downhole safety valve supplier

Our downhole safety valves provide your testing operations with fail-safe sustained control downhole in the event of an emergency or to facilitate test procedures.

Surface-controlled subsurface safety valves (SCSSVs) are critical components of well completions, preventing uncontrolled flow in the case of catastrophic damage to wellhead equipment. Fail-safe closure must be certain to ensure proper security of the well. However, this is not the only function in which it must be reliable—the valve must remain open to produce the well. Schlumberger surface controlled subsurface safety valves exceed all ISO 10432 and API Spec 14A requirements for pressure integrity, leakage acceptance criteria, and slam closure.

Through decades of innovation and experience, Schlumberger safety valve flapper systems are proven robust and reliable. The multizone dynamic seal technology for hydraulic actuation of subsurface safety valves is a further improvement in reliability performance when compared with traditional seal systems in the industry.

The multizone seal technology is currently available in the GeoGuard high-performance deepwater safety valves, which is validated to API Spec 14A V1 and V1-H.

Designed to provide protection from well-control events, Superior surface-controlled subsurface safety valves are built and tested to the highest API standards. Our field-proven line will allow you to quickly close a well when needed, protecting assets and people. Available in sizes from 2-3/8” to 7”, our retrievable safety valves are designed for setting depths of up to 3,000 feet and pressures of up to 10,000 psi.

Halliburton provides proven, high-performance tubing-retrievable and wireline-retrievable subsurface safety valves (SSSV) designed to reliably shut-in (fail safe) if a catastrophic event occurs, allowing operators to maintain safe operations.

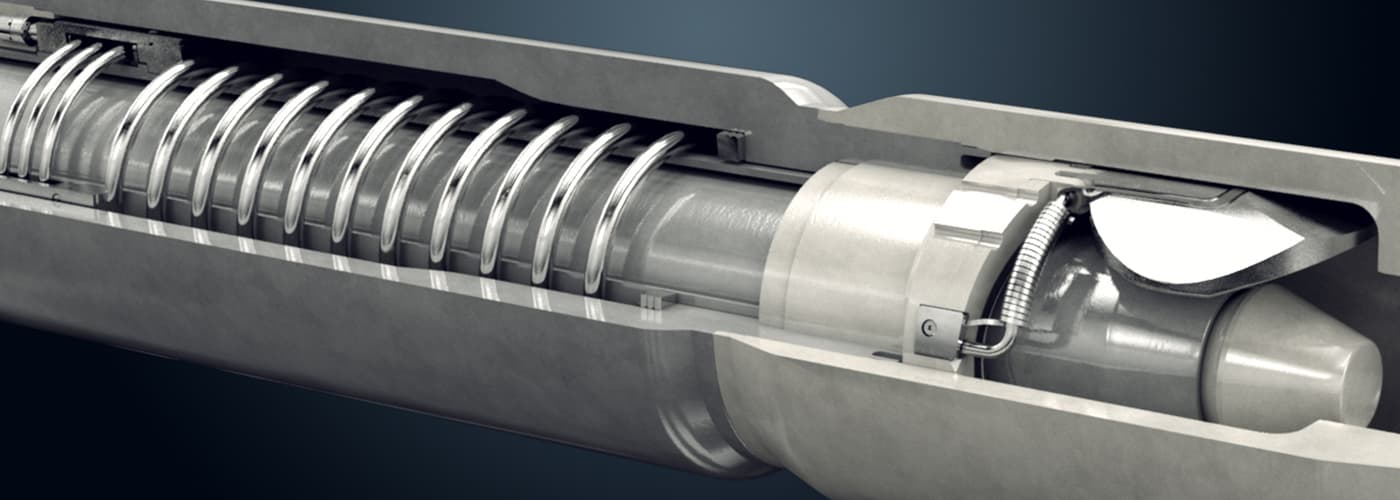

We design, test and manufacture downhole safety valves that are tubing run and surface controlled, as well as wireline run. Our range of tubing retrievable surface controlled subsurface safety valves suits 2-3/8” to 7” tubing sizes, in both standard and slim designs. It is a compact design using a concentric piston mechanism and a flapper system. Minimum metal-to-metal body connections are used to eliminate potential leak paths. All our valves include a nickel alloy flapper/flapper seat to ensure long term reliability of the valves in protecting surface facilities from uncontrolled flow from producing wells.

