consolidated pilot operated safety valve price

The Type 13900 Series pilot-operated safety relief valve combines high capacity with simple construction, designed to ASME section VIII. It consists of a small conventional, fail-safe pilot valve and a high capacity main valve platform. The main valve can be configured with orifice sizes up to 200 square inches to help reduce the number of valves required for system overpressure protection.

Greater total system efficiency driven by the main valve"s ability to handle in excess of 3,000,000 lbs. of steam per hour. It has 7:1 discharge capacity over "T" orifice and 2:1 over "W" orifice valves.

Taking into account a variety of important factors, our valve experts can help determine the right pressure relief valve solutions for your power and energy applications:

The 2900/2900 TM Series Gen II is a full-nozzle pilot-operated safety relief valve (POSRV) matching API 526 direct-spring PRV dimensions. Its patented full-nozzle integral sense design allows for easy maintenance as well as simple spring-loaded to pilot-operated PRV conversions throughout the lifecycle of the valve. The 2900 Triple Media (TM) Series is the first full nozzle POSRV engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both valve series use the same pilot valve technology as the 3900 Series including the ‘True Zero Leakage’ modulating pilot, providing a modernized overpressure protection solution for reducing carbon footprint and emissions.

Through its improved seat tightness to 98 percent of set pressure, and adjustable blowdown to 2 percent of set pressure, the 2900 series valve allows higher system pressures that can increase the yield of the process

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Chalmers & Kubeck –provides prompt delivery from one of the largest pressure relief valve inventories available anywhere. We have in excess of $10 Million in new Baker Hughes Consolidated * pressure and safety relief valves and OEM replacement parts in our C&K family of companies plus an additional $50 Million available from our Green Tag network associates. Strategically located,our knowledgeable, factory trained technicians, are available 24/7 to provide prompt, factory authorized repair service in both our shops or at the customer’s plant site. Territorial restrictions apply.

This unique and patented design offers the ultimate API 526 Direct-Spring to Pilot-Operated PRV upgrade opportunity by allowing the end user to select either Remote Sense or Integral Sense (depending…

The Consolidated Series 3500 Electromatic Ball Valve (EBV) is designed to provide automatic or manual overpressure protection for steam boilers, and can also be used to assist start-up and shut-down…

ASME Section I and VIII approved, the Consolidated Type 2700 steam safety valve is configured to meet the specific requirements of the co-generation and waste-to-energy segments.

The Consolidated Type 1811 is a cost effective, high capacity flanged steel safety valve that offers seat tightness and high performance making it a solution well-suited for steam service applications.

Suitable for steam and other compressible fluid applications, the Consolidated Type 1541 and 1543 safety valves are ASME Section I and VIII approved. They are most commonly used in pharmaceutical,…

The Consolidated Type 1511 safety valves are designed for low pressure steam heating boilers, steam generators and air applications. This valve is ASME Section I and VIII approved.

