evt safety valve testing for sale

The Electronic Valve Tester, (EVT), is a digital computerized, hydraulic assisted device, designed to test and set safety/relief valves while in service. The EVT is portable and can be used under normal operating conditions without over pressuring the system.

Our Factory and National Board certified technicians, provide total safety/relief valve evaluation utilizing EVT technologies... at your convenience. The Electronic Valve Tester has been approved by the ASME for set point evaluation and or adjustment.

EVT service eliminates the need to overpressure the system for testing. Under normal operating conditions, we save test medium and unnecessary stress on the overall system.

BHGE’s EVT-PRO true in-place valve testing enables you to meet local safety requirements for periodic testing and documentation without shutting down processes or dismantling or removing valves from service. You get the true “hot set pressure” of the valve, since it is tested under actual operating conditions. The EVT-PRO device simultaneously examines two critical variables of the relief device—the upward force applied to the spindle and the actual system pressure. Using sophisticated sensors, including an acoustic device, EVT-PRO testing accurately determines the pressure relief valve’s set pressure. It can also immediately sense and automatically close a relief device should it remain open during a test—a unique safety feature built into the software and hardware.

Along with its rugged yet lightweight test fixture, EVT-PRO has state-ofthe-art electronics and proprietary software, including an interface to ValvKeep valve maintenance and management software. You can view test results in both tabular form and colorful graphs that depict the exact set pressure, and historical data and tests are readily available 24/7 with ValvKeep software’s database capabilities.

The Electronic Valve Tester, (EVT), is a digital computerized, hydraulic assisted device, designed to test and set safety/relief valves while in service. The EVT is portable and can be used under normal operating conditions without over pressuring the system.

Our Factory and National Board certified technicians, provide total safety/relief valve evaluation utilizing EVT technologies... at your convenience. The Electronic Valve Tester has been approved by the ASME for set point evaluation and or adjustment.

EVT service eliminates the need to overpressure the system for testing. Under normal operating conditions, we save test medium and unnecessary stress on the overall system.

Control Valve Testing is the best way to make sure your current system is performing to an optimal standard. If you’re curious about where your valves are falling short or how you can improve their performance, Pioneer has the solution to get your safety relief valves where they need to be. At Pioneer, we provide specialized equipment to help your pressure relief valves adhere to required standards and certifications. The EVT-Pro from GE offers cutting-edge testing, diagnostics, and reporting for your valves for comprehensive evaluation. The EVT-Pro works for all brands of pressure relief valves.

In today’s world, with the automation technology available, human error can be significantly reduced. Valve service and repair within the valve industry is no exception.

Designed with the valve technician in mind, The AccuTEST offers many competitive advantages including: ease of use, modern software, portability of equipment, and repeatability of results regardless of which technician conducts the test.

In today’s world, with the automation technology available, human error can be significantly reduced. Valve service and repair within the valve industry is no exception.

Designed with the valve technician in mind, The AccuTEST offers many competitive advantages including: ease of use, modern software, portability of equipment, and repeatability of results regardless of which technician conducts the test.

The old way of pressure relief valve testing could be summarized in one word: downtime. First, the plant went down, then valves were disassembled, and finally, the valves were transported offsite for testing. Time-consuming. Costly. High risk. But using the AccuTEST System, pressure relief valve testing comes to you, right where the valves actually operate. Time saver. Cheaper. Lower risk.

The AccuTEST System is a recognized leader in the valve service and repair industry. Why? Think fully automated one-touch testing for ease of use and repeatable results. It’s compact and portable to reduce the load of pressure relief valve technicians. Ongoing product enhancement based on technicians’ input. And we offer responsive technical support, anytime, directly from our engineers – not from a third-party representative.

The AccuTEST System is an recognized leader in the valve service and repair industry. Why? Think fully automated one-touch testing for ease of use and repeatable results. It’s compact and portable to reduce the load of safety valve technicians. Ongoing product enhancement based on technicians’ input. And we offer responsive technical support, anytime, directly from our engineers – not from a third-party representative.

Unsurpassed for accuracy, reliability and safety, the advanced technology of AccuTEST was developed to test safety valves while in position, under a full load, for consistently superior, reproducible results.

