fire safety valve fusible link factory

Fusible link valves are designed to automatically shut off any gas or liquid in the pipeline when the fire is present. This ensures that fires don’t spread and offers better performance than standard shut-off valves.Heat-sensitive elements will shrink and cause the fusible top work assembly to open, cut off fluid flow through a pipe, and prevent fuel leakage.

The fusible link serves as a pressure release and shutoff valve used to prevent the overpressurization of equipment and/or piping systems. It allows pressurized fluid to discharge through a pipe into the atmosphere or into another section of piping.

The fusible link can be set to melt at different temperatures depending on the type of gas or liquid that is being used, such as natural gas, propane, oil, water, etc.

Fusible links are fast-acting shutoff devices that, once activated by high temperature, release pressure rapidly to protect equipment and/or systems from damage due to overpressurization. The fusible link consists of a length of wire or ribbon of fusible metal with two small arms at either end. The fusible metal used is an alloy that has a low melting point, generally the same as or lower than the pressure-containing medium being protected against overpressurization.

A fire-safety valve with a fusible link is an important safety device in the event of a fire on naval vessels, as a fire extinguisher is not sufficient on its own to prevent the risk of explosion from overheating oil tanks.

Contact us today if you would like more information about our fire-safety valves with fusible links! We offer competitive pricing and excellent customer service! You can get fusible link valves from THINKTANK, and build your own brand.

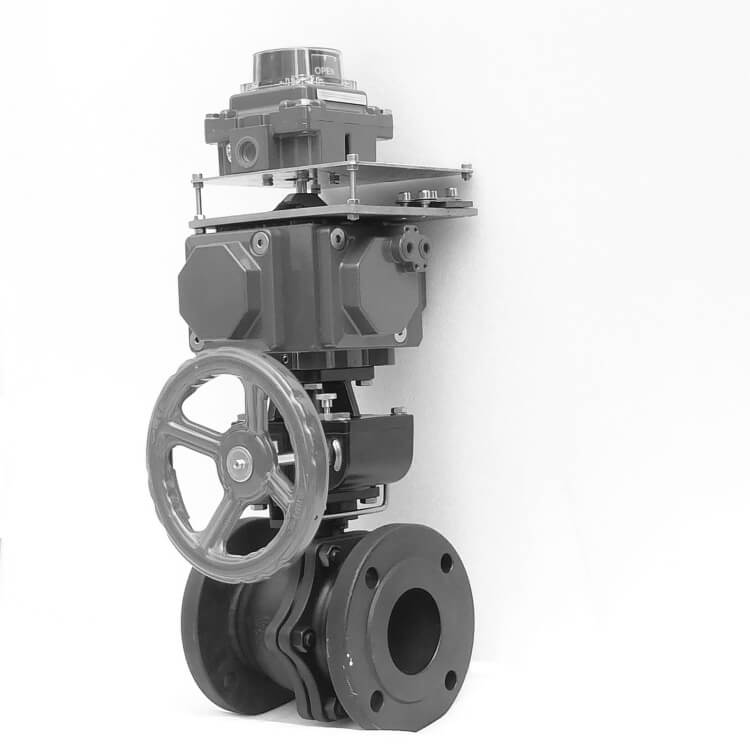

Assured Automation"s FM Fire-Safe Thermal and Electro-Thermal ball valve and butterfly valve assemblies are designed to shut off automatically and control hazardous conditions. The heat actuated, U.L. listed thermal links automatically shut off or open the valve at predetermined temperatures. Ball and Butterfly assemblies are available with manual levers or gear operator which will allow the valve to operate manually at any time without affecting the fusible links or removing the spring loaded canister.

A crucial component in any fire protection system our customized fusible link shut-off valves (also referred to as “thermal shut-off valves”) are ideal for any pipeline handling flammable liquids. With OSHA, Factory Mutual (FM) and insurance companies increasingly requiring that automatic shut-off valves be used in these applications, the need for our product is greater than ever.

