co2 tank safety valve free sample

Whether you use individual CO2 cylinders or a bulk CO2 tank system, you should be aware of CO2 tank safety. Thousands of liquid carbon dioxide cylinders and tanks are used across the country for soda or beer carbonation, for refrigeration, industrial purposes, medical and scientific facilities, fire suppression systems, and even indoor agriculture. All of these vessels are a potential safety hazard if not installed and maintained properly.

The primary safety concern is gas leakage after the cylinder or tank. While the cylinders or tanks are designed to withstand pressure and damage, the pipes, hoses, and fittings used to distribute the gas after the vessel are not.

CO2 cylinder pressure is about 860 psi at normal room temperature. Typical CO2 cylinders store about 50 lbs. of liquid CO2. Two pounds of liquid CO2 expands to about 20 cubic feet of pure CO2 at atmospheric pressure, or expands at a rate of 535:1. This means that in an enclosed room the CO2 gas can quickly fill with CO2 and either poison an individual or displace all the oxygen available for breathing. Because CO2 is heavier than air it will also fill any low areas like basements or under floor service areas first. If there is little air movement, pools of CO2 can exist for many hours.

Liquid CO2 temperature is also important. If the gas escapes quickly (like a fire extinguisher) it is discharged at sub zero temperatures and produces a mixture of CO2 gas and "snow". This “CO2 snow” is momentarily the same temperature as dry ice (about -110F or -79C) and can quickly result in frostbite or frozen skin.

Bulk CO2 tanks and cylinders along with their delivery systems should be installed by a professional. In most cases the person to ask about professional installation is your CO2 supplier. Either they can install the tanks or direct you to someone they recommend. If your facility offers soda fountain drinks or draft beer, ask these suppliers too. It never hurts to have more than one quote.

CO2Meter is also delighted to partner with Chart Industries, the leading designer and manufacturer of bulk storage tanks to provide education and information about bulk storage solutions.

CO2 cylinders stored indoors should be stood upright against a wall and secured with a chain to insure they cannot fall over and potentially damage or rupture the valve. Bulk CO2 tanks should be bolted to the floor to insure they do not tip over as well. The area around the tank and cylinders should be well-ventilated if possible and should be monitored by a CO2 safety alarm.

Repairs to CO2 delivery systems should only be done by trained personnel. Even the smallest leak in a hose or fitting can have potentially dangerous results. While it may be tempting to wrap a leaking hose with tape as a temporary fix, it may not only be unwise, but could leave management open to a lawsuit or denial of insurance coverage in the case of an accident.

If you need recommendations for a gas distributor or service company in your area please contact CO2Meter. We will be delighted to provide a comprehensive list of partners in your area.

Accidental damage to CO2 delivery systems can and does happen. For example, a worker opening boxes with a utility blade might inadvertently slip and puncture a CO2 line. A cylinder tank cart might fall over while being moved over an uneven floor. It is important that employees who work with or around bulk CO2 tanks are trained to understand the dangers of leaking tanks and understand what to do when a leak happens. Proper training and signage are critical for protecting employees and customers around stored CO2.

The use of bulk storage of carbon dioxide in cylinders or outdoor tanks has grown exponentially over the last several years. Every restaurant, brewery, welding supplier, indoor grower as well as many manufacturers rely on bulk CO2 as part of their business.

Note that installing your CO2 storage vessel outside does not mitigate the potential for a safety hazard. The gas is being used inside and the people are inside creating the hazard. When CO2 storage vessels are installed outside safety monitors should still be installed inside your facility.

Because we offer CO2 storage safety alarms, we get asked questions about CO2 storage tanks and cylinders. Here are some of the most common questions with links to additional resources.

It starts off with collecting the gas. CO2 is a natural byproduct of many different chemical processes. The two most common are capturing it from the production of ethanol or ammonia. Ethanol production is used as a fuel additive and ammonia is used as plant fertilizer for the farming industry worldwide. Natural "wells/pockets" of CO2 also exist where the gas is extracted from underground like the Jackson Dome in the US. Additionally, CO2 can be captured in the exhaust streams of industrial burners or energy plants. While not as common, CO2 can also be captured during industrial fermentation, cement production or even removed from the air, although these processes are not yet scalable to meet the world demand.

Once the CO2 is collected it is scrubbed to get to the proper purity, then compressed into a liquid and transported via ocean cargo ships, rail tanker or truck to a regional or local CO2 distributor. The distributor is responsible for certifying the purity of the gas, then transporting it either by portable cylinder or by tanker truck to the end user.

There are 2 color standards for CO2 cylinders: the United States, and the rest of the world. In addition, the color standards in the US are a recommendation and not law. Therefore, you should never rely on the color of the CO2 cylinder to tell you what gas is inside. Instead, you should rely on the label on the side of the cylinder, which is required.

