dead weight safety valve manufacturer

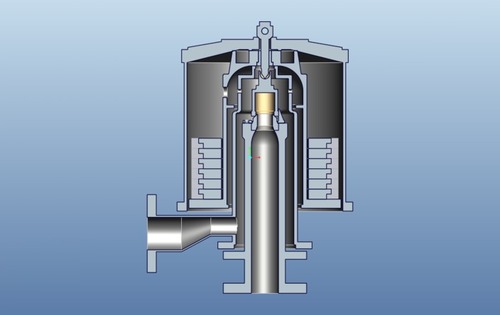

To prevent damage to the tank and help ensure safe operations, the Alfa Laval SB Pressure Relief Valve protects a pressurized tank during an overpressure event. It is designed for hygienic processes in the brewery, dairy, food and beverage industries. The valve can be integrated with a SCANDI BREW® tank top system.

The advantages of an integrated Pressure Relief Valve are lower initial costs, superior hygiene and smaller area required for the valve. The size and setting of the Pressure Relief Valve is based on the tank design data and process requirements.

afety valve consists of a valve seat where the pressure in the boiler or pressure vessel when it exceeds the normal working pressure lifts the valve seat with its weight. The excess pressure fluid therefore escapes through the pipe to the atmosphere, until the pressure reaches its normal value. It is the simplest type of safety valve; it is suitable for stationary boilers and pressure vessels only, because it cannot withstand the jerks and vibration of mobile boilers or pressure vessels. Another disadvantage of this valve is the heavy weight required to balance the pressure. Hence, it is not suitable for high pressure boilers.

With wide and rich industrial experience, we are able to offer the best in class Dead Weight Safety Valves. These valves are used in industrial boilers for safety purpose and ensure safety by releasing excess pressure. Provided valve is highly recognized for high performance, requires less maintenance and smooth operations. Our offered safety valve is made available in number of specifications for our clients to choose from. Our valued clients can avail these Dead Weight Safety Valves from us at market leading price.

Level and Flow Control Engineers manufacturing and exporting Dead Weight Safety Valves which is mainly used in the Power Plants, CPP, Sugar Plants for Low Pressure applications. Brand Name : Beekay-Made in INDIa

If you rate our Dead Weight Safety Valve on attributes such as ergonomics and operational efficiency, you will find it right there at the top of the class. We have used only the highest quality materials and components in manufacturing our Valve assembly, which exhibits in the performance. No denying, we are among the leading manufacturers, exporters and suppliers from Chennai, Tamil Nadu.

Design Standardas per API,ANSI,ASME,DIN,BSLFCE manufacturing and exporting dead weight safety valve and pressure relief valves to the process industry. It low cost and high efficiency valves which can work for slurry and high viscosity fluids.

Out side weight can be moved forward and downward to adjust the set pressure. Pressure 0 to 10 bar and size 25NB to 500NB bigger sizes available on request

TemperatureUpto 300 Deg CWe are the manufacturer, and exporter of Dead Weight Safety Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines, and reactors to control the excess pressures. If the pressure exceeds the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment is in safe.

LFCE manufacturing and exporting dead weight safety valve and pressure relief valves to the process industry. It low cost and high efficiency valves which can work for slurry and high viscosity fluids.

Out side weight can be moved forward and downward to adjust the set pressure. Pressure 0 to 10 bar and size 25NB to 500NB bigger sizes available on request

We are the manufacturer, and exporter of Dead Weight Safety Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines, and reactors to control the excess pressures. If the pressure exceeds the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment is in safe.

Stainless Steel Dead Weight Safety Relief Valve is designed with Counter adjustment facility for use with flash dryers. The Dead Weight Safety Relief Valve is available in the size of 2" X 3". Stainless Steel Dead Weight Safety Relief Valve is manufactured by Diamond Engineering Works.

Diamond Engineering Works also manufactures a wide range of Valves for industrial instrumentation, OEMs and defence services. The Stainless Steel Dead Weight Safety Relief Valve can operate under a set pressure range of 60 Kg/cm2.

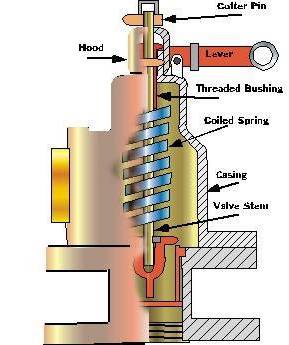

Asafety valveis a device that prevents a system from overpressurizing. It consists of a valve with a spring-loaded mechanism that increases in force when the pressure exceeds a preset limit. It is generally used in compressed air or fluid systems. In some cases, it can prevent overpressure from resulting in system failures. This design of safety valves helps prevent disasters.

