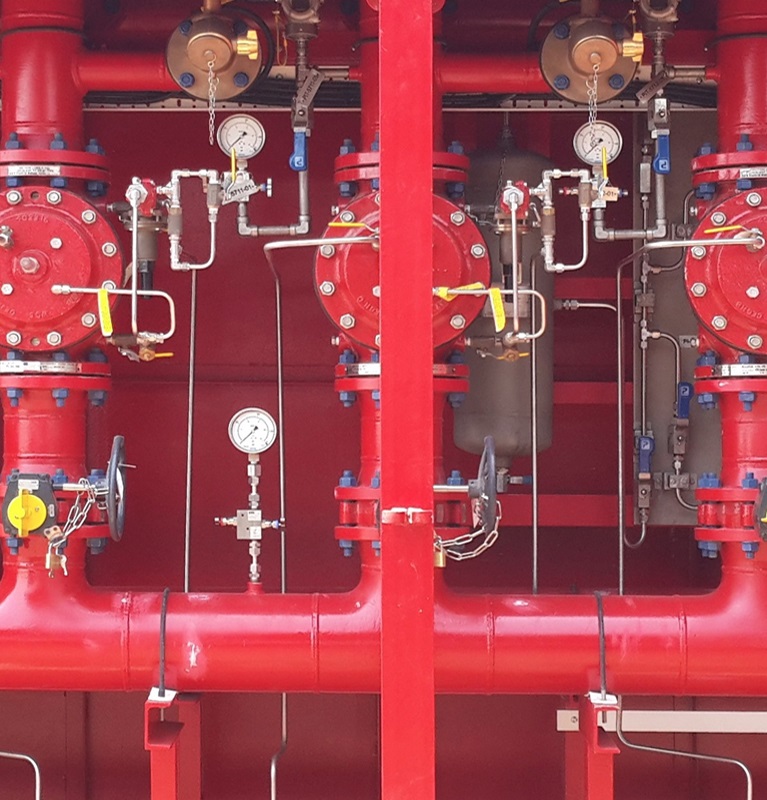

fire safety valve factory

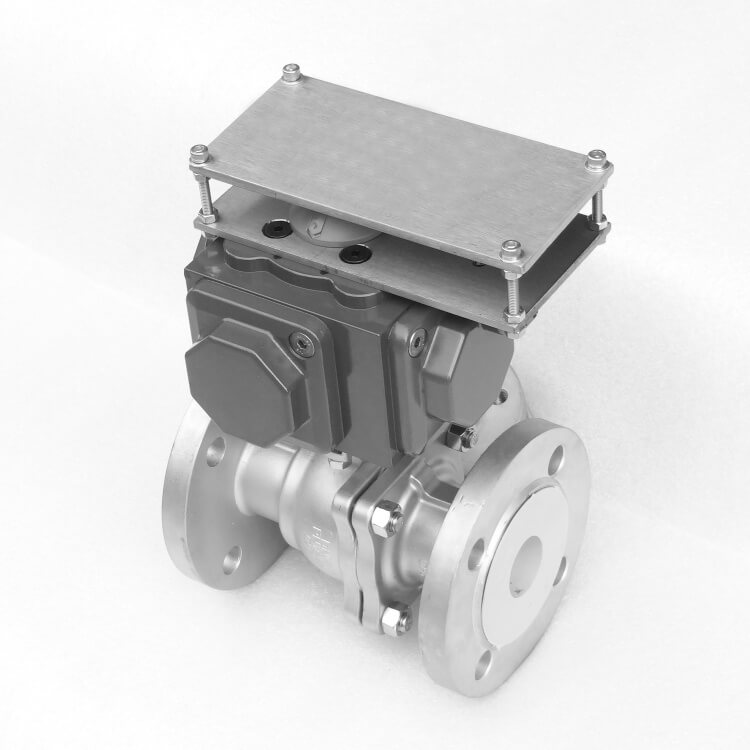

Valtorc USA Fire Safe Ball Valves are generally supplied with manual hand lever or gear actuator operated, depending on valve size. We also offering Ball Valves with Pneumatic Single Acting Actuator, Pneumatic Double Acting Actuator, Rotary Actuator, Quarter Turn Actuator or Electrical actuator operated for automation.

Valtorc USA"s Process Valves & Automation Fire Safe Design Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) to suit special requirement of client.

