fire safety valve manufacturer

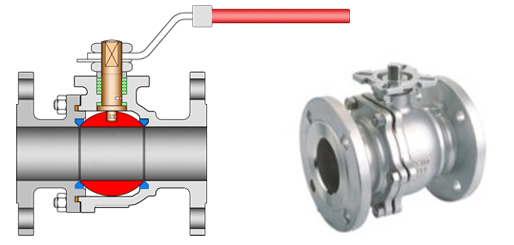

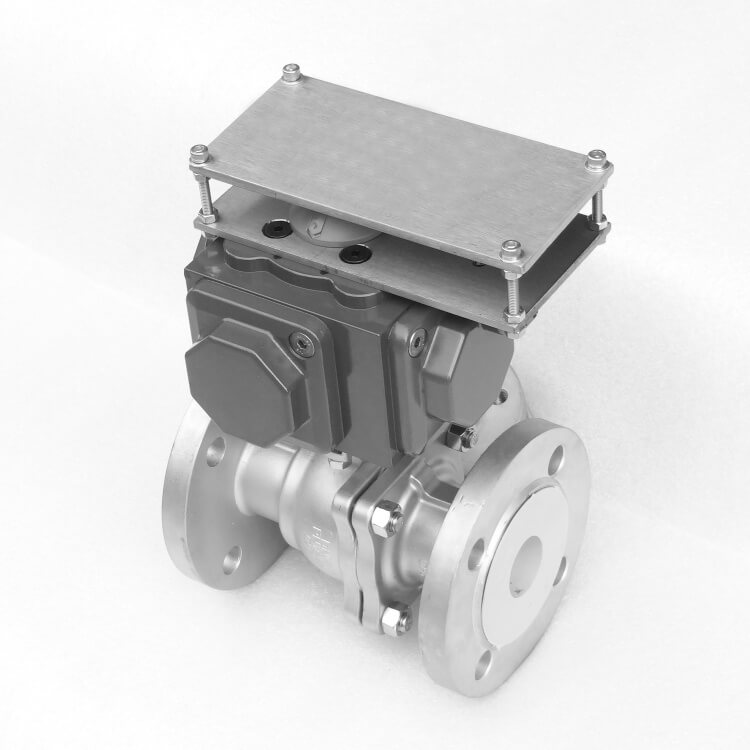

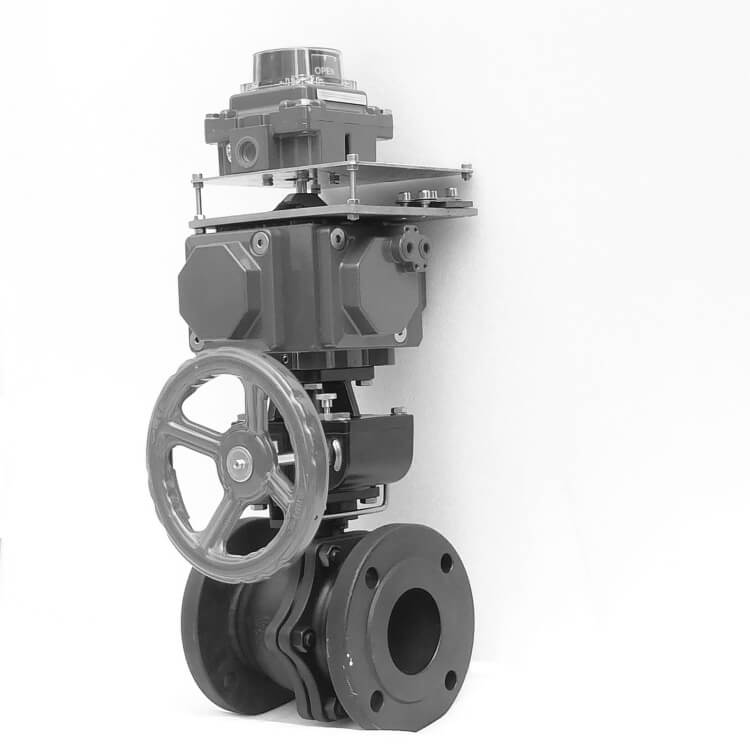

Valtorc USA Fire Safe Ball Valves are generally supplied with manual hand lever or gear actuator operated, depending on valve size. We also offering Ball Valves with Pneumatic Single Acting Actuator, Pneumatic Double Acting Actuator, Rotary Actuator, Quarter Turn Actuator or Electrical actuator operated for automation.