All our safety valves come with an exercise and lock-out facility. With a landing nipple profile in the top sub a wireline retrievable safety valve can be installed within the tubing run valve bore after lock-out allowing the well to continue to produce.

A full range of accessories is available for the downhole safety valves including exercise/lock-out tools, separation sleeves and nipple protection sleeves.

Baker Hughes’s portfolio of subsurface safety valves deliver reliable performance when it matters the most, providing emergency closure in the event that well control is lost. We offer a full range of valves to suit applications ranging from shallow- to deep-set, and the valves are available in surface- and subsurface-controlled, tubing-retrievable, and wireline-retrievable options. All Baker Hughes valves undergo stringent prototype testing and conform to standards and specifications such as API and ISO, as well as requirements requested for your unique situation.

(271).jpg)

Maintaining fluid control and well protection is critical in your shallow depth well operations. The SelecT™ subsurface safety valve from Baker Hughes addresses the unique challenges that shallow set safety valves (typically <1,000 ft) endure.

The tubing-retrievable SelecT valve includes an ultra-strong power spring that delivers the high closing forces needed to reliably and consistently close the valve in the presence of paraffin and other produced solids.

The SelecT is engineered to avoid failures due to wireline damage during downhole interventions. The valve’s advanced flapper design prevents damage and ensures that all seal surfaces are protected from wireline contact—even during accidental closure of the valve during wireline operations.

Ensure greater seal integrity with the SelecT valve’s patented advances that include thru-the-flapper self-equalizing system. And the radial punch control fluid communication system eliminates accidental communication associated with linear shifting sleeves.

The Camco* type T-4 Slickline Retrievable Safety Valve operates on the ambient pressure principle. The T-4 valve closes when the tubing pressure at the valve drops below a preset closing pressure threshold. To facilitate deeper operating pressure settings or higher production pressures, a gas charged chamber is used to offset tubing pressure.

The T-4 Safety Valve utilizes a unique ball and seat design as the primary closure mechanism and offers a large flow area to handle high producing rates with minimum production pressure losses through the valve.

Using the proper lock adapter the T-4 safety valve will attach to most manufacturers’ locking mandrel and is installed in the well with standard slickline methods. These devices can be located and locked within a landing nipple in the production tubing string. If the T-4 safety valve is to be used in tubing string without a landing nipple the valve must be attached to a collar lock and tubing pack-off, or a slip-lock.

The Camco* type A-1 Injection Safety Valve is designed to prevent wells from flowing back or blowing out in the event of an emergency. The A-1 will open at preset injection flow rates†, have unlimited setting depth and, are suitable for severely corrosive environments. These valves are available to 10,000-psi [68,950-kPa] working pressure.

The Camco* type A Series Subsurface Velocity Safety Valve is designed to prevent wells from overproducing or blowing out in the event of an emergency. The A-3 is differential pressure-operated and set to close at a predetermined rate of flow. The A-3 can be adjusted to close at different flow rates by changing the spring, using spring spacers, and/or varying the inside diameter of the valve’s replaceable flow tube choke bean†.

The Camco* type B-Series Wireline Retrievable Surface Controlled Subsurface Safety Valve is manufactured in compliance with API 14A and may be monogrammed upon request. Materials of construction are NACE approved and may be specified to any customer requirements. The B-Series SCSSV features a large, straight-through bore for minimum restriction and a concentric piston actuation system for long-term, reliable performance.

