gas meter safety valve free sample

Caution: If the pressure will exceed the above-mentioned set pressure, the safety valve will open. However, if the flow rate from the gas source exceeds the above-mentioned max. flow rate, the valve would not be able to vent the meter quickly enough.

This article explains how to visually inspect natural or piped-in gas meters for defects and safety concerns. This document provides free sample draft home inspection report language for reporting defects in oil and gas piping at residential properties.

Here we provide descriptions and photographs of unsafe gas piping, indications of unsafe or improperly operating gas appliances, gas meters, and other gas installation defects are provided.

Do not do anything that is likely to cause a gas explosion, such as lighting a match, operating an electrical switch, or even using a telephone in the building

In this photo the gas meter shown is an obsolete model (so perhaps at higher risk of dangerous natural gas leaks into the building (an explosion hazard), and we saw no gas regulator and no vent from the meter to outside.

Natural gas or piped-in gas safety warning: improper installation and even improper inspection and testing methods involving natural or "LP" gas can involve

If you smell gas you should leave the building immediately and should do so without doing anything that could create a spark such as operating a light switch or telephone. From a safe location, call your gas company"s

where the piped-in natural gas meter is outside partly buried and inside the gas meter resting on and touching brick in a wet basement, there is a danger of gas meter corrosion

Outside the soil needs to be removed so that the meter is not touching dirt. If this corrective measure means that we"ve created a low area by the foundation it"s important to keep roof spillage out of the low spot or we may invite building foundation leaks and basement water entry.

Safety Suggestion: gas meter adequacy: If additional gas equipment has been added to this building since the installation of the original gas service meter, it is possible that the added demand can result in low gas pressure or unsafe operation.

We are still needing parts/whole meter for our 1960 American Gas Meter Company 5B-225. If you know where to find any parts for this meter and/or for The Cincinnati Gas and Electric Company (CG&E) around this era, please contact us @ 937-783-2729 (landline).. I have attached a picture of our restored meter in its "close to" original color of atomic turquoise. Thank you...

&E) around this era, please contact us @ 937-783-2729 (landline).. I have attached a picture of our restored meter in its "close to" original color of atomic turquoise. Thank you...

The third picture down used on this website (green gas meter with black pipes) is a 1965ish American Meter Co 225 Cu Ft Per Hr. We are restoring our gas meter and need parts and/or whole meter

I"ve certainly come across multiple-occupant buildings where the landlord didn"t get separate meters for gas or water or electricity, and one poor tenant ends up paying for the utilities consumed by her neighbours.

can the gas meter in your home be linked to another home/business? gas company just changed my meter and told me the meter they have on file is not the one they removed..

In my opinion it"s dangerous for a gas meter to be buried at all. The concern is that the meter base is exposed to additional corrosive forces and therefore could leak. The hazards of a gas leak are obvious, explosion and Fire.

GAS METERS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

At geocities.com/rainforest/6847/report1.html is an interesting and detailed though not “neutral” report on the components and contaminants in the combustion of natural gas. You’ll see a long long list of emissions products, but look again – most of the contaminant levels listed are in the picograms.

Kroschwitz, Jacqueline I., and Mary Howe-Grant (eds.). "Gas, Natural." In Encyclopedia of Chemical Technology. 4th ed., vol. 12. New York: John Wiley and Sons, Inc., 1993.

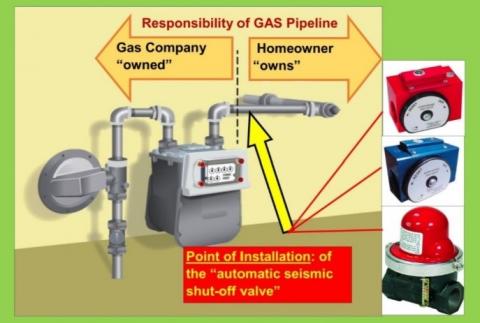

Seismic shut-off valves are a simple, but effective way to ensure you never experience a gas fire after an earthquake. They are designed for earthquakes, accidents and any event of impact. We have installed thousands of automatic gas shut off valves to the manufacture’s specification to ensure safe, trouble free use.