Valtorc USA"s Process Valves & Automation Fire Safe Design Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) to suit special requirement of client.

In a typical globe valve, if the yoke is exposed to the direct flame of a fire, it will expand at a rate much greater than the stem. Thermal effects cause the yoke arms to grow, which makes the disc lift up off the seat, leading to considerable leakage. This is true of virtually all globe valves now on the market.

Conval has developed a simple mechanism that compensates for thermal expansion. The stem bushing is allowed to float in a recess in the top of the yoke and is loaded by a series of Belleville washers. The Bellevilles maintain a load, forcing the stem assembly down into the seat, even when the yoke expands at the high temperatures of a refinery or chemical fire.

The Conval fire-safe Clampseal® valve has been tested and successfully passed the rigorous test procedure defined by the American Petroleum Institute (API) Standard 6FA. In brief, this procedure calls for the test valve to be placed in line and pressurized to 75% of rated pressure, then subjected to a 1400-1800°F fire for 30 minutes. The valve is then quenched with water to cool it to ambient temperature, cycled to prove operability, and then subjected to further pressure testing. The valve is required to maintain strict leakage allowances during and after the burn.

Our entire line of Clampseal® globe valves may be retrofitted with this fire-safe capability, including: Y-pattern stop and stop check valves; T-pattern stop and stop check valves; angle pattern and stop check valves.

In extreme environments, the simpler the design and the fewer the parts, the better. The durable single-piece stainless steel gland contributes to the longevity of the valve.

With secure leak-proof bonnet, this chamber allows rapid access to valve trim for inspection and maintenance. Pressure boundary is sealed at the smallest diameter possible, to ensure maximum strength and low stress.

The Clampseal® pressure-actuated backseat provides maximum valve integrity by ensuring a positive internal stop for the valve stem and disc assembly. The pressure actuated backseat also extends packing life by securely isolating the packing from the pressure when the valve is fully open.

The Axial design ensures tight concentricity, which eliminates side loading of the packing and minimizes wear forces on the trim components. This feature is critical for superior valve performance.

The CLAMPSEAL® Valve is much easier to renew than anything else on the market. The CLAMPSEAL® Valve line provides a modular solution to rising maintenance expenses. Low acquisition cost is not as important as low cost over the serviceable life of a valve. Maintaining a Conval valve is far easier and much less costly than replacing a competitor’s valve.

