consolidated pressure safety valve factory

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

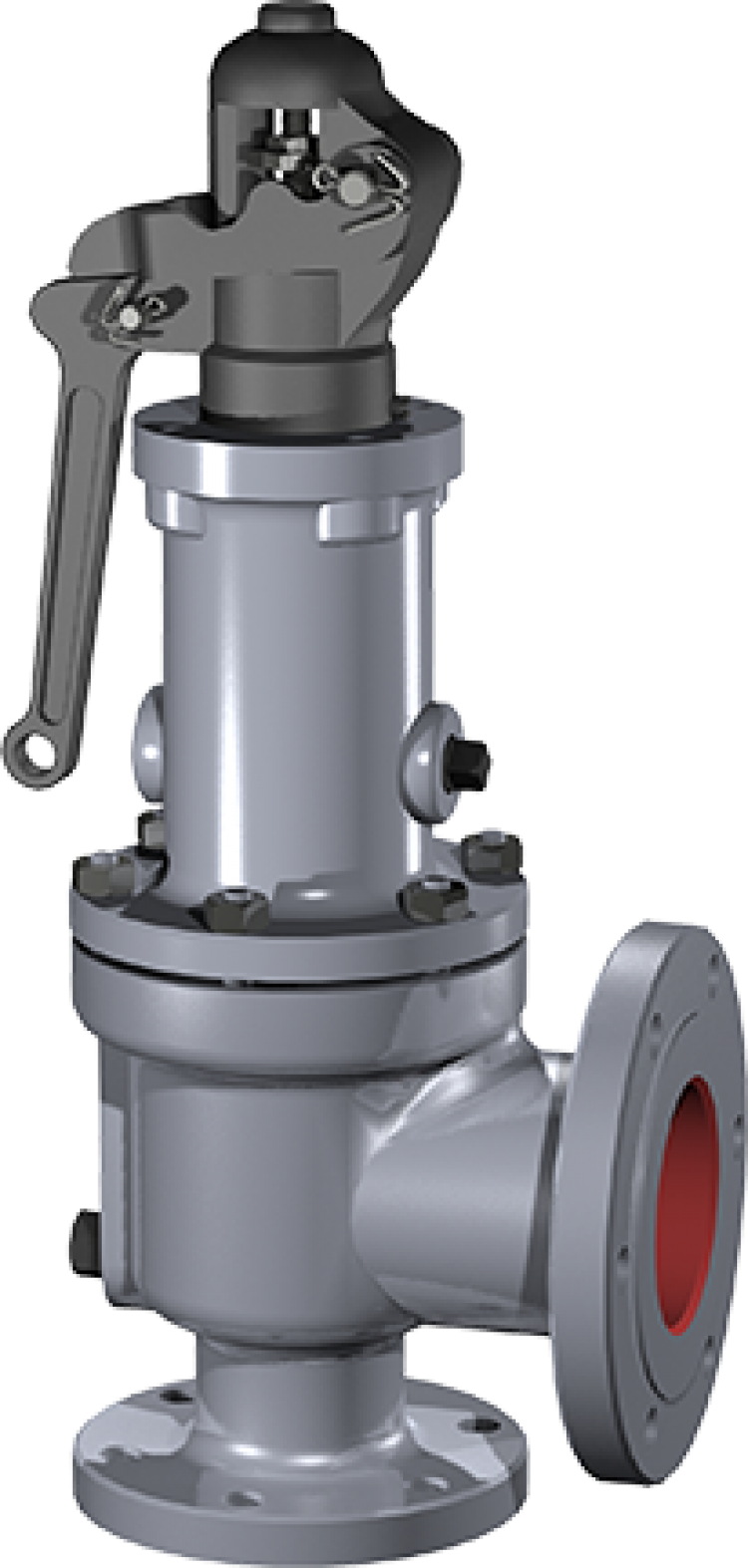

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Chalmers & Kubeck –provides prompt delivery from one of the largest pressure relief valve inventories available anywhere. We have in excess of $10 Million in new Baker Hughes Consolidated * pressure and safety relief valves and OEM replacement parts in our C&K family of companies plus an additional $50 Million available from our Green Tag network associates. Strategically located,our knowledgeable, factory trained technicians, are available 24/7 to provide prompt, factory authorized repair service in both our shops or at the customer’s plant site. Territorial restrictions apply.

The Consolidated Series 3500 Electromatic Ball Valve (EBV) is designed to provide automatic or manual overpressure protection for steam boilers, and can also be used to assist start-up and shut-down…

ASME Section I and VIII approved, the Consolidated Type 2700 steam safety valve is configured to meet the specific requirements of the co-generation and waste-to-energy segments.

The Consolidated Type 1811 is a cost effective, high capacity flanged steel safety valve that offers seat tightness and high performance making it a solution well-suited for steam service applications.