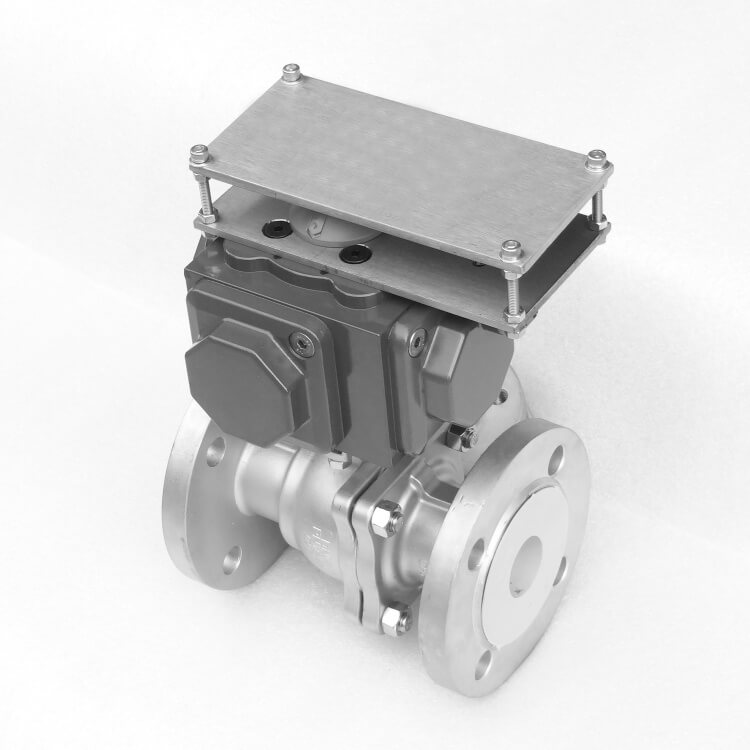

Our complete line of API 607 certified quarter-turn valves suit a wide range of applications. Carbon and stainless steel ball valves are available in 1/4” through 6” sizes with ANSI flanges and NPT, socket weld or BSP ends. Fire safe high performance butterfly valves come in 2” through 24” sizes.

A fire-safety shut-off valve, also known by thermal shut-off valve or simply afusible link valve, is a safety device designed to provide automatic valve shut-off in the event of a fire. Fire-safety valves of this type are designed for facilities that utilize flammable or toxic gases and chemicals in their production or for fuel systems of all types.

The fusible link is an FM and/or UL approved two-part linkage held together by a specialized heat-sensitive solder. These link(s) hold the fire safety valve open by keeping tension on a spring pack through a trigger assembly.

A fire safety shut-off valve is comprised of five main components – API 607 fire-safe valve, spring pack, mounting hardware, trigger assembly, and fusible link. The last four of these components work in unison to close the API 607 valve should a fire be detected within a facility.

The fusible link portion is the linchpin of the assembly and keeps the fire safety valve open by keeping tension on a spring pack through the trigger assembly. When a fire breaks out, the link separates when its rated temperature is met, releasing the spring pack and allowing it to close the valve.

The API 607 standard is a specification for the fire testing of quarter-turn valves. For fire-safety valve with fusible links, this means that the valves have a primary drop-tight seat, typically made of TFE, along with a secondary seat made of metal for isolation in a fire. The secondary seat is coupled with graphite seals for further protection. This means the top works of the shut-off valve can be paired with any quarter-turn API 607 fire safe valve – ball valve, butterfly valve, or plug valve.

Fusible link fire-safety valves are used in a variety of industries within an organization’s overall fire safety system for widespread fire protection. Most modern facilities have at diesel generators and day tanks that that requires this type of safety valve at a minimum. Other locations where flammable or toxic media are part of the production process, this valve type is placed at strategic locations throughout facilities including storage tanks, pumps, entryways into a building, and at key piping junctions. Entryways into buildings are especially key so that have employees, customers, and patients have as much time for notification and evacuation as possible.

A fire safety valve should be used as a safety precaution on any system that utilizes flammable or hazardous media. Designed to save lives and enable quick resumption of operations after a fire has been handled, fusible link assemblies are necessary for the safe daily operations of many commercial operations, plants, and manufacturing facilities. Many of these operations will find that insurance for their business is not available without a fire safety valve with fusible link.

BI-TORQ has been designing this type of assembly for over two decades. Let’s have a conversation about your fire safety needs and how our products can provide safety for your workers and operation. Contact us for more information on fire safety valves with fusible links, or to discuss any of our wide range of valve solutions.

Howell provides Firesafe API 607 ball and butterfly valves with BI-TORQ® fusible link assemblies. These thermal shutoff valves are designed for automatic shutoff in case of a fire. They are used in applications requiring media containment in systems conveying flammable gases or liquids, solvents, alcohols, toxic fluid or any other potentially dangerous media.

