fire safety valve in stock

Valtorc USA Fire Safe Ball Valves are generally supplied with manual hand lever or gear actuator operated, depending on valve size. We also offering Ball Valves with Pneumatic Single Acting Actuator, Pneumatic Double Acting Actuator, Rotary Actuator, Quarter Turn Actuator or Electrical actuator operated for automation.

Valtorc USA"s Process Valves & Automation Fire Safe Design Ball Valves are also available with different type of Seat, Seal & Packing material such as P.T.F.E. (Virgin) / Glass Filled P.T.F.E. / Carbon Filled P.T.F.E. / Graphite (Grafoil) to suit special requirement of client.

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

The Model 7000 is a pressure relief valve specifically designed to relieve excess pressure caused by pressure surges or temperature changes in all wet fire sprinkler systems. Model 7000 pressure relief valves comply with NFPA 13 requirements stipulating that a pressure relief valve must be installed on all wet systems and downstream of all pressure-reducing valves. Model 7000s feature a bronze body, stainless steel spring, and flushing handle to remove debris. The Model 7000 can be purchased individually or as part of the TESTanDRAIN Kit with all necessary drainage piping and connections for use with all AGF TESTanDRAIN valves. Pressure relief valves can be installed on a TESTanDRAIN valve without removing the valve from the line or draining the system completely. The 7000 features a 1/2" MIPT inlet and FIPT outlet and is UL Listed and FM Approved. It is rated for 175 PSI Systems. Other Ratings Available: 205, and 250. Please specify PSI when ordering.

UL and FM standards for sprinkler system pressure relief valves require relief valves to operate within a range of their ratings. FM requires a relief valve to OPEN at a pressure no less than 85% of their rating and UL requires OPENING at a pressure no greater than 105% of their rating. Both standards require the relief valves to CLOSE within a percentage below OPEN. Choose the relief valve comparing static pressure to 90% of the relief valve"s rating to determine the estimated minimum OPENING and 80% of the relief valve"s rating for the approximate maximum CLOSING. The relief valve should be installed where it is easily accessible for maintenance. Care should be taken that the relief valve CANNOT be isolated from the system when the system is operational. A relief valve should NEVER have a shutoff valve or a plug downstream of its outlet.

TheAH Stock Newton 1050 Gate-Style Quick Dump Valve, also referred to as a 1050 flip-up dump valve, is manually operated.The handle for the 1050 gate valve is a two position handle mounted on the top of the valve. This 1050 dump valve is available in mild or stainless steel construction.In testing, the 1050 series Dump Valve had a flow rate of 3570 GPM and was able to completely empty a 2500 Gallon tank in 42 seconds. To order this valve and customize it for your specific needs, please contact us.Features:

Fusible link valves are designed to automatically shut off any gas or liquid in the pipeline when the fire is present. This ensures that fires don’t spread and offers better performance than standard shut-off valves.Heat-sensitive elements will shrink and cause the fusible top work assembly to open, cut off fluid flow through a pipe, and prevent fuel leakage.

The fusible link serves as a pressure release and shutoff valve used to prevent the overpressurization of equipment and/or piping systems. It allows pressurized fluid to discharge through a pipe into the atmosphere or into another section of piping.

A fire-safety valve with a fusible link is an important safety device in the event of a fire on naval vessels, as a fire extinguisher is not sufficient on its own to prevent the risk of explosion from overheating oil tanks.

Contact us today if you would like more information about our fire-safety valves with fusible links! We offer competitive pricing and excellent customer service! You can get fusible link valves from THINKTANK, and build your own brand.

Distributor of fire protection system valves. Hose angel, resilient wedge, slow closing and grooved type butterfly, dry, floor control test and drain valves are available. Offered in different specifications and features. Made of brass, bronze, stainless steel and ductile iron materials. Capabilities include design, installation, training, service, inspection, repairing, CAD engineering services, testing and maintenance. Used for indoor and outdoor and potable water systems. Applications include commercial, retail, restaurants, food service, schools, worship assemblies, hospitals, healthcare providers, property management, industrial manufacturing and warehousing facilities. 24 x 7 emergency services are available. UL® listed and FM approved. NICET certified.