Starpetrotech Type Tubing Retrievable Safety Valves are self-equalizing, flapper type safety valves designed to shut in a well at a point below the surface. The safety valve is a surface controlled subsurface safety valve and is normally closed. The valve is held open by hydraulic control pressure and remains open until the control-line pressure is exhausted. The hydraulic control pressure is transmitted from a remote location through a control line to operate the valve. The valves are value engineered to provide long-lasting, safe, and reliable operation.

Rod Piston Safety Valves are designed and built for performance and reliability. The rugged hydraulic actuator of the safety valve provides durability and isolates the internal workings from well fluids through its unique construction. The metal-to-metal sealing integrity in the body joints and closure mechanism places it in a premium valve category while featuring an economical price. The simple, compact design enhances the valve’s overall reliability and provides for trouble-free operation. Rod piston safety valves are available with working pressure rating to 10,000psi.

Single Rod Piston Safety Valves are used a single rod piston with reliable spring-energized, no-elastomer dynamic seals; a static, full-closed, metal to metal seal. The valves are designed for general production with enhanced reliability and long life. The valves provide reduced OD, premium piston system, deep set design and many other optional features. Single Rod piston safety valves are available with working pressure rating to 10000psi and always be used in the wells with extreme downhole conditions.

Subsurface Safety Valve TRSSSV is a kind of tubing retrievable safety valve which is controlled at the surface. It directly connects to the tubing string. There is a hydraulic control line connecting to the safety valve from the ground. While a certain amount of pressure is supplied through this control line to the safety valve, the valve remains open; while the pressure is released, the safety valve will close and the tubing pass is closed at the same time.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale subsurface safety valve on Alibaba.com. When you search for subsurface safety valve and related items, you will be able to find many types of subsurface safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of subsurface safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

DHSV is an abbreviation for “Downhole Safety Valve”. DHSVs are considered as one of the important and critical objects during the completion process of a well as these are fail-safe devices that act immediately to prevent an uncontrolled hydrocarbon fluid release that causes an immediate surge in the pressure inside the wellbore and creates a situation of blowout.

DHSVs can move only in one direction i.e. either close or open position. When these valves are closed they completely isolate the reservoir fluids from the surface. These valves are hydraulically operated from the control panel located at the surface. When hydraulic pressure is applied down a control line, the hydraulic pressure forces a sleeve within the valve to slide downwards. Because of this hydraulic pressure, the flapper of the valve is compressed downwards thereby opening the valve. When the hydraulic pressure is released, the spring pushes the sleeve back and causes the flapper to shut.

The downhole safety valves are surface controlled sub surface safety valves abbreviated as (SCSSV or SVSSVs). There are two basic types of SCSSV: Wireline Retrievable surface controlled sub surface safety valves (WR – SCSSV) and

PLUSCO 621-622 Safety Valve Sealant will improve the overall performance of the safety valve by insuring a continuous seal for extended operation. It eliminates line leaks, improves the hydraulic pump performance, maintains tighter seals and valve seating and reduces fluid friction in the system. The benefits of sealing, lubricity and operations efficiency are provided by PLUSCO 621-622 Safety Valve Sealant. Safety Valve Sealant will insure a continuous flow of the gas well without interruption or unnecessary shutdown.PLUSCO 621-622 Safety Valve Sealant is available in two grades depending on the severity of the leak in the system.

PLUSCO 621-622 Safety Valve Sealant is a high tech safety valve additive specifically designed for sealing hydraulic controlled surface or subsurface safety valves.PLUSCO 621 is designed for slow weeping leaks while PLUSCO 622 is for heavy pinhole type leaks.

The TSS series subsurface safety valves are tubing retrievable surface controlled subsurface safety valves. Compared with the TS series, the safety valve features super slim outer diameter design. The control line connects the valve to the surface, and the pressurization from surface on the control line controls the opening and closing of the flapper. This series of products includes self-equalizing and non-equalizing types.

8613371530291

8613371530291