top or side of this appliance. It’s a valve that’s connected to a plastic or metal discharge tube that points up.

This is for safety reasons. Everything has been done according to standards that have been mandated by plumbing codes. So if you’re having any issues with the valve, you’ll have to call a professional to have it fixed.

If you suspect there’s a problem with your water heater pressure relief valve, you can do a test. This is actually good idea if you don’t have any problems at all, as this type of maintenance will protect your water heater—and yourself.

To get started, identify where the relief valve shut off is. Usually, you can find it upon the cold water feed, which is on top of the water tank, on the right side where the inlet is.

Finally, release the level so that it quickly snaps into the original position. If it doesn’t snap quickly into this original position, then your water heater valve isn’t working and needs to be replaced.

When your water heater pressure relief valve isn’t functioning properly, it’s usually for one of to two reasons. It either sticks so that it doesn’t properly open or close, or it has a leak, which means that it’s continually dripping, lowering your water pressure.

If your valve is sticky, then it becomes stuck in a closed (downward) or open (extended position). If it’s closed, then the valve won’t be able to relieve the heat or pressure that builds up in the closed water heater system. There could be a rupture as a result.

Sometimes, you can easily fix this problem by opening and closing the valve lever a few times. However, if it continues to stick, then you’ll need to replace it.

Your water heater is leaking? Make sure that it doesn’t come from the valve before replacing it. If your pressure relief valve is leaking, then this maybe because it isn’t seated properly in the tank’s threaded opening. This is quite a common issue if you’ve recently replaced your old valve with a new one. To fix this issue with this cause, you have to take several steps.

If the lever snaps into its original position and it’s still leaking, you need to turn off the gas valve by turning it to the off position. Then, shut the water off so you can replace the valve safely.

If a water pressure issue is what is causing the water heater pressure relief valve to not work, then it might be dangerous for you to change the valve yourself. Generally speaking, it’s a good idea to hire a professional to protect yourself.

Now that we’ve reviewed everything you should know about a water heater pressure relief valve you might have realized that you need to replace your water heater valve. However, to be as safe as possible, you want to hire a professional.

We explain where a pressure relief valve is usually installed on well water pressure tanks, how the valve works, and why pressure relief valves are an important safety feature on well tanks.

The water tank pressure relief valve shown in our photo (above) is marked indicating that it will open at water pressure equal to or greater than 75 psi. That pressure is pretty standard and you"ll see the 75 psi figure on valves used on water tanks and on some tankless water heaters too.

Excess water pressure can damage water system component as well as the pressure tank if not corrected immediately, and can also cause leaks within the piping system or at faucets and fixtures. Therefore on all building water supply systems using a private well and pump, a pressure-relief valve is recommended.

Water pressure relief valves are spring-controlled and open only in response to system pressure. That is, water temperature is not a controlling factor for these valves. For water service, these important safety devices are generally adjusted to relieve pressure higher than 75 psi. [1]

There was no pressure relief valve on the water system; a submersible well pump was installed; the well pump pressure control switch stuck in the "on" position.

It was the practice of the operator to maintain the water level in the tank at about 4 in. above the center. This he accomplished by pumping at approximately two-hour intervals from 7:00 AM to 3:00 PM, at 6:00 PM, 8:30 PM, and at midnight. The daily consumption of water was about 18,000 gal. The pressure tank, 8 ft. in diameter and 36 ft. long, had been in service for 36 years. It was provided with a pressure relief valve which when tested opened at a pressure of 66 lb. psi.

Expert Analysis: An inspection of the system revealed that the tank was in good condition, with no signs of corrosion or other damage. The 120-gallon water tank had a label indicating the maximum working pressure for the tank was 75 psi and must be equipped with an adequate size pressure relief valve; however, there was no pressure relief valve in this system.

... it was determined that the pressure regulator failed during operations, allowing air to continuously flow into the tank. The lack of a pressure relief valve allowed the tank pressure to increase until the tank failed.

Watts 53 pressure relief valves in 1/2-in NPT and 3/4-in NPT. Model 53L includes a test or relief lever. Quoting from Watts® product literature for this product:

Series LF530C Lead Free* Calibrated Pressure Relief Valves are used in commercial, residential and industrial applications to protect against excessive pressure in systems containing water, oil, or air.

Series LF530C has a calibrated adjustment feature for setting the valve to the required relief pressure, and is ideal for by-pass thermal expansion pressure relief (not ASME approved).

