crosby safety valve catalogue brands

Crosby pressure relief valves have maintained leadership in overpressure protection for over 140 years. The direct spring-operated safety and pressure relief valves are among the world’s most widely used for oil and gas production and refining, petrochemical and chemical processing, and conventional and nuclear power. Crosby pressure relief valves maintain the industry’s most extensive and capable flow facilities for testing in air, steam, and water.

EMERSON. CROSBY H-SERIES DIRECT SPRING SAFETY VALVESDirect spring safety valves that provide comprehensive overpressure protection for ASME Boiler and Pressure Vessel Code Section I, and Section VIII steam safety applicationsFEATURES HCI ISOFLEX" • ASME/NB certified capacities for steam. • Set and tested on steam. • Full nozzle flanged option. • Restricted lift for customized capacity. • Long service life. • Low maintenance. • Two ring set pressure and blowdown control. • ISOFLEX seat tightness up to 93%. For seat tightness greater than 93% consult factory. TECHNICAL DATA GENERAL APPLICATION H-Series direct spring operated safety valves are the proven solution for comprehensive overpressure protection on steam safety applications including economizers, steam drums, superheaters, reheaters and more. Sizes: Orifices: Connections: Temperature range: Set pressures: IVi" F IV2" to 6" RR 10" 0.307 to 19.29 in2 (1.98 to 124.45 cm2) Flanged or welded inlet 1120 °F (604 °C) 15 to 5000 psig (1 to 345 barg) Code: ASME Boiler and Pressure Vessel Code Section I, and Section VIII Emerson.com/FinalControl © 2017 Emerson. All Rights Reserved VCTDS-00595-EN 17/11

Complete overpressure protection for ASME B&PVC Section I A complete safety valve package for utility and industrial steam generators and steam systems. • Boilers with design pressures to 3000 psig (207 barg). • Valves designed to increase plant up-times, extend maintenance intervals and increase total valve life. Steam System Components 7. Boiler feed water pump 8. Cold reheat inlet VALVE SELECTION APPLICATIONS AND RECOMMENDED™ VALVE SELECTION NOTES 1. Selection matrix shows valves in optimum locations - Styles HSJ and HCI may be interchanged to suit a specific application or to obtain a...

STYLE HE ISOFLEX® Style HE ISOFLEX® safety valves are high pressure, high capacity reaction type valves designed specifically for saturated steam service on boiler drums with design pressures above 2000 psig (138 barg) up to critical pressure. FEATURES TECHNICAL DATA • Extends Up-time - ISOFLEX® seat tightness to 93% of set pressure ensures maximum generating times, extending maintenance intervals. For seat tightness greater than 93% consult factory. • Reduces Maintenance Costs - Exceptional seat tightness minimizes maintenance resources and repair times and reduces spare parts purchase and...

PRODUCT OVERVIEW The HE ISOFLEX incorporates our latest field proven seat tightness design which allows boilers to operate close to set pressure without leakage across the valve seat. The HE ISOFLEX also has a unique patented eductor control that permits the valve to attain full capacity lift at a pressure 3% above popping pressure to the requirements of Section I of the ASME Boiler and Pressure Vessel Code. APPLICATION The HE ISOFLEX safety valve is a high pressure, high capacity reaction type valve, designed specifically for saturated steam service on boiler drums having design pressures...

CROSBY H-SERIES STYLE HE ISOFLEX 28 Part name Body Nozzle Nozzle ring Nozzle ring set screw Disc insert Disc holder Disc holder retaining nut Eductor Guide ring Guide ring set screw Spindle assembly Piston Piston retaining ring Spindle nut Bonnet Bonnet studs Bonnet stud nuts Material Carbon steel SA-216 Gr. WCC Stainless steel Stainless steel Stainless steel Inconel® Nickel alloy Stainless steel Nickel alloy Stainless steel Stainless steel Stainless steel Nickel alloy Steel Steel Carbon steel SA-216 Gr. WCC Alloy steel SA-193 Gr. B7 Steel SA-194 Gr. 2H Bottom spring washer Top spring...

2500 psig maximum pressure 1. These style designations are for standard welded inlets. For optional CL 2500 flanged inlet valves, the "W" is dropped from the style designation. 2. Weld prep per customer"s specifications. Safety valves must be mounted on a nozzle with an inlet diameter equal to or greater than the nominal valve inlet size, dimension A. See ASME boiler and pressure vessel code Section I and ANSI/ASME B31.1 for recommended installation. 3. Bolt holes straddle centerline on flanged connections. 4. Dismantling height: an additional 20 inches (508 mm) is required. Drain: main...

