consolidated pilot operated safety valve pricelist

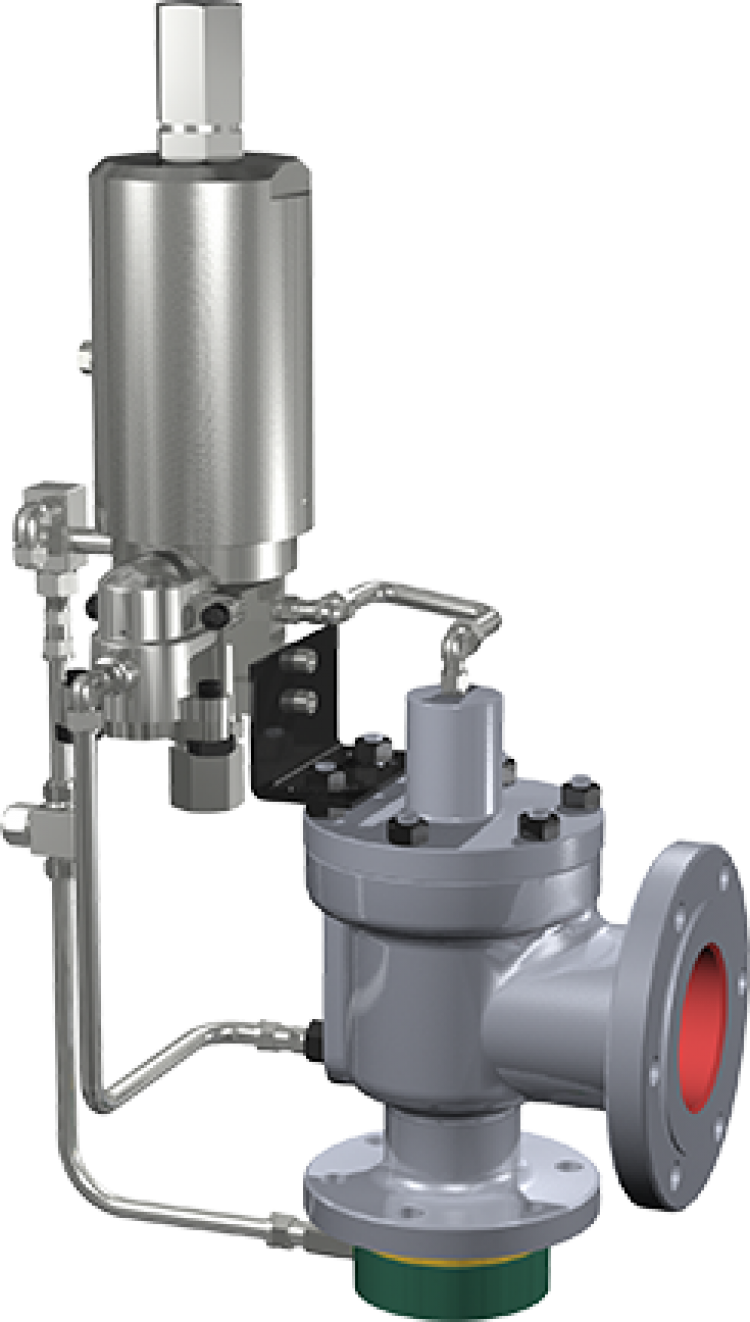

The 2900/2900 TM Series Gen II is a full-nozzle pilot-operated safety relief valve (POSRV) matching API 526 direct-spring PRV dimensions. Its patented full-nozzle integral sense design allows for easy maintenance as well as simple spring-loaded to pilot-operated PRV conversions throughout the lifecycle of the valve. The 2900 Triple Media (TM) Series is the first full nozzle POSRV engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both valve series use the same pilot valve technology as the 3900 Series including the ‘True Zero Leakage’ modulating pilot, providing a modernized overpressure protection solution for reducing carbon footprint and emissions.

Maximizes throughput by allowing economizer to operate at higher pressures with the use of pilots without seat leakage. Increases efficiency by providing repeatable seat tightness.

For overpressure protection of economizers when a liquid certified safety relief valve or pilot operated safety relief valve cannot be used due to a steam relief scenario. ASME Section 1 certified on steam and water per ASME Code Case 2446.