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

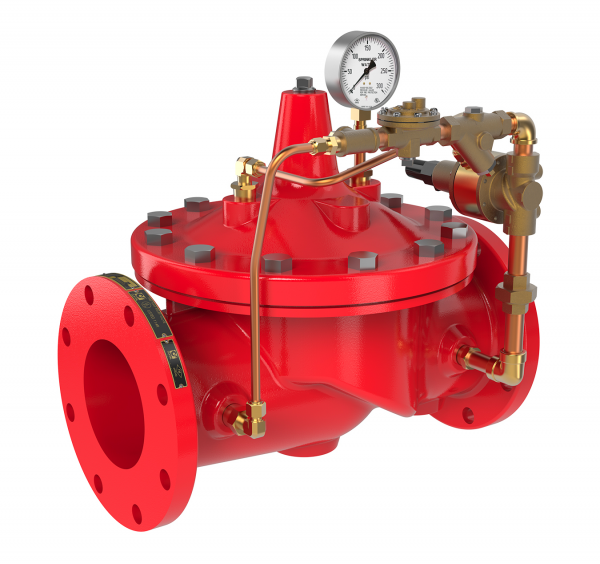

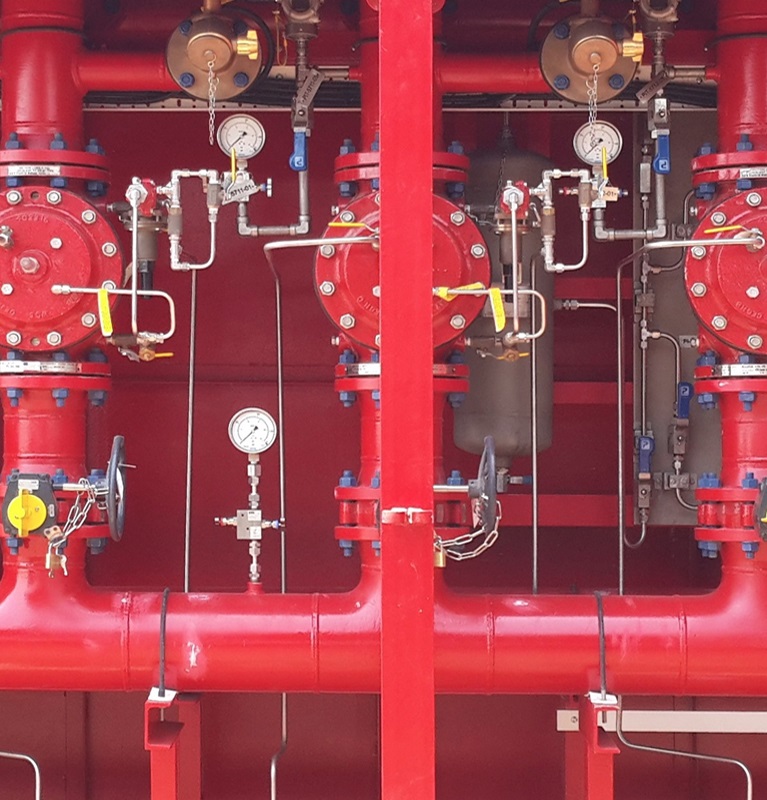

In minutes, a fire can engulf an entire building or consume a home — damaging or destroying everything in its wake. When a catastrophe happens, there’s no time for error. That’s why Singer Valve’s fire protection valves are built to the same high-quality standard as all of our water valves, and beyond the standard of many of our competitors. As industry leaders, we understand that when it comes to protection from the ravages of fire, you need a valve you can rely on every time.

Fusible link valves are designed to automatically shut off any gas or liquid in the pipeline when the fire is present. This ensures that fires don’t spread and offers better performance than standard shut-off valves.Heat-sensitive elements will shrink and cause the fusible top work assembly to open, cut off fluid flow through a pipe, and prevent fuel leakage.

The fusible link serves as a pressure release and shutoff valve used to prevent the overpressurization of equipment and/or piping systems. It allows pressurized fluid to discharge through a pipe into the atmosphere or into another section of piping.

A fire-safety valve with a fusible link is an important safety device in the event of a fire on naval vessels, as a fire extinguisher is not sufficient on its own to prevent the risk of explosion from overheating oil tanks.

Contact us today if you would like more information about our fire-safety valves with fusible links! We offer competitive pricing and excellent customer service! You can get fusible link valves from THINKTANK, and build your own brand.

AGF Manufacturing Inc is a solutions provider to the fire sprinkler industry, specializing in manufacturing products that are reliable, versatile, and code compliant. The company was founded on the principles of reliability, versatility, and code compatibility, and has been introducing original products that accommodate the varying demands of the fire sprinkler industry. AGF is committed to continuously improving existing products and introducing new ones to meet the needs of the fire protection industry. The company has a strong commitment to customer service and has a close interaction with the fire sprinkler community. AGF aims to help manage fire sprinkler systems more efficiently by engineering more intuitive products, resulting in more reliable systems that better protect lives and save resources.

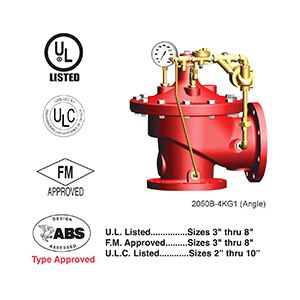

Distributor of fire protection system valves. Hose angel, resilient wedge, slow closing and grooved type butterfly, dry, floor control test and drain valves are available. Offered in different specifications and features. Made of brass, bronze, stainless steel and ductile iron materials. Capabilities include design, installation, training, service, inspection, repairing, CAD engineering services, testing and maintenance. Used for indoor and outdoor and potable water systems. Applications include commercial, retail, restaurants, food service, schools, worship assemblies, hospitals, healthcare providers, property management, industrial manufacturing and warehousing facilities. 24 x 7 emergency services are available. UL® listed and FM approved. NICET certified.

... deluge valve. Designed specifically for advanced fire protection systems and the latest industry standards. The 400Y-2MC is activated by a 3-Way solenoid valve, that ...