1 Increases Operating Efficiency Sizes: - Restricted Lift Option for customized capacity, reduced reaction forces, and boiler design standardization Orifices: - Seat tightness up to 93% of valve set pressure. For seat tightness greater than Connections: 93% consult factory - Two ring control to adjust overpressure and Maximum blowdown independently temperature: - May also be used for ASME Boiler and Maximum Pressure Vessel Code Section VIII off boiler set pressure: steam applications for higher operating Codes: pressures 1 Reduces Maintenance Costs CROSBY H-SERIES STYLE HCI ISOFLEX DIRECT...

CROSBY H-SERIES STYLE HCI ISOFLEX PRODUCT OVERVIEW The HCI ISOFLEX safety valve is a high capacity nozzle type valve suitable for saturated and superheated steam service. The valves are available in inlet sizes of 1½”, 2", 2½”, 3", 4" and 6" and in orifice sizes H2 to RR specifically designed for the power industry. Welded inlets and flanged outlets are standard, with flanged inlets (1) with full (removable) nozzles (2) also available. Blowdown control is precise with two adjustable rings (3 and 12) - one each on the nozzle (1B or 2) and guide (11). Blowdown may be adjusted from 2 to 4%...

Large orifice closed bonnet pressure relief valves. Also available with open bonnet as Styles HS/HSU; and as large orifice pilot operated pressure relief valves. Style JPV-A, for air, gas and steam. Ask for Catalog No. 307. Specifications:

A unique, completely sealed pressure relief valve for transportation and storage of chlorine and other toxic and corrosive fluids. Ask for Catalog No. 306. Specifications:

A sanitary pressure/vacuum pressure relief valve for the beverage, food processing and pharmaceutical industries. This valve provides three modes of self actuated operation:

Non-flowing, snap-acting, pilot operated, pressure relief valves. High performance valves for overpressure protection of pipes and vessels containg gases and vapors. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of gas, vapor, liquid and steam. Mounted on the same main valve used with Style JPV. Ask for Catalog No. 318. Specifications:

Non-flowing, modulating, pilot operated, pressure relief valve. Used for overpressure protection of high temperature fluids including hydrocarbons, inert gases and steam. Ask for Catalog No. 318. Specifications:

Pressure relief valve with single trim for liquid, gas and steam service. Precision lapped flat metal to metal seats or elastomer and TFE O-ring soft seats provide the ultimate in seat tightness. Blowdown is typically less than 20%. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Series 800 pressure relief valves are designed for use on air, gas, vapor and steam service. External precise blowdown control provides shorter blowdown then the Series 900, typically in the range of 5 to 15 percent. Capacities certified by National Board of Boiler and Pressure Vessel Inspectors. Ask for Catalog No. 902. Specifications:

Nozzle type safety valve for saturated and superheated steam service. Seat tightness up to 95% of valve set pressure. Ask for Catalog No. 408. Specifications:

Protect superheaters from overheating during startup, prolong the life and reduce maintenace of safety valves. Ask for Catalog No. 403. Specifications:

We’ve got your back. Let us find the exact part you’re looking for in our 100,000 sq. ft. warehouse stocked with 35,000 ready-to-ship valves from the world’s most renowned brands. We’ll put our decades of experiencing cross-referencing valves to work fast. Just give us a call.

WPC provides customers with total pressure relief management solutions that support a facility’s entire lifecycle, transforming the way you ensure plant safety. Using Emerson comprehensive range of Pressure Safety Valves and WPC Engineering Services team ensures that the design of your pressure relief system is done correctly to respond to every overpressure scenario.

Since 1874, Crosby direct spring operated safety and relief valves have been among the world’s most widely used relief valves for gas, liquid, steam and multi-phase applications in Oil & Gas production, refining, petrochemical and chemical processing systems as well as for utility and industrial steam generators & steam systems in power generation facilities.

In the highly specialized field of pressure relief devices, no manufacturer can match the diversified products and experience of Emerson comprehensive range of Pilot operated Pressure Safety Valves with brands like Anderson Greenwood and Birkett.

With more designs than any other worldwide manufacturer, Anderson Greenwood’s and Birkett"s product technology solves applications from the most severe problem to very basic service conditions. These designs include a high temperature metal seated pilot valve, premium performance spring operated valves, API 526 flanged conventional and balanced bellows valves and an extensive iron and bronze product range.

Pressure and Safety Relief Valves - We offer easy-to-maintain Anderson Greenwood™, Crosby™and Kunkle™ pressure and safety relief valves that prevent process overpressure and ensure downstream equipment protection.

TESCOM™ Regulators, Valves and Systems deliver a wide range of standard and custom engineered precision pressure control solutions of process and specialty gases and liquids across a wide range of applications up to 20,000 psig. You can count on our expert application and customer support ranging from single point solutions to complex projects serving a wide number of industries.Pressure Reducing and Back Pressure Regulators

Crosby™ direct spring pressure relief valves have been among the world’s most widely used and field-proven safety valves for process applications, industrial steam generators and steam boilers. Crosby products are known throughout the industry for solving difficult overpressure protection applications ranging from low pressure through supercritical boiler requirements.