The seismic valves work on a simple, consistent and accurate principle. A sensor moves when the valve is subjected to a 5.4 magnitude or larger earthquake, releasing the valve float which blocks the line and prevents gas going in to the building. The valve is then manually reset once a safety inspection has been done and you’re sure there are no leaks in the building.

Each valve is tested and certified before leaving the factory to meet approval from the State Board of Architect and LA Counties stringent requirements. They are tested to ASCE 25-97, State of California 12-23-1 & ANSI Z21.70-1981 Standards for Seismic Gas Valves.

Some cities and counties in California have regulations that require the installation of automatic gas shut-off devices, which may include excess flow gas shut-off valves and/or seismic gas shut-off valves. Regulations vary, but generally apply to new building construction, or significant alterations or additions to existing buildings.

If a customer installs an automatic gas shut-off valve, it should be one that is certified by the State of California and it should be installed by a licensed plumbing contractor in accordance to the manufacturers instructions.PG&Edoes not install or service seismic actuated or excess flow gas shut-off valves, or recommend specific contractors for customer applications.

Non-emergency shut-offs will occur if the automatic gas shut-off is not installed according to manufacturer’s specifications. For example, the impact of heavy vehicles can trigger a non-emergency shut-off. They operate on movement and shut off the supply of gas to a building, when triggered by a 5.4 magnitude or larger Earthquake.

To ensure the safe delivery of natural gas to your home or business, over the next several months, we will be in your neighborhood conducting a safety inspection of your natural gas meter. As required for your safety, the inspections will assess the condition of the service line pipe and can be quickly completed.

The health and safety of our customers and employees is a top priority as we conduct these inspections. Our inspectors will follow CDC best practices and recommendations, including engaging in physical distancing and wearing appropriate personal protective equipment. There will be no paperwork to sign, nor will it be necessary to interact closely with our inspectors.

Our inspectors will use a combustible gas indicator device to detect gas leakage and complete a visual inspection for corrosion on all exposed piping connected to the natural gas meter inside your home and business. We will also obtain a meter reading while we are completing the work.

Yes, and we need your help to complete the work. In order to ensure the safe delivery of natural gas to your home or business, we are required by the New York Public Service Commission (PSC) to perform a routine leak inspection and corrosion inspection periodically.

All natural gas meters and service line piping in basements and meter rooms are required to be inspected. Our inspectors and contractors will be in your neighborhood, walking door-to-door, requesting access to your meter.

If you are not available and we are unable to access the meter and/or service line at the time of the inspection, we will leave an informational card and attempt to make a second visit at a later time. According to the NY PSC regulation and to ensure your safety, if we are unable to gain access to your meter, your gas could be shut off until your service line pipe is deemed safe, and a fee of $100 may be imposed.

But there’s one more thing affected by snow and ice that you may not think of: your natural gas meter. If gas is what keeps your home warm in the winter (or at least runs some of your appliances), you’ll need to give it a little love when it snows.

Gas meters have a vent that regulates the pressure – but it has to be unobstructed to work properly. This isn’t a problem in warmer months, but when the snow begins to pile up, it’s important to keep the pressure regulator vent clear. If it’s blocked with snow or ice, the consequences aren’t fun. At best, it could lead to a service interruption, which is pretty much the last thing you need when you’re trying to stay warm inside. At worst, it could lead to a gas leak, which could cause a fire or even an explosion.

If there is ice on your gas meter that won’t come off with a brush or your hands, call your utility company. You might be tempted to try to kick the ice off the meter, or chop away at it with a snow shovel – but this could damage the meter. Your utility company can send a professional who has the proper training and tools to clear the vent safely.

With below-freezing temperatures and possible snow predicted in the coming days, you’ll definitely want to keep warm inside. You and your family can stay warm and safe if you take a few moments to clear the snow and ice off your natural gas meter.

