consolidated pilot operated safety valve supplier

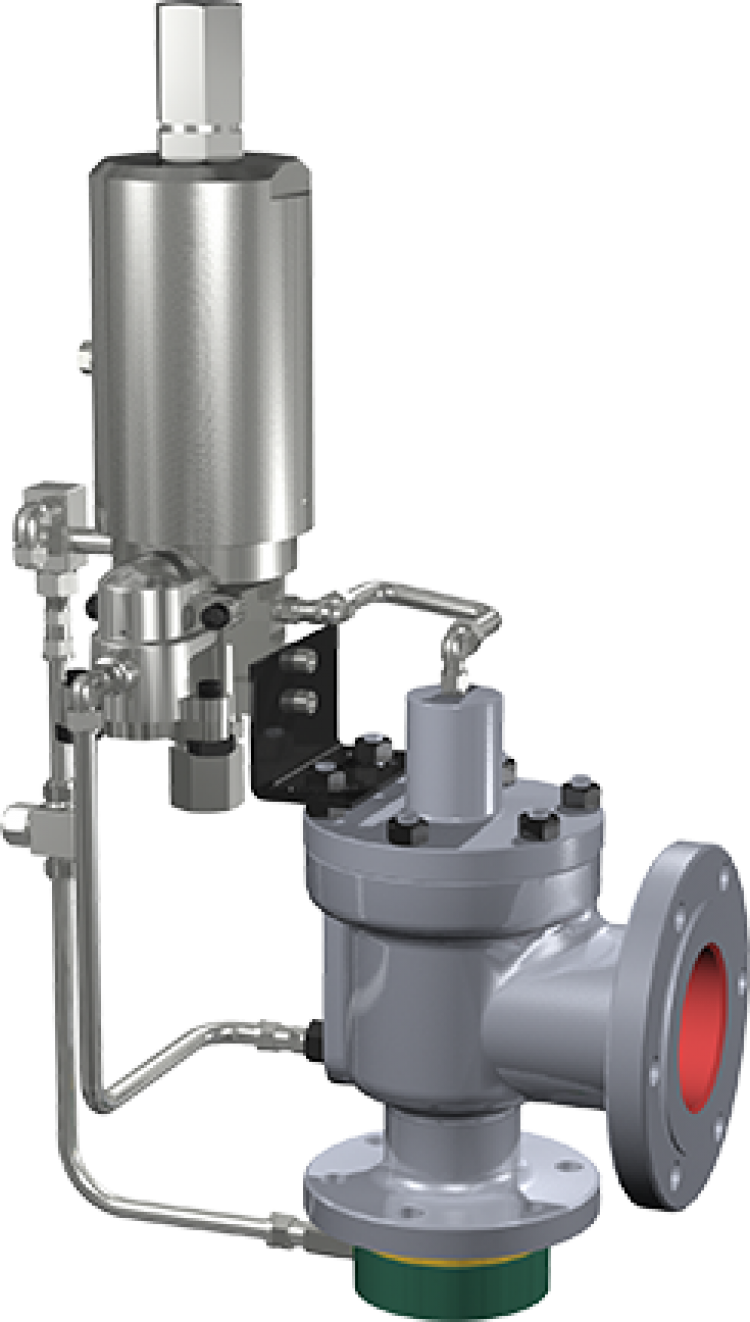

Consolidated 3900/3900 TM Series Pilot-Operated Safety Relief Valves (POSRVs) feature a semi-nozzle main valve design that meets API 526 center-to-face dimensional requirements for POSRVs. The 3900 Triple Media (TM) Series is one of the first POSRVs engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both 3900 series come standard with a non-flowing pilot valve that is suitable for compressible and incompressible fluids. Optional pilot valve constructions are available for either pop or modulating action functionality to meet various pressure range, seat tightness, and blowdown requirements. Highly versatile, these valve technologies offer ease of maintenance, high reliability, flexibility, and efficient operation and performance.

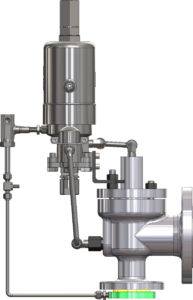

The 2900/2900 TM Series Gen II is a full-nozzle pilot-operated safety relief valve (POSRV) matching API 526 direct-spring PRV dimensions. Its patented full-nozzle integral sense design allows for easy maintenance as well as simple spring-loaded to pilot-operated PRV conversions throughout the lifecycle of the valve. The 2900 Triple Media (TM) Series is the first full nozzle POSRV engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both valve series use the same pilot valve technology as the 3900 Series including the ‘True Zero Leakage’ modulating pilot, providing a modernized overpressure protection solution for reducing carbon footprint and emissions.

