full opening safety valve for sale

Packard Safety Valves are designed to either stab into the drill pipe or tubing at the rig floor or are used as part of the drill string to shut off a well kick. Use of these valves in the drill string enhances rig safety.

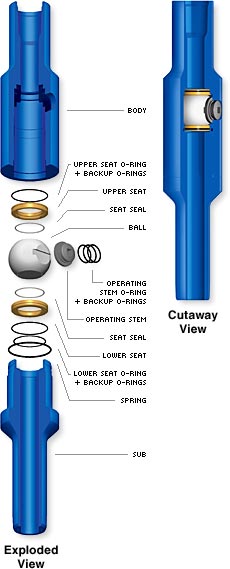

The Packard two-piece safety valve offers the convenience of a two-piece body for easy maintenance. Its full bore also allows the unrestricted flow of drilling fluid; reducing wear on critical parts while providing unrestricted access for downhole tools.

Packard International"s Safety Valves are built with enough length on each end to allow fully recutting the connections in the event of damage to the threads or shoulders where sealing takes place.

High and low pressure sealing is assured by the Teflon and metal sealing system of the ball and seats. The ball and lower seat float while the upper seat is fixed in the body. This floating/fixed design aids in low pressure sealing and enables the operator to pressure balance the valve under full rated working pressure.

Alibaba.com offers 37 full opening safety valve for drilling products. About 75% % of these are mining machine parts, 10%% are valves, and 8%% are other oil field equipments.

A wide variety of full opening safety valve for drilling options are available to you, such as energy & mining, construction works and manufacturing plant.You can also choose from 1.5 years, 6 months and 3 years full opening safety valve for drilling,As well as from bearing, {2}, and {3}. and whether full opening safety valve for drilling is russia, kazakhstan, or egypt.

Full Opening Safety Valve is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

Our Full Opening Safety Valve is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

Full Opening Safety Valve (short for FOSV) is designed to be stabbed into the top joint of drill pipe or tubing at the rig floor and closed quickly in case a well kicks. After weight material is added to the mud, the Kelly can be reconnected, the safety valve opened, and circulation initiated.

Like the Kelly valve, the Safety Valve is full opening. The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Available in 5000 PSI, 10000 psi and 15000 psi at your requeres.

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

Our FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

TIANHE FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

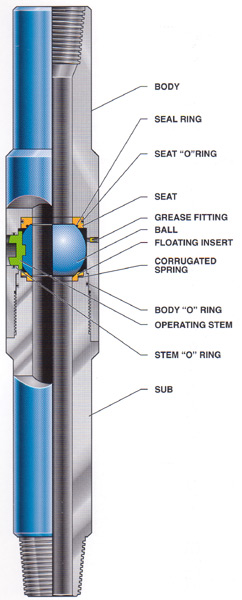

The WN-2 Ball Type Safety Valve is designed to be stabbed into the top joint of drill pipe or tubing at the rig floor and closed quickly in case a well kicks. Safety valves are not designed to rotate in the drill pipe string, rotate on a swivel or pull on a stuck string of tubing.

Like the kelly valve, the WN-2 Safety Valve is full opening. The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000 pounds, but higher pressure ratings are available.

When ordering please specify threads, O. D. and I. D. WNCO SAFETY VALVES are available in virtually any size and configuration our customers may require.

TIW is the original designer and manufacturer of ball type Safety and Kelly valves. Our strict adherence to API specifications as well as our own quality requirements ensures TIW valves are the highest quality valves in the market.

TIW Class I & Class II Kelly Valves may be utilized as a Drill Stem Safety Valve or as an Upper or Lower Kelly Cock and is designed to hold pressure from both directions.

TIW Kelly Valve Design and Quality System are certified by API.TIW Safety and Kelly Valves are also offered for H2S service, meeting all NACE standards. Standard Pressure rating is 10,000 PSI Test with higher pressure ratings available.

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

Our FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

BACK PRESSURE VALVE (INSIDE BOP/ GRAY VALVE)is a heavy-duty drop check valve that is positioned in the drill string to controlformation pressure during kicks. It controls the backflow through the inside of the drill pipe itself,preventing damage to the swivel, drilling hose, standpipe and circulation equipment.During normal circulation of drilling fluids down the drill pipe, the valve remains open to permit the flowthrough it. A conical plug, or dart, minimizes the erosive action of the drilling fluid on the valve seatand assures a long lasting seal between the valve dart and valve seat.When any backflow occurs, the valve closes automatically to contain it, protecting the drillingequipment as well as controlling the kick that could otherwise lead to a blowout.

The M&M International CANISTER GUARD® encapsulates its internal spring loading within the canister itself, which is a significant feature that cannot be overstated. During disassembly of one-piece valves made by other manufacturers, the internal spring must be compressed prior to removal of the locking mechanism. Considering the application, it is typical for mud, cement, debris, and/or corrosion to accumulate in this area. This makes it difficult or even impossible to compress the spring enough to remove the locking mechanism from valves of this kind, even when using the special tools required by the competitor manufacturer. These and other issues can make field dressing impractical and shop dressing a much longer and more expensive process than necessary. M&M International’s CANISTER GUARD® technology completely eliminates these issues, saving both time and money.

M&M International’s CANISTER GUARD® reduces the need for customer locations to keep large spare valve parts inventories on hand. In most cases, CANISTER GUARD® valves utilize identical parts within each size range. This low inventory ability allows a customer to operate with one spare canister and one or two spare operating stems in inventory, if necessary.

M&M’s Top Drive Safety Valve Bottom Load™ lower valves have an extended pin nose profile that matches the mating ID profile of M&M’s Top Drive Safety Valve Bottom Load™ upper valves. These valve systems have the all-important, rig downtime saving, Bottom Load™ feature. When the time comes for scheduled routine maintenance, the lower valve only needs to be removed to allow quick and easy access to the upper valve’s internal components.

Along with its innovative design features and our CANISTER GUARD® technology, the Top Drive Safety Valve Bottom Load™ system allows for the quickest possible inspection and/or redress procedure. Since its inception over 20 years ago, M&M’s Top Drive Safety Valve Bottom Load™ system has saved countless hours of rig downtime.

FULL OPENING SAFETY VALVE, OD: 3.1/2", MIN ID: 2-1/4", WORKING PRESSURE 5000 PSI, CONNECTION 3.1/2" IF , COMPLETE WITH WRENCH, WITHOUT HYDROGEN SULFIDE

The IBOP, also called Gray Valve or BVR, is a back pressure valve used in the drill string to prevent the well from flowing uncontrollably up the drill string. It is generally used in 2 ways:

The RDCV, also called Dart Valve or a Back-Pressure Valve, controls backflow through the drill pipe during a kick or when tripping pipe into the hole against pressure. Check-valve compatibility should be checked with Kelly Cock free passage.

Full Opening Safety Valve(short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

8613371530291

8613371530291