Natural gas is odorless until we add mercaptan, an odorant similar to rotten eggs, to help detect leaks. If you smell natural gas or have a natural gas emergency, leave immediately and call us from another location.

Each year, we sponsor contractor workshops to reinforce safety guidelines for construction crews that work around natural gas and electric facilities.

PECO is committed to delivering natural gas safely and reliably to our more than 523,000 gas customers in Southeastern Pennsylvania. This includes actively monitoring our system during storms and other emergencies. PECO"s preparations for storms include strategically positioning gas mechanics near areas of potential flooding and across the entire service area for a quicker response to reported leaks or damages.

Flooding, poor drainage, and rushing water can erode the ground near buried utilities. Excessive water can potentially cause breaks in natural gas mains, allowing water and dirt to enter the system and disrupt service. Excessive snowfall can impact the functionality of the gas service regulator associated with the customer"s meter. It is the customer"s responsibility to ensure that the regulator can vent properly by clearing snow around the meter set.

For PECO to safely make repairs, crews may need to shut off service to certain customers while isolating the damaged gas main. Therefore, gas mechanics will need to access these customers" natural gas meters.

If a customer is not available to provide access, PECO will work with local authorities to gain access to the property and shut off gas service. This can prolong the restoration of natural gas service for all nearby customers.

The time it takes to restore natural gas service depends on the amount of damage to the natural gas mains. Repair durations depend first on flood water receding and then the time it takes crews to clear all water and debris from the gas mains.

Once all the natural gas meters in the area are disconnected and the gas mains repaired, then PECO can reintroduce natural gas to the mains and restore service to individual customers. This requires a gas mechanic to access customers" gas meters to restore service and relight gas appliances.

Maintain adequate clearance around your natural gas meter. Structures such as porches, decks, paving, building additions or other structures should not obstruct the underground service line leading to the gas meter.

Make sure customer-owned natural gas piping and equipment located after the gas meter is well maintained and regularly inspected for corrosion and leaks by a licensed plumber or HVAC contractor.

Immediately report abnormal natural gas pressure, a loss of service, or water in natural gas pipes, equipment, or appliances to PECO at 1-800-841-4141 or (alternate number) 1-844-841-4151.

Contact PECO to arrange an inspection of its gas equipment if flood waters have shifted your home or caused other stresses to the gas pipes, creating the possibility for a natural gas leak.

During a natural gas outage, please make every effort to be available or to make your gas meter accessible to allow a gas mechanic to disconnect service at your gas meter and eventually to restore service and relight your appliances.

If you suspect a gas leak, do not attempt to find the source or to repair it. Leave the area immediately. Then from a safe place contact PECO at 1-800-841-4141 or (alternate number) 1-844-841-4151 to report the leak.

Keep electrical safety in mindWhen dealing with natural gas issues due to floods and storms, you always should keep electrical safety in mind as well:Do not enter a room with standing water, particularly if it covers electrical outlets or cords or appliances plugged into outlets.

Natural gas smells bad on purpose. That “rotten egg” smell is the smell of natural gas. If you think you smell gas, leave the area immediately and then call PGW at 215-235-1212 from a safe location.

PGW"s priority and most important responsibility is protecting the safety of our employees, customers, communities, stakeholders and ensuring safety throughout all of our operations. We are improving service safety and reliability with an aggressive

In 2020, Philadelphia Gas Works (PGW) invested approximately $85 million to install more than 37 miles of new natural gas pipeline across the City of Philadelphia; marking the largest number of miles of new main replaced in a year since its Long-Term Infrastructure Improvement Program (LTIIP) began in 2015.

Each and every day, PGW’s experienced workforce navigates Philadelphia’s complex matrix of narrow streets to safely install new, underground pipes and service lines, inspect for potential leaks utilizing state of the art equipment, and repair natural gas pipelines and service lines. PGW utilizes multiple advanced laser methane detection technology equipment.