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Chalmers & Kubeck –provides prompt delivery from one of the largest pressure relief valve inventories available anywhere. We have in excess of $10 Million in new Baker Hughes Consolidated * pressure and safety relief valves and OEM replacement parts in our C&K family of companies plus an additional $50 Million available from our Green Tag network associates. Strategically located,our knowledgeable, factory trained technicians, are available 24/7 to provide prompt, factory authorized repair service in both our shops or at the customer’s plant site. Territorial restrictions apply.

This unique and patented design offers the ultimate API 526 Direct-Spring to Pilot-Operated PRV upgrade opportunity by allowing the end user to select either Remote Sense or Integral Sense (depending…

The Consolidated Series 3500 Electromatic Ball Valve (EBV) is designed to provide automatic or manual overpressure protection for steam boilers, and can also be used to assist start-up and shut-down…

ASME Section I and VIII approved, the Consolidated Type 2700 steam safety valve is configured to meet the specific requirements of the co-generation and waste-to-energy segments.

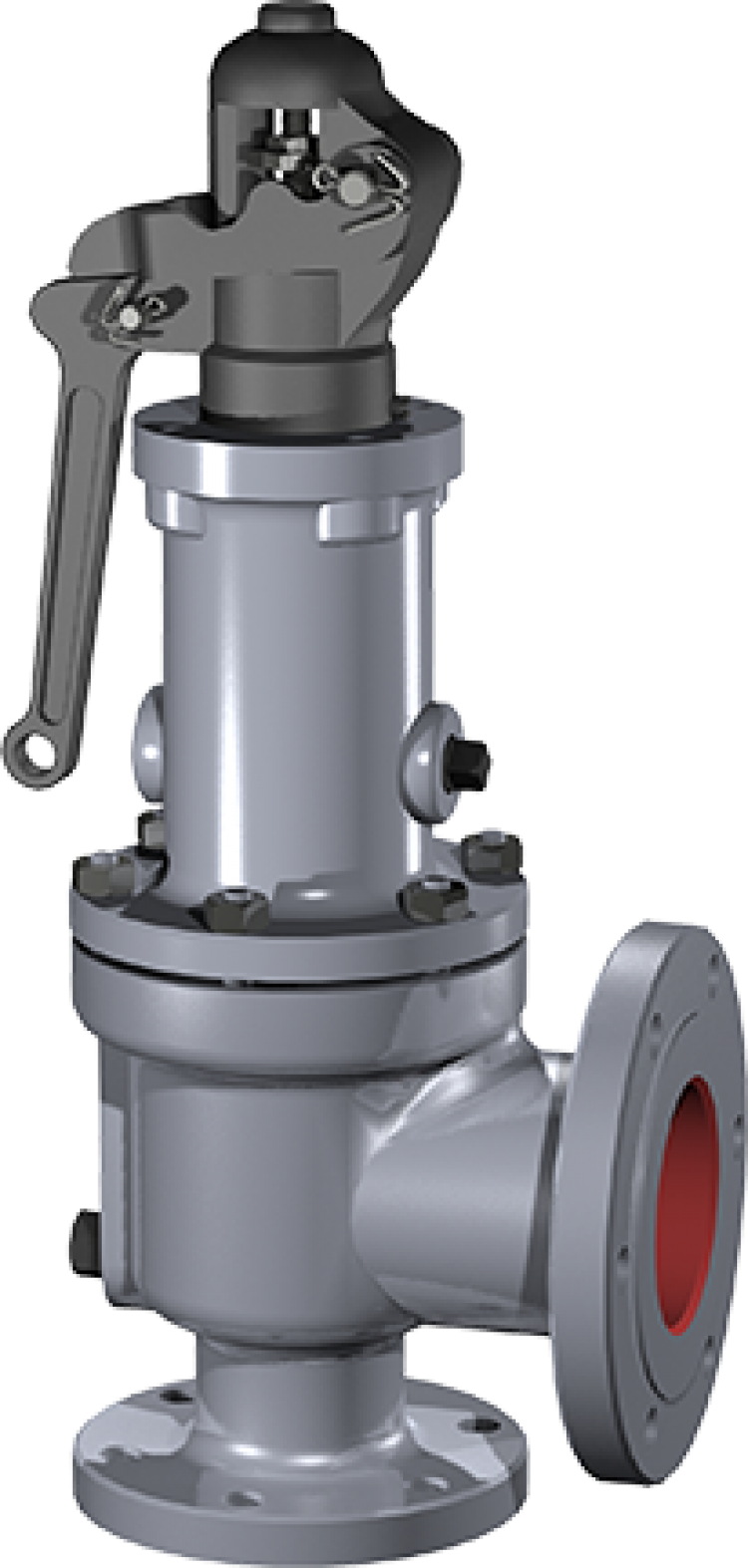

The Consolidated Type 1811 is a cost effective, high capacity flanged steel safety valve that offers seat tightness and high performance making it a solution well-suited for steam service applications.