One of the more recent developments in industrial tools to prevent fire is the introduction of fire safety valves. These valves are designed to prevent a fire from spreading if the fuel valve gets damaged or causes a leakage.

A valve is a device that adjusts, directs, or controls the flow of a fluid by opening, closing, or partially blocking various passageways. Valves are technically a type of fitting but are usually discussed separately. In an open valve, fluid flows from higher pressure to lower pressure. The simplest kind of valve is simply a freely hinged flap that drops to obstruct flow one way but is pushed open by fluid flowing the opposite way. This ancient valve is called a check valve, as it stops or "checks" the flow in one direction. Modern valves may regulate pressure or flow downstream and operate on sophisticated automation systems.

Valves have industrial applications for controlling processes, residential uses such managing water flow to dish and clothes washers and taps in the home. They are found in almost every industrial process, including mining, water and sewage processing, power generation, food manufacturing, processing of oil, gas and petroleum, chemical and plastic manufacturing, and many other fields.

Fire-safe valves are spring-loaded valves that are thermally actuated. In case of fire, they close automatically and stop the fuel flow. The fuel flow from the crankcase of the engine and the reserve oil supply gets hindered, thus minimizing the chances of leakage.

Spring-loaded valves help with preventing the flow of fuel such as oil, gas, petrol, and other combustibles, and are useful and effective against any damage. The benefits of using fire-safe valves in a system are the protection of human life, lower insurance rates, and the protection of equipment and the building.

It is because of these benefits that the use of these valves is highly recommended and appreciated. These days, many companies offer an extensive range of fire-safety valves to provide protection even in high temperature and high-pressure conditions.

A fire safety valve aims to keep ignitable fluids away from a flame. These valves close when exposed to heat, separating a flammable liquid from the heat source. They close in the midst of overheating of the pipeline, brought on by fire or similar events. The obligation to use fire safety valves is subject to any tenets, regulations, and laws concerning the unique methodology, plant, pipeline, or vessel.

Fire-safe ball valves use a combination of a floating ball, graphoil seals, and metal-to-metal seating to provide tight shut-off while preventing external stem leakage. In normal working conditions, the ball rests against two seats, ensuring bubble-tight closure. When the valve is exposed to a temperature above the limits the seats can withstand (for example, +450°F), the seats become deformed and are subject to extrusion. When the seats have been completely destroyed, the ball in the valve will come to rest firmly against the end cap, producing a metal-to-metal closing. Stem seals, which have high temperature-resistant properties, further restrict leakage in conjunction with a blow-out-proof anti-static stem, so that the flammable fluid stays separate from the heat source that may ignite it.

A fire-safe valve may also be made up of four main mechanisms: a spring pack, a trigger assembly, mounting hardware, and a fusible link. The components work in unison to close the valve should a fire be detected within a facility. The fusible link is the key part of the assembly. It keeps the valve open by maintaining tension on a spring pack through the trigger assembly. When a fire breaks out, the fusible link separates once it is heated to a certain high temperature, which releases the spring pack and allows it to close the valve.

A fire-safety valve with fusible links has a primary drop-tight seat, usually made of TFE, along with a second seat made of metal for isolation in a fire. The secondary seat also has graphite seals for further protection. This means that the shut-off valves can be paired with any quarter-turn ball valve, butterfly valve, or plug valve.

This article presents an understanding of fire safety valves. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

Fire Protection Resilient Seat NRS Gate Valve Groove End Non rising stem gate valve by Arita Fire Solutions, has the option of operation of handwheel or use in combination of indicator post.

Fire Safety Valves are critical safety devices designed to isolate flammable liquids and gases from extreme heat and open flames. When exposed to high temperatures, the fire safety valve closes to prevent flammable liquids from coming into contact with heat sources, whether in a fire or an overheated system. These hot shutoff valves are usually available in two configurations: Fire Ball Valves and butterfly valves.

The fire safety ball valve is designed to American Petroleum Institute (API) Standard 607. One of the characteristics of the fire safety ball valve is that it operates under operating conditions similar to ordinary valves. In case of fire, the resilient seat will burn off, but a secondary metal will come into play and allow the ball to seal against it. The valve also includes graphite body seals and packing to prevent external leakage.