Unsurpassed for accuracy, reliability and safety, the advanced technology of AccuTEST was developed to test safety valves while in position, under a full load, for consistently superior, reproducible results.

At each of our 12 convenient locations, the Chalmers & Kubeck Valve and Actuation Technicians are factory trained and certified. Each expert Technician is required to meet stringent factory standards prior certification so you can be confident that we will provide the expert, efficient, and comprehensive service that you expect.

Our services include field trouble shooting, actuator refurbishment, control enhancement, electronic valve testing, torque verification, turnkey overhauls / repairs, retrofits, and valve testing / certification. We offer complete reconditioning of ball valves, butterfly valves, check valves, control valves, gate valves, globe valves, parallel slide valves, pilot operated valves, plug valves, pressure relief valves, pressure safety valves, vacuum break valves, and other specialty valves.

Baker Hughes manufactures the premier boiler safety valves and pressure relief valves in the industry, Consolidated®, and authorizes a very select group of companies to be their exclusive factory authorized repair and service centers, known as Green Tag Centers® (GTC). Ten of the 12 C&K Service Locations are GTCs, which means that you will receive best-in-class aftermarket product support. With our OEM trained and certified valve technicians, you know that your relief valves will be rebuilt correctly to exacting standards. Prior to certification, each of our valve technicians must go through Baker Hughes classroom training that includes applicable codes and standards, proprietary repair procedures, and practical hands-on instruction. The technician must prove their proficiency during both written and practical examinations covering relief valve repair, assembly, and testing. With our certified Green Tag Technicians, you can rest assured that your valves will be serviced in compliance with ASME and NBBI (National Board of Boiler and Pressure Vessel Inspectors) standards so they perform their critical safety function as intended.

Each of our GTC service locations has compete machining capabilities, calibrated measuring and testing equipment, specialized electronic valve testing equipment, and ValvKeep, a proprietary electronic data management system, so you can track and trend the repair history of your valves. We also carry significant inventory of Consolidated pressure relief valves and OEM certified replacement parts ensuring rapid response to your urgent repair needs. If for some reason we don’t have a part in stock locally, we have access to all parts stocked by GTCs throughout the entire United States and can have them overnight shipped to one of our service centers. We are your trusted local pressure relief valve service center whether your valves are Consolidated or another manufacturer’s brand.

Since the first installation of its Limitorque Machine (limit & torque capable) in 1929, Limitorque has been manufacturing some of the most innovative and dependable motor-operated valve actuators for demanding industrial applications. Flowserve, the parent company of Limitorque, authorizes a select group of companies to be their “Limitorque Blue Ribbon” service and repair centers. Chalmers & Kubeck is proud to be the largest Limitorque Distributor east of the Mississippi River and that all twelve (12) of our locations are Limitorque Blue Ribbon Service Centers. With over 20 years providing outstanding Blue Ribbon Service, C&K is your go-to solution for actuator sizing, selection, adaptation, installation / certification, maintenance, repair, and field service.

This team of valve and instrument specialists works closely together to provide customer assistance in technical sales, quotations and delivery. Chalmers & Kubeck maintains around-the -clock service, which includes the assembly and test of new CONSOLIDATED® pressure relief valves, plus full machining and repair operations for industrial valves of many types and manufacturers. Additionally, C&K provides comprehensive design and manufacturing services to adapt your existing manual valve or a new manual valve to a motor operated actuator for enhanced process control and operator safety.

Precision of proud to be recognized as your local authorized Green Tag Center (GTC) for GE Consolidated® safety and safety relief valve products. The GTC authorization gives you the best-in-class benefits of GTC exclusive programs such as factory trained GTC repair technicians, EVTPRO® auxiliary PRV in line testing, SRVSpeQ® valve sizing program,

ValvKeep® IIis a state-of-the-art, fully customizable valve management database system designed to assist our customers with the storage, management and maintenance of their safety, safety relief, control and block/line valve historical information. With a variety of reporting methods, this program can greatly assist our customers in maintaining their equipment with day-to-day and outage maintenance needs required to comply with OSHA regulations.

Offering a comprehensive range of specialised valve maintenance services, with a strong focus on delivering customer care, combined with high level standards on both safety and quality.