With all those caveats, large CO2 cylinders typically have a gray shoulder at the top of the tank and below the valve stem worldwide. CO2 tanks are typically stainless steel. Small CO2 cylinders or cartridges could be any color.

While carbon dioxide is a naturally occurring gas, too much of it in the air can cause at the least headaches, drowsiness and at the worst, poisoning or suffocation. Fresh air contains 0.04% CO2 (400 parts per million) CO2. However a leaking tank or cylinder valve, or a leaking hose or manifold can quickly raise the CO2 level in an enclosed area up to 3% or more very quickly. This is because liquid CO2 under pressure expands to 535 times its volume as a gas.

Most bulk CO2 isn’t processed from fresh air, but is collected as a byproduct of other industrial processes like ethanol production. Once the CO2 is collected it is rated according to its purity. For example the industrial CO2 in a welding shop is rated at 99.5% purse, while beverage grade CO2 used in restaurants must be at least 99.9% pure.Learn more about CO2 purity levels here.

Absolutely. While food grade CO2 is rated as 99.9% pure, that means there are 0.1% of other gases in the tank. At CO2Meter we like to measure gases in parts-per-million. This means there are up to 1,000ppm of other gases in the tank or cylinder that could impact the overall taste, especially in beer. For this reason, it is important to both periodically clean bulk tanks and to verify the CO2 quality with your CO2 distributor.

The National Boiler Inspection Code and the International Fire Code recommend that any business that stores more than 100lbs. of CO2 use aCO2 Storage Safety Alarm. A 100lb. cylinder is 62” tall and 10.5” wide. This size is used in venues who want to reduce the number of tank changes each day. While the old-style cylinders are smaller, if the total combined weight of CO2 is over 100lbs. an alarm must also be used.

Small CO2 cylinders can be refilled at many local gas supply stores. Larger cylinders can be refilled or exchanged at welding supply stores. For businesses that use lots of CO2, the best solution is to contact a local, independent CO2 distributor that will schedule a truck to bring you CO2 cylinders or refill an bulk tank.

Note that transporting CO2 cylinders is dangerous. While CO2 cylinders are virtually indestructible, if the neck is broken it can become a virtual missile. This is why it is illegal to ship CO2 without proper safeguards and registration.

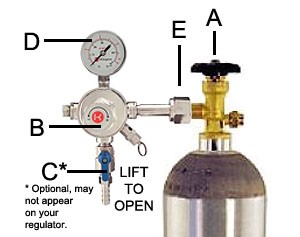

You have 2 options: if your tank has a dual gauge regulator, you can read the amount of pressure on the dial. The pressure will go down as the tank empties. The downside of this method is that once the pressure begins to drop it will run out fairly quickly. For portable CO2 cylinders, the most accurate way to determine the amount of remaining CO2 is to weigh it. The empty cylinder’s weight should be printed on the side, or you can google it. Subtract the cylinder weight from the actual weight, and you know how many pounds or kilos of CO2 you have remaining.

While putting other gases in a CO2 tank or cylinder is possible it is inadvisable, dangerous, and in some situations could be illegal. Tanks are marked with the gas that is in them for safety. A grey shoulder around the nipple on a CO2 cylinder is the universal code for CO2.See a chart here (pdf). In addition, a sticker on the side of a larger cylinder or tank has hazard warning pictograms. On CO2, it is a green triangle that says “non flammable gas” If you were to fill this tank with a flammable gas, it would be dangerous to others in the future.

With their sturdyDepartment of Transportation DOT-3AL rated design, a new CO2 tank or cylinder will not leak for decades. By law, refillable tanks must be retested using a hydrostatic (water pressure) cylinder wall expansion test or ultrasonic wall thickness test and a visual inspection every 5 years before refilling. The date of each test must be stamped on the cylinder.

The possibility of leaks is much more likely via the valves and fittings used to route the CO2 from the tank or cylinder to the place the gas is dispensed. If you’ve ever had a water leak at home, you know that they can be difficult to find and fix. The same goes with CO2 leaks.

While there is no way to prevent all leaks, you can reduce the likelihood by having a CO2 delivery system installed by a qualified technician and inspected regularly. If the CO2 valves and fittings are in an enclosed area in a business, by regulation you should also have aCO2 safety alarmto warn occupants if a leak occurs.Read more about CO2 leak training here.

At CO2Meter, we are proud to provide our customers with integral educational and training resources as it pertains to CO2 safety monitoring. However, as an important rule of thumb, you should always remember that when working around confined spaces and dealing with inert gases like CO2, CO2 monitors are vital.

By measuring the CO2 gas concentrations, this can help ensure employee and worker safety and minimize the risk of serious, negative health effects from occurring. Without proper CO2 monitoring, individuals can put themselves at risk and may walk into a space with high concentrations, unknowingly. This can result in experiencing negative effects such as: headaches, fatigue, dizziness, nausea, and even fatality.