Consolidated* 3900 MPV Series Pilot-Operated Safety Relief Valve Overview GE’s unique pilot valve design combines enhanced performance, capabilities and features within an economical, modular assembly. The 3900 series valve design provides an optimized safety system that offers application versatility while providing cost-effective standardization. Specifications INLET SIZES OUTLET SIZES INLET RATINGS ASME Class 150 through 2500 OUTLET RATINGS ASME Class 150 through 300 ORIFICE SIZES Eleven inlet sizes: D through T and Full bore options PRESSURE RANGE psig (1.03 barg) to 6250 psig (431 barg) 15 TEMPERATURE RANGE MATERIALS MAIN VALVE (Std.) Carbon steel base and 316 stainless steel internal components 316 stainless steel base and internal components Closed bonnet for spring protection. Pilot gag prevents the pilot-operated relief valve from opening while equipment is undergoing operational hydrostatic testing. Pop action and modulating pilot allows for application versatility. Unique pilot seat design allows for self cleaning operation and is tolerant to icing and dirty conditions. Adjustable blowdown - the first and only non-flowing modulating pilot with main valve blowdown control. Remote actuation and sensing. Operation closer to set point improves process efficiency versus direct spring operated valves. The metal seat option incorporates proven technology from the 1900 series safety relief valve seat design. The addition of the 2900 series POSRV heat exchanger increases the metal seat option temperature range to -320°F (-196°C) to 650°F (343°C). fact sheet

Consolidated* 2900 MPV Series Pilot-Operated Safety Relief Valve Overview The 2900 series pilot-operated safety relief valve is another innovative Consolidated product line offering from GE, a world leader in pressure relief valve technology. The 2900 series valve is a blend of GE"s Consolidated type 1900 safety relief valve and GE"s Consolidated type 3900 pilot-operated safety relief valve. These GE products have a proven track record for performance, versatility and ease of maintenance. Remote sensing can eliminate problems caused when an inlet pressure drop to the SRV exceeds 3 percent. Retrofit kits easily and economically convert an existing Consolidated 1900 SRV to the new 2900 POSRV design. Replacing and/or upgrading the existing population of safety relief valves with the 2900 series valve eliminates costly piping changes. Process temperatures that range from -450°F (-267 .8°C) to 1200°F (648 .9°C) can be met by using the heat exchanger option.. GE"s Consolidated pilot valve has a unique design that combines top performance, capabilities and features within an economical, modular assembly. This is based on the successful design of an optimized safety “system” that offers versatility of application, yet provides cost-effective standardization. Here are the key characteristics of the 2900 series valve: The Dirty Service option ensures operation in dirty, precipitating and viscous fluids. Bonnet is now standard for all pilot valves. 39MV22 [751 - 3750 psig (51 .78 - 258 .55 barg)] The 39MV22 modulator, which replaces the 39MV37, is built internally into the pilot valve. This design reduces product cost, improves modulating performance and increases energized seal life. 39MV72 [3751 - 6250 psig (258 .62 - 430 .92 barg)] Based on the same design as the 39MV22, this pilot allows the Consolidated product line to expand into the 2500# class pressure range. Pilot Gag This prevents the pilot-operated relief valve from opening while equipment is being subjected to an operational hydrostatic test. 2900 series POSRV Backflow Preventer. When the 2900 pilot-operated relief valve initially was released, a backflow preventer was required for high back pressure conditions. During additional testing, it was discovered that a backflow preventer is not required for non-bellows valves equipped with a standard piston O-ring. Valves equipped with a Teflon® energized seal still will require a backflow preventer. The 2900 pilot valve enables enhanced performance with a variety of solutions. Through its improved seat tightness to 98 percent of set pressure, and adjustable blowdown to 2 percent of set pressure, the 2900 series valve allows higher system pressures that can increase the yield of the process. fact sheet

Relief and safety Valves are used in high pressure systems to control the pressure and keep balance of the system. The different between safety valves and relief valves is that the safety valves fully open or close under a certain pressure while the relief valves can open in proportion to the pressure in front of them. The safety and pressure relief valves are used automatically. They both operate under similar conditions. When the pressure builds up in a system, it has to be managed by releasing the material to flow through. These valves have a threshold pressure at which they open. The consolidated safety and safety relief valves comprise of a bonnet vent and bellow with springs.

