consolidated safety valve distributors quotation

Relief valves are often the last point of protection against dangerous events, so they must be dependable and ready to operate under high pressure situations. With Consolidated’s 140+ years of dedicated Pressure Relief Valve (PRV) engineering and manufacturing expertise under their belt, they know pressure relief valves and offer a wide range of safety relief valve and safety valve styles, sizes, options and configurations for all kinds of applications, environments and media.

Consolidated works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments, to name a few:

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

Improved leak protection and safety. A soft seat design feature helps keep the valve leak free at 95 percent of set pressure over 100 psig., while a backup metal seat provides additional safety.

Compliance to API Standard 526-2002. These valves comply with API Standard 526 Fifth edition, 2002. When required for replacement , Consolidated 1900/P series valves are also available with connections and dimensions in accordance with supplanted API Standard Third edition 1984 and prior editions.

Safety and Safety Relief valves play an important role in keeping people and equipment safe, and Consolidated valves are known for their exceptional quality, performance, and dependability.

With a range of styles, models, options, and configurations, Baker Hughes"s Consolidated safety valves are reliable in even the most demanding applications. They comply with the ASME Section I code for boiler applications and are built with many features that meet ASME requirements for steam-compressible fluids.

Get the support you need, as well, with Contro Valve’s Consolidated Green Tag Centers (GTC) with responsive and effective service through OEM-certified repairs, ValvKeep* valve management and maintenance software, and the EVT* Pro, an electronic valve testing device.

Baker Hughes works closely with customers and regulatory organizations to configure, engineer and manufacture safety valves that can help maintain safer operating conditions in a full range of environments.

Features: Consolidated Maxiflow® high pressure safety valves are premium products used on a majority of power generating stations worldwide to protect boilers from overpressure conditions.

Maxiflow valves are high capacity, Thermodisc® seat, spring loaded safety valves designed for sub critical steam service of 3000 psig at 1200 degrees F, and also for supercritical steam service of 4500 psig at 1050 degrees F. All valves in this series are produced to exceed AME requirements to minimize steam losses.

Features: Consolidated Electromatic relief valves provide manual or automatic overpressure control by the plant operator. These electrically actuated safety devices are utilized on superheated and saturated steam applications at sub critical and supercritical pressures to 4500 psig.

Use of Electromatic relief valves provides the plant operator with a control system that can instantaneously open or close a pressure relief valve on a distantly located header or drum. This advantage results in the capability of accurately balancing boiler operations at peak load conditions, while extending operating life of super heater safety valves.

Features: Consolidated type 2700 safety valves are high capacity, spring loaded valves designed specifically for the co-generation, independent power production and industrial boiler markets. Consolidated’s well known Thermodisc Seat design provides leak tight operation at 94% of the valve’s set pressure. The valves are available in ANSI 900 and 2500 classes at temperatures up to 1050 degrees F. The 2700 is approved for ASME Code Section I and VIII applications.