A fire safety valve with a fusible connector includes a spring assembly with a clock and a trigger attached to the fusible connector. The connecting Rod keeps the valve open during normal operation by maintaining tension on the spring. When exposed to heat above a certain temperature, the connecting rod disconnects, releasing the Spring and closing the valve.

Fire Safety Valves are essential for all operations from building safety systems to process equipment. THINKTANK provides those fire safety valves to the following applications which have excellent performance. Main Generator and backup generator

Fire Safe Valves are the valves that has the ability to maintain their pressure holding capacity during and after exposure to fire. The reason for using this kind of valve we use is because of the higher possibility of hazardous/flammable fluid getting leaked from the valves during an event of a fire.

As opined by an expert Valve Stockist in USA,if non-fire safe valves are used for a fluid that is flammable having a higher chance to be exposed to the pool of fire during an accident, then leakage will occur from the valve stem seal that already might have melt. Thus, as suggested a need for a fire-safe valve that doesn’t leak when exposed to fire is the need of the hour.

There are actually two kinds of leak that is supposed to be avoided when a valve is exposed to a fire accident which leads to leakage from the stem and leakage from the seat. Owing to this there are two distinct methods to achieve a fire-safe design, as formulated by expert Valve Manufacturersby the usage of a fire-proof component or by use of a non-fire proof component which is supported by a special design that prevents leakage after the components melt in case of a fire mishap.

Fire safety valves being a recent development in the industrial tools to prevent fire are basically designed to prevent a fire from spreading if the fuel valve gets damaged causing a leakage.

Actually these valves are spring-loaded valves that are thermally actuated which in case of fire, close automatically stopping the fuel flow from the crankcase of the engine thus the reserve oil supply gets stopped, minimizing the chances of leakage occurring.

The benefits of using these valves are the protection of human lives, lowered insurance rates, and the protection of equipments along with the buildings it is placed.

Under the scorching high temperatures, it is necessary to use metal construction for the valves, the reasons why the primary valve types to be considered for fire-safe are gate and globe valves because of their metal-to-metal seating.

The soft-seated rotary valves include the ball valves, plug valves and butterfly valves. All the manufacturers of rotary stem valves in order to prove bubble-tight shutoff in the normal valve operation as well as fire safety are employing two types of valve seating arrangements.

Here in the first system, for the fire-safe ball valves,a metal sealing usually occurs when, the floating ball moves downstream to contact a machined surface in the body which matches the shape of the ball.

The second system typically used by some of the high-performing butterfly valve supplier and manufacturers is not wholly depending on the total seat burn since a resilient seat and metal seat primarily contacts the disc at the same point of time.

If the valves are of a two/ three-piece body design, then utmost attention must be paid to the body seal materials to prevent a worst leakage during a fire accident. The butterfly valves generally use a rigid disc and a stem connection where the packing material is graphite due to its ability to withstand higher temperatures of 700°C). The one-piece body design of all most all of the high-performance valves ensure to eliminate body seal leakage efficiently.

Our fire safe valves are ball valves and butterfly valves availabe for a maximum custom configuration. As a leading Valve Stockist in UAE, we ensure that our valves are available in all sizes. All fire safe valves are UL FM approved valves that have a higher temperature range.