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

One of the more recent developments in industrial tools to prevent fire is the introduction of fire safety valves. These valves are designed to prevent a fire from spreading if the fuel valve gets damaged or causes a leakage.

A valve is a device that adjusts, directs, or controls the flow of a fluid by opening, closing, or partially blocking various passageways. Valves are technically a type of fitting but are usually discussed separately. In an open valve, fluid flows from higher pressure to lower pressure. The simplest kind of valve is simply a freely hinged flap that drops to obstruct flow one way but is pushed open by fluid flowing the opposite way. This ancient valve is called a check valve, as it stops or "checks" the flow in one direction. Modern valves may regulate pressure or flow downstream and operate on sophisticated automation systems.

Valves have industrial applications for controlling processes, residential uses such managing water flow to dish and clothes washers and taps in the home. They are found in almost every industrial process, including mining, water and sewage processing, power generation, food manufacturing, processing of oil, gas and petroleum, chemical and plastic manufacturing, and many other fields.

Fire-safe valves are spring-loaded valves that are thermally actuated. In case of fire, they close automatically and stop the fuel flow. The fuel flow from the crankcase of the engine and the reserve oil supply gets hindered, thus minimizing the chances of leakage.

Spring-loaded valves help with preventing the flow of fuel such as oil, gas, petrol, and other combustibles, and are useful and effective against any damage. The benefits of using fire-safe valves in a system are the protection of human life, lower insurance rates, and the protection of equipment and the building.

It is because of these benefits that the use of these valves is highly recommended and appreciated. These days, many companies offer an extensive range of fire-safety valves to provide protection even in high temperature and high-pressure conditions.

A fire safety valve aims to keep ignitable fluids away from a flame. These valves close when exposed to heat, separating a flammable liquid from the heat source. They close in the midst of overheating of the pipeline, brought on by fire or similar events. The obligation to use fire safety valves is subject to any tenets, regulations, and laws concerning the unique methodology, plant, pipeline, or vessel.

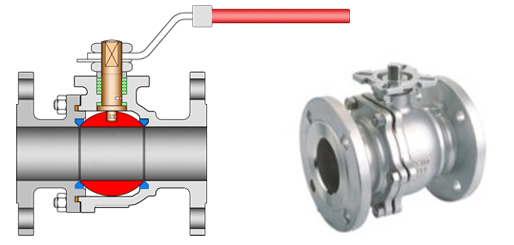

Fire-safe ball valves use a combination of a floating ball, graphoil seals, and metal-to-metal seating to provide tight shut-off while preventing external stem leakage. In normal working conditions, the ball rests against two seats, ensuring bubble-tight closure. When the valve is exposed to a temperature above the limits the seats can withstand (for example, +450°F), the seats become deformed and are subject to extrusion. When the seats have been completely destroyed, the ball in the valve will come to rest firmly against the end cap, producing a metal-to-metal closing. Stem seals, which have high temperature-resistant properties, further restrict leakage in conjunction with a blow-out-proof anti-static stem, so that the flammable fluid stays separate from the heat source that may ignite it.

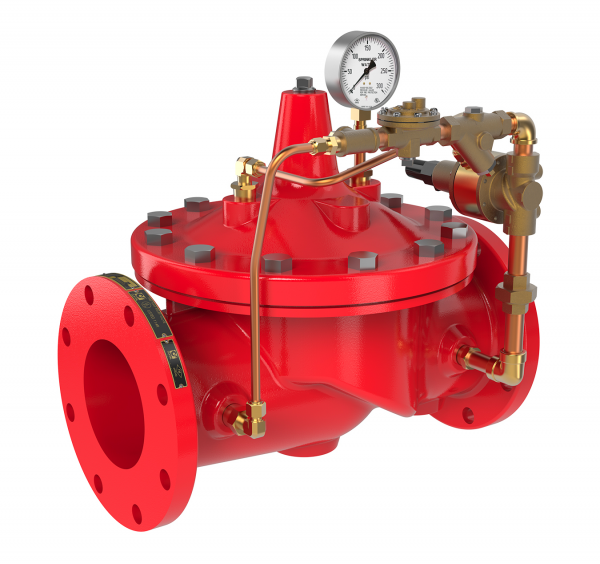

A fire-safe valve may also be made up of four main mechanisms: a spring pack, a trigger assembly, mounting hardware, and a fusible link. The components work in unison to close the valve should a fire be detected within a facility. The fusible link is the key part of the assembly. It keeps the valve open by maintaining tension on a spring pack through the trigger assembly. When a fire breaks out, the fusible link separates once it is heated to a certain high temperature, which releases the spring pack and allows it to close the valve.

