dead weight safety valve supplier

To prevent damage to the tank and help ensure safe operations, the Alfa Laval SB Pressure Relief Valve protects a pressurized tank during an overpressure event. It is designed for hygienic processes in the brewery, dairy, food and beverage industries. The valve can be integrated with a SCANDI BREW® tank top system.

The advantages of an integrated Pressure Relief Valve are lower initial costs, superior hygiene and smaller area required for the valve. The size and setting of the Pressure Relief Valve is based on the tank design data and process requirements.

With wide and rich industrial experience, we are able to offer the best in class Dead Weight Safety Valves. These valves are used in industrial boilers for safety purpose and ensure safety by releasing excess pressure. Provided valve is highly recognized for high performance, requires less maintenance and smooth operations. Our offered safety valve is made available in number of specifications for our clients to choose from. Our valued clients can avail these Dead Weight Safety Valves from us at market leading price.

Level and Flow Control Engineers manufacturing and exporting Dead Weight Safety Valves which is mainly used in the Power Plants, CPP, Sugar Plants for Low Pressure applications. Brand Name : Beekay-Made in INDIa

If you rate our Dead Weight Safety Valve on attributes such as ergonomics and operational efficiency, you will find it right there at the top of the class. We have used only the highest quality materials and components in manufacturing our Valve assembly, which exhibits in the performance. No denying, we are among the leading manufacturers, exporters and suppliers from Chennai, Tamil Nadu.

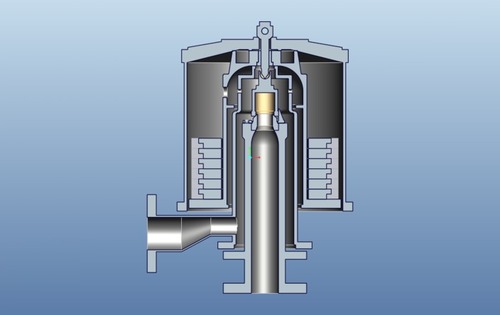

afety valve consists of a valve seat where the pressure in the boiler or pressure vessel when it exceeds the normal working pressure lifts the valve seat with its weight. The excess pressure fluid therefore escapes through the pipe to the atmosphere, until the pressure reaches its normal value. It is the simplest type of safety valve; it is suitable for stationary boilers and pressure vessels only, because it cannot withstand the jerks and vibration of mobile boilers or pressure vessels. Another disadvantage of this valve is the heavy weight required to balance the pressure. Hence, it is not suitable for high pressure boilers.

Design Standardas per API,ANSI,ASME,DIN,BSLFCE manufacturing and exporting dead weight safety valve and pressure relief valves to the process industry. It low cost and high efficiency valves which can work for slurry and high viscosity fluids.

Out side weight can be moved forward and downward to adjust the set pressure. Pressure 0 to 10 bar and size 25NB to 500NB bigger sizes available on request

TemperatureUpto 300 Deg CWe are the manufacturer, and exporter of Dead Weight Safety Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines, and reactors to control the excess pressures. If the pressure exceeds the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment is in safe.

Stainless Steel Dead Weight Safety Relief Valve is designed with Counter adjustment facility for use with flash dryers. The Dead Weight Safety Relief Valve is available in the size of 2" X 3". Stainless Steel Dead Weight Safety Relief Valve is manufactured by Diamond Engineering Works.

Diamond Engineering Works also manufactures a wide range of Valves for industrial instrumentation, OEMs and defence services. The Stainless Steel Dead Weight Safety Relief Valve can operate under a set pressure range of 60 Kg/cm2.

We are leading manufacturers, suppliers & exporters of Dead weight Safety Valve - Heat Transfer Training Systems and Heat Lab Engine Trainers for engineering schools. Contact us to get high quality designed Dead weight Safety Valve - Heat Transfer Training Systems and Heat Lab Engine Trainers for engineering schools and Lab Education & Training Products for schools, colleges, TVET, universities, training laboratory, research lab, hospital and medical lab and various Industrial Laboratory Training Program. We accept bulk orders for government tenders in all countries around the globe.

Pressure relief valves (safety relief valves) are designed to open at a preset pressure and discharge fluid until pressure drops to acceptable levels. The development of the safety relief valve has an interesting history.

Denis Papin is credited by many sources as the originator of the first pressure relief valve (circa 1679) to prevent overpressure of his steam powered “digester”. His pressure relief design consisted of a weight suspended on a lever arm. When the force of the steam pressure acting on the valve exceeded the force of the weight acting through the lever arm the valve opened. Designs requiring a higher relief pressure setting required a longer lever arm and/or larger weights. This simple system worked however more space was needed and it coud be easily tampered with leading to a possible overpressure and explosion. Another disadvantage was premature opening of the valve if the device was subjected to bouncing movement.