Fusible link valves are a type of valve that is used in shutoff applications as a safety measure. These valves are designed to be used in control systems that deal with flammable, combustible, or toxic materials. The fusible link refers to the part of the valve that is designed to fail. In the event that a certain preset temperature is exceeded, this link releases the tension on a spring, which closes the valve and prevents any process media from flowing past the point in the pipeline where the valve is located.

Fusible link valves mainly consist of a valve connected to a high tension spring. When the valve is opened, the spring is compressed. The link keeps the valve open and the spring tensed. The fusible link is designed to fail at a certain temperature. In case of a fire, the link breaks, releasing the tension on the spring and slamming the valve shut. This keeps any flammable or toxic media contained in the pipeline, reducing the spread of fire and helping prevent unnecessary damage, injury, or loss of life. In terms of safety, this type of valve is an integral part of safety systems and can help a company ensure the least amount of damage or loss in the event of a fire.

Fusible link valves should be used in conjunction with fire-safe valves. These are normally either ball valves or butterfly valves. It is important to make sure the valve used is rated as fire-safe, since it will be used for containment of flammable liquids. These valve assemblies can usually be found on storage tanks, mixing tanks, or transport vessels that require automatic shutoff in the event of a fire.

There are many different applications that benefit from the use of fusible link valves. These applications include petrochemical, pharmaceutical, tank farms, fueling stations, airports, biodiesel, diesel fuels, fire suppression systems, paint applications, and natural gas lines. Any one of these applications requires a fail-closed safety shutoff, which this type of valve can supply. In fact, most insurance companies require the use of these valves before they will provide insurance coverage for the plant or application.

In addition to fail-close applications, fusible link valves can also be used in fire safety protection systems as fail-open valves. This is useful in application where the valve is used to transport water or fire suppression media to the site of a fire when it is necessary. This ensures that the flow of water or fire suppression media is uninterrupted even if the valve fails. These fluids can be used to extinguish a fire or cool a storage tank, among other uses.

Our customized fusible link shut-off valves (also referred to as thermal shut-off valves) are ideal for any pipeline handling flammable liquids, oils or gasses. With OSHA, Factory Mutual (FM) and insurance companies requiring that automatic shut-off valves be used with this type of media, our valves are a necessary part of any fire protection system.

Threaded fire safe fusible link ball valves: Fire-safe, fusible link ball valves are a great way to protect a valve line that is exposed to extreme heat. With automatic shut off once the FM approved links are broke, the valve will close without human assistance. All fusible links are FM approved and all valves are API fire safe approved. Flanged fire safe, fusible link ball valves are a great way to protect a valve line that is exposed to extreme heat. With automatic shut off once the FM approved links are broke, the valve will close without human assistance. All fusible links are FM approved and all valves are API fire safe approved.

Flanged fusible link fire safe ball valves: ANSI flanged fire safe, a fusible link ball valve in carbon steel. Available in sizes from 1/4″ to 4″ with FM approved fusible links. All fusible link valves are API approved and made in the USA.

Flanged fire safe, fusible link ball valves are a great way to protect a valve line that is exposed to extreme heat. With automatic shut off once the FM approved links are broke, the valve will close without human assistance.

Fire-safe fusible link butterfly valve package: Fire-safe, fusible link butterfly valve. Available in carbon steel, in wafer or lug designs, from sizes 1/4″ to 6″ and 6″ to 24″. Butterfly valves are offered actuated and fusible links are FM approved.

Fusible link fire safe butterfly valves are the perfect solution to a hazardous project which needs automatic shut off in case of a fire. Fusible links are FM approved and available in heats up to 300F. You can operate these valves while they are engaged.

Valtorc USA Fabricated Fusible Link packages are available for immediate delivery, featuring all-USA fabrication testing and assembly. Valtorc’s fire safe, fusible link valves are available in ball valves and butterfly valves for maximum configuration. Fusible link valves are available in sizes from 1/4″ – 4″ (for ball valve series) and 2″- 8″ for our butterfly valve series. All fusible links are UL or FM approved and have a temperature range of 165F – 300F. Fusible link valves are available in stainless steel, and carbon steel.

Industries served include petrochemical, oil, gas, and nuclear. The fusible link fire safe valves are ARRA compliant and always shipped out of Valtorc’s USA factory location.