ATEX certified mobile workshops, suitable for use in Zone II classified hazardous areas. Offering our clients greater flexibility to have repairs and testing carried out at site, minimising the turnaround time during planned outages.

Steel lined test bays with safety door interlocks CCTV system and ballistic glass viewing panel, are designed for pressure testing up to 25,000psi. Stand-alone PSV testing equipment for all sizes of PSV including vacuum breather valves. Purpose built control panels for testing of control valves and manual valves.

The Electronic Valve Tester (EVT) is a digital computerised hydraulic assisted device, designed to test and set safety/relief valves while in service. The EVT is portable and can be used under normal operating conditions without over pressuring the system. This is an ideal solution to situations where the removal of a valve is not practical..

The complete repair, maintenance and retrofitting of electric, hydraulic and pneumatic actuators. Pakscan allows the remote control of actuators and valves over a single twisted pair data highway. Pakscan is capable of controlling up to 300 actuators, split between a wired current loop option card and a wireless option card.

Profibus can operate over a range of communication speeds and provides the mechanism for control of the actuator and feedback of data about the valve.

Explosion relief valves are reusable, flameless venting device, which are made for the protection of personnel and equipment in case of gas or oil-mist explosions. In the event of an explosion, the valve plate lifts up and relieves the overpressure through the integrated flame arrester, allowing pressure relief while stopping flame transmission. Immediately after the pressure event, the valve plate closes, allowing continual process operation.

•• In-Place Testing: No Problem•• Manages Global Safety Standards•• Tests All Manufacturers Pressure relief Valves•• Helps to Improve Plant Uptime and Increases Revenue Helping You Comply With Global Technologically Advanced Testing Safety Standards Exact Set Pressure Measurement EVT-Pro’s true in-place valve testing enables you to meet local also immediately sense and automatically close a relief device safety requirements for periodic testing and documentation should it remain open during a test – a unique safety feature without shutting down processes or dismantling or removing built into the software and hardware. Protection from Harmful Chemical The Compliance Solution valves from service. You get the true “hot set pressure” of the Releases By integrating with ValvKeep, EVT-Pro lets you effectively Along with its rugged yet lightweight test fixture, EVT-Pro has valve, since it is tested under actual operating conditions. Global Safety Standards like OSHA’s Process Safety manage the OSHA requirements. Since you can use the device state-of-the-art electronics and proprietary software, including Management (PSM) standard was published to help minimize to test any brand of pressure relief device, you don’t need to The EVT-Pro device simultaneously examines two critical an interface to ValvKeep* valve maintenance and manage- the consequences associated from a catastrophic release manage multiple test suppliers. EVT-Pro and ValvKeep put all variables of the relief device — the upward force applied to the ment software. You can view test results in both tabular of toxic, reactive, flammable, or highly explosive hazardous your documents in order, so test reports, procedures and other spindle and the actual system pressure. Using sophisticated form and colorful graphs that depict the exact set pressure, chemicals. This standard covers several areas, specifically related documents are always available to meet compliance sensors, including an acoustic device, EVT-Pro testing accu- and historical data and tests are readily available 24/7 with relief and vent systems and devices. It requires that written requirements. You are better prepared rately determines the pressure relief valve’s set pressure. It can ValvKeep software’s database capabilities. procedures, inspection and testing, [and] appropriate job skills for audits and lessen the odds be deployed, [and that] records and management of change of receiving citations and be in place. Failure to do these things may result in severe penalties. And EVT-Pro’s See Exact Set Pressures consequences. in-place functionality •• Colorful and clear graphics assist the end user in seeing lets you keep plant exact set pressures for the valve in test. Failure to comply with OSHA 29 CFR operations going while 1910.119 it tests your valves. •• Unique acoustic sensor feature provides confirmation of set Process Safety Management requirements is one of the most pressure on force curves delivering confidence in each test. frequent infractions. There are several reasons for this: deficient pressure relief devices, inadequate documentation, and lack FEATURE BENEFIT of pressure relief information, procedures, or training and associated documentation. Inline Testing Helps to Maximize Plant Uptime