Direct-acting deadweight pressure relief valves: Later to avoid the disadvantages of the lever arrangement, direct-acting deadweight pressure relief valves were installed on early steam locomotives. In this design, weights were applied directly to the top of the valve mechanism. To keep the size of the weights in a reasonable range, the valve size was often undersized resulting in a smaller vent opening than required. Often an explosion would occur as the steam pressure rose faster than the vent could release excess pressure. Bouncing movements also prematurely released pressure.

Direct acting spring valves: Timothy Hackworth is believed to be the first to use direct acting spring valves (circa 1828) on his locomotive engine called the Royal George. Timothy utilized an accordion arrangement of leaf springs, which would later be replaced with coil springs, to apply force to the valve. The spring force could be fine tuned by adjusting the nuts retaining the leaf springs.

Refinements to the direct acting spring relief valve design continued in subsequent years in response to the widespread use of steam boilers to provide heat and to power locomotives, river boats, and pumps. Steam boilers are less common today but the safety relief valve continues to be a critical component, in systems with pressure vessels, to protect against damage or catastrophic failure.

Each application has its own unique requirements but before we get into the selection process, let’s have a look at the operating principles of a typical direct acting pressure relief valve.

In operation, the pressure relief valve remains normally closed until pressures upstream reaches the desired set pressure. The valve will crack open when the set pressure is reached, and continue to open further, allowing more flow as over pressure increases. When upstream pressure falls a few psi below the set pressure, the valve will close again.

Most commonly, pressure relief valves employ a spring loaded “poppet” valve as a valve element. The poppet includes an elastomeric seal or, in some high pressure designs a thermoplastic seal, which is configured to make a seal on a valve seat. In operation, the spring and upstream pressure apply opposing forces on the valve. When the force of the upstream pressure exerts a greater force than the spring force, then the poppet moves away from the valve seat which allows fluid to pass through the outlet port. As the upstream pressure drops below the set point the valve then closes.

Piston style designs are often used when higher relief pressures are required, when ruggedness is a concern or when the relief pressure does not have to be held to a tight tolerance. Piston designs tend to be more sluggish, compared to diaphragm designs due to friction from the piston seal. In low pressure applications, or when high accuracy is required, the diaphragm style is preferred. Diaphragm relief valves employ a thin disc shaped element which is used to sense pressure changes. They are usually made of an elastomer, however, thin convoluted metal is used in special applications. Diaphragms essentially eliminate the friction inherent with piston style designs. Additionally, for a particular relief valve size, it is often possible to provide a greater sensing area with a diaphragm design than would be feasible with a piston style design.

The reference force element is usually a mechanical spring. This spring exerts a force on the sensing element and acts to close the valve. Many pressure relief valves are designed with an adjustment which allows the user to adjust the relief pressure set-point by changing the force exerted by the reference spring.

The chemical properties of the fluid should be considered before determining the best materials for your application. Each fluid will have its own unique characteristics so care must be taken to select the appropriate body and seal materials that will come in contact with the fluid. The parts of the pressure relief valve in contact with the fluid are known as the “wetted” components. If the fluid is flammable or hazardous in nature the pressure relief valve must be capable of discharging it safely.

In many high technology applications space is limited and weight is a factor. Some manufactures specialize in miniature components and should be consulted. Material selection, particularly the relief valve body components, will impact weight. Also carefully consider the port (thread) sizes, adjustment styles, and mounting options as these will influence size and weight.

In many high technology applications space is limited and weight is a factor. Some manufactures specialize in miniature components and should be consulted. Material selection, particularly the relief valve body components, will impact weight. Also carefully consider the port (thread) sizes, adjustment styles, and mounting options as these will influence size and weight.

A wide range of materials are available to handle various fluids and operating environments. Common pressure relief valve component materials include brass, plastic, and aluminum. Various grades of stainless steel (such as 303, 304, and 316) are available too. Springs used inside the relief valve are typically made of music wire (carbon steel) or stainless steel.

Brass is suited to most common applications and is usually economical. Aluminum is often specified when weight is a consideration. Plastic is considered when low cost is of primarily concern or a throw away item is required. Stainless Steels are often chosen for use with corrosive fluids, when cleanliness of the fluid is a consideration or when the operating temperatures will be high.

The materials selected for the pressure relief valve not only need to be compatible with the fluid but also must be able to function properly at the expected operating temperature. The primary concern is whether or not the elastomer chosen will function properly throughout the expected temperature range. Additionally, the operating temperature may affect flow capacity and/or the spring rate in extreme applications.

Beswick Engineering manufactures four styles of pressure relief valves to best suit your application. The RVD and RVD8 are diaphragm based pressure relief valves which are suited to lower relief pressures. The RV2 and BPR valves are piston based designs.

We LFCE are manufacture and Exporter of BeeKay Pressure Relief Valves globally which is used to release the excess pressure in the tanks and vessels to prevent from explosions.

Our Safety valve, Safety Relief Valve, Dead Weight Safety Valves are most accurate in Set pressure Opening and Re-Setting within 5% to 10% of Accumulation and Blow Down.