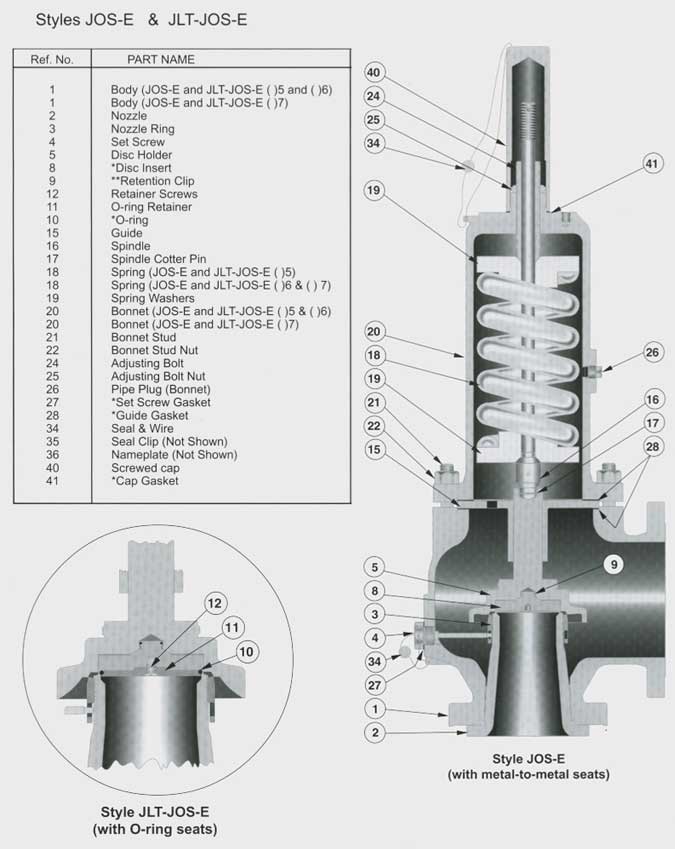

J-Series valves provide high quality and dependable overpressure protection for air, gas, steam, vapor, liquid and two-phase applications in one simple design.

Direct spring safety valves that provide comprehensive overpressure protection for ASME Boiler and Pressure Vessel Code Section I, and Section VIII steam safety applications.

A large orifice pressure relief valve engineered to provide high quality, dependable overpressure protection for air, gas, vapor and steam applications.

Anderson Greenwood™ pressure relief valves are recognized as a worldwide technology leader in pressure management. Compact in design and built to perform in the most demanding environments, their premium performance solutions enable customers to maintain high levels of safety, while also controlling emissions and reducing product loss.

Maximize operating pressure and minimize emissions with the Series 90/9000 pilot operated relief valve; a high performance alternative to weight loaded relief devices.

A modulating pilot operated pressure relief valve for economizer applications that meets the stringent requirements of ASME Section I at high temperatures.

Bronze safety valves to ASME section I and VIII, steam, ‘V’ and ‘UV’; section VIII, air/gas, ‘UV’ National Board certified including models to ASME section IV, steam ‘HV’. PED certified for non-hazardous gas.

Cast iron ASME section I steam and section VIII, air, steam and gas ‘UV’ National Board certified safety valves including model 6254 to ASME section IV ‘HV’, PED certified for non-hazardous gas.

Fike provides certified rupture discs to meet all applications for process industries including isolating pressure relief valves from corrosive materials, reducing involuntary emissions, insuring pressure relief in critical applications, and rupture discs for sanitary/pharmaceutical processes.

A backpressure regulator maintains a desired upstream pressure by varying the flow in response to changes in upstream pressure. A pressure relief valve limits pressure build-up (prevents overpressure) at its location in a pressure system. The relief valve opens to prevent a rise of internal pressure in excess of a specified value. The pressure at which the relief valve begins to open pressure is the relief pressure setting.

Relief valves and backpressure regulators are the same devices. The name is determined by the application. Fisher relief valves are not ASME safety relief valves.

Varec™ tank protection products provide vapor and fugitive emissions control in addition to fire and explosion protection through an integrated line of conservation and emergency vents, flame arrestors, regulators, gauge hatches, manway covers, and floating suction units. With the Varec line of products, in combination with Anderson Greenwood tank products (low-pressure pilot-operated relief valves, blanketing regulators, specialty tank valves) and Whessoe tank products (venting and flame arrestors), Emerson provides a full set of tank protection options.

Enardo tank vents and hatches are designed to control evaporation and emission losses, allow vapors to flow freely, and protect tanks against excessive pressure or vacuum.Pressure/Vacuum Relief ValvesInstalled on storage tanks to control evaporation and emission losses resulting from hazardous vapor-producing products

8613371530291

8613371530291