A fire-safety valve with fusible links has a primary drop-tight seat, usually made of TFE, along with a second seat made of metal for isolation in a fire. The secondary seat also has graphite seals for further protection. This means that the shut-off valves can be paired with any quarter-turn ball valve, butterfly valve, or plug valve.

This article presents an understanding of fire safety valves. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

The feedback signal of the limit switch is combined to indicate the valve opening and closing position. The appearance design is exquisite, and the installation with the actuator is more compact and convenient. The device can effectively monitor the specific switching status of the valve and realize the local and remote monitoring functions.

When testing or repairing the fused emergency shut-off valve, the switch device (valve) installed upstream must be turned off. The fused emergency shut-off valve only operates in emergency situations. In order to enable it to operate correctly in an emergency, it should be manually opened and closed more than three times a year to avoid debris deposits or other conditions that may cause the valve to not work properly.

Fire Safety Valves are critical safety devices designed to isolate flammable liquids and gases from extreme heat and open flames. When exposed to high temperatures, the fire safety valve closes to prevent flammable liquids from coming into contact with heat sources, whether in a fire or an overheated system. These hot shutoff valves are usually available in two configurations: Fire Ball Valves and butterfly valves.

The fire safety ball valve is designed to American Petroleum Institute (API) Standard 607. One of the characteristics of the fire safety ball valve is that it operates under operating conditions similar to ordinary valves. In case of fire, the resilient seat will burn off, but a secondary metal will come into play and allow the ball to seal against it. The valve also includes graphite body seals and packing to prevent external leakage.

A fire safety valve with a fusible connector includes a spring assembly with a clock and a trigger attached to the fusible connector. The connecting Rod keeps the valve open during normal operation by maintaining tension on the spring. When exposed to heat above a certain temperature, the connecting rod disconnects, releasing the Spring and closing the valve.

Fire Safety Valves are essential for all operations from building safety systems to process equipment. THINKTANK provides those fire safety valves to the following applications which have excellent performance. Main Generator and backup generator

In a typical globe valve, if the yoke is exposed to the direct flame of a fire, it will expand at a rate much greater than the stem. Thermal effects cause the yoke arms to grow, which makes the disc lift up off the seat, leading to considerable leakage. This is true of virtually all globe valves now on the market.

Conval has developed a simple mechanism that compensates for thermal expansion. The stem bushing is allowed to float in a recess in the top of the yoke and is loaded by a series of Belleville washers. The Bellevilles maintain a load, forcing the stem assembly down into the seat, even when the yoke expands at the high temperatures of a refinery or chemical fire.

The Conval fire-safe Clampseal® valve has been tested and successfully passed the rigorous test procedure defined by the American Petroleum Institute (API) Standard 6FA. In brief, this procedure calls for the test valve to be placed in line and pressurized to 75% of rated pressure, then subjected to a 1400-1800°F fire for 30 minutes. The valve is then quenched with water to cool it to ambient temperature, cycled to prove operability, and then subjected to further pressure testing. The valve is required to maintain strict leakage allowances during and after the burn.

Our entire line of Clampseal® globe valves may be retrofitted with this fire-safe capability, including: Y-pattern stop and stop check valves; T-pattern stop and stop check valves; angle pattern and stop check valves.

In extreme environments, the simpler the design and the fewer the parts, the better. The durable single-piece stainless steel gland contributes to the longevity of the valve.

With secure leak-proof bonnet, this chamber allows rapid access to valve trim for inspection and maintenance. Pressure boundary is sealed at the smallest diameter possible, to ensure maximum strength and low stress.

The Clampseal® pressure-actuated backseat provides maximum valve integrity by ensuring a positive internal stop for the valve stem and disc assembly. The pressure actuated backseat also extends packing life by securely isolating the packing from the pressure when the valve is fully open.

The Axial design ensures tight concentricity, which eliminates side loading of the packing and minimizes wear forces on the trim components. This feature is critical for superior valve performance.