We recommend individuals either use portable or wall-mounted CO2 safety devices to ensure peace of mind for yourself, your employees, or your customers.

This accurate, easy-to-adjust CO2 regulator and flow meter support from 0.5 to 15 SCFH (Standard Cubic Feet Per Hour) with an electronic solenoid valve. It comes with a tank pressure gauge, an easy-to-read square-shaped flow meter, and 6-foot power cord. It will work with any 120VAC control device.

Designed to work with our Day/Night CO2 Monitor & Controller for Greenhouses, simply add overhead tubing (CO2 is heavier than air) to disperse CO2 evenly throughout your grow room.

This model is designed to be used in the U.S. only.The fitting for the cylinder is not metric. The regulator supports 60hz 120VAC only. We recommend this for grow-roomsupplementalCO2 applications - not for cryogenic or oxygen applications!

The Supply Line Shut-off Solenoid is a normally closed shutoff valve that is held open by the Aerosphere® Carbon Dioxide Monitoring System. In instances where a leak is detected, the Solenoid will shut-off the supply of gas (fail-safe) at the CO2 tank (Dewar tank). This valve may be programmed to operate at any alarm level.

Many jurisdictions require the use of a solenoid valve to shut-off the gas tank in the event of a high-level alarm condition. For example, a restaurant (or an insulated system) will typically require a shut-off valve at 30,000 ppm or 3%, while a grow house will typically require a shut-off valve at 5,000 ppm or 0.5%.

The 247Garden CO2 regulator is a device that is used to control the flow of carbon dioxide (CO2) in a gas mixture. It is commonly used in a variety of applications, such as aquariums, hydroponics, and welding, to maintain the correct level of CO2 in the air or water. In aquariums, for example, a CO2 regulator is used to provide plants with the CO2 they need for photosynthesis, which helps to create a healthy and balanced ecosystem for the fish and other aquatic life. In hydroponics, a CO2 regulator is used to maintain the optimal level of CO2 in the water for plant growth. In welding, a CO2 regulator is used to control the flow of CO2 in a gas mixture used for welding, which helps to improve the quality of the weld and make it more durable.

The 247Garden CO2 Regulator with Solenoid Valve allow you to maintain ideal and accurate CO2 levels for optimum growth. Easy to adjust, it also comes with a 4000 PSI tank pressure gauge, easy-to-read square-shaped flow meter, and electronic solenoid void with 6 feet power cord. Works with any 120 V device. Simply add the tubing to disperse CO2 evenly throughout your room. If you are not using a digital CO2 controller, you will need to use a timer. To avoid leak, please make sure the nylon washer is in place when attaching to CO2 tank. Also make sure you have a wrench to screw tight the attachment. To check for leaks after installing, spray some soapy water or StarSan solution on the CO2 regulator connectors. Usually if there"s leaks, you will see or hear the bubbles. All 247Garden CO2 Regulators come with 100% Customer Satisfaction Guaranteed. Warning: 1)All CO2 tanks should be placed on a flat surface and securely mounted to a permanent structure such as a wall or metal frame. These tanks are under extreme pressure. Should one fall or be knocked over, personal injury may result. 2)Follow all local laws when transporting, storing or handling CO2. 3)PPM levels should be kept below 2500 PPM. Levels above 5000 PPM can be harmful. 4)Always completely turn off the tank valve before attaching or detaching the regulator.

247Garden CO2 Regulator w/Solenoid Valve 110V, Forged Brass Body, Nylon Washer, 4000 PSI Pressure Gauge, 0.5-15 SCFH Compatiable for Indoor Gardening & Hydroponics, Beer & Wine Kegs Brewing.

This is the perfect regulator if you would like to serve at different pressures at the same time. Has one high pressure gauge that tells you how much CO2 is left in your tank and two low pressure gauges, which allow you to set a different pressure for different CO2 lines.

Catalina Cylinders recommends that anyone storing CO2 cylinders should be aware of the hazards associated with CO2 and be trained in safe practices of storing CO2 cylinders. All practices of storing CO2 cylinders ought to include or reference information from CGA pamphlets G-6; Carbon Dioxide and G-6.3; Carbon Dioxide Cylinder Filling and Handling Procedures. Catalina Cylinders has compiled the following list of items that should be included in any safe storage practice of CO2 cylinders.

CO2 cylinders should always be stored in a specified area. The storage area should:Be well ventilated. CO2 gas in small concentrations, as little as 15%, can cause unconsciousness in less than one minute.

Be selected away from the edge of any elevated areas. Cylinders falling from elevated areas can cause damage to the cylinder, valve or property or injury to personnel.