Watts 30L Pressure Relief Valves for Well Systems, with test lever. These valves, intended for protection against excessive pressure in well water systems, are designed for pressure relief only [compared with pressure and temperature relief valves that should be used on water heating equipment -

Series 30L Pressure Relief Valves for Wells are used to protect against excessive pressures in well systems. It is not diaphragm actuated and is used for pressure-relief service only.Series 30L consists of a bronze body construction with NPT threaded male inlet and NPT threaded female (drain) outlet connections, stainless steel spring, and test lever. Standard Pressure Setting: 75psi (5.17 bar), Optional Settings: 100, 125, and 150psi (6.9, 8.6, and 10.3 bar). - Watts®

These valves are installed as an auxiliary bleeder pressure relief valve to provide relief of increased water pressure due to thermal expansion, and they are typically installed on a hot water supply pipe downstream from the water heater and over a laundry sink or drain. Watts points out in their product literature that these valves are also installed on cold water piping.

Standard water tank pressure relief valves are sold at plumbing suppliers and are pre-set with a "safe" pressure for most home water tanks, provided that the water tank, piping, and controls are properly installed and adjusted.

A professional plumber would select and install a water tank pressure relief valve that opens to spill water and relieve pressure at a point well below the rated burst pressure of the tank.

The burst-pressure of a water tank, provided it"s undamaged and properly installed, should be well above the opening pressure on the tank relief valve. But to choose a specific valve matched to your water tank, you should consult the manual for your water tank and pump and their manufacturer to be sure you"ve got the right part.

Dan I"m not entirely clear on what is your situation, but if you have a 1" diameter pressure relief valve it is unsafe to downsize its discharge to 1/2" -

I have a well water 1 inch relief valve with a 0.5 inch output. It is leaking and would like to buy another, but cannot find one. Also my water tank holds 50 gal and the tank pressure should be 40psi.

Allen we dont" want the valve to spit water; I suspect that the water level is too high in the tank OR the float is sticking and not closing the valve OR there is dirt on the valve seat.

My bladder type tank has an air release valve similar to a schrader valve. Lately in addition to expelling the air when the tank is filling, I"m getting a "spit" of water or condensation with it. Is this something to be concerned with? I"m in the humid Houston area, so I guess it could be condensation, but I also don"t want that dripping down my tank and eventually corroding it.

Jon, Definitely, I"ve heard various valves in plumbing systems make a horrible screeching sound if the pressure and flow rate happen to be just right (or wrong).

But you should not be having a discharge from a pressure relief valve on a water supply system - the valve should only open if the system is at abnormally high (and unsafe) water pressure. So if there is no water discharge from the valve, I"d look elsewhere.

Can a bad pressure relief valve give off a high pitched squeal? I have such a noise coming from the area of my well equip, but not on a regular or constant basis.

WATER TANK PRESSURE RELIEF VALVE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Watts Corporation, Series 53 Pressure Relief Valves, for commercial and residential applications, publication ES-53 1010, Watts Corporation, 815 Chestnut St., No. Andover, MA 01845-6098; www.watts.com and Watts Corporation in Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca.

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

A boiler leaking water is usually a sign that a seal or a valve has developed a fault. However, if the problem is left untreated, a leaking boiler can cause other components to erode as well as cause damage to the electrical components within the boiler. Your best option when you notice a leak is to fix the problem quickly to prevent further damage.

Before you can do anything with your boiler, you need to find out why it’s leaking, but this isn’t always easy. The first thing to do is find where the water is coming from, as this will give you a better idea of why. Below, we’ve listed some of the main causes of a leaking boiler.

Have you ever noticed the gauge on the front of your boiler? This is important as it tells you how much water pressure there is in the system. Too little or too much pressure can cause a problem, so you should check the valve regularly and add or remove water as required.

If your boiler is leaking, you should check the pressure gauge to see if the pressure is too high. If this is the case, it’s likely that the pressure relief valve is trying to release some of the water in the system to bring the pressure back down to a comfortable level, which can lead to your boiler dripping water. The valve needle should be between 1 and 1.5 bar (usually shown on the gauge as a green zone). If the needle is higher than this, or in the red zone, you may need to bleed the radiators to release extra water.

Corrosion can be a problem in older boiler systems as it can cause rust and other debris to build up within your radiators and pipework. As the water runs around the system, it can pick up this debris and return it to your boiler. The older the system, the more likely you are to have issues with corrosion, which in turn can lead to your boiler leaking water from the bottom. Unfortunately, many people don’t know corrosion is there as it can’t be seen.

Corrosion can break the rubber seals around the joints of pipes, so water may be leaking through here. If the corrosion is on an individual component, an experienced contractor will be able to replace this with ease. However, if the corrosion is widespread, then you may need to replace the boiler completely.