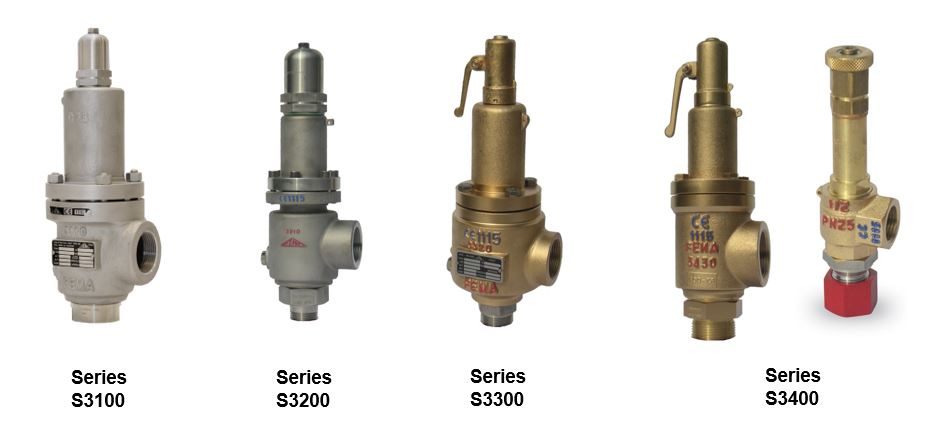

Don’t settle in for the cheaper competitions its time to invest in a higher quality product from Fevisa – the quickest and most economical choice for the fire safe valves. Our fire safe valves are also WRAS approved Valves. We are also fire valve suppliers and we called as european valve manufacturers.

Fevisa is ever ready to help you out in the choice of ex-stock valves. If you have any query about valve selection, or if you don’t fina a valve that meets your precise specifications, please contact us for complete assistance.

Cla-Val is a world-leading designer and manufacturer of automatic control valves. From reducing and relief valves to deluge, air valves and more, Cla-Val manufactures and provides a wide variety of solutions for use in some of the world’s most demanding applications.

Do you want to control, restrict or shut something off? Then we should talk to each other about our high-pressure ball valves, flow control valves, needle valves and check valves. Because we are really good at controlling, restricting and shutting off. So good, that we are represented with this know-how in each of the three main time zones. So fast, that our short processing times allow series products to be delivered within 48 hours. So diverse, that reading our standard program will take you some time. And so well founded, that the competence of our large engineering team will amaze you. And why all of these superlatives? So that we can deliver the best product for you as quickly and as well as possible. And all from a single source – consulting, development, manufacturing and assembly of our high-pressure ball valves and high-pressure valves.

MILWAUKEE – (June 16, 2020) – Johnson Controls announces the launch of two new TYCO® pressure control valves for fire protection systems: the TYCO® Model RV-1A Pressure Relief Valve and the TYCO® Model PRV-1A Pressure Reducing Valve. The new valves offer simple, low-maintenance solutions for controlling and maintaining optimal water pressure within commercial fire protection systems.

The TYCO® RV-1A Pressure Relief Valve automatically relieves excess pressure in fire protection systems to maintain a relatively constant system pressure as flow demands change. Its simple design eliminates the need for users to bleed trapped air from the diaphragm chamber. The valve offers users a nominal relief “set pressure” range of 30 to 250 psi (2.1 to 17.2 bar).

"With a simple trim configuration and just one moving part, just like the DV-5A, these new valves provide optimal pressure control with minimal maintenance and dependable, consistent operation over time." – Gijsbert van Rooijen, global product manager, Johnson Controls

The TYCO® PRV-1A Pressure Reducing Valve reduces a higher inlet pressure to a lower outlet delivery pressure in water-filled pipes. It automatically maintains the outlet "set pressure" (static and residual) within a close range, regardless of fluctuations in the higher-pressure inlet line or varying flow rates.

“We developed both valves using the same diaphragm design as the TYCO® DV-5A deluge valve, said Gijsbert van Rooijen, global product manager, Johnson Controls. “With a simple trim configuration and just one moving part, just like the DV-5A, these new valves provide optimal pressure control with minimal maintenance and dependable, consistent operation over time.”

The RV-1A and PRV-1A valves are UL and ULc Listed and FM Approved. Both valves are factory assembled and fully trimmed. They are available in sizes ranging from two inches to eight inches, with flange-by-flange and grooved-by-grooved end connection options.

At Johnson Controls, we transform the environments where people live, work, learn and play. From optimizing building performance to improving safety and enhancing comfort, we drive the outcomes that matter most. We deliver our promise in industries such as healthcare, education, data centers and manufacturing. With a global team of 105,000 experts in more than 150 countries and over 130 years of innovation, we are the power behind our customers’ mission. Our leading portfolio of building technology and solutions includes some of the most trusted names in the industry, such as Tyco®, YORK®, Metasys®, Ruskin®, Titus®, Frick®, Penn®, Sabroe®, Simplex®, Ansul® and Grinnell®. For more information, visit www.johnsoncontrols.com or follow us @johnsoncontrols on Twitter.

8613371530291

8613371530291