consolidated pilot operated safety valve for sale

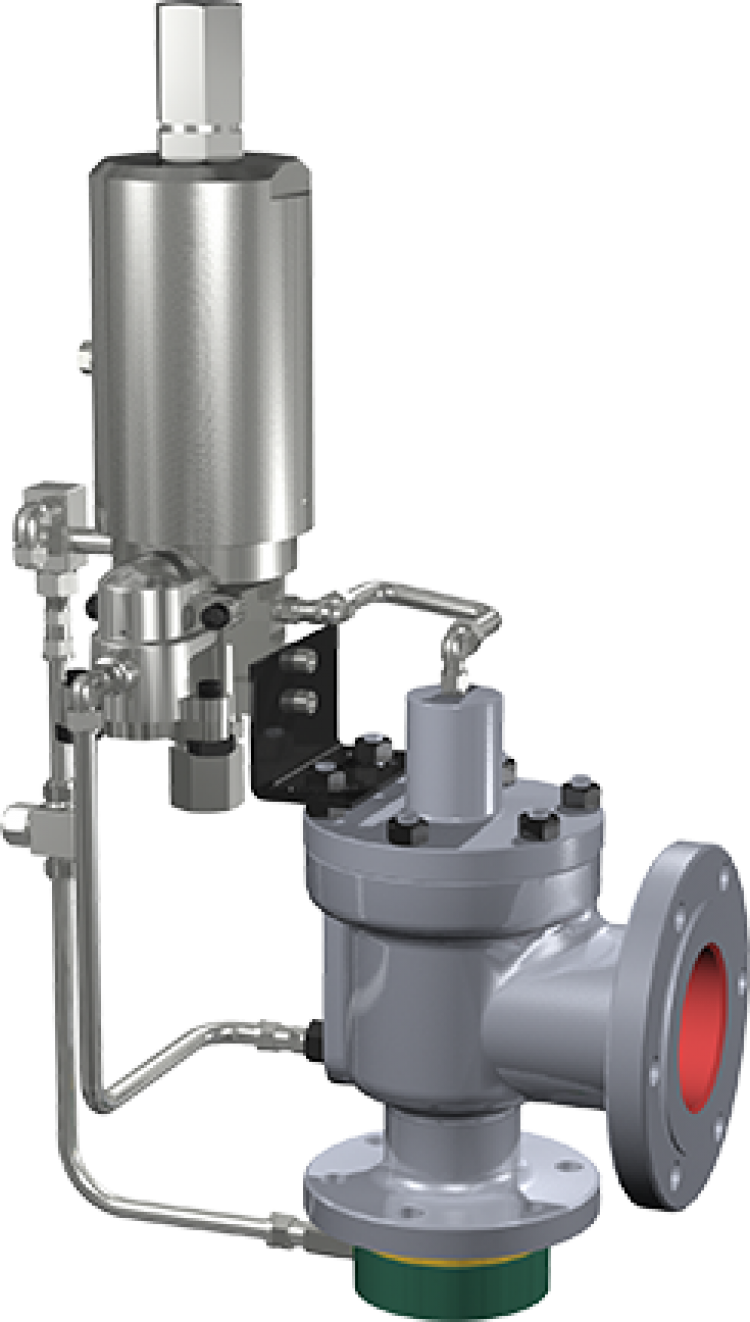

The 2900/2900 TM Series Gen II is a full-nozzle pilot-operated safety relief valve (POSRV) matching API 526 direct-spring PRV dimensions. Its patented full-nozzle integral sense design allows for easy maintenance as well as simple spring-loaded to pilot-operated PRV conversions throughout the lifecycle of the valve. The 2900 Triple Media (TM) Series is the first full nozzle POSRV engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both valve series use the same pilot valve technology as the 3900 Series including the ‘True Zero Leakage’ modulating pilot, providing a modernized overpressure protection solution for reducing carbon footprint and emissions.

Consolidated 3900/3900 TM Series Pilot-Operated Safety Relief Valves (POSRVs) feature a semi-nozzle main valve design that meets API 526 center-to-face dimensional requirements for POSRVs. The 3900 Triple Media (TM) Series is one of the first POSRVs engineered to perform on liquid, air/gas, and steam media and is multi-media certified to meet multiple media capacity stamping per ASME B & PVC Code Case 2787. Both 3900 series come standard with a non-flowing pilot valve that is suitable for compressible and incompressible fluids. Optional pilot valve constructions are available for either pop or modulating action functionality to meet various pressure range, seat tightness, and blowdown requirements. Highly versatile, these valve technologies offer ease of maintenance, high reliability, flexibility, and efficient operation and performance.