A contractor will be able to advise you if a new system is required or if a new boiler and a flush of the system would be adequate. If you have an old boiler, replacing it with a newer model could make your home more efficient and could save money on your gas bills, too.

Boilers are wonderful home heating systems that have stood the test of time. Instead of heating air like furnaces do, boilers heat water and turn it into steam. Because boilers contain a lot of water, what should you do when you notice the system leaking?

Depending on where the leak is and how much water is coming out of the boiler can determine your state of panic. Theboiler experts at Poston Brothers are here to help you troubleshoot your leaking boiler and let you know when to call us for boiler services.

As soon as you notice your boiler leaking water, clean up the water to prevent water damage. Then, monitor the leak to see how fast it is leaking water. See if you can identify where the leak is coming from. A leaking boiler will need to be fixed by an HVAC technician, but doing some troubleshooting yourself can help save time. Not every leaking boiler needs to be replaced, but having the professional team at Poston Brothers look at your boiler is the only way to be sure.

Leaks are never a good sign, but there are a few steps you can take to stop them. Boilers use both gas and very hot water to supply heat to your home. If you are not comfortable being around these elements, call Poston Brothers right away.

The pressure relief valve on your boiler can get clogged with sediment and cause leaks. Boilers need to release pressure regularly, and if it cannot release steam, it will release water instead. Turn off your boiler and let it cool. Then open the pressure relief valve to release the water for 3-4 seconds. The water should come out clean. If you shut the valve and it continues to leak, that means there’s more sediment inside. Repeat this process until the boiler leaks stop. If they don’t stop, then call Poston Brothers.

Corroded pipes and tanks are a common reason your boiler is leaking water. Corrosion is a problem, and you’ll need to consult with a technician to see how bad the corrosion is and what repairs you’ll need.

If your boiler was recently installed and you’re noticing leaks, then there’s a good chance that the installation was done incorrectly. Occasionally, some joints and pipe fittings aren’t installed correctly, and that can cause a leaking boiler. Poston Brothers is always happy to provide a second opinion on boiler installation.

Just like pipes, seals and parts can break down over time. A broken seal will spray a lot of water, so you’ll notice it right away. It’s important to turn off your boiler if the leaking water is constant to prevent water damage.

The temperature control valve regulates the temperature of the water in the boiler. If your temperature valve is malfunctioning and setting your boiler temperature too high, it could be causing boiler issues like leaks.

Boilers, like any central heating system, need to be maintained on an annual basis. If it’s been a long time since you’ve had a reputable HVAC company like Poston Brothers look at your boiler, now is the time. If it’s hard to remember to schedule your yearly maintenance, then join our Poston Club maintenance plan.

When you’re a member, we’ll remind you when your boiler is due for service and then we’ll schedule your appointment around your schedule. Member benefits also include a discount on all repairs, replacement credits, and discounts on service calls. Call Poston Brothers today for boiler repairs, and ask your technician about joining the Poston Club maintenance program.

Choose these valves for small steam-heating boilers requiring pressure relief between 5 psi and 12 psi. They spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. All have a bronze body for durability and a long service life.

A little product education can make you look super smart to customers, which usually means more orders for everything you sell. Here’s a few things to keep in mind about safety valves, so your customers will think you’re a genius.

A safety valve is required on anything that has pressure on it. It can be a boiler (high- or low-pressure), a compressor, heat exchanger, economizer, any pressure vessel, deaerator tank, sterilizer, after a reducing valve, etc.

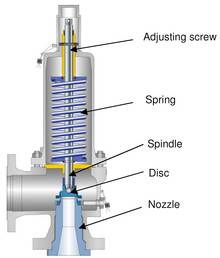

There are four main types of safety valves: conventional, bellows, pilot-operated, and temperature and pressure. For this column, we will deal with conventional valves.

A safety valve is a simple but delicate device. It’s just two pieces of metal squeezed together by a spring. It is passive because it just sits there waiting for system pressure to rise. If everything else in the system works correctly, then the safety valve will never go off.

A safety valve is NOT 100% tight up to the set pressure. This is VERY important. A safety valve functions a little like a tea kettle. As the temperature rises in the kettle, it starts to hiss and spit when the water is almost at a boil. A safety valve functions the same way but with pressure not temperature. The set pressure must be at least 10% above the operating pressure or 5 psig, whichever is greater. So, if a system is operating at 25 psig, then the minimum set pressure of the safety valve would be 30 psig.

