evt safety valve testing made in china

The Electronic Valve Tester, (EVT), is a digital computerized, hydraulic assisted device, designed to test and set safety/relief valves while in service. The EVT is portable and can be used under normal operating conditions without over pressuring the system.

Our Factory and National Board certified technicians, provide total safety/relief valve evaluation utilizing EVT technologies... at your convenience. The Electronic Valve Tester has been approved by the ASME for set point evaluation and or adjustment.

EVT service eliminates the need to overpressure the system for testing. Under normal operating conditions, we save test medium and unnecessary stress on the overall system.

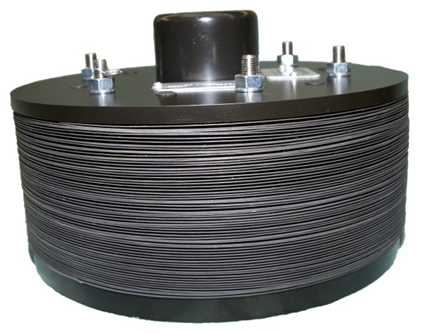

Explosion relief valves are reusable, flameless venting device, which are made for the protection of personnel and equipment in case of gas or oil-mist explosions. In the event of an explosion, the valve plate lifts up and relieves the overpressure through the integrated flame arrester, allowing pressure relief while stopping flame transmission. Immediately after the pressure event, the valve plate closes, allowing continual process operation.

VTB is the Chinese lead Valve Test Bench Manufacturer in Designing, Engineering and manufacturing of valve testing system. Since 2001 VTB have been supplying valve test bench throughout the valve industry to Petrochemical, Refining, Oil, Gas, Nuclear Power, Automotive and Diesel Engine industries, Governments and Government Contractors, Valve Manufacturing Companies, Valve Repair Companies and a host of related industries. We are proud for delivering quality test equipments that have performed stable and safely for years in the field.

We specialized in hydrostatic and pneumatic testing for valves. We offer a complete line of valve testing systems and services to satisfy custom testing requirements. Our systems can exceed API-598, API-576, API-527, API-6D, ASME B16.34, MSS & ISA standards. The main parts of test bench has high quality. Water passage pipes use 304SS material. Using pressure regulating valve, it can supply low, medium & high air pressure for valve testing. Hydraulic valve test bench has unique structure and hydraulic clamp system. The clamp force can be regulation.Test medium water, air or nitrogen for optional. We also have servo system “ Touch screen & PLC “ intelligent control system and “ safety door “ for optional.

Our hydraulic valve test bench with the international similar products quality, and with competitive price. Hydraulic valve test bench used by many enduser in china and abroad. We carefully nurtured talents and increase investment of technical research & develpoment and make every effort to provide all kinds of advanced technology, high quality valve test equipment and satifsactory service for our valve industry.

Control Valve Testing is the best way to make sure your current system is performing to an optimal standard. If you’re curious about where your valves are falling short or how you can improve their performance, Pioneer has the solution to get your safety relief valves where they need to be. At Pioneer, we provide specialized equipment to help your pressure relief valves adhere to required standards and certifications. The EVT-Pro from GE offers cutting-edge testing, diagnostics, and reporting for your valves for comprehensive evaluation. The EVT-Pro works for all brands of pressure relief valves.

Valve test benches can be used for various applications like intermediate and final inspections by valve manufacturers, testing new valves upon delivery, and routine or post-repair testing of in-service valves. These consist of pressure tests of valve housings, leakage tests of the valve seats, and testing of the set pressure of safety valves, for example.

Other components can be subjected to pressure testing as well like tanks, motor housings, pump housings, pipe fittings, insulators, etc. Special clamping arrangements may be required to clamp these test pieces.

An EFCO valve test bench consists of a clamping unit and a control panel for operation, measurement, and control. The test piece is held securely by the clamping device and sealed on the inlet and outlet for the test. Clamping forces up to 1500t can be implemented (on request, even higher).

The operating/measuring/control console is used for the filling of the valve, building up of test pressure, controlling the clamping unit, and measuring of test pressure.

The Valve Repair Technician will be skilled and understand the purpose and principles of operating pressure relief and/or control valves. In this role, you will be responsible for installation, connection, servicing, testing, adjustment, repair, maintenance, removal, trouble shooting, inspection and replacement of safety and relief valves.

The Repair Technician will be skilled and understand the purpose and principles of operating pressure relief and/or control valves. In this role, you will be responsible for installation, connection, servicing, testing, adjustment, repair, maintenance, removal, trouble shooting, inspection and replacement of safety and relief valves.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

8613371530291

8613371530291