Suitable for steam and other compressible fluid applications, the Consolidated Type 1541 and 1543 safety valves are ASME Section I and VIII approved. They are most commonly used in pharmaceutical,…

The Consolidated Type 1511 safety valves are designed for low pressure steam heating boilers, steam generators and air applications. This valve is ASME Section I and VIII approved.

The Type 3900 modular pilot-operated safety relief valve (MPV) features a separate, non-flowing pilot sub-assembly design making it well-suitable for use with both compressible and incompressible fluids. Optional pilot valve…

The Consolidated Type 1982 conventional process safety relief valve provides seat tightness and blowdown performance for vapor, liquid and steam applications. It is well-suited for applications requiring high relief capacity…

The Consolidated 19000 Series valve provides quality performance in seat tightness, capacity, and blowdown on most media. It surpasses ASME code requirements and is CE compliant to European PED specifications…

The first valve of its size capable of handling liquid and gas interchangeably without adjustments while remaining stable, the Type 1900 safety relief valve offers an innovative solution for multi-phase…

Consolidated Maxiflow high pressure safety valves are premium products that are installed on many power generating stations worldwide to help protect boilers from overpressure conditions. With a proven design, the…

Through its improved seat tightness to 98 percent of set pressure, and adjustable blowdown to 2 percent of set pressure, the 2900 series valve allows higher system pressures that can increase the yield of the process

Over the years we have refined our products so that our customers only have top quality options. Our service offerings are custom-fit to our customer’s individual needs. Our technicians and engineers are some of the most experienced and educated industrial experts available. We never compromise on safety and your satisfaction is our only goal.

Pioneer’s cutting-edge Baker Hughes Consolidated relief valves offer Green Tag Center (GTC) support to help your high-pressure safety valve operate efficiently. We offer comprehensive audit programs to validate your product, so the solution we provide for your facility is built to last. Safety relief valves function as the main protection point against dangerous substances; it’s crucial the system you have in place is operating to its optimal potential. Baker Hughes Consolidated safety valves offer styles, sizes, options, and configurations to fit seamlessly into your existing environment for optimal performance.

Consolidated* 3900 MPV Series Pilot-Operated Safety Relief Valve Overview GE’s unique pilot valve design combines enhanced performance, capabilities and features within an economical, modular assembly. The 3900 series valve design provides an optimized safety system that offers application versatility while providing cost-effective standardization. Specifications INLET SIZES OUTLET SIZES INLET RATINGS ASME Class 150 through 2500 OUTLET RATINGS ASME Class 150 through 300 ORIFICE SIZES Eleven inlet sizes: D through T and Full bore options PRESSURE RANGE psig (1.03 barg) to 6250 psig (431 barg) 15 TEMPERATURE RANGE MATERIALS MAIN VALVE (Std.) Carbon steel base and 316 stainless steel internal components 316 stainless steel base and internal components Closed bonnet for spring protection. Pilot gag prevents the pilot-operated relief valve from opening while equipment is undergoing operational hydrostatic testing. Pop action and modulating pilot allows for application versatility. Unique pilot seat design allows for self cleaning operation and is tolerant to icing and dirty conditions. Adjustable blowdown - the first and only non-flowing modulating pilot with main valve blowdown control. Remote actuation and sensing. Operation closer to set point improves process efficiency versus direct spring operated valves. The metal seat option incorporates proven technology from the 1900 series safety relief valve seat design. The addition of the 2900 series POSRV heat exchanger increases the metal seat option temperature range to -320°F (-196°C) to 650°F (343°C). fact sheet

Safety relief valves often serve as the point-of-protection against potentially dangerous circumstances, so it is important that they be dependable. GE Energy’s Consolidated safety relief valves have maintained a reputation for excellence and reliability for more than a century.

The Consolidated product line has demonstrated a number innovative solutions, too. Safety relief valve innovations from the product line include the Thermodisc® temperature compensating disc and the first modular pilot-operated valve.

GE’s unique pilot valve design combines enhanced performance, capabilities and features within an economical, modular assembly. The 3900 series valve design provides an optimized safety system that offers application versatility while providing cost-effective standardization.