Safety valves come in three basic types. These include heavy hammer lever, spring, and pulse valves. The heavy hammer lever type of valve uses a lever or a heavy hammer to balance the force on the valve flap. The principle behind this type of safety valve is called leverage, which means it can use a small weight to exert a large amount of force. This type of safety valve also allows you to adjust the opening pressure.

What are the different types of safety valves available? Here is a quick breakdown. A safety valve can be a spring-loaded valve; a Lever loaded valve, or a dead-weight safety-weight valve. The main differences between these valves are the mechanism by which they work and how they function. Spring-loaded safety valves can be easily adjusted. A lever-loaded safety-weight valve is generally less expensive.

There are several types of safety valves. One of them is a dead-weight safety valve. A dead weight safety valve is a safety valve that relies on a heavy disc that acts as a weight against a valve seat to prevent overpressure. A dead weight safety valve is a good choice for low-pressure vessels. Unlike other safety valves, dead weight safety valves do not have a spring. The weight of the disc acts to adjust the valve seat. When the pressure on the valve exceeds the normal pressure limit, it discharges the excess steam through a pipe.

The core of any safety valve is the spring. It must be durable and conform to all the specified requirements, including temperature and working medium. The spring material must be corrosion-resistant. For moderate temperature applications, carbon steel is used. For higher temperature and corrosive duty applications, tungsten steel or stainless steel is used. If the temperature is extremely high, special materials are used. Whether the safety valve is used in the air or water, it must be certified.

When purchasing a safety valve, you will find that there are several different options. Some safety valves have manual operation options. Typically, the manual operation will be performed during routine safety checks or maintenance. The actual flowing capacity will be reduced by 10%. The derated coefficient of discharge will also be calculated. As with most safety valves, there are several terms and definitions that are not included in the DIN 3320 standard.

Generally, a boiler will be fitted with high steam and low water safety valve. The low water safety valve is a combination of two valves. It operates when the water level in the boiler drops below a predetermined level. When the level drops too low, the lever safety valve operates, blowing with a loud noise. Fig. 5-4 shows how these safety valves work. They are located on the top or side of the boiler and are attached to the fire box or furnace.

Fluidyne manufactured Safety Valves and Safety Relief Valves, Thermal Relief Valves, Boiler Safety Valves, Dead weight Safety and Relief Valves, Pilot operated Safety Relief Valve conform to API, ASME and IBR codes. Fluidyne carried out an extensive market research to design and manufacture durable and effective Safety Valves and Safety Relief Valves that are highly suitable for most chemical, petrochemical, oil, pharmaceutical, fertilizer, power and engineering industries and more. These industrial safety relief valves, flanged safety relief valves, dead weight relief valves, sanitary safety relief valves are high reliability and are approved by factory inspectors, inspectors under Indian Boiler Regulation (IBR), B.V., Lloyds and Chief Controller of Explosives. FLUIDYNE safety and relief valves are in used in above industries for over 35 years. Fluidyne Safety Valves and Safety Relief Valves are Full Lift, "Pop" action type, Full Nozzle or half nozzle having Screwed Butt/Socket weld or Flanged connections. Various Models are available as per requirements of customers. Sizes Range : ¼”(6 NB) to 12” (300 NB). All API standard Orifice sizes are available. Both Angle and Straight (in-line) Patterns are available. Inverted-Bottom spring mounted types available for mounting inside mobile pressure vessels. Connection offered are Screwed, Sanitary or Socket Weld / Butt Weld ends and Flanged ends to 150#, 300#, 600#, 900#, 1500# and 2500# rating. Flanged connections are offered with FF, R/F and RTJ ends to ANSI B16.5, BS, DIN,. Safety Valves and Safety Relief Valves are manufactured from castings and by fabrication from bar stock and all special trims provided as per customer requirements. Fluidyne manufactured Safety Valves and Safety Relief Valves, Thermal Relief Valves, Boiler Safety Valves, Dead weight Safety and Relief Valves, Pilot operated Safety Relief Valve conform to API 520, API 526, API RP 527, ASME SEC VIII DIV I and IBR codes Set pressure and hydro tests as per specification or standard are carried and provided. FLUIDYNE manufactures following types of Safety Valves and Safety Relief Valves :-

These Safety and Relief Valves are Standard models manufactured to API 520, API 526, API RP 527, ASME SEC VIII DIV I and IBR codes having full lift and high capacity and fitted as original equipments on boilers, reactors, pressure vessels and reactors.