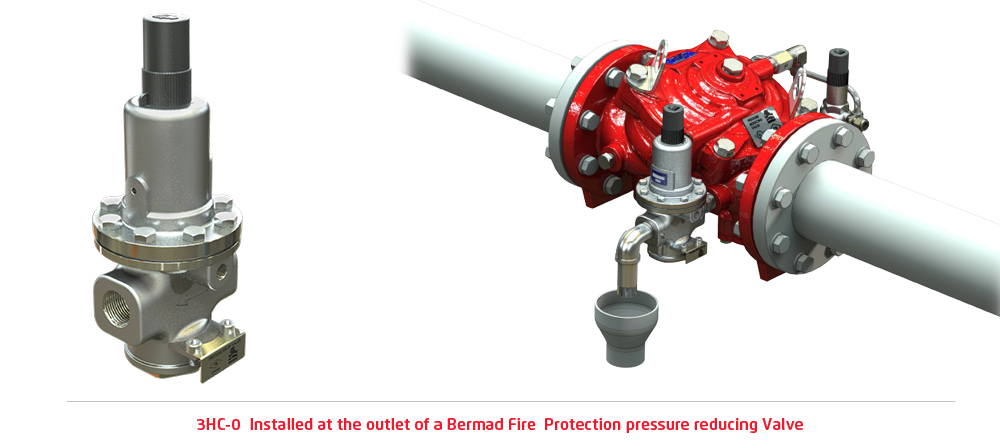

The BERMAD model 42T is an elastomeric, line pressure driven pilot operated pressure control valve.Designed specifically for advanced fire protection systems and the latest industry standards. ...

... Model FP 450-66 Level Control Valve with Bi-Level Vertical Float is a hydraulically controlled, diaphragm actuated control valve that controls reservoir filling in response to a hydraulic on/off float ...

... Butterfly Valves are indicating type valves designed for use in fire protection systems where a visual indication of open or closed valve condition ...

Resilient seat gate valves are type of gate valves with an elastomer lined wedge. They are especially used for waste water, drinking water supply fire protection and ...

The NIBCO® bronze angle globe valve is recommended for trim valve application in an automatic fire sprinkler system. Typically it is used as the "Main Drain" in the fire ...

... Iron 250 psig AWWA Resilient Wedge Gate Valve is designed for use in drinking water, sewage and fire protection systems as well as irrigation and backflow control systems. The Series ...

Z85X Valve is a manually operated,Non rising stem resilient wedge gatevalve designed for use in fire protectionsystems for on/off operation only. Thelightweight ductile iron body allows for bothvertical ...

... DPV-1 Dry Pipe Valves are differential valves used to automatically control the flow of water into dry pipe fire protection sprinkler systems upon operation of one or ...

NAFFCO landing valves are suitable for installation on wet risers in a building for fire fighting purposes with permanently charged water from a pressurised supply.

Mostly made of FiberTech composite, Leader WYES have ultra lightweight PN16 wye ball valves. Equipped with wide opening/closing handles for excellent grip with gloves, they also have swivel inlet ...

“Our customer was in a shutdown and needed a 2.5” valve immediately. OCV stepped up and was able to build the 2.5” valve in one day and ship it next day air to the customer. Fantastic work!!”

“OCV and Jim Gibson are the #1 supplier of control valves in our circle of vendors. Their integrity is never compromised as they strive for Complete Customer Satisfaction. Their word is their bond and they live by it. Their intimate knowledge of their products and our industry is unsurpassed and we look forward to many years of a mutually successful relationship as we continue to grow together and discover new markets.”

“Since 1996DakotaPump & Control has partnered with OCV. DPC takes who we represent on our line card very seriously, and we couldn’t be happier with this partnership. OCV has a catalog that covers all our needs, as well as the support a service based company like ours demands. We look forward to whatever valve challenges are presented to us, because we have the right manufacturer that can support us every step of the way.”

“The Otoe-MissouriaTribe of Oklahoma has been doing business with OCV since 1993. We have utilized them for all types of valves, as well as parts. OCV always has the answers. Working with Robert and Jarrod has been a pleasure!”

“A lotof companies preach customer service, but their actions don’t reflect it. That’s not the case when it comes to OCV. I have met many associates at OCV, from Plant to Sales to Engineering – all are focused on taking care of their customers. OCV is expedient in quoting projects and has even been known to troubleshoot valves from other manufacturers and construct valves in an emergency to get a city out of a jam. OCV practices what they preach!”

“We represent several prominent manufacturers, but OCV distinguishes themselves with their customer focused approach. It seems as if every valve they fabricate is going to their neighbor. Their quality and workmanship is second-to-none and when you call for support, you feel like family.”