Auto Shutdown Safety Feature Superb Safety Feature Allows for Closure of Valve Under Full-Lift Circumstances End-User Feedback “In the past I had to know where my test records Interface to ValvKeep Software Comprehensive Asset Management Tool Exclusive to GE’s GTC’s were located to demonstrate compliance to our local inspector; this is very important for Acoustic Indicator Device Sensor Takes Guess Work out of Determining Set Pressure the OSHA Process Safety Management require- ment. With ValvKeep and EVT-Pro, my files are linked and updated so I have quick access to ATEX/UL Certified Intrinsic Safety Certified; Available on Certain Models them. Several months ago an inspector was at my plant, standing next to me, asking for the Test Gas, Liquid and Steam Capable of Testing all Media paperwork on the safety relief valves. Using ValvKeep I was able to get the reports, show the NBBI Accepted (Part 3, para 4.5.3) National Board Compliance inspector that the valves were all certified and had been serviced within the service guidelines.” ASME-Qualified Meets ASME Code Requirements

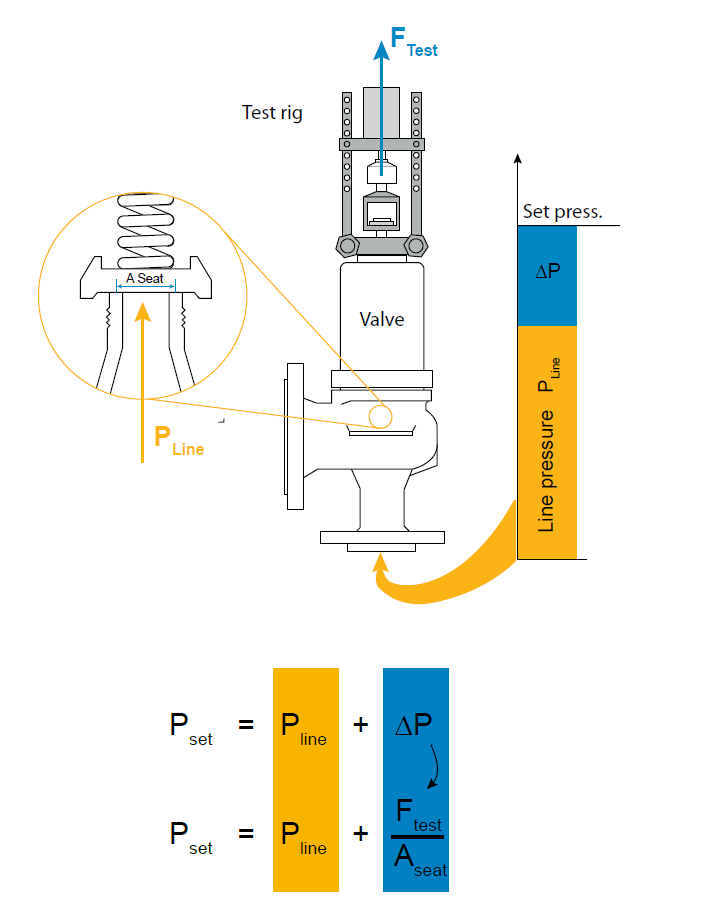

2 | GE Energy Consolidated Valves - EVT *-Pro Valve Testing Device | 3 How EVT-Pro Works F3 = Artificial “pull” on the EVT-Pro and ValvKeep spindle supplied by the Wide Scope of Documentation Force Balance Analysis: F3 + F2 = F1 hydraulic pump Record keeping is important to providing proof of your efforts Normally, with the pressure relief valve online, the much stron- to comply with Global Safety Standards, OSHA included. The ger force of its spring -- F1 -- is all that is required to prevent scope of documentation is wide, and the more accurately system inlet pressure -- F2 -- from forcing the valve open. records are maintained, the better it is for audits. Using EVT-Pro However, should F2 increase beyond the operational limit of electronic diagnostics and ValvKeep software will lessen the the system, the valve will first simmer and then discharge. F1 = Spring force stress of a Safety Inspection inspection and reduce the odds pressing down of receiving citations and penalties. As one well known safety To prevent the valve from discharging during the EVT-Pro test, on the disc organization, OSHA states, “OSHA’s primary goal is correcting the GE-trained service technician introduces just enough pull hazards and maintaining compliance, rather than issuing on the spindle – F3 -- to balance the force of the spring. This citations or collecting penalties.” causes the disc to only crack open or simmer.

