certified safety valve repair for sale

SVI Industrial offers both shop and field diagnostic and control valve repair services. By utilizing “Bench Mark” diagnostic equipment, we can input your control valve’s configuration information, run baseline tests, then provide detailed documentation that will show the valve’s performance. This information can be used to determine if your control valve needs minor instrumentation calibrations or possibly a major overhaul.

We can work independently or with your reliability engineers to establish a database of your safety relief devices throughout your plant. You can count on our experience and knowledge to establish a recommended frequency of safety valve testing and repairs of your safety valves, that meet your corporate requirements and requirements set by your state inspector and insurance auditor based on “best practices” from the National Board.

SVI Industrial holds three “VR” certificates from the National Board of Boiler and Pressure Inspectors authorizing our technicians to repair, set and certify safety pressure valves inline, on our customer’s site and at any of our shop locations for both ASME Section I and VIII code stamped safety valves. Our skilled valve technicians will evaluate the condition of your safety valve, make the proper recommendations and work diligently to get your safety valves tested, repaired and set to the correct specifications and back in-line as quickly as possible in order to minimize interruption of your daily operations.

We are a turnkey service provider with the capability to service, repair or replace your welded in-line steam safety valves, including pipe prep, welding, removal and heat treating. SVI Industrial is your one-stop source for all of your industrial safety valve repair and other maintenance needs.

Specialized in maintenance and repair services for valves, boilers, heat exchangers, regulators, actuators, turbines and other products. Capabilities include in-line machining, fabrication, turning, welding, engineering, inspection, testing and consulting. Suitable for petrochemical, pharmaceutical, commercial, construction, power generation, HVAC, pulp and paper applications. Additional services include polishing, sandblasting, powder coating, plating and painting. Serves the chemical, hospital, oil, gas, manufacturing plant, food and beverage industries. Meets ASME standards and military specifications. 1-year warranty.

Certified Safety Valve Repair, located in Linden, NJ, has served the tri-state area for over 30 years. Providing service to Power Generating, Chemical and Manufacturing Plants and even our U.S. Navy Vessels.

Certified Safety Valve Repair has been authorized by the National Board of Pressure Vessel Inspectors, VR program to repair and certify any Section I or Section VIII Pressure Relief Device.

We are also the authorized repair facility for Anderson Greenwood Crosby Valve. This corporation is one of the leaders in the industry for manufacturing Section I, and Section VIII Safety-Relief Valves.

Our corporation is fully insured and certified by the Association of Safety Valve Calibrators, The Defense Manufacturers & Suppliers Association and the Quality Control Motivations Program, just to name a few.

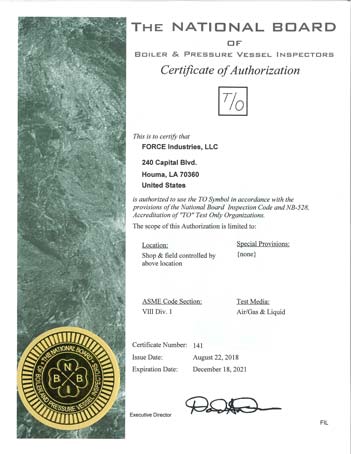

Our relief valve team repairs, maintains, & reconditions relief valves to suit our customers’ requirements. Our team offers VR Certified PSV repairs, scheduled testing, and Certified Test Reports. We also offer new & reconditioned relief valve sales. We are certified by “The National Board” of Boiler & Pressure Vessel Inspectors for Shop & Field services, ASME Code VIII Div. 1 Air/ Gas & Liquid. We also test, inspect, & repair PVSVs (Pressure Vacuum Safety Valves)

VSI is your premier source for control valves, pressure relief valves, and safety relief valves. Our factory-certified experts are on-call 24/7 for repairs, testing, sizing & selection, replacement, and installation.

As your trusted source for factory-certified service solutions and consistent value and quality, VSI offers excellent customer service and world-class products and services. VSI has been focused on a legacy of quality and service since its inception in 1975 in Oklahoma City by founder Bill Campbell. Over the years, VSI has expanded its footprint to include four locations, offering service, repair, installation, and custom solutions across the United States. We offer excellent customer service, best-in-class products, and a wide variety of solutions for the process industry. VSI is the premier source for safety valves, pressure relief valves, control valves, and actuation products and services. Contact us to find out how we can help you.