BI-TORQ® Valve Automation fire safe fusible link valve assembly allows factories to meet facility wide safety certifications by preventing the spread of fire. Flammable liquids or gasses will be contained once API 607 fire-safe certified valve automatically closes based on thermal release of a fusible link. Torque outputs range from 55-21,000 and assemblies can be used with fire safe ball or butterfly valves from ½ through 24 in. line sizes. Valve seat options include TFE®, RTFE®, TFM, PEEK and Delrin.

BI-TORQ® Valve Automation"s fusible link shut-off valve assemblies used in systems requiring automatic shut-off in case of a fire have received Factory Mutual (FM) approval. These state-of-the-art assemblies prevent the spread of fire by containing flammable liquids or gasses once the API 607 (American Petroleum Institute) fire-safe certified valve automatically closes based on thermal release of a fusible link.

FM approval means that BI-TORQ® Valve Automation fire safe fusible link valve assemblies can help reduce insurance costs and allow factories to meet facility-wide safety certifications. With torque outputs ranging from 55 to 21,000, FM-approved fusible link assemblies can be used with fire safe ball or butterfly valves from ½" through 24" line sizes. BI-TORQ® Valve Automation"s unique design allows for manual operation of most units even when the unit is armed, reducing the need for secondary valves.

API 607 fire safe approved valves can be customer-specified or provided by BI-TORQ® Valve Automation in carbon or stainless steel construction with NPT, socket weld or 150# ANSI flanged end connections. With valve seat choices in TFE®, RTFE®, TFM, PEEK and Delrin, BI-TORQ® Valve Automation"s fire safe valves are suitable for a wide variety of industries. Applications for these automatic shut-off assemblies include tank farms, petrochem, airport and truck refueling stations, paint and toxic chemicals, and biofuel operations. More information on this product is available at http://www.bitorq.com/fusible.html.

BI-TORQ® provides full service valve automation, including quarter-turn pneumatic and electric actuators; ball valves in SS, WCB/SS, brass, bronze, PVC, and CPVC; butterfly valves from 2"-24"; and automation accessories including limit switches, positioners, solenoids and customized mounting assemblies. For more information on FM-approved fusible link assemblies or other BI-TORQ Valve Automation products, contact David Marut at dmarut@bitorq.com or 630-208-9343

BI-TORQ® Valve Automation has received Factory Mutual (FM) approval on its fusible link assemblies used in systems requiring automatic shut-off in case of a fire. These state-of-the-art assemblies prevent the spread of fire by containing flammable liquids or gasses once the API 607 (American Petroleum Institute) fire-safe certified valve automatically closes based on thermal release of a fusible link.

FM approval means that BI-TORQ® Valve Automation fire safe fusible link valve assemblies can help reduce insurance costs and allow factories to meet facility-wide safety certifications. With torque outputs ranging from 55 to 21,000, FM-approved fusible link assemblies can be used with fire safe ball or butterfly valves from ½” through 24″ line sizes. BI-TORQ® Valve Automation’s unique design allows for manual operation of most units even when the unit is armed, reducing the need for secondary valves.

API 607 fire safe approved valves can be customer-specified or provided by BI-TORQ® Valve Automation in carbon or stainless steel construction with NPT, socket weld or 150# ANSI flanged end connections. With valve seat choices in TFE®, RTFE®, TFM, PEEK and Delrin, BI-TORQ® Valve Automation’s fire safe valves are suitable for a wide variety of industries. Applications for these automatic shut-off assemblies include tank farms, petrochem, airport and truck refueling stations, paint and toxic chemicals, and biofuel operations.

The Model 119-O fire safety oil shut-off valve combines an API rated oil shutoff valve with a fusible link making a complete 3rd party approved fire safety valve assembly for fuel oil applications.

Each valve is shipped with a red protective safety link that must be removed prior to putting the valve into operation. A hand lever or wheel is provided to manually close the valve regardless of the action of the spring pack. Once put into operation, the valve is held open against the torque of the spring pack by the fusible link. If subjected to temperatures greater than 165° F the fusible link melts and the valve slams closed.

The Model 119-O may be used in any oil fueling system to ensure positive oil shutoff in the event of a fire. This includes boiler rooms, diesel generator rooms, tank farms, refineries, and chemical plants. It must be installed in a horizontal run of pipe with the spring pack pointed upward.

8613371530291

8613371530291