The CLAMPSEAL® Valve is much easier to renew than anything else on the market. The CLAMPSEAL® Valve line provides a modular solution to rising maintenance expenses. Low acquisition cost is not as important as low cost over the serviceable life of a valve. Maintaining a Conval valve is far easier and much less costly than replacing a competitor’s valve.

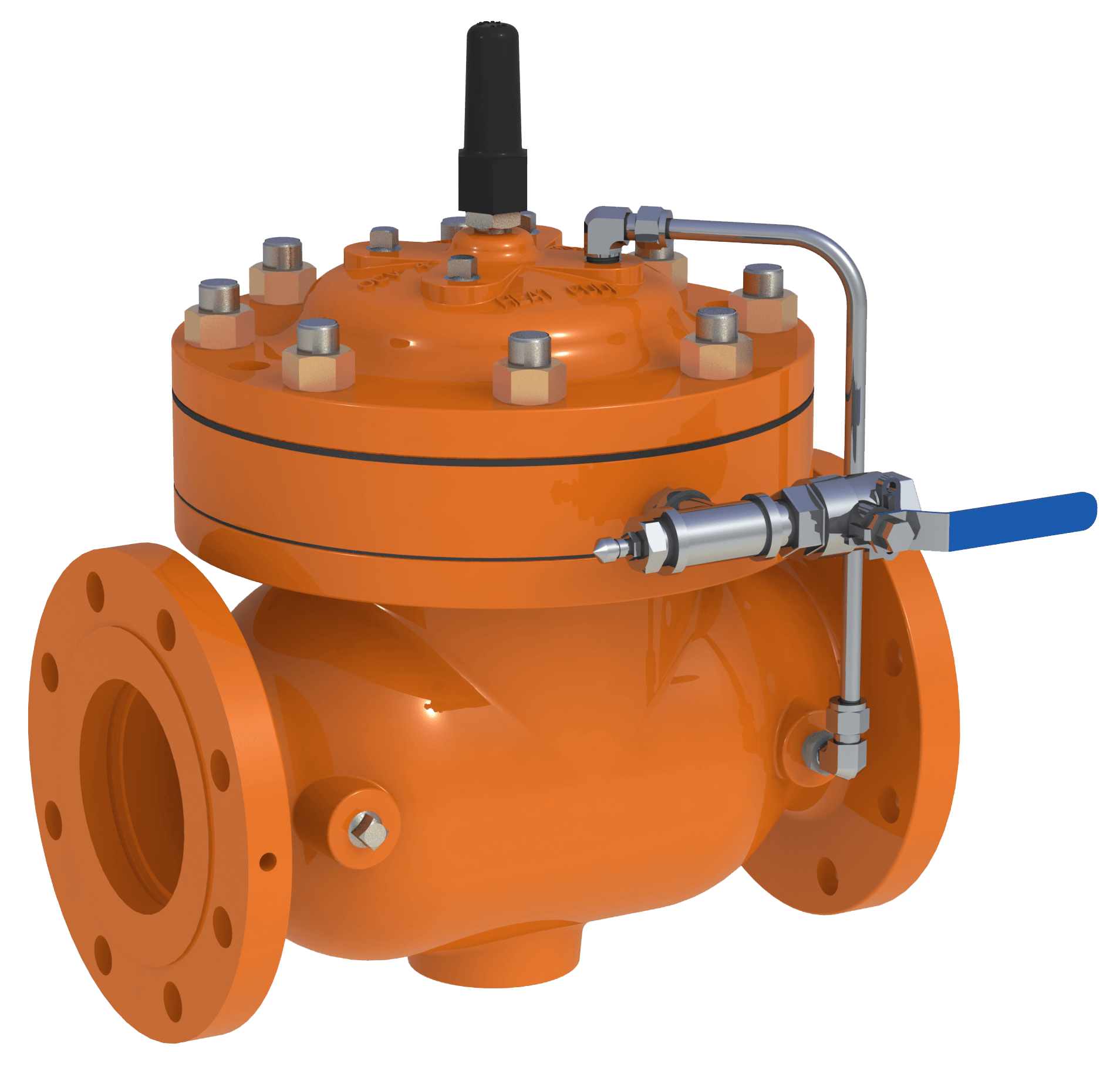

In minutes, a fire can engulf an entire building or consume a home — damaging or destroying everything in its wake. When a catastrophe happens, there’s no time for error. That’s why Singer Valve’s fire protection valves are built to the same high-quality standard as all of our water valves, and beyond the standard of many of our competitors. As industry leaders, we understand that when it comes to protection from the ravages of fire, you need a valve you can rely on every time.