Suitable for steam and other compressible fluid applications, the Consolidated Type 1541 and 1543 safety valves are ASME Section I and VIII approved. They are most commonly used in pharmaceutical,…

The Consolidated Type 1511 safety valves are designed for low pressure steam heating boilers, steam generators and air applications. This valve is ASME Section I and VIII approved.

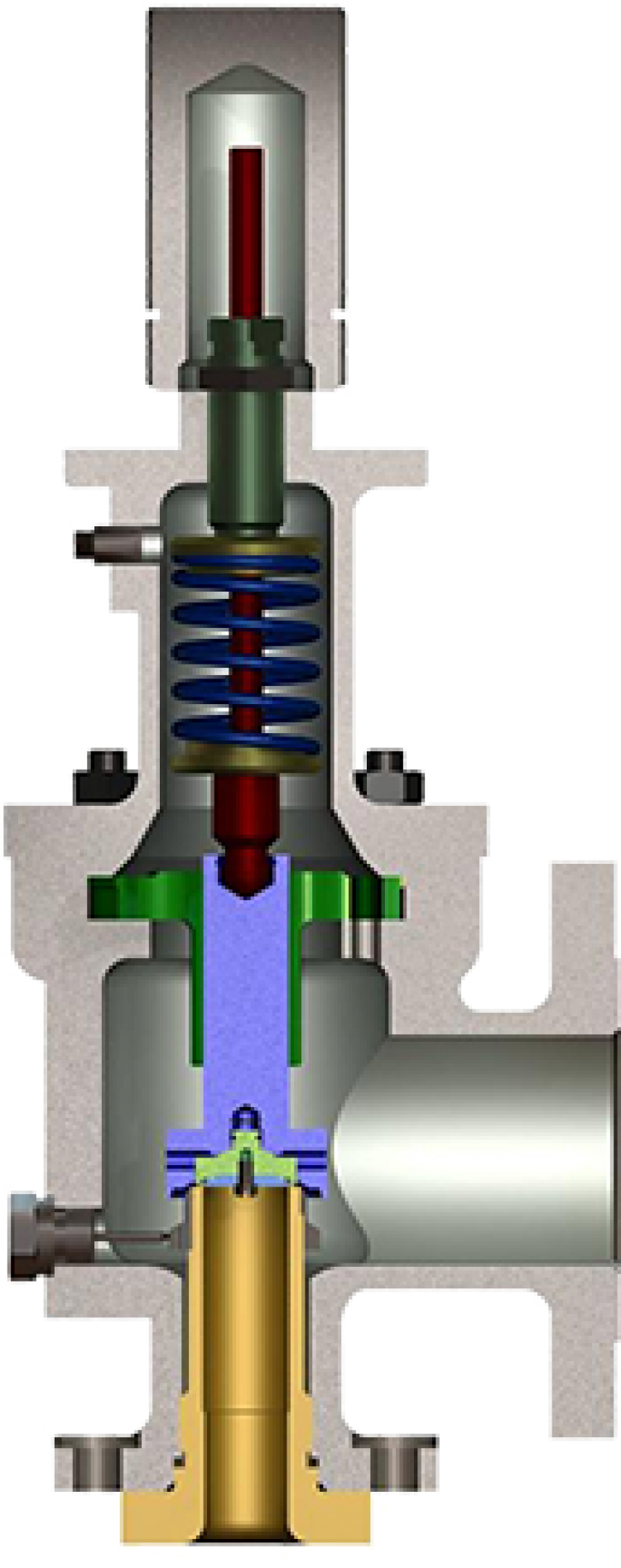

The Type 3900 modular pilot-operated safety relief valve (MPV) features a separate, non-flowing pilot sub-assembly design making it well-suitable for use with both compressible and incompressible fluids. Optional pilot valve…

The Consolidated Type 1982 conventional process safety relief valve provides seat tightness and blowdown performance for vapor, liquid and steam applications. It is well-suited for applications requiring high relief capacity…

The Consolidated 19000 Series valve provides quality performance in seat tightness, capacity, and blowdown on most media. It surpasses ASME code requirements and is CE compliant to European PED specifications…

The first valve of its size capable of handling liquid and gas interchangeably without adjustments while remaining stable, the Type 1900 safety relief valve offers an innovative solution for multi-phase…

Consolidated Maxiflow high pressure safety valves are premium products that are installed on many power generating stations worldwide to help protect boilers from overpressure conditions. With a proven design, the…

Pioneer’s cutting-edge Baker Hughes Consolidated relief valves offer Green Tag Center (GTC) support to help your high-pressure safety valve operate efficiently. We offer comprehensive audit programs to validate your product, so the solution we provide for your facility is built to last. Safety relief valves function as the main protection point against dangerous substances; it’s crucial the system you have in place is operating to its optimal potential. Baker Hughes Consolidated safety valves offer styles, sizes, options, and configurations to fit seamlessly into your existing environment for optimal performance.

Improved leak protection and safety. A soft seat design feature helps keep the valve leak free at 95 percent of set pressure over 100 psig., while a backup metal seat provides additional safety.