“OCV Control Valves delivered the products on time, made them perform as proposed and helped answer our questions. There was good teamwork all around.”

“Personally having 18 years of verifiable field experience, OCV is very easy to work with. They have knowledgeable tech support, their sales team is exceptional, and there have been no hiccups with lead times. Everyone I talk to at OCV knows the valves and know the equipment they are selling.”

“OCVwas very helpful. Not only did they always answer our questions and make sure the valves were exactly what we needed. but they were also able to provide us with two new pre-set valves in about three to four weeks.”

In addition to being installed aboard nearly every ship in the US Navy’s fleet, helping to keep our country’s servicemen safe in the event of a fire, our globally proven fire protection products can be found in nearly any type of facility on or offshore, including oil platforms, FPSOs, refineries, power plants, chemical storage facilities, mines, tunnels, aviation facilities, high-rise office and residential buildings, hospitals and historic landmarks.

No matter how challenging your requirements are, Cla-Val has the fire protection product you need to protect lives and property. Cla-Val fire products are UL and ULC listed and have Factory Mutual approval along with other industry approvals and certifications.

Fire Protection Resilient Seat NRS Gate Valve Groove End Non rising stem gate valve by Arita Fire Solutions, has the option of operation of handwheel or use in combination of indicator post.

One of the more recent developments in industrial tools to prevent fire is the introduction of fire safety valves. These valves are designed to prevent a fire from spreading if the fuel valve gets damaged or causes a leakage.

A valve is a device that adjusts, directs, or controls the flow of a fluid by opening, closing, or partially blocking various passageways. Valves are technically a type of fitting but are usually discussed separately. In an open valve, fluid flows from higher pressure to lower pressure. The simplest kind of valve is simply a freely hinged flap that drops to obstruct flow one way but is pushed open by fluid flowing the opposite way. This ancient valve is called a check valve, as it stops or "checks" the flow in one direction. Modern valves may regulate pressure or flow downstream and operate on sophisticated automation systems.

Valves have industrial applications for controlling processes, residential uses such managing water flow to dish and clothes washers and taps in the home. They are found in almost every industrial process, including mining, water and sewage processing, power generation, food manufacturing, processing of oil, gas and petroleum, chemical and plastic manufacturing, and many other fields.

Fire-safe valves are spring-loaded valves that are thermally actuated. In case of fire, they close automatically and stop the fuel flow. The fuel flow from the crankcase of the engine and the reserve oil supply gets hindered, thus minimizing the chances of leakage.

Spring-loaded valves help with preventing the flow of fuel such as oil, gas, petrol, and other combustibles, and are useful and effective against any damage. The benefits of using fire-safe valves in a system are the protection of human life, lower insurance rates, and the protection of equipment and the building.

It is because of these benefits that the use of these valves is highly recommended and appreciated. These days, many companies offer an extensive range of fire-safety valves to provide protection even in high temperature and high-pressure conditions.

A fire safety valve aims to keep ignitable fluids away from a flame. These valves close when exposed to heat, separating a flammable liquid from the heat source. They close in the midst of overheating of the pipeline, brought on by fire or similar events. The obligation to use fire safety valves is subject to any tenets, regulations, and laws concerning the unique methodology, plant, pipeline, or vessel.

Fire-safe ball valves use a combination of a floating ball, graphoil seals, and metal-to-metal seating to provide tight shut-off while preventing external stem leakage. In normal working conditions, the ball rests against two seats, ensuring bubble-tight closure. When the valve is exposed to a temperature above the limits the seats can withstand (for example, +450°F), the seats become deformed and are subject to extrusion. When the seats have been completely destroyed, the ball in the valve will come to rest firmly against the end cap, producing a metal-to-metal closing. Stem seals, which have high temperature-resistant properties, further restrict leakage in conjunction with a blow-out-proof anti-static stem, so that the flammable fluid stays separate from the heat source that may ignite it.

A fire-safe valve may also be made up of four main mechanisms: a spring pack, a trigger assembly, mounting hardware, and a fusible link. The components work in unison to close the valve should a fire be detected within a facility. The fusible link is the key part of the assembly. It keeps the valve open by maintaining tension on a spring pack through the trigger assembly. When a fire breaks out, the fusible link separates once it is heated to a certain high temperature, which releases the spring pack and allows it to close the valve.