We possess both the Heath RMLD (remote methane leak detector) and the Sensit LZ-30, which are methane specific and allow PGW to detect methane at very low parts per million level from a distance of up to 100’. This is used in conjunction with the Sensit G2 combustible gas indicator which can detect in %volume gas in air in order to have the capability to find and grade leaks as hazardous and non-hazardous on the spot. PGW also utilizes the Sensit PMD (portable methane detector) which allows us to detect methane specific leaks as low as 1 part per million. PGW also deploys multiple vehicular survey crews that detect methane using an open path infrared technology that is methane specific and can detect levels of gas as low as 1 part per million. The equipment PGW uses is widely used by other local distribution companies in the industry. In addition to the cutting edge technology PGW currently uses, we are consistently evaluating new and more sensitive technologies that can detect methane from greater distances as those products become available.

The leak detection program utilized by PGW’s industry-trained and operator-qualified technicians and field crews strictly adhere to all guidelines and best practicesput forth by thePipeline and Hazardous Materials Safety Administration (PHMSA) of the U.S. Department of Transportation (DOT), the PA Public Utility Commission (PUC), and natural gas industry experts.

To maintain our commitment to safety, PGW must inspect the natural gas meter and service lines at your property every three years. If you receive a Gas Safety Home Inspection request from PGW, please contact us at 215-235-1000, M-F between 8 a.m. and 6 p.m. to schedule your appointment.

PGW employees must be able to easily access your meter to perform meter readings, periodic safety checks, routine maintenance, and manage critical tasks in an emergency.

In the winter, carefully clear ice and snow from the meter as well as any appliance exhaust vents. Be sure to clean and repair leaky seams in your eaves, gutters and downspouts to prevent melting snow and ice from dripping onto the meter.

Carbon monoxide (CO) is a dangerous gas produced when heating systems are not working correctly and cause severe sickness and even death. You can"t smell, taste or see CO.

The Pennsylvania Public Utility Commission (PUC) has established regulations (52 Pa. Code §59.18) designed to enhance gas safety by requiring that “meters and regulators must be located outside and above ground.”

Meter relocation enhances safety, access and customer convenience. Outside meter locations allow PGW to shut off gas more quickly in the event of an emergency. In addition, PGW is required to periodically inspect and service customer meters; outside meter locations allow us to conduct routine service/inspection without inconveniencing customers.

If you received notification that your meter will be moved to an outside location and have questions, call us at 215-787- 4867, Monday through Friday, 7 a.m. to 3:30 p.m. Please provide your name, address and phone number.

Pressure regulators reduce the high pressures of the stored gas in the cylinder to lower pressures that can be safely used in an operating system. Proper regulator selection is critical for both safety and effectiveness of operating systems. Regulators are designed to control pressure; they do not measure or control flow, unless equipped with devices such as a flow meter specifically designed for such purposes.

Regulator connections to cylinder valves must be completely free of dirt, dust, oil, and grease. "Crack" the valve slowly (by opening the valve slightly and then reclosing it) before attaching the regulator in order to blow out dust and debris from the opening. Note: Cylinders containing highly toxic gases should not be "cracked".

Regulators are attached to the cylinder, or manifold, at the inlet connection. This connection should be tested for leaks with a non-petroleum based product. Note that many soaps contain petroleum! The connection is marked with a Compressed Gas Association (CGA) number and will be left-hand or right-hand threaded to match the nut or fitting. This prevents a piece of incompatible gas equipment from being connected to the wrong gas supply.

Opening a Regulator - Stand on the valve side of the cylinder at arms length so you do not have to reach in front of the regulator face. Turn your head away from the regulator and open the valve, turning counter clockwise, to blow out dust and debris, and then reclose the valve.

Changing a Regulator - Close the valve and drain the regulator by backing out the adjusting screw. Disconnect the regulator, making sure not to touch the nut and gland areas. Connect the regulator to the new cylinder.

Closing a Regulator - Turn the valve clockwise to close the valve. Drain the regulator by turning (opening) the adjusting crew to release any gas. Reclose the adjusting screw.