Most valve manufacturers prefer a 10 psig differential just so the customer has fewer problems. If a valve is positioned after a reducing valve, find out the max pressure that the equipment downstream can handle. If it can handle 40 psig, then set the valve at 40. If the customer is operating at 100 psig, then 110 would be the minimum. If the max pressure in this case is 150, then set it at 150. The equipment is still protected and they won’t have as many problems with the safety valve.

Here’s another reason the safety valve is set higher than the operating pressure: When it relieves, it needs room to shut off. This is called BLOWDOWN. In a steam and air valve there is at least one if not two adjusting rings to help control blowdown. They are adjusted to shut the valve off when the pressure subsides to 6% below the set pressure. There are variations to 6% but for our purposes it is good enough. So, if you operate a boiler at 100 psig and you set the safety valve at 105, it will probably leak. But if it didn’t, the blowdown would be set at 99, and the valve would never shut off because the operating pressure would be greater than the blowdown.

All safety valves that are on steam or air are required by code to have a test lever. It can be a plain open lever or a completely enclosed packed lever.

Safety valves are sized by flow rate not by pipe size. If a customer wants a 12″ safety valve, ask them the flow rate and the pressure setting. It will probably turn out that they need an 8×10 instead of a 12×16. Safety valves are not like gate valves. If you have a 12″ line, you put in a 12″ gate valve. If safety valves are sized too large, they will not function correctly. They will chatter and beat themselves to death.

Safety valves need to be selected for the worst possible scenario. If you are sizing a pressure reducing station that has 150 psig steam being reduced to 10 psig, you need a safety valve that is rated for 150 psig even though it is set at 15. You can’t put a 15 psig low-pressure boiler valve after the reducing valve because the body of the valve must to be able to handle the 150 psig of steam in case the reducing valve fails.

The seating surface in a safety valve is surprisingly small. In a 3×4 valve, the seating surface is 1/8″ wide and 5″ around. All it takes is one pop with a piece of debris going through and it can leak. Here’s an example: Folgers had a plant in downtown Kansas City that had a 6×8 DISCONTINUED Consolidated 1411Q set at 15 psig. The valve was probably 70 years old. We repaired it, but it leaked when plant maintenance put it back on. It was after a reducing valve, and I asked him if he played with the reducing valve and brought the pressure up to pop the safety valve. He said no, but I didn’t believe him. I told him the valve didn’t leak when it left our shop and to send it back.

If there is a problem with a safety valve, 99% of the time it is not the safety valve or the company that set it. There may be other reasons that the pressure is rising in the system before the safety valve. Some ethanol plants have a problem on starting up their boilers. The valves are set at 150 and they operate at 120 but at startup the pressure gets away from them and there is a spike, which creates enough pressure to cause a leak until things get under control.

If your customer is complaining that the valve is leaking, ask questions before a replacement is sent out. What is the operating pressure below the safety valve? If it is too close to the set pressure then they have to lower their operating pressure or raise the set pressure on the safety valve.

Is the valve installed in a vertical position? If it is on a 45-degree angle, horizontal, or upside down then it needs to be corrected. I have heard of two valves that were upside down in my 47 years. One was on a steam tractor and the other one was on a high-pressure compressor station in the New Mexico desert. He bought a 1/4″ valve set at 5,000 psig. On the outlet side, he left the end cap in the outlet and put a pin hole in it so he could hear if it was leaking or not. He hit the switch and when it got up to 3,500 psig the end cap came flying out like a missile past his nose. I told him to turn that sucker in the right direction and he shouldn’t have any problems. I never heard from him so I guess it worked.

If the set pressure is correct, and the valve is vertical, ask if the outlet piping is supported by something other than the safety valve. If they don’t have pipe hangers or a wall or something to keep the stress off the safety valve, it will leak.

There was a plant in Springfield, Mo. that couldn’t start up because a 2″ valve was leaking on a tank. It was set at 750 psig, and the factory replaced it 5 times. We are not going to replace any valves until certain questions are answered. I was called to solve the problem. The operating pressure was 450 so that wasn’t the problem. It was in a vertical position so we moved on to the piping. You could tell the guy was on his cell phone when I asked if there was any piping on the outlet. He said while looking at the installation that he had a 2″ line coming out into a 2×3 connection going up a story into a 3×4 connection and going up another story. I asked him if there was any support for this mess, and he hung up the phone. He didn’t say thank you, goodbye, or send me a Christmas present.

Relief valves are designed to open at a preset pressure (or temperature) level and relieve the system when it has exceeded the desired level. The valve"s relief of elevated liquid, gas, or steam pressures prevents damage to the system. We offer a wide selection of relief valves for any application.

8613371530291

8613371530291