AGF Manufacturing Inc is a solutions provider to the fire sprinkler industry, specializing in manufacturing products that are reliable, versatile, and code compliant. The company was founded on the principles of reliability, versatility, and code compatibility, and has been introducing original products that accommodate the varying demands of the fire sprinkler industry. AGF is committed to continuously improving existing products and introducing new ones to meet the needs of the fire protection industry. The company has a strong commitment to customer service and has a close interaction with the fire sprinkler community. AGF aims to help manage fire sprinkler systems more efficiently by engineering more intuitive products, resulting in more reliable systems that better protect lives and save resources.

In addition to being installed aboard nearly every ship in the US Navy’s fleet, helping to keep our country’s servicemen safe in the event of a fire, our globally proven fire protection products can be found in nearly any type of facility on or offshore, including oil platforms, FPSOs, refineries, power plants, chemical storage facilities, mines, tunnels, aviation facilities, high-rise office and residential buildings, hospitals and historic landmarks.

No matter how challenging your requirements are, Cla-Val has the fire protection product you need to protect lives and property. Cla-Val fire products are UL and ULC listed and have Factory Mutual approval along with other industry approvals and certifications.

Threaded fire safe fusible link ball valves: Fire-safe, fusible link ball valves are a great way to protect a valve line that is exposed to extreme heat. With automatic shut off once the FM approved links are broke, the valve will close without human assistance. All fusible links are FM approved and all valves are API fire safe approved. Flanged fire safe, fusible link ball valves are a great way to protect a valve line that is exposed to extreme heat. With automatic shut off once the FM approved links are broke, the valve will close without human assistance. All fusible links are FM approved and all valves are API fire safe approved.

Flanged fusible link fire safe ball valves: ANSI flanged fire safe, a fusible link ball valve in carbon steel. Available in sizes from 1/4″ to 4″ with FM approved fusible links. All fusible link valves are API approved and made in the USA.

Flanged fire safe, fusible link ball valves are a great way to protect a valve line that is exposed to extreme heat. With automatic shut off once the FM approved links are broke, the valve will close without human assistance.

Fire-safe fusible link butterfly valve package: Fire-safe, fusible link butterfly valve. Available in carbon steel, in wafer or lug designs, from sizes 1/4″ to 6″ and 6″ to 24″. Butterfly valves are offered actuated and fusible links are FM approved.

Fusible link fire safe butterfly valves are the perfect solution to a hazardous project which needs automatic shut off in case of a fire. Fusible links are FM approved and available in heats up to 300F. You can operate these valves while they are engaged.

A crucial component in any fire protection system our customized fusible link shut-off valves (also referred to as “thermal shut-off valves”) are ideal for any pipeline handling flammable liquids. With OSHA, Factory Mutual (FM) and insurance companies increasingly requiring that automatic shut-off valves be used in these applications, the need for our product is greater than ever.

Our complete line of API 607 certified quarter-turn valves suit a wide range of applications. Carbon and stainless steel ball valves are available in 1/4” through 6” sizes with ANSI flanges and NPT, socket weld or BSP ends. Fire safe high performance butterfly valves come in 2” through 24” sizes.

The Model 119-O fire safety oil shut-off valve combines an API rated oil shutoff valve with a fusible link making a complete 3rd party approved fire safety valve assembly for fuel oil applications.

Each valve is shipped with a red protective safety link that must be removed prior to putting the valve into operation. A hand lever or wheel is provided to manually close the valve regardless of the action of the spring pack. Once put into operation, the valve is held open against the torque of the spring pack by the fusible link. If subjected to temperatures greater than 165° F the fusible link melts and the valve slams closed.

The Model 119-O may be used in any oil fueling system to ensure positive oil shutoff in the event of a fire. This includes boiler rooms, diesel generator rooms, tank farms, refineries, and chemical plants. It must be installed in a horizontal run of pipe with the spring pack pointed upward.

Fire Protection Resilient Seat NRS Gate Valve Groove End Non rising stem gate valve by Arita Fire Solutions, has the option of operation of handwheel or use in combination of indicator post.

8613371530291

8613371530291