Recommendation: To provide easier access and additional safety, purchase wall-mounted regulators which connect to the supply cylinder by hose. This will reduce the handling of the regulator and reduce the likelihood of damage.

Diaphragm Valve - This valve uses a two piece stem separated by non-perforated diaphragms. These diaphragms prevent leakage along the valve stem. The lower part of the stem is encased in a spring, which forces the stem away from the seat whent eh valve is opened. The upper stem is threaded into the diaphragm retainer nut. When the handwheel is rotated to the closed position, the upper stem pushes on the diaphragms, which deflect downward, forcing the lower stem against the valve seat. Advantages of this type of valve are that they provide superior leak integrity and have no threads or lubricants in the gas stream to generate particles or contaminants. This type of valve is required for mos

Compressed gas cylinders shall have a pressure relief device installed to prevent the rupture of a normally pressurized cylinder when inadvertently exposed to fire of high temperatures. There are four basic types of pressure relief devices:

Rupture Disk Devices - A flat disk typically made of metal that is designed to burst at a predetermined pressure to permit the release of gas. The pressure rating of the disk is typically stamped onto the face of the device. Examples of gases using this type of device include compressed air, argon, helium, nitrogen, and oxygen.

Fusible Plug Devices - A plug made of fusible metal designed to yield or melt at low temperatures (usually 165 or 212 degrees F). The temperature rating of the fusible metal is stamped onto the face of the device. An examples of a gas that uses this type of device is acetylene.

Combination Ruture Disks/Fusible Plug Devices - A rupture disk backed by a fusible plug. In the event of a fire, the fusible metal melts and cylinder overpressure is relieved by the bursting of the disk. The burst pressure of the disk and the melting point of the plug will be marked with the ratings. Medical grade gas cylinders typically have this type of pressure relief device.

Pressure Relief Valves - A spring-loaded valve opens when the cylinder pressure exceeds the pressure setting of the spring to discharge contents. Once the cylinder pressure decreases to the valve"s pressure setting, the valve will normally reseat without leakage.

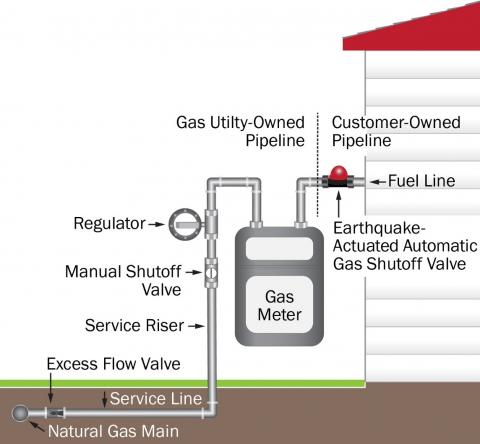

While it"s possible to manually shut off your natural gas, the following specialized valves are available that can automatically shut off your service in case of an emergency:

Earthquake natural gas shut-off valve (also known as a seismic natural gas shut-off valve) automatically shuts off your natural gas service when an earthquake of a sufficient magnitude occurs at your home.

An excess-flow valve (EFV) automatically closes and restricts the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter.

If you want to have an earthquake natural gas shut-off installed, or are required to have one by your insurance company or the local Department of Building and Safety, the valve must be installed on your house line.

If installation requires natural gas service closure, you"ll need to contact us to shut off the service and restore service when installation is completed. Natural gas service shut off and restoration of service orders can be scheduled by contacting us at 1-800-427-2200.