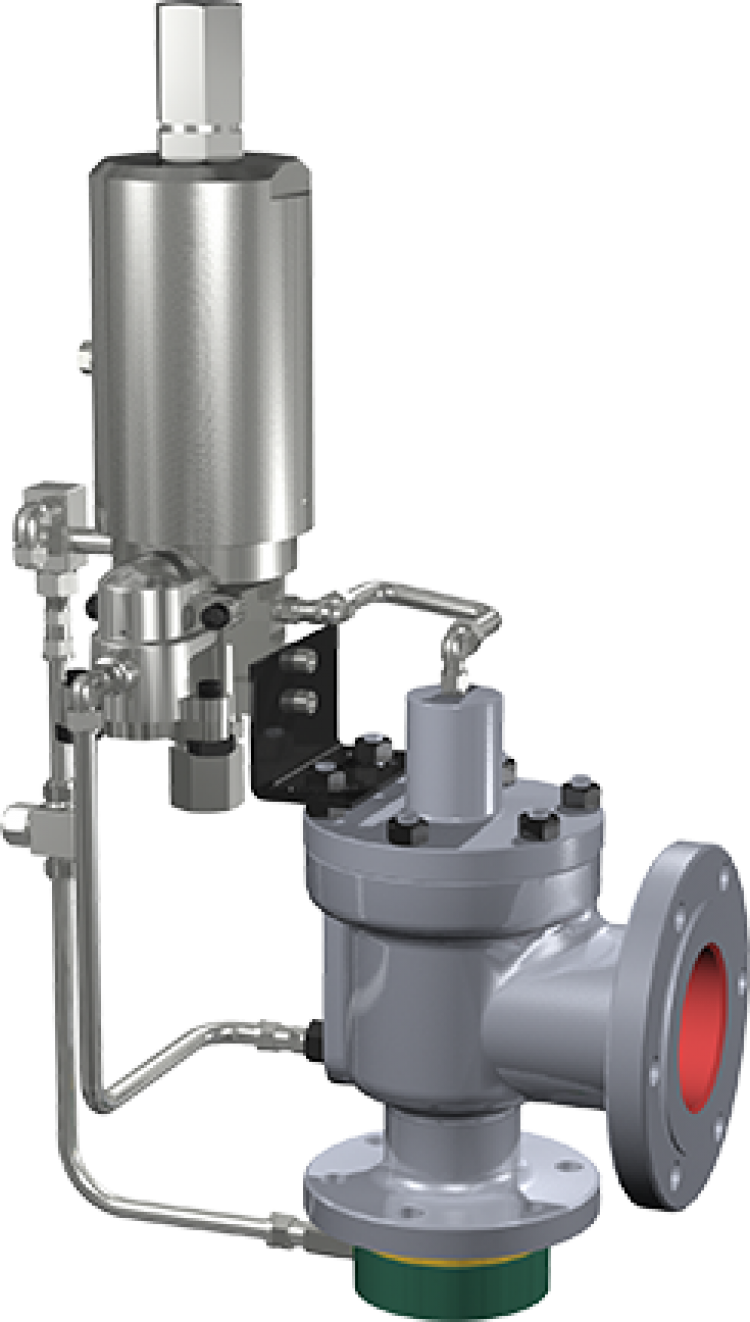

The Type 3900 modular pilot-operated safety relief valve (MPV) features a separate, non-flowing pilot sub-assembly design making it well-suitable for use with both compressible and incompressible fluids. Optional pilot valve…

The Consolidated Type 1982 conventional process safety relief valve provides seat tightness and blowdown performance for vapor, liquid and steam applications. It is well-suited for applications requiring high relief capacity…

The Consolidated 19000 Series valve provides quality performance in seat tightness, capacity, and blowdown on most media. It surpasses ASME code requirements and is CE compliant to European PED specifications…

The first valve of its size capable of handling liquid and gas interchangeably without adjustments while remaining stable, the Type 1900 safety relief valve offers an innovative solution for multi-phase…

Consolidated Maxiflow high pressure safety valves are premium products that are installed on many power generating stations worldwide to help protect boilers from overpressure conditions. With a proven design, the…

Consolidated* 2900 MPV Series Pilot-Operated Safety Relief Valve Overview The 2900 series pilot-operated safety relief valve is another innovative Consolidated product line offering from GE, a world leader in pressure relief valve technology. The 2900 series valve is a blend of GE"s Consolidated type 1900 safety relief valve and GE"s Consolidated type 3900 pilot-operated safety relief valve. These GE products have a proven track record for performance, versatility and ease of maintenance. Remote sensing can eliminate problems caused when an inlet pressure drop to the SRV exceeds 3 percent. Retrofit kits easily and economically convert an existing Consolidated 1900 SRV to the new 2900 POSRV design. Replacing and/or upgrading the existing population of safety relief valves with the 2900 series valve eliminates costly piping changes. Process temperatures that range from -450°F (-267 .8°C) to 1200°F (648 .9°C) can be met by using the heat exchanger option.. GE"s Consolidated pilot valve has a unique design that combines top performance, capabilities and features within an economical, modular assembly. This is based on the successful design of an optimized safety “system” that offers versatility of application, yet provides cost-effective standardization. Here are the key characteristics of the 2900 series valve: The Dirty Service option ensures operation in dirty, precipitating and viscous fluids. Bonnet is now standard for all pilot valves. 39MV22 [751 - 3750 psig (51 .78 - 258 .55 barg)] The 39MV22 modulator, which replaces the 39MV37, is built internally into the pilot valve. This design reduces product cost, improves modulating performance and increases energized seal life. 39MV72 [3751 - 6250 psig (258 .62 - 430 .92 barg)] Based on the same design as the 39MV22, this pilot allows the Consolidated product line to expand into the 2500# class pressure range. Pilot Gag This prevents the pilot-operated relief valve from opening while equipment is being subjected to an operational hydrostatic test. 2900 series POSRV Backflow Preventer. When the 2900 pilot-operated relief valve initially was released, a backflow preventer was required for high back pressure conditions. During additional testing, it was discovered that a backflow preventer is not required for non-bellows valves equipped with a standard piston O-ring. Valves equipped with a Teflon® energized seal still will require a backflow preventer. The 2900 pilot valve enables enhanced performance with a variety of solutions. Through its improved seat tightness to 98 percent of set pressure, and adjustable blowdown to 2 percent of set pressure, the 2900 series valve allows higher system pressures that can increase the yield of the process. fact sheet

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

8613371530291

8613371530291