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

The Consolidated Type 2900-40 pilot-operated safety relief valve offers exceptional performance and meets demanding ASME Section I Economizer and Boiler Applications.

The Consolidated Type 2900 pilot-operated safety relief valve combines the advantages of two products into one— the 1900 safety relief valve and the 3900 POSRV. The 2900 POSRV can replace spring-loaded relief valves without requiring modified outlet piping.

The Consolidated Type 3900 pilot-operated safety relief valve is a non-flowing design available in a modulating or pop-action pilot. The 3900 POSRV is suitable for the overpressure protection of many pressurized systems and vessels in the chemical, petrochemical, paper mill, oil and gas production and transmission industries.

Chalmers & Kubeck –provides prompt delivery from one of the largest pressure relief valve inventories available anywhere. We have in excess of $10 Million in new Baker Hughes Consolidated * pressure and safety relief valves and OEM replacement parts in our C&K family of companies plus an additional $50 Million available from our Green Tag network associates. Strategically located,our knowledgeable, factory trained technicians, are available 24/7 to provide prompt, factory authorized repair service in both our shops or at the customer’s plant site. Territorial restrictions apply.

This unique and patented design offers the ultimate API 526 Direct-Spring to Pilot-Operated PRV upgrade opportunity by allowing the end user to select either Remote Sense or Integral Sense (depending…

The Consolidated Series 3500 Electromatic Ball Valve (EBV) is designed to provide automatic or manual overpressure protection for steam boilers, and can also be used to assist start-up and shut-down…

ASME Section I and VIII approved, the Consolidated Type 2700 steam safety valve is configured to meet the specific requirements of the co-generation and waste-to-energy segments.

The Consolidated Type 1811 is a cost effective, high capacity flanged steel safety valve that offers seat tightness and high performance making it a solution well-suited for steam service applications.

Suitable for steam and other compressible fluid applications, the Consolidated Type 1541 and 1543 safety valves are ASME Section I and VIII approved. They are most commonly used in pharmaceutical,…

The Consolidated Type 1511 safety valves are designed for low pressure steam heating boilers, steam generators and air applications. This valve is ASME Section I and VIII approved.

The Type 3900 modular pilot-operated safety relief valve (MPV) features a separate, non-flowing pilot sub-assembly design making it well-suitable for use with both compressible and incompressible fluids. Optional pilot valve…

The Consolidated Type 1982 conventional process safety relief valve provides seat tightness and blowdown performance for vapor, liquid and steam applications. It is well-suited for applications requiring high relief capacity…

The Consolidated 19000 Series valve provides quality performance in seat tightness, capacity, and blowdown on most media. It surpasses ASME code requirements and is CE compliant to European PED specifications…

The first valve of its size capable of handling liquid and gas interchangeably without adjustments while remaining stable, the Type 1900 safety relief valve offers an innovative solution for multi-phase…

Consolidated Maxiflow high pressure safety valves are premium products that are installed on many power generating stations worldwide to help protect boilers from overpressure conditions. With a proven design, the…

Consolidated Pilot Operated Safety Relief Valves (POSRVs) offer the safety you expect, the dependability you require, and the efficiency you need to keep your operations running smoothly. These valves offer a premium performance and numerous technical benefits and operating advantages over traditional Pressure Relief Devices.

Pilot Operated Safety Relief Valves are designed with several features that differentiate it from traditional spring loaded safety relief valves with superior performance, and with a compact design are lighter weight and easier to install in most applications.

Consolidated Pilot Valves offer industry leading performance with both main valve and pilot seat tightness up to 98% of set pressure. This advanced design ensures zero-leakage during normal operating conditions for even the most demanding high-pressure applications.

Remote sense configuration eliminates rapid cycling valve chatter in applications with >3% inlet line loss, enabling Consolidated POSRVs to open and relieve pressure in a stable and efficient manner. The modulating style opens proportionally to your overpressure pilot, ensuring a smooth opening cycle and relieving only required capacity, keeping your operation safe, efficient and reliable.

Certified on gas, liquid and steam, and configured to suit your application with flexible features including an adjustable blowdown, bolt-on modulator, pilot line pressure surge snubber and dozens of optional accessories, ConsolidatedPOSRVs can be configured for any service.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

meets numerous application requirements. For example. the type 1900-UM valve is capable of flowing liquid, gas or steam with no adjustment required to switch between different media with the same set pressure.