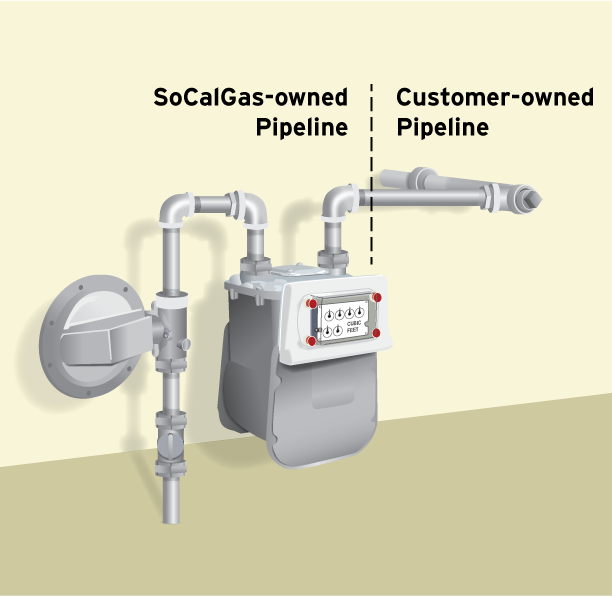

Under the regulations of the California Public Utilities Commission (CPUC), General Order 112-E, only SoCalGas® or its certified contractors are authorized to operate the natural gas service shut-off valve.

When you hire a qualified professional to install your earthquake valve, you"ll need to make sure that the valve is installed on your house line, not on SoCalGas" facilities. SoCalGas" facilities include all of the pipe fittings installed and maintained by SoCalGas, up to and including the last elbow or tee connecting to your house line. See the diagram below for to see where your house line starts.

All unauthorized valve installations found on SoCalGas" facilities will be removed. In addition, earthquake valves are not permitted in utility curb meter vaults.

If an earthquake or other significant event causes your earthquake shut-off or excess-flow valve to close, you can follow the manufacturer"s instructions for resetting the valve so that natural gas flows again. However, we recommend that you contact a qualified professional or SoCalGas to reset the valve, and to perform a safety check of your natural gas appliances before they are placed back in operation to verify that no natural gas leaks exist, and to re-light your pilot lights.

Remember that following a major emergency it may take many days or even weeks before someone can come to your location. (SoCalGas charges a fee to reset valves and re-light pilot lights when your earthquake shut-off valve has closed due to a non-earthquake occurrence.)

Price: The cost of the valve is going to vary based on the type and size of the valve, as well as the installation requirements and the company installing it.

Choosing a valve: In order to choose the right valve size and manufacturer, contact your local Department of Building and Safety to find out their earthquake valve requirements.

Where to buy a valve: You can purchase an earthquake valve at supply retailers, licensed plumbing contractors, or directly from the valve manufacturer.

Using a contractor: You can hire a qualified professional to install the earthquake or excess-flow valve on your house line. SoCalGas will not install a valve for you.

Effective February 10, 2002, California Public Utility Commission (CPUC) Decision 01-11-068 prohibits installation of an earthquake valve on SoCalGas" facilities. In addition, SoCalGas no longer installs earthquake shut-off valves for its customers, and does not allow any customer owned equipment, including excess-flow valves, be installed on SoCalGas" facilities.

If you have an earthquake valve that was installed by SoCalGas or one of its authorized contractors on or before the February 10, 2002 cutoff date, that is located on SoCalGas" facilities, with proper documentation your installation may be allowed to remain in place. Authorized contractors are those who participated in SoCalGas" earthquake program and were trained by SoCalGas to work on their facilities.

Additional information regarding earthquake valves and natural gas service restoration after a valve activates can be found in Tariff Book, Rule 10, Section G, "Earthquake Valve Service."

An Excess Flow Valve, or EFV, is a safety device installed on natural gas distribution pipelines to automatically close and restrict the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter. These conditions are typically caused by digging or construction but can also be caused by damage to your natural gas meter by a vehicle impact.

EFV can reduce the risk of explosions, fires, and personal injury because they close or restrict any unplanned or excessive natural gas flow. Installation of an EFV will not protect a customer from household appliance malfunctions, small punctures in underground pipelines, and pipeline damage from earthquakes or flooding. It is

important to understand that an EFV does not shut off the flow of natural gas completely. Some leakage may still occur resulting in a hazardous condition.

An EFV is installed on the service pipeline that runs underground between the natural gas main (usually located in or near the street, alley or easement) and the SoCalGas® meter on the customer’s property).