Fluidyne range of small bore safety valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves offer superior performance and maximum functionality. They are available in Screwed, Socket weld, Sanitary, Conflat and Flanged Construction type or flanged-inlet, Screwed-outlet connection type. Their simplicity in construction makes them pretty cost effective and easy to use.

Fluidyne Boiler Full Lift Full Flow Safety Relief Valve is a high performance valve designed and developed for steam and water service. It can also be used for most other applications like gases and vapors, saturated steam, superheated steam. Fluidyne Safety Relief Valve is designed for steam service. The valves are designed as per API 520, API 526 and meets the requirements of ASME Sec VIII-Division I. Fluidyne Boiler Safety Valves are offered with IBR Certification in Form III-C. The valves have a full nozzle or half nozzle and guided at the guide of the valve body, increasing the eficiency of the valve assembly. Specially designed disc holder ensures full lift within 5% to 10% overpressure or increase of pressure above the set pressure value. Blow down of a maximum of 5% to 10% is achieved in this design. Lapping of valve seat to optical flatness ensures leak tightness at seat. Full lift of valve disc ensures that the certified flow of the safety valve is discharged. Spring made of chrome vanadium steel is precisely selected and assembled so that the valve operates precisely and a good leak tightness is achieved at high temperatures with great repeatability.

Fluidyne Deadweight Safety valve consists of a valve seat where the pressure in the boiler or pressure vessel when it exceeds the normal working pressure lifts the valve seat with its weight. The excess pressure fluid therefore escapes through the pipe to the atmosphere, until the pressure reaches its normal value. It is the simplest type of safety valve; it is suitable for stationary boilers and pressure vessels only, because it cannot withstand the jerks and vibration of mobile boilers or pressure vessels. Another disadvantage of this valve is the heavy weight required to balance the pressure. Hence, it is not suitable for high pressure boilers.

FLUIDYNE Backpressure Safety Relief or Surplus or Diaphragm Assisted Safety Relief Valve is single seated, diaphragm controlled and spring regulated valve where the pressure of the system being relieved, acting upon the diaphragm provides a sensitive control of the valve opening in accordance with the regulating spring setting. The application or ideal for installations where a direct spring loaded type is too insensitive to pressure or flow changes. The Fluidyne Backpressure Relief Valve Protects systems from overpressure and Monitors pump outputs. Fluidyne Backpressure Relief Valve is most suitable for water, air, gas, steam, oil or chemical services.

Designed for installation on pressurised vessels and storage tanks, FLUIDYNE PIPE AWAY Pressure Relief Valve is designed to protect the vessel or tank from excessive internal pressure.

In the closed position the spring-loaded pallet and diaphragm assembly is held tightly against a seal to prevent the loss of vapour to atmosphere. As the internal pressure in the tank increases, due to product filling and vapour development, the pressure in tank increases and reaching set pressure of the unit, the diaphragm will open and discharge the air, gas or steam to the atmosphere. The opening set-point is selectable from a range between +50 mbar and +1000 mbar (other settings available on request), and the valve will close when the tank returns to a safe pressure.

Several features are inherent in the valve design to ensure a smooth, positive and effective operation. The body is self-draining and drip rings prevent condensate from settling on seating surfaces. A diaphragm and seal manufactured from Teflon reduce the possibility of ice formation and sticky residues hindering the valve from opening, while the pallet assembly moves freely on guideposts. Set pressure can be adjusted by adjusting spring settings.

The integrity of the seal is tested for leakage in accordance with API Standards. The size of the valve shall be calculated in accordance with API Standard, ASME or IBR codes

We LFCE are manufacture and Exporter of BeeKay Pressure Relief Valves globally which is used to release the excess pressure in the tanks and vessels to prevent from explosions.

Our Safety valve, Safety Relief Valve, Dead Weight Safety Valves are most accurate in Set pressure Opening and Re-Setting within 5% to 10% of Accumulation and Blow Down.

We are the manufacturer, supplier and exporter of Breather Valves from Chennai-India to Globally are extensively used for automatic venting and for conservation of losses due to evaporation. Breather valves minimizes the risk of fire, explosion and collapsing of tank by relieving automatically the dangerous pressure and vacuum occurring in the tank due to any reason. Products are mainly used in the low pressure tanks and vessels.