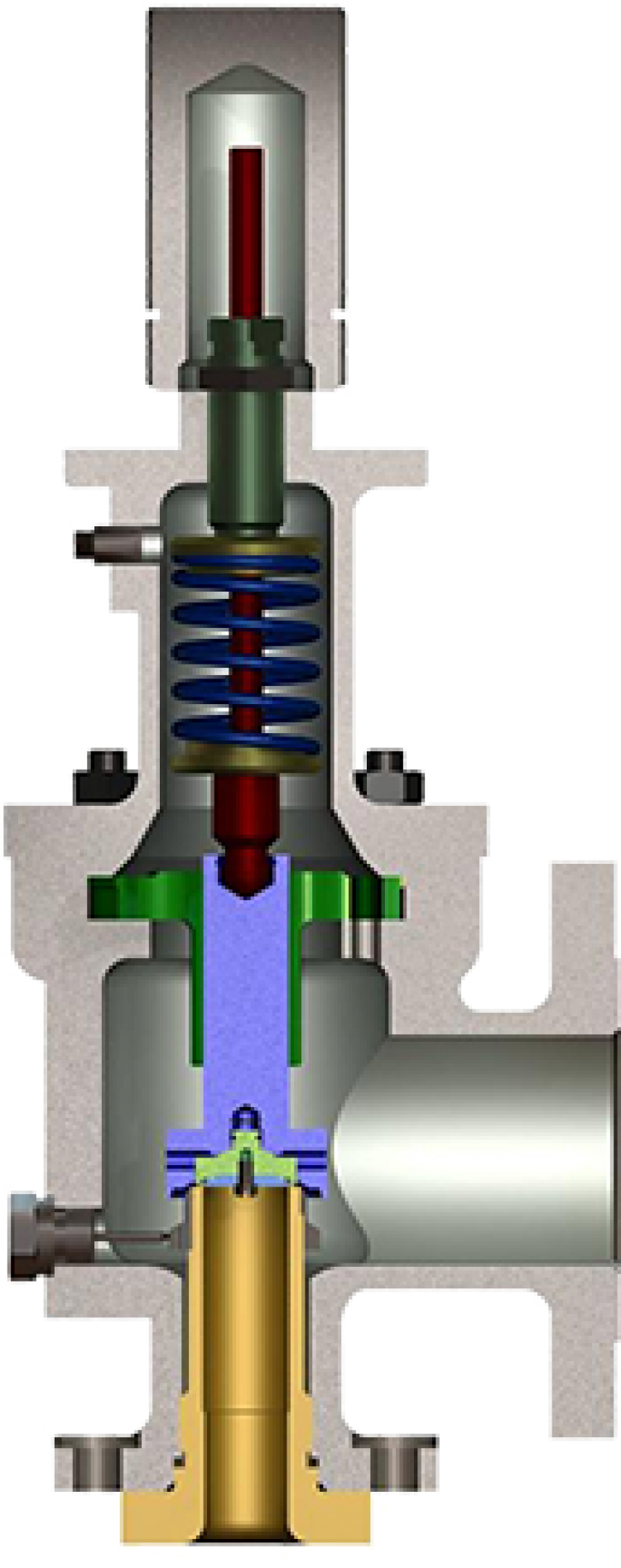

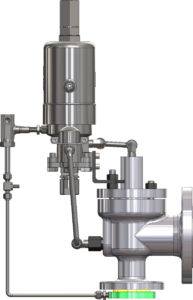

Features: Consolidated 3900 series pilot operated valves are utilized for the process and general industrial market with inlet sizes ranging from 1″ to 8″. Pressure range is from 15 psig through 3750 psig.

Consolidated pilot operated valves are available in pop type non-flowing, and modulating type flowing and non-flowing designs to meet the most rigorous requirements of the process and gas transmission industries. This product line complies with ASME Code Section VIII.

Features: Consolidated 1900 series steel flanged safety relief valves are designed for gas, vapor, steam and liquid service. Pressure classes range from ANSI 150 to 2500, with temperature ratings up to 1000 degrees Fahrenheit.

Valves are available as standard with bellows for back pressure compensation as well as various soft seating materials for maximum seat tightness. Designs for H2S service are also standard. All 1900 series valves are provided with stainless steel internal parts, and are built to meet ASME Code Section VIII requirements.

Features: Consolidated safety relief valves are designed for general service applications. Sometimes referred to as “portable,” this valve series also may be supplied with flanged or other connections. Valves are closed bonnet, spring loaded with connections from 1/2′ to 2′.

The 1990/1982 series is available up to 800 degrees F with a pressure limit of 8500 psig. Specific models are supplied for H2S as well as all stainless steel construction. Valves comply with ASME Code Section VIII.

Safety relief valves often serve as the point-of-protection against potentially dangerous circumstances, so it is important that they be dependable. Baker Hughes General Electric provides various valve styles, sizes, options and configurations for multiple industries and applications.

Baker Hughes General Electric continues to pursue quality and pro-active approach through regular collaboration with our customers and by staying actively involved in the development of regulatory compliance standards. We configure, engineer, and manufacture safety relief valves that adhere to industry regulations and global and regional standards while helping meet our customers’ evolving needs.

Safety relief valves often serve as the point-of-protection against potentially dangerous circumstances, so it is important that they be dependable. Baker Hughes General Electric provides various valve styles, sizes, options and configurations for multiple industries and applications.