We are the manufacturer, supplier and exporter of Breather Valves from Chennai-India to Globally are extensively used for automatic venting and for conservation of losses due to evaporation. Breather valves minimizes the risk of fire, explosion and collapsing of tank by relieving automatically the dangerous pressure and vacuum occurring in the tank due to any reason. Products are mainly used in the low pressure tanks and vessels.

We are the manufacturer, supplier and exporter of Pressure Relief Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines and reactors to control the excess pressures. If the pressure is exceed the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

We are the manufacturer, supplier and exporter of Safety Valves from Chennai-India to Globally. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of Gauge Glass Valves from Chennai-India to Globally and cocks for the sake of market demands. Gauge glass valves are widely used across the industries because it is a convenient tool to visually monitor the liquid level in tanks. Its rigid construction produces corrosion resistance and its compact design permits it to be safely located close to the tank. Our skilled workforce is capable enough to customize as per client"s requirements.

We are the manufacturer, supplier and exporter of SafetyRelief Valvefrom Chennai-India to Globally are spring loaded-right angled which are used in the pressure vessels, pipelines, and reactors to control the excess pressures. If the pressure exceeds the set point then the safety and relief valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

We are the manufacturer, supplier and exporter of Tank Breather Valve. Spring Loaded-right angled safety valves & safety relief valves in Chennai and India. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of Vacuum Relief Valve from Chennai-India to Globally. Clients in a wide range of spring loaded-right angled safety valves & safety relief valves. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of SafetyRelief Valves from Chennai-India to Globally are spring loaded-right angled which are used in the pressure vessels, pipelines, and reactors to control the excess pressures. If the pressure exceeds the set point then the safety and relief valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

We are manufacturer and exporter of Pressure Relief Valve, Safety Valves, Pressure cum Vaccum Relief Valves, Vaccum Relief Valves. Our range of Products are mainly exported to Europe and South Asian Countries and Gulf Countries. Pressure Relief Valve is mainly used in the Pressure Vessels, Boilers, Pipelines, and Other Big Storage Tanks. If the Pressure is exceed the limit. Valve automatically open and reset for the related pressure.

We are the manufacturer, supplier and exporter of Pressure Relief Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines and reactors to control the excess pressures. If the pressure is exceed the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe.

LEVEL AND FLOW CONTROL ENGINEERS manufacturing and Exporting Safety Relief Valve under the Brand name of BEEKAY - Made in INDIA which is well know in the process industry. Safety Relief Valves are used in the Pipe lines, Pumps, Compressor, Boiler, Tanks, Reactors.

LFCE manufacturing, supplying and exporting Dead Weight Safety Valve and Safety Relief Valves under brand name BEEKAY. Dead weight safety valve is most suitable for Low Pressures and slurry, high viscosity applications. Set Pressures are adjustable very easy by moving weight front and back.

Level and Flow Control Engineers Manufacturing Dead Weight Safety Valve and Safety Relief Valves as per API standards which is meant for Low Pressure applications. Cost effective and easy pressure adjustments without opening of the valve. Weight will be adjusted thro the Lever.

LEVEL AND FLOW manufacturing and exporting Air Valves are designed to withstand vibrations, therefore it is unaffected by any external vibrations. Valve finds application of automatic venting of air in large size water distribution pipes (e.g. distribution manifolds in the central system) and in all cases where it is necessary to eliminate large quantities of air from the system. Valve opening and closing is determined by the float movement (up-down). When there is air in the Pipeline (or) in the Capital Equipments, the force of the float weight acts on the lever which is integral with the plug, thus causing it to move down. In such situation the seat is free and allows the air to be vented outside. Due to this the Pipeline or the capital equipment is safe without any airlocks.

We are the manufacturer, supplier and exporter of Direct mechanical lever operated Ball Float Valves from Chennai-India to Globally, single or double ported in C.I.,C.S., and SS, non metallic constructions operating mechanism is specially designed to be mounted on all types of tank equipment and serves the purpose of a liquid level controlling. Automatic filling and maintaining is done at the said levels.

Clients in a wide range of spring loaded-right angled safety valves & safety relief valves. Used for controlling excess pressures, their precision construction standards make them extensively used in equipment like pressure vessels, pipelines & reactors.

We are the manufacturer, supplier and exporter of Ball Float Valve in Chennai-India to Globally is a cost effective level control device for water or non hazardous liquids. The ball float valves may be mounted inside the tank.

We are the manufacturer, and exporter of Dead Weight Safety Valves from Chennai-India to Globally are spring loaded right angled which are used in the pressure vessels, pipelines and reactors to control the excess pressures. If the pressure is exceed the set point then the valves can open and close automatically as per the pre-settled pressure ratios. Hence the capital equipment are in safe. We are majorly looking inquiries from Dubai, Abu Dhabi, Sharjah, UAE, Kuwait, Oman, Qatar, Egypt, Thailand, Indonesia, Singapore, Malaysia, Myanmar, Vietnam, Brunei, Australia, Europe, Italy, Belgium.

8613371530291

8613371530291