Adapt almost any rotary actuator to a linear valve. Converting pneumatic actuation to electric helps increase operational efficiency and lower emissions.

VSI is a Consolidated™ Green Tag Center™ offering factory-certified repairs, installation, maintenance, and the full range of Consolidated pressure and safety relief valves. We have in-house certified technicians and product experts, and a large inventory to ensure fast delivery.

Our factory-certified and safety-trained, field service technicians are ready to be dispatched to your site. Capabilities include optimization, repair, and maintenance on pressure relief valves, safety valves, control valves, line valves, and actuation.

Valve Sales Inc. provides outstanding service and support for all of our valve needs. Their dedication to quality and consistency allows our equipment to run more reliably and improves overall performance of our facility. Our goal is to provide consistent high performing products to our customers and VSI allows us to achieve this goal.

The entire team at VSI has always been able to meet my needs and always exceeds my expectations. I have a great relationship with both the sales and service teams they are always ready to answer technical questions and provide excellent advice on ways to solve problems in the field and are always ready with solutions no matter how obscure or unusual the problem. VSI is more than ready and able to meet all my valve needs at any given moment.

VSI has been helpful in many ways, from greasing valves, valve repair, valve replacement, and training our guys as well. We can’t say enough about quotes, labor support, material delivery time, and billing. Aaron has helped us out of several jams over the years and we appreciate it.

VSI has rebuilt our pressure relief valves here at [our processing plant] for several years now and I have always been very pleased with their service and quality of work. The work is always completed on time and we have had no reliability issues with the valves they’ve worked on. It’s always a pleasure working with VSI and I look forward to continuing the relationship.

TULSA, OK – August 31, 2022 - Valve Sales Inc. (VSI), and Baker Hughes have partnered to distribute, service, and repair the complete line of Consolidated™ pressure relief valves. VSI’s service and… Read More

This 1/4" MNPT safety relief valve is constructed with the same materials as ASME safety valves, but is not national board certified so they cannot be used on applications requiring ASME components. The non-coded valve is equipped with a lift ring for instant relief and is stacked at the factory at the pre set pop-off pressure. Has a pop-off pressure of 125 PSI. These valves are not for use on compressors with a capacity over 15 CFM, 3 HP or 12 gallon storage tank.

F.H. Gaskins Company, Inc., specializes in the sale, repair, modification, calibration and certification of safety valves and relief valves. We proudly hold the “V” and “UV” stamps approved by ASME and a “VR” (valve repair) stamp approved by the National Board. We are a designated “Green Tag Center” for Dresser/Consolidated valve products and the Technical Representative Agent/Distributor of Everpure water filtration systems for Maryland and Virginia. F.H. Gaskins is also a recognized manufacturer for the Government (Cage Code 58837).

Tired of keeping track of your valve inventory’s annual certification records? We offer complete management of your safety relief valves. With an inventory of repair parts and in stock relief valves of all sizes, we can respond to any customer emergency. We offer annual certification services as well as repair of all major brands, including Kunkle, Conbraco, Consolidated, Dresser, Apollo and more.

At Precision Pump and Valve, we built our business around service. We provide comprehensive on- and off-site services including troubleshooting, repair, and testing of your equipment ranging from standard pumping equipment to specialty control equipment. We have experience in marine, upstream, midstream, and downstream facilities. We know what it takes to get the job done right, on time, and most importantly, safely.

We are also proud to be a VR-Certified business that can provide Pressure Safety Valve / Pressure Relief Valve, Control Valve, and Regulator testing, repair, and recertification. Precision Pump and Valve is leading the charge on safe work and we operate under industry-leading HSE Programs. We have experience in Upstream, Midstream, and Downstream facilities and we know what it takes to get the job done right, get the job done on time, and most important – get the job done safely. We back this claim up every day by our ISNetworld information.