Your Local GTC* More than 125 Years of Expertise Consolidated pressure and safety relief valves from GE Oil The GE Green Tag Center (GTC) network is the only place you F2 = Inlet pressure pushing & Gas have been available for more than 125 years. The can access GE’s advanced technology, which tests any brand upward against the disc EVT-Pro diagnostic tool is the most technologically advanced or type of pressure or safety relief valve you have. Your local Consolidated field test device ever. EVT-Pro testing meets high GTC has the EVT-Pro electronic diagnostics, ValvKeep valve standards for quality and accuracy. management software and factory-trained and certified technicians to meet your testing and compliance needs.

4 | GE Energy Consolidated Valves - EVT *-Pro Valve Testing Device | 5 Integrated Performance Solution

Asset Management Coal-Fired Power Plant ValvKeep Valve Management and Maintenance Software

Valve Repair GTC Green Tag Center Green Tag Center

6 | GE Energy Consolidated Valves - EVT *-Pro Valve Testing Device | 7* Consolidated, EVT, Green Tag Center, and ValvKeep are trademarks of the General Electric Company.Other company names and product names used in this document are the registered trademarks or trademarks of their respective owners.© 2012 General Electric Company. All rights reserved.

The CALDER PROSET Pilot Valve Tester is a cost-effective way to perform the functionality of the pilot in Pressure Operated Relief Valves (PORV) with unsurpassed quality and ease of use. ROBUST, EASY TO USE, AND STATE OF THE ART Tests both modulating and snap-acting pilot...

The CALDER QUICKSET™ Safety Relief Valve Testers set a new standard for Pressure Relief Valve Testing and provide valve technicians with unrivaled performance, volume, flow, and ease of use. ROBUST, EASY TO USE, MODULAR, AND HIGHLY CONFIGURABLE The unique high flow design allows for free...

The new lineup of CALDER QUICKSET™ Safety Relief Valve Testers raises the bar with unrivaled performance and ease of use. QUICKSET™ SRV Testers are designed to match all your valve testing needs with base machines of different tonnage while offering more than 50 different configurations...

40 years ago, CALDER began manufacturing Valve Testers because founder, John Emmitte, realized that companies were not testing valves properly. Even today, many pressure relief valve testers are homemade or fabricated in a manner that does not provide the valve with enough volume, and are...

The CALDER HYDROPRO™ Universal Straight Valve Tester (USV) and Universal Flange Valve Tester (UFV) are the safest, most accurate, and most versatile advanced valve testing systems in the industry. When paired with the HYDROPRO™ Console, HYDROPRO™ valve testing systems are capable of hydrostatic tests up...

Customized to Mobilize Your Specific Valve Testing Needs! CALDER Valve Testers has been customizing valve testing systems for almost 40 years designing and creating unique solutions to meet all your valve testing challenges head-on. The CALDER Mobile Valve Workshop is no exception, offering unrivaled flexibility...

CLIMAX | CALDER invites you to visit us at the Valve World Americas Expo & Conference on October 13 – 14, 2021, at the George R Brown Convention Center in Houston, Texas, booth 1521. Valve World Americas Expo & Conference is the largest exhibition for services, equipment, and other valve needs. CLIMAX, the leading...

When safety and time are critical, look no further than CALDER for your valve testing solutions. We offer a variety of valve testing and repair machines, including the new TURN-AROUND-TESTER™ (TAT). The TURN-AROUND-TESTER™ offers the ability to put it in the back of a truck, get it on site,...

Visit us at our CALDER Valve Tester locations in Saudi Arabia and UAE. Meet the experts and get a first-hand look at the latest technology available from CALDER. See live demonstrations of the machines our customers are raving about, like the new CALDER Portable Valve...

See the CALDER TURN-AROUND-TESTER LIVE on April 28, 2021 Over 50 years ago, CLIMAX pioneered the portable machine tool industry, with state-of-the-art tools that solve the world’s toughest machining challenges. In 2013, CLIMAX acquired CALDER Testers and brought portable to the valve testing industry. The...

CLIMAX, the world’s #1 choice for portable machining, welding, and valve testing invites you to visit us in Houston on February 15 – 26, 2021. This is a great opportunity to get a first-hand look at the latest technology available from CLIMAX, BORTECH, CALDER & H&S TOOL. Meet the experts...