Baker Hughes General Electric continues to pursue quality and pro-active approach through regular collaboration with our customers and by staying actively involved in the development of regulatory compliance standards. We configure, engineer, and manufacture safety relief valves that adhere to industry regulations and global and regional standards while helping meet our customers’ evolving needs.

Masoneilan isa leading provider of control valve solutions with over a century of proven performance, optimized with advanced digital instrumentation and innovation.

BS&B Safety Systems is best suited to finding the safest solution to your pressure problem. They were the originators of the Rupture Disk (Bursting Disc) and have developed the BPRV™ Buckling Pin Relief Valve for in-line pressure or vacuum relief offering quick and simple external resetting.

Challenger Valve wholly owned Canadian valve manufacturer established in 1996. They manufacture valves and controls that can meet your flow control requirements

Research Control Valves manufactures a complete range of precision, compact, low flow control valves, and accessories that meet the most demanding applications.

Since 1997, Severe Service Technology® (SST®) has engineered, manufactured and delivered reliable, durable severe service metal-seated ball valve systems for the most demanding applications in the power, oil & gas, mining, chemical processing and pulp & paper industries.

Since 1973, Weamco, Inc. is a premier manufacturer of liquid meter provers, and associated products to the industries they serve globally. Achieving and maintaining the highest level of standards in quality, service and safety in all business practices is Weamco"s primary goal without compromise.

These valves come from many of the top brands, like Titan, Apollo, Milwaukee, Consolidated Safety Valves, Jayco and others, so you can always rely on us for high-quality options. In fact, with more than 10,000 SKUs in stock we can supply 97 percent of orders for pipes, valves, fittings and other pipefitting products in their entirety. We’ll also provide integrated supply services for any of the other supplies you need as a member of Affiliated Distributors and supplyFORCE. Through these organizations, you can find all the MRO materials you need with services from reliable, local suppliers like FIP, wherever your business operates.

For more information on our selection of relief valve products and other PVF supplies, contact FIP today. Our company proudly serves customers in Orlando, Miami, Clewiston, Tampa and all other Florida cities.

Whatever your project, budget, or time requirement, you’ll find the right solution with VSI. We offer valves, actuators, flame arresters, rupture discs, pipeline pigs, and a variety of other top-quality products. VSI is a leader in custom-engineered solutions, new and remanufactured options, and the customer service you deserve.

When you partner with Valve Sales Inc, you have access to thousands of products from the biggest brands in the industry that include: Aberdeen Dynamics, ABZ, Argus, Asahi, ATI, Automation Service, Balon, Bettis, Cash Valve – CryogeniCc, Cash Valve – Industrial, Continental Disc Corporation, Cyclonic, Dualco, Flo-tite, Flow-Tek, Girard Groth Corporation, Hydroplex, Inline, JBT Products, Kimray, Kunkle, Ledeen, Mercer, Moniteur Devices, Morin, Norriseal, Omni Valve, Peaktronics, ProMation Actuator Company, Sealweld, Taylor, Tiger Valve Company (TVC), Vanessa, Wellmark,WKM and more.

Safety Relief Valves............................................................................................................................................................................................4

Type 1900-UM Safety Relief Valve.........................................................................................................................................................5

Type 1900 Safety Relief Valve..................................................................................................................................................................6

Type 19000 Safety Relief Valve................................................................................................................................................................7

Type 1982 Safety Relief Valve..................................................................................................................................................................7

Type 2900 Pilot Operated Safety Relief Valve...................................................................................................................................8

Type 3900 Pilot Operated Safety Relief Valve...................................................................................................................................8

Type 4900 Pilot Operated Safety Relief Valve...................................................................................................................................9

Safety Valves.......................................................................................................................................................................................................10

Safety Valve........................................................................................................................................................11

Type 2700 Safety Valve.............................................................................................................................................................................11

Type 1811 Safety Valve.............................................................................................................................................................................12

Type 1511 Safety Valve.............................................................................................................................................................................12

Type 1541-3, 1543-3 Safety Valve........................................................................................................................................................13

Type 2478 Safety Valve.............................................................................................................................................................................13

Type 1900/P Pilot Operated Safety Relief Valve............................................................................................................................14

Type 2900-40 Pilot Operated Safety Relief Valve..........................................................................................................................14

Ball Valve......................................................................................................................................................15

8613371530291

8613371530291