Be a continuously cool place. Do not store cylinders adjacent to any source of heat, intermittent or continuous. Safety relief devices of CO2 cylinders are designed to operate when the pressure of the cylinder exceeds 2800 – 3000 psi (depending on the design of the safety relief device). A properly charged CO2 cylinder could vent through it’s safety relief device at approximately 150 oF (65.6 oC). A slightly overfilled CO2 cylinder could vent through its safety relief device when exposed to a much lower temperature. The CGA recommends that CO2 cylinders be stored in areas with a temperature less than 125 oF (51.7 oC).

Cylinders, which have been manufactured to accommodate a valve protective carrying handle or a protective cap, should be stored with these accessories in place.

It is the intent of D.O.T. to provide safety for all concerned during the transportation of hazardous materials. Samples in the oil and gas industry are hazardous. Some more so than others, but they all can be dangerous. If you follow the rules, the hazard can be significantly reduced and almost completely eliminated. The rules are for everyone’s protection…YOURS TOO!

The cylinders must be properly packaged and protected. This includes relief valves in accordance with D.O.T. and Compressed Gas Association (CGA) rules and regulations. The valves must be protected and the cylinders restrained from free movement, i.e., carrying cases or boxes that comply with D.O.T. packaging guidelines.

These are but a few of the important aspects in the handling and transport of sample cylinders. Who should be aware of these rules? 1) Anyone who transports sample cylinders, 2) Anyone who offers sample cylinders for transport, 3) Anyone who prepares sample cylinders for transport, 4) Anyone who receives sample cylinders for transport. Simply stated, if a sample cylinder is moved off of your company property on to any city, county, state, or federal roadway, airway, railway or ship, you must be in compliance with D.O.T. CFR-49 and local regulations. Whether you are using specially designed sample cylinders, homemade sample cylinders, old compressed gas cylinders or any other conceivable method of transporting a hydrocarbon sample, if you are handling these cylinders in your vehicle or are presenting them for transport on a common carrier, you must be aware of the rules that govern the transport of these cylinders. Failure to comply will not only jeopardize the safety of the public and your safety, but will also make you and your company liable for penalties and fines.

Safety relief valves are relatively maintenance-free devices. Even so, it is recommended that a periodic inspection of these devices be done every six to 12 months.

A common maintenance error is to add a second relief valve onto the outlet of an existing relief valve that is leaking. This “stacking” of relief valves is not permissible by code.

By installing two relief valves in sequence, you add back pressure above the first relief valve piston, causing a change in the pressure setting. For example, the estimated relieving pressure of a valve stack could be:

As the relief flow then passes through the second valve, the stack also experiences a change in relieving capacity. If any of these conditions exist, the valve should be replaced.

The condition of the discharge piping should also be inspected. Valves should be piped to ensure that they do not collect dirt and debris. The vent pipes should be protected to prevent the entrance of rain water, which would inhibit valve operation.

Relief valves should be changed out after discharge to ensure safeguarding a system with a properly set relief valve. Most systems are subject to accumulations of piping debris (i.e., metal shavings and solder impurities) as the system is fitted for installation.

These impurities are generally blown into the relief valve seats at the time the valve is discharged. The impinged debris then inhibits the relief valve from reseating at its original set pressure.

Replacement intervals for valves that have not discharged may be dictated by city, state, or federal regulations. In addition, they may also be regulated by industry standards, company policies, insurance requirements, or unwritten, accepted standards of good practice.

In the case of city, state, or federal regulations and insurance regulations, there appear to be no written rules covering the replacement schedule. However, these agencies do govern by verbal requirements requesting that system operators-owners provide proof of the reliability of existing relief valves.

Industry standardsThe International Institute of Ammonia Refrigeration (IIAR), in its Bulletin 109, IIAR Minimum Safety Criteria for a Safe Ammonia Refrigeration System, recommends that the relief valve be replaced or inspected, cleaned, and tested every five years.

ANSI STD K61.1-1989, Safety Requirements for the Storage and Handling of Anhydrous Ammonia, is very specific in its requirements. Paragraph 6.8.15 states:

“No container pressure relief devices shall be used after the replacement date as specified by the manufacturer of the device. If no date is specified, a pressure relief valve shall be replaced no later than five years following the date of its manufacture.”

In industrial refrigeration, the current recommendation is to replace the relief valve on a five-year cycle. Be sure to check with other agencies to verify that a more stringent regulation is not applicable.

Provide a pressure vessel that will permit the relief valve to be set at least 25% above the maximum system pressure. However, the relief valve setting cannot exceed the maximum allowable working pressure as stamped on the vessel the relief valve is protecting.

Use the proper size and length of discharge tube or pipe. Correct sizing is required to prevent back pressure from building up in the discharge line, preventing the relief valve from discharging at its rated capacity.

The use of a three-way valve with two relief devices, which complies with the code requirements for vessels 10 cu ft or more in gross volume, is recommended for any installation containing a large quantity of expensive refrigerant.

8613371530291

8613371530291