The CALDER HYDROPRO™ Universal Straight Valve (USV) tester is the most versatile and user-friendly tester in the industry, designed to clamp a wide variety of straight bodied valves. When paired with the HYDROPRO™ Console, the HYDROPRO™ USV is ideal for hydrostatic tests up to 9700 psi...

Congratulations to Dave Briggs and the CLIMAX | CALDER engineering team for officially receiving the Patent for the CALDER Safety Interlock System. The Safety Interlock System is designed with interlocking knobs and valve handles that will not release the clamp pressure until the internal test pressure...

CALDER Advanced Valve Testing & Repair Systems by CLIMAX is excited to announce TOMCO Industrial as an exclusive sales and service representative for all CALDER products in Canada. This new partnership with TOMCO will allow CALDER, the leading global manufacturer of valve pressure test benches...

The CALDER HYDROPRO™ Universal Straight Valve (USV) Tester is the most versatile and user-friendly tester in the industry! The USV system uses our patented Easy-Out Seal Plate™ holders which allows quick change-out of seal plates from flanged to other valve end type connections with minimal effort....

CLIMAX | CALDER invites you to visit us at the Valve World Americas Expo & Conference on June 19-20, 2019 at the George R Brown Convention Center located in Houston Texas. Valve World Americas Expo & Conference is the largest exhibition for services, equipment, and...

The CALDER TURN-AROUND-TESTER™ can efficiently perform a wide variety of pressure tests and can be easily transported for use on job sites. Valve repair shops and technicians are now taking their shop on the road. With superior quality, safety, durability, and performance, owning a CALDER TURN-AROUND-TESTER™ ...

CALDER Advanced Valve Testing Systems proudly announces the appointment of Mr. Kevin Vincent to the position of General Manager. CALDER is a subsidiary of CLIMAX Portable Machining & Welding Systems, headquartered in Newberg, Oregon. Mr. Vincent has been in commercial positions of increasing responsibility at CLIMAX for five years, serving most recently as a...

Fisher Price, CALDER Product Line Manager, focused on CALDER Advanced Valve Testers, has been working in the valve industry since 2004. Spending much of his career with Nuclear power companies, Fisher has held several roles machining, welding, testing, and repairing valves, as well as, providing expertise...

Oil & Gas News, November 2018: CLIMAX Portable Machining and Welding Systems is the world’s premier supplier of portable machining and welding equipment. Under its CALDER product line, the corporation provides the world’s most advanced line of valve testing and repair systems. CLIMAX | CALDER...

CALDER Advanced Valve Repair & Testing Systems cordially invites you to the GRAND OPENING of our new CALDER Saudi Arabia sales office, customer service center and product showroom in Dammam, Saudi Arabia. Please stop by on Monday, November 19 any time between 10:30 AM and 2:00...

Clark Turner has been in the valve industry for more than 35 years, where he’s done everything including repairing, hydrotesting, and installing line valves, as well as installing safety and relief valves in various processes. He also spent significant time as an ASME Section VIII design...

CALDER Valve Testing Systems recently introduced a new, enhanced lineup of valve testing systems that have proven to be a reliable solution for valve repair shops. The new valve testers have quickly earned a reputation as the safest, highest quality, and most durable, versatile, and productive systems...

The new CALDER TURN-AROUND-TESTER™ can efficiently perform a wide variety of pressure tests and can be easily transported for use on job sites, giving valve repair shops and technicians the opportunity to take their shop on the road. Contact us today at +1.985.974.6070 or [email protected] to...

The TURN-AROUND-TESTER™ (TAT) is the perfect solution for service teams to complete in-field testing of freshly refurbished Control and Safety Relief valves. The self-contained TURN-AROUND-TESTER™ will fit in any full-sized pickup bed with the controls positioned to ergonomically allow the operator to complete the testing even when...

Over 50 years ago, CLIMAX pioneered the portable machine tool industry, with state-of-the-art tools that solve the world’s toughest machining challenges. In 2013, CLIMAX acquired CALDER Testers, and now CLIMAX | CALDER has brought portable to the valve testing industry. The new CALDER TURN-AROUND-TESTER™ can efficiently...