Compliance to API Standard 526-2002. These valves comply with API Standard 526 Fifth edition, 2002. When required for replacement , Consolidated 1900/P series valves are also available with connections and dimensions in accordance with supplanted API Standard Third edition 1984 and prior editions.

To ensure the quality and reliability of each new Consolidated® valve product, we inspect, test, and fine-tune every valve before shipment. We test the valve for the application needed to ensure it will stand up to the daily pressure of your industry. Whether it is chemical, power, oil, gas, or another valued business, we make it our mission to provide the highest quality valve in the safest condition possible.

Gulf Valve Service Company also repairs Consolidated® safety valves and Consolidated® safety relief valves back to operational and efficient states. Certified by the American Society of Mechanical Engineers and The National Board of Boiler and Pressure Vessel Inspectors, we verify that every repaired valve meets their repair standards and that of our own high-set repair standards.

The CONSOLIDATED Pressure Relief Valve has been a leader in the industry since 1879, thus offering over a century of experience in design, engineering and product manufacture.

CONSOLIDATED�S history of dependable and reliable valve service assures that today�s products and designs are consistent with the industry�s current requirements. Rigid manufacturing standards controlled by an ASME approved Quality Assurance Program and a certified/registered ISO 9001 Quality Assurance Program ensure that each valve will be manufactured in accordance with established design criteria and tested for functional performance. This quality-controlled manufacturing and test program assures that each valve manufactured will provide long and reliable service.

CONSOLIDATED ASME Code Sections I and VIII Spring Loaded Pressure Relief Valves have been flow tested in accordance with the applicable ASME Code rules for the establishment of rated capacities and are listed in The National Board of Boiler and Pressure Vessel Inspectors publication Pressure Relieving Device Certifications.

F.H. Gaskins Company, Inc., specializes in the sale, repair, modification, calibration and certification of safety valves and relief valves. We proudly hold the “V” and “UV” stamps approved by ASME and a “VR” (valve repair) stamp approved by the National Board. We are a designated “Green Tag Center” for Dresser/Consolidated valve products and the Technical Representative Agent/Distributor of Everpure water filtration systems for Maryland and Virginia. F.H. Gaskins is also a recognized manufacturer for the Government (Cage Code 58837).

Some of the manufacturers we represent are: Allpax, Anderson, Apollo (Conbraco), Ashcroft, Bonomi, Circle Seal, Consolidated, Dewrance, Dixon, Dwyer, Everpure, Garlock, Hancock, F.C. Kingston, Merit, Pyrex, Roberts, Wager, Watts, Zurn-Wilkins and others.

Consolidated Safety-Valve Co. v. Crosby Steam Gauge & Valve Co., 113 U.S. 157 (1885), was a patent case to determine validity of patent No. 58,294,safety valves.

Richardson was the first person who made a safety valve which, while it automatically relieved the pressure of steam in the boiler, did not, in effecting that result, reduce the pressure to such an extent as to make the use of the relieving apparatus practically impossible because of the expenditure of time and fuel necessary to bring up the steam again to the proper working standard.

His valve was the first which had the strictured orifice to retard the escape of the steam and enable the valve to open with increasing power against the spring and close suddenly, with small loss of pressure in the boiler.

The direction given in the patent that the flange or lip is to be separated from the valve seat by about one sixty-fourth of an inch for an ordinary spring, with less space for a strong spring and more space for a weak spring, to regulate the escape of steam as required, is a sufficient description as matter of law, and it is not shown to be insufficient as a matter of fact.

Letters patent No. 85,963, granted to said Richardson January 19, 1869, for an improvement in safety valves for steam boilers or generators, are valid.

The patents of Richardson were infringed by a valve which produces the same effects in operation by the means described in Richardson"s claims, although the valve proper is an annulus and the extended surface is a disc inside of the annulus, the Richardson valve proper being a disc and the extended surface an annulus surrounding the disc, and although the valve proper has two ground joints, and only the steam which passes through one of them goes through the stricture, while, in the Richardson valve, all the steam which passes into the air goes through the stricture, and although the huddling chamber is at the center instead of the circumference, and is in the seat of the valve, under the head, instead of in the head, and the stricture is at the circumference of the seat of the valve instead of being at the circumference of the head.

The fact that the prior patented valves were not used and the speedy and extensive adoption of Richardson"s valve support the conclusion as to the novelty of the latter.

Text of Consolidated Safety-Valve Co. v. Crosby Steam Gauge & Valve Co., 113 U.S. 157 (1885) is available from:CourtListenerGoogle ScholarJustiaLibrary of Congress

Safety valves are used in a variety of applications, including air/gas, vapor, steam and liquid service. Flotech has been approved by the National Board of Boiler and Pressure Vessel Inspectors to perform safety and relief valve testing, repair and certification.

Our valve experts will focus on getting your valves tested, repaired and quickly set to the exact specifications. We evaluate the repair condition of every valve and will recommend the right solution to manage your maintenance program.

8613371530291

8613371530291