Renew-CVG specializes in industrial valve parts and repair services for the power, steel, refining, paper and chemical industries. Based in both Monroe, MI, and Cleveland, OH, our technical staff brings more than 100 years of combined experience to every customer we serve. We have earned a trusted reputation in the industry by maintaining close working relationships with our customers" engineering and maintenance staffs in order to address fluid handling challenges and provide customized process solutions.

Established in 1960 by Oscar "Dale" Blair, the original Renew Valve began repairing valves for Detroit Edison at the two local power plants. Over the next 20 years, it became a valuable supplier to the entire Detroit Edison system, both in machining and valve repair and new valve replacements. The company built up a complete machine shop and testing facility, manufacturing parts when needed for the valves, pumps, and boilers for the growing number of customers in the Detroit area.

Founded in Cleveland by the George Ruf family in 1857, the original Cleveland Steam Gauge Company manufactured a line of steam and vacuum pressure gauges and maintained a complete machine shop which manufactured parts when needed for the valves, pumps and boilers for the growing number of steamships then navigating the Great Lakes.

In 1965, Vernon Schill, Dan Cardina and Anthony Brock purchased the company and focused more on valve repair – becoming the recognized authority on all types of gate, globe, ball, check, plug and control valves. It became a founding member of the National Board "VR" Safety Relief Valve Repair certification program.

In 2004, Renew Valve & Machine Company and Cleveland Valve & Gauge joined forces. Together they have become the recognized authority on all types of gate, globe, ball, check, plug and control valves in Michigan, Ohio and Indiana. It was a founding member of the National Board "VR" Safety Relief Valve repair certification program as well as an early constructive Green Tag Service Center for Dresser Industries and their Consolidated, Dewrance, and Hancock valve product lines.

Whether it"s a specific valve component, a complex Infield machining project, an obsolete valve part fabrication, a pre-shutdown valve survey or a packing or gasketing solution, our team is available to address you flow control challenge on-site or at our repair facility.

Pressure safety valves are designed to protect process piping and equipment in case of an overpressure event. TEAM Valve Solutions inspects, tests, repairs and re-certifies safety valves at 17 service centers across three continents, and in our fleet of mobile facilities, all of which are audited under the jurisdiction of relevant governing bodies.

Our solutions cover all major safety valve brands and support our customers through an inventory of spare parts and loose-assembled valves. In addition, our facilities are audited and governed by the National Board of Boiler and Pressure Vessel Inspectors. Testing, repair, and assembly are performed under license and guidelines of NBIC, and ASME Section I and VIII.

To ensure accurate in-line setpoint verification, TEAM Valve Solutions utilizes Trevitest, the pioneering system for validating safety valve performance in Conventional and Nuclear Power plants, as well as in other industrial process facilities.

Kings Energy Services provides service, repairs, and testing for a wide variety of safety/relief valves and devices. We will happily provide skilled valve servicing in-house or on-location (field servicing is only available for ANSI or API valves). To reduce downtime for producers, Kings Energy has an assortment of valves in stock for exchange and/or sale.We also carry stock inventory, enabling quicker turn-around times and reduced customer costs.

Our experienced and technically trained staff are knowledgeable about appropriate industry codes, regulations, and manufacturer guidelines. To maximize efficiency, we utilize an assembly-line operations system to service and repair relief valves. The process goes through several stages in order to maintain a high-quality assurance program, and valve data is entered into our database at every station.Receiving and Dismantling

Valves are given a visual inspection to record the received condition, identification numbers, make, model, and serial number, code stamps, set pressure, capacity, and any irregularities. After proper safety precautions are completed, a pre-test is performed and recorded. The valve is then dismantled in accordance with the manufacturer’s recommendations.

Special care is taken to properly assemble each valve using quality OEM manufactured parts. After assembly, each valve is tested to its appropriate PSI range; a final inspection is performed to re-confirm the valve data previously recorded, and the valve is sealed according to industry regulations.

Pressure Safety Valve (PSV) Repairs can be done on our in Red Deer, Drayton Valley, Provost, Grande Prairie, Dawson Creek and Cambridge, Ontario service facilities. We also have a fully mobile valve servicing unit that can come to your facility to provide servicing.

8613371530291

8613371530291