The 2900 series pilot-operated safety relief valve is another innovative Consolidated product line offering from GE, a world leader in pressure relief valve technology. The 2900 series valve is a blend of

GE’s Consolidated pilot valve has a unique design that combines top performance, capabilities and features within an economical, modular assembly. This is based on the successful design of an optimized safety “system” that offers versatility of application, yet provides cost-effective standardization.

GE’s Consolidated* 1982 Series Safety Relief Valves are designed and manufactured in compliance with ASME B & PVC, Section VIII and Section III (Class I, II and III). Mainly used for steam and liquid applications.

Our comprehensive portfolio of safety valves can help to run operations smoothly and cost effectively, particularly in steam service environments. Consolidated safety valves feature a unique pop-action release that can relieve steam over-pressurization if pressures upstream from the valve reach a set point.

What is more, GE’s Consolidated safety valves comply with the ASME Section I code for boiler applications. They are built with many features that meet ASME requirements for steam-compressible fluids. For example, all models feature a lifting lever, required by the code for testing, instead of deadweight or weighted levers. Consolidated safety valves can also withstand set pressures up to 103 percent with a blowdown value of 4 percent, or 96 percent of set pressure drop before the valve re-seats.

The type 1900-30 valve includes the addition of a balanced bellows that is necessary to compensate for the effects of variable back pressure. By isolating the upper structure and allowing the use of less expensive materials, the bellows is also a cost-effective solution in applications where the valve is exposed to highly viscous or corrosive fluids.

The type 1900-DA valve contains an additional O-ring seat seal. This soft seat is the primary seal and it allows the valve to remain leak free at 95 percent of set pressure over 100 psig (6.89 barg). A backup metal seat provides additional safety for fire-relief applications when O-rings can be destroyed by high temperature exposure.

GE’s Consolidated* 19000 Series valves are designed and manufactured in compliance with ASME B & PVC, Section VIII and Section III (Class I, II and III), and are CE compliant to the European Pressure Equipment Directive 97/23/EC.

For over 130 years Consolidated has worked closely with our customers and regulatory organizations to configure, engineer, and manufacture a comprehensive portfolio of

HOUSTON - Dresser Consolidated® today announced it has been selected as relief valve supplier for a major oil company"s offshore drilling and production tension-leg platform (TLP) in the deepwater Gulf of Mexico.

The offshore tension-leg platform will be constructed in the Mississippi Canyon Block of the Gulf of Mexico, approximately 130 miles off the coast of New Orleans. Dresser Consolidated will supply the 3900 Modular Pilot-Operated Safety Relief Valve (MPV) that will provide overpressure protection for the main production and gas lift manifold of the platform. Both 2-inch and 3-inch valves will be supplied in pressure classes up to 2500 class ratings in both duplex and 316 stainless steel.

"Dresser Consolidated offers competitive products and solutions for offshore oil and gas applications in high pressure and corrosive environments," said Nathan Brunell, vice president of marketing and product management for the Flow Technologies Segment of Dresser Inc. "The 3900 is one of our many pilot-operated safety relief valves that provide customers with flexibility and potential cost savings by enabling them to use a common platform to cover a wide range of applications, helping to reduce overall inventory and maintenance costs."

The 3900 MPV features a separate non-flowing pilot sub-assembly design, making it suitable for use with both compressible and incompressible fluids. Optional pilot valve constructions offer either pop action or modulating action functionality to meet various pressure range, seat tightness and blowdown requirements. Highly versatile, the valve offers outstanding benefits, including easy maintenance, high reliability, flexibility and efficient operation and performance. Key features include the modular pilot valve construction, top-entry main valve configuration and the multiple standard pilot options available. Stainless steel construction is used for the standard pilot, accessories and main valve trim. The top-entry main valve design provides easy access for maintenance and parts replacement. Users can also improve plant operating efficiency by optimizing pilot function with the specific pressure relief application requirements.

Dresser Consolidated, headquartered in Houston, Texas, has been an international leader in dependable pressure relief valves and solutions for more than 100 years. A business segment of Dresser, Inc., the division delivers the trusted expertise to provide and service reliable flow safety systems in critical applications around the world. To learn more, please visit www.dresserconsolidated.com.

Dresser Inc. is a global leader in providing highly-engineered infrastructure products for the global energy industry. Leading brand names within the Dresser portfolio include Dresser Wayne® retail fueling systems, Waukesha® natural gas-fired engines, Masoneilan® control valves, Consolidated® pressure relief valves, and ROOTS® blowers and rotary gas meters. The company has manufacturing and customer service facilities strategically located worldwide and a sales presence in more than 150 countries. www.dresser.com

8613371530291

8613371530291