We live in a world with valves, and those valves need to be repaired and tested. Today we’re asking all valve repair shops, power plants, refineries, and owners of valves: How much downtime and money could you save if you could repair and TEST your...

GOING PORTABLE WITH A WHOLE NEW TECHNOLOGY We live in a world with valves and those valves need to be repaired and tested! 51 years ago, CLIMAX disrupted traditional repair processes, introducing undeniable value by inventing the portable key mill, bringing portable machining technology directly...

CLIMAX | CALDER invite you to visit our booth (1628) at the VALVE WORLD AMERICAS EXPO, June 20 – 21, 2017 in Houston Texas. VALVE WORLD AMERICAS EXPO is the largest exhibition for services, equipment, and other valve needs. CLIMAX will showcase their valve grinding and...

The CALDER HYDROPRO™ Universal Straight Valve Tester (USV) and Universal Flange Valve Tester (UFV) are the safest, most accurate, and most versatile advanced valve testing systems in the industry. When paired with the HYDROPRO™ Console, HYDROPRO™ valve testing systems are capable of hydrostatic tests up to 9700...

The CALDER Safety Relief Valve Tester (SRV) sets a new industry standard for testing safety relief valves with unsurpassed performance and ease of use. EASY TO USE, WITH UNRIVALED QUALITY, SAFETY & CUSTOMER SUPPORT Every component in the SRV pressure circuit is designed to work...

A Dozen Questions That Can Save You Millions in Your Valve Testing Program! When purchasing a valve testing system, the top concerns have to be safety, quality, durability, performance, versatility, usability, productivity and – ultimately – total cost of ownership and return on the investment....

The Most Versatile & Cost-Effective Way to Test Straight Bodied Valves! The CALDER HYDROPRO™ Universal Straight Valve (USV) Tester is the most versatile and user-friendly tester in the industry, designed to clamp a wide variety of straight bodied valves. When paired with the HYDROPRO™ Console,...

With vastly superior quality, safety, durability, flexibility, performance and support owning a CALDER Advanced Valve Testing System is by far the most flexible and cost-effective way to manage your valve testing program, reduce your total cost of ownership and maximize your return on investment over the...

BIC Magazine, April 2017 When purchasing a valve testing system, the top concerns have to be safety, quality, durability, performance, versatility, productivity and return on investment. Ask these 12 pivotal questions when purchasing a valve tester: Is every component in the tester certified by the...

Our engineers and valve test experts asked customers what they want in the next generation of valve testers. One message was loud a clear: customers want fast, responsive, expert service and support. So we’ve built that right into the foundation of our new CALDER offering!...

CALDER engineers, in collaboration with key industry experts, spent countless hours designing this next generation of CALDER advanced valve testing systems. Not only are CALDER systems more versatile, accurate, durable and cost-effective, they’re designed with “Safety First!” in mind. Our systems maximize user protection and ensure test...

The new lineup of CALDER advanced valve testing systems, manufactured by CLIMAX, are the most flexible and versatile systems on the market. The CALDER test system can seamlessly expand and evolve with your business, giving you the lowest total cost of ownership (TCO) and the...

The HYDROPRO™ Console – The Most Versatile & Cost-Effective Way to Test Valves! The HYDROPRO™ Console is the most versatile and user-friendly tester in the industry, capable of performing a wide variety of valve tests when paired with a CALDER hydraulic clamping system or even blind...

Introducing the new CALDER Product Family The new platform of CALDER advanced valve testing systems manufactured by CLIMAX are the safest, most accurate and most versatile systems on the market, and we are pleased to announce our new line-up of valve testing equipment. HYDROPRO™ CONSOLE The...

Are you ready? On January 16th, CALDER will transform the valve testing industry, unveiling EIGHT new products! We’re going to show customers, world-wide, a whole new vision of industrial valve testing, a quantum leap in performance, safety, reliability, versatility, and cost-effectiveness. We’ve made a major investment...

Get ready – CALDER valve test systems will transform the valve testing industry starting January 16th! We’re going to show customers, worldwide, a whole new vision of industrial valve testing, a quantum leap in performance, safety, reliability, versatility, and cost-effectiveness. HOW? We have been working...

8613371530291

8613371530291