The springs are set up for the threshold pressure and when the pressure exceeds the threshold, the spring is pushed into the bonnet vent and the bellow opens the valve. The Safety Relief Valves can be open and shut valves. They either open or shut off at any given pressure. This is mostly for the safety of an application not to explode under high pressure. The Pressure Relief Valve on the other hand releases the material after the threshold pressure, but not fully. If the pressure is slightly higher the threshold, then the valve opens slightly. If the pressure is very high above the threshold, it opens wider. It also functions in the same manner when the pressure drops down. The valve closes in proportion to the pressure. The safety valve shuts down at once only when the pressure is below the threshold.

Ready Stock of ASTM A351 CF8M Spring Loaded Safety Valve in wide range of Sizes, Stainless Steel Air Compressor Pressure Relief Valve Manufacturers In India

Relief Valves are designed to control pressure in a system While Safety Valves are used for controlling the pressure in a system they release pressure immediately in the event of an emergency or system failure

The Setpoint of relief valve is usually set at 10 Percent above working pressure limit while safety valve is usually set at 3% above working pressure limit.

If you are operating systems that can only be off for short periods of time, it is sensible to keep a spare valve to swap over and then the removed valve can be inspected and recertified.

A pilot-operated pressure relief valve SVP-P is a pressure relief valve in which the major relieving device is combined with, and is controlled by, a self-actuated auxiliary pilot.

When the relief valve is closed, system pressure pushes upwards against the piston seat seal on an area equal to the inside diameter of the seat. Simultaneously, the same system pressure passes through the pilot, exerting a downward force on the piston acting on an area approximately 50% greater than the inside diameter of the seat. The resulting differential force holds the valve tightly closed. As the system pressure rises, the force against the piston seal increases.

When the system pressure reaches the relief valve discharge set pressure , the pilot cuts off system pressure and opens the top of the piston to vent pressure, the pilot valve discharge the chamber of the main valve (releasing pressure) and the main valve opens completely (h=D)

When the predetermined blowdown pressure is reached (93-97,5% of set pressure), the pilot shuts off the exhaust and reopens the flow of system pressure to the top of the piston with higher presure value, which effectively close the relief valve.

Therefore, the basic advantage of the pilot operated safety relief valve is that it, when coming closer to the pre-set discharge pressure, force increases and seat-tightness is better. With the conventional valve it is the opposite – when coming close to the opening pressure, valve starts gradually to release. This valve can be operated in applications with a back pressure ratio of up to 70% which makes it ideal for a non stabile systems.

Flange dimensions can be modified on request to fit most existing installations. This permits SVP-P pilot-operated safety relief valve to be used as replacements for older spring-loaded valves which may not conform to new safety standards.

This pilot has a fixed blowdown for controlling relief valve opening and closing pressure set points. The opening set pressure is determined by the force of a control spring, which holds the relief control section of the valve closed. When system pressure acting on the relief control valve seat area equals the spring force, the relief line opens, and the blowdown control section closes, blocking system pressure from passing into the chamber above the main valve piston. As the relief line opens, the pressure underneath the control seat is exposed to a larger pressure area which emidiatelly makes the control pilot to quickly reduce pressure in the piston area.

This pressure reduction causes the main valve piston to lift, relieving system pressure. After the system pressure is reduced to a point determined by the control spring, the relief control valve closes, and the open blowdown line valve allows system pressure to re-enter the piston area, forcing the main piston down to a closed valve position.

- Flange dimensions can be modified on request to fit most existing installations. This permits SVP-P pilot-operated safety relief valve to be used as replacements.

Over the years we have refined our products so that our customers only have top quality options. Our service offerings are custom-fit to our customer’s individual needs. Our technicians and engineers are some of the most experienced and educated industrial experts available. We never compromise on safety and your satisfaction is our only goal.

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for Pilot Operated Safety Valve, High Pressure Gate Valve, Water Pump, Drain Valve For Steam-Water System,Wafer Swing Check Valve. "Passion, Honesty, Sound service, Keen cooperation and Development" are our goals. We are here expecting friends all over the world! The product will supply to all over the world, such as Europe, America, Australia,Toronto, Islamabad,Switzerland, Egypt.Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

8613371530291

8613371530291