The ConsolidatedType 19000valve is ASME and PED certified. It meets and exceeds API seat tightness performance. The 19000 offers enhanced capacity and blowdown performance on many media types. In most cases, it does not require parts changes to accommodate different media.

choice for OEM and skid manufacturers requiring high-relief capacity from a small valve. The 1982 offers superior seat tightness and blowdown performance for most media applications.

The ConsolidatedType 11000Series Safety Relief Valve combines performance, quality, reliability and value into a single overpressure device. The 11000 SRV is specifically designed for the most demanding upstream and midstream oil and gas applications where safety is of prime importance.

Valve Sales Inc. (VSI), and Baker Hughes have partnered to distribute, service, and repair the complete line of Consolidated pressure relief valves. VSI’s service and distribution agreement with Consolidated covers the entire state of Oklahoma, southern Kansas, and the Northwest corner of Arkansas.

Announcing the new agreement, Chris Chernisky, President of VSI said, “Our customers have asked us for a valve line they can trust, and we are excited to be able to deliver on that request. The Tulsa-based Center of Operational Excellence will now become a Consolidated Green Tag Center. That means its customers can expect factory-trained technicians, expert technical support, and local inventory of OEM valves and parts for quick delivery.”

Consolidated has the most diversified portfolio of safety and pressure relief valves in the industry, including the innovative technologies of the 1900-DM (Dual Media), and 2900 Gen II pilot-operated safety relief valve. In addition to this best-in-class product line, VSI has the capability to service valves both in-house and on-site. The MOBILELAB is fully equipped with testing, machining, and repair capabilities. “We can dispatch the MOBILELAB quickly for tight turnarounds or emergency service, which is a very valuable resource to our customers,” Chernisky said.

Over the years we have refined our products so that our customers only have top quality options. Our service offerings are custom-fit to our customer’s individual needs. Our technicians and engineers are some of the most experienced and educated industrial experts available. We never compromise on safety and your satisfaction is our only goal.

It is a common question asked amongst process engineers on why use a pilot valve for a particular application ? The following article I hope will answer this question and provide some insights into the different types of pilot valves available on the market today and their many features and benefits.

A pilot valve allows higher system operating pressure for maximum process output thus increasing the throughput of your process meaning greater product yield.

Diagram above illustrates seat tightness of a traditional spring loaded relief valve versus a pilot valve illustrating how much closer to set point a pilot valve can operate.

Pilot valves operate on a very simple set up. A sensing line, usually connected into the inlet piping, is connected into the pilot control. Another line is piped from the pilot control into the top of the main valve assembly. The pilot, which contains a small spring assembly, is set at a certain set pressure. During normal operation the inlet pressure passes through the sensing line through the pilot and continues into the dome of the main valve. The inlet pressure in effect is placing pressure onto the piston inside the main valve to keep the valve closed. At set point the spring inside the pilot causes a small piston to slide down allowing the inlet pressure sitting on top of the main valve piston to relieve through the pilot’s exhaust. This causes the main inlet pressure to be relieved through the main valve. The diagrams below illustrate this principle.

Have a look at the following diagram which illustrates how pop action pilots open the main valve fully at set point whilst modulating pilots open the main valve according to relief demand.

Powerflo Solutions has been providing pilot valve sales and technical support to our Australian customer base for over 30 years. We are the sole distributors of the Dresser Consolidated brand of safety relief valves in Australia including the Consolidated 3900 series and 2900 series of pilot valves. These valves offer all of the usual pilot valve benefits already mentioned plus additional options that can be tailored to meet each individual’s needs. Options include:

Consolidated is the only relief valve manufacturer that offers the ability to retrofit an existing spring loaded relief valve into a pilot valve. Any 1900 series Consolidated spring loaded relief valve can be converted into a 2900 series pilot valve that will give you all of the benefits a pilot valve can offer.

Powerflo – Consolidated have the experience and safety and relief valve product range to meet your requirements. Just ask Shell who are enjoying the benefits of using Consolidated pilot valves for their recent clean fuels upgrade.

For more information on Consolidated pilot valves or any other safety and relief valve requirements you have feel free to contact one of our sales offices located around Australia.

Other Valves & Manifolds└ Valves & Manifolds└ Hydraulics, Pneumatics, Pumps & Plumbing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

8613371530291

8613371530291