We are the manufacturer, supplier and exporter of Pressure Relief Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines and reactors to control the excess pressures. If the pressure is exceed the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

We are the manufacturer, supplier and exporter of Safety Valves from Chennai-India to Globally. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of Gauge Glass Valves from Chennai-India to Globally and cocks for the sake of market demands. Gauge glass valves are widely used across the industries because it is a convenient tool to visually monitor the liquid level in tanks. Its rigid construction produces corrosion resistance and its compact design permits it to be safely located close to the tank. Our skilled workforce is capable enough to customize as per client"s requirements.

We are the manufacturer, supplier and exporter of SafetyRelief Valvefrom Chennai-India to Globally are spring loaded-right angled which are used in the pressure vessels, pipelines, and reactors to control the excess pressures. If the pressure exceeds the set point then the safety and relief valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

We are the manufacturer, supplier and exporter of Tank Breather Valve. Spring Loaded-right angled safety valves & safety relief valves in Chennai and India. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of Vacuum Relief Valve from Chennai-India to Globally. Clients in a wide range of spring loaded-right angled safety valves & safety relief valves. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of SafetyRelief Valves from Chennai-India to Globally are spring loaded-right angled which are used in the pressure vessels, pipelines, and reactors to control the excess pressures. If the pressure exceeds the set point then the safety and relief valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

We are manufacturer and exporter of Pressure Relief Valve, Safety Valves, Pressure cum Vaccum Relief Valves, Vaccum Relief Valves. Our range of Products are mainly exported to Europe and South Asian Countries and Gulf Countries. Pressure Relief Valve is mainly used in the Pressure Vessels, Boilers, Pipelines, and Other Big Storage Tanks. If the Pressure is exceed the limit. Valve automatically open and reset for the related pressure.

We are the manufacturer, supplier and exporter of Pressure Relief Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines and reactors to control the excess pressures. If the pressure is exceed the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

LEVEL AND FLOW CONTROL ENGINEERS manufacturing and Exporting Safety Relief Valve under the Brand name of BEEKAY - Made in INDIA which is well know in the process industry. Safety Relief Valves are used in the Pipe lines, Pumps, Compressor, Boiler, Tanks, Reactors.

LFCE manufacturing, supplying and exporting Dead Weight Safety Valve and Safety Relief Valves under brand name BEEKAY. Dead weight safety valve is most suitable for Low Pressures and slurry, high viscosity applications. Set Pressures are adjustable very easy by moving weight front and back.

Level and Flow Control Engineers Manufacturing Dead Weight Safety Valve and Safety Relief Valves as per API standards which is meant for Low Pressure applications. Cost effective and easy pressure adjustments without opening of the valve. Weight will be adjusted thro the Lever.

LEVEL AND FLOW manufacturing and exporting Air Valves are designed to withstand vibrations, therefore it is unaffected by any external vibrations. Valve finds application of automatic venting of air in large size water distribution pipes (e.g. distribution manifolds in the central system) and in all cases where it is necessary to eliminate large quantities of air from the system. Valve opening and closing is determined by the float movement (up-down). When there is air in the Pipeline (or) in the Capital Equipments, the force of the float weight acts on the lever which is integral with the plug, thus causing it to move down. In such situation the seat is free and allows the air to be vented outside. Due to this the Pipeline or the capital equipment is safe without any airlocks.

We are the manufacturer, supplier and exporter of Direct mechanical lever operated Ball Float Valves from Chennai-India to Globally, single or double ported in C.I.,C.S., and SS, non metallic constructions operating mechanism is specially designed to be mounted on all types of tank equipment and serves the purpose of a liquid level controlling. Automatic filling and maintaining is done at the said levels.

Clients in a wide range of spring loaded-right angled safety valves & safety relief valves. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of Ball Float Valve in Chennai-India to Globally is a cost effective level control device for water or non hazardous liquids. The ball float valves may be mounted inside the tank.

We are the manufacturer, and exporter of Dead Weight Safety Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines and reactors to control the excess pressures. If the pressure is exceed the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe. We are majorly looking inquiries from Dubai, Abu Dhabi, Sharjah, UAE, Kuwait, Oman, Qatar, Egypt, Thailand, Indonesia, Singapore, Malaysia, Myanmar, Vietnam, Brunei, Australia, Europe, Italy, Belgium.

8613371530291

8613371530291