A fire-safety valve with fusible links has a primary drop-tight seat, usually made of TFE, along with a second seat made of metal for isolation in a fire. The secondary seat also has graphite seals for further protection. This means that the shut-off valves can be paired with any quarter-turn ball valve, butterfly valve, or plug valve.

This article presents an understanding of fire safety valves. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

Kennedy Valve began operations in 1877 in Lower Manhattan, N.Y. In 1890, the operation was moved to Coxsackie, and then in 1907, Kennedy Valve moved to Elmira, N.Y., where it remains a cornerstone of the community.

In the 135 plus years since its founding, Kennedy Valve has expanded to be a full-line waterworks valve and hydrant manufacturer, supplying resilient seated gate valves, fire hydrants, check valves, butterfly valves, indicator posts, grooved butterfly valves and an assortment of related products and appurtenances.

Kennedy Valve and its employees are dedicated to supplying quality products that meet or exceed current specifications to ensure customer satisfaction. We pride ourselves on being easy to do business with and providing superior customer service backed by knowledgeable and courteous employees.

Kennedy Valve products stand the test of time in reliability. Our goal is to supply the highest quality products with the shortest lead times at a competitive price, while at the same time remaining a good steward of the environment and maintaining a safe workplace for our most valued asset — Kennedy Valve’s employees.

Fire Safe Valves are the valves that has the ability to maintain their pressure holding capacity during and after exposure to fire. The reason for using this kind of valve we use is because of the higher possibility of hazardous/flammable fluid getting leaked from the valves during an event of a fire.

As opined by an expert Valve Stockist in USA,if non-fire safe valves are used for a fluid that is flammable having a higher chance to be exposed to the pool of fire during an accident, then leakage will occur from the valve stem seal that already might have melt. Thus, as suggested a need for a fire-safe valve that doesn’t leak when exposed to fire is the need of the hour.

There are actually two kinds of leak that is supposed to be avoided when a valve is exposed to a fire accident which leads to leakage from the stem and leakage from the seat. Owing to this there are two distinct methods to achieve a fire-safe design, as formulated by expert Valve Manufacturersby the usage of a fire-proof component or by use of a non-fire proof component which is supported by a special design that prevents leakage after the components melt in case of a fire mishap.

Fire safety valves being a recent development in the industrial tools to prevent fire are basically designed to prevent a fire from spreading if the fuel valve gets damaged causing a leakage.

Actually these valves are spring-loaded valves that are thermally actuated which in case of fire, close automatically stopping the fuel flow from the crankcase of the engine thus the reserve oil supply gets stopped, minimizing the chances of leakage occurring.

The benefits of using these valves are the protection of human lives, lowered insurance rates, and the protection of equipments along with the buildings it is placed.

Under the scorching high temperatures, it is necessary to use metal construction for the valves, the reasons why the primary valve types to be considered for fire-safe are gate and globe valves because of their metal-to-metal seating.

The soft-seated rotary valves include the ball valves, plug valves and butterfly valves. All the manufacturers of rotary stem valves in order to prove bubble-tight shutoff in the normal valve operation as well as fire safety are employing two types of valve seating arrangements.

Here in the first system, for the fire-safe ball valves,a metal sealing usually occurs when, the floating ball moves downstream to contact a machined surface in the body which matches the shape of the ball.

The second system typically used by some of the high-performing butterfly valve supplier and manufacturers is not wholly depending on the total seat burn since a resilient seat and metal seat primarily contacts the disc at the same point of time.

If the valves are of a two/ three-piece body design, then utmost attention must be paid to the body seal materials to prevent a worst leakage during a fire accident. The butterfly valves generally use a rigid disc and a stem connection where the packing material is graphite due to its ability to withstand higher temperatures of 700°C). The one-piece body design of all most all of the high-performance valves ensure to eliminate body seal leakage efficiently.

Our fire safe valves are ball valves and butterfly valves availabe for a maximum custom configuration. As a leading Valve Stockist in UAE, we ensure that our valves are available in all sizes. All fire safe valves are UL FM approved valves that have a higher temperature range.

Don’t settle in for the cheaper competitions its time to invest in a higher quality product from Fevisa – the quickest and most economical choice for the fire safe valves. Our fire safe valves are also WRAS approved Valves. We are also fire valve suppliers and we called as european valve manufacturers.

Fevisa is ever ready to help you out in the choice of ex-stock valves. If you have any query about valve selection, or if you don’t fina a valve that meets your precise specifications, please contact us for complete assistance.

8613371530291

8613371530291