The best way to prevent damage to a natural gas pipeline due to digging is to call 811, the Underground Service Alert program, at least two working days before digging. Underground Service Alert will coordinate with SoCalGas to mark the locations of buried utility-owned lines - absolutely FREE.

If you are interested in having an EFV installed on the service pipeline serving you[1], please call SoCalGas at 1-800-427-2200. SoCalGas will first check to see if your service already has an EFV installed and, if not, an estimate to install the EFV will be provided. The cost to install an EFV can vary widely depending on site specific conditions and can range from $2,500 to $5,000 or more.

If you decide to have an EFV installed, we will coordinate with you to schedule the installation (note that it is possible that natural gas service will be interrupted to install the EFV). The construction crew will dig around the natural gas line in order to install the EFV and when the job is complete natural gas service will be restored (if it was shut off). If paving or concrete needs repair that work will be scheduled at a later date.

These upgraded meters, which now have a small, two-way communication devices installed, provide timely and accurate data about your natural gas use, eliminating the need for estimated meter reads and ensuring you only pay for the gas you use. The reliable and accurate readings from these upgraded meters provide insight into your energy consumption and give you greater control over your energy use and natural gas bills. Customers can also use this valuable data to reduce their home or business’ carbon footprint.

The ability to read meters without the need for a field visit simplifies the process of moving properties and reduces the expense and environmental impact of our service vehicles on the road.

Traditionally, a meter reader would visit your home or business to check your natural gas meter and notate how much gas you used, which was then used to generate your utility bill. These new two-way communication devices feature state-of-the art technology that securely transmits your usage data Nicor Gas via private radio frequencies in compliance with the U.S. Federal Communications Commission.

According to a report posted on the US Homeland Security’s US Fire Administration website, the United States has one of the highest fire death rates per capita among Western Nations. To understand what can be done to improve fire safety, we examine US and European fire safety systems differences.

We know US fire deaths occur predominately in homes during the winter months when the number of cooking and heating fires increases. According to the National Fire Protection Association (NFPA), the U.S. fire departments face 2,110 home fires per year where natural gas is the first material ignited, and 1,170 home fires each year where LP-gas is involved with the start of a fire. Most home gas fires originate in the kitchen at the stove or gas range.

Although heat is generated from any number of fuel sources (gas, electric, oil, wood, coal), this article focuses on current European practices for gas fire safety, starting at the curb, to the gas meter and then throughout the home.

A universal shut-off valve designed to remain tight at high temperatures. If a fire does occur and the gas expands from the heat, the valve is able to withstand the additional gas pressure, preventing the gas from exploding.

An excess flow valve to stop gas flow when the flow rate dramatically changes. For example, if a back hoe damages the piping, the excess flow valve will automatically shut off the gas flow.

A combined active and passive mechanism which includes both a manual shut-off valve and an automated thermal shut-off fusible device, such as the TECO Americas FireBag®. This automatic shut-off device is triggered by a fusible plug and piston and it does not need a fire or heat detector to set it off. The TECO Americas’ FireBag is designed for rugged applications, and it can undergo mechanical or thermal stress without misshaping. Since the FireBag is virtually maintenance free, it does not require regular inspections like active safety devices.

Typical gas meter installations in Europe include two passive safety devices and a plug to safely test gas pressure and tightness. The gas meter is equipped with an excess flow valve and a shut-off valve armed with an automatic thermal shut-off device.

European standards (UNI TS 11147 February 2007) require a pressure plug placed right after the meter. To test gas pressure safely and quickly – in 30 seconds or less – the meter is equipped with a double safety valve to avoid risk of gas leakage. TECO America’s CheckPoint was designed to meet this European standard. It includes an intercepting ball valve, and a pressure plug with the second safety valve which is installed with a safety handle that cannot be inadvertently turned. This double valve design allows pressure tests to be performed while the gas installation is operating.

Unlike their U.S. counterparts, some European countries such as Germany have mandated safety fusible devices for all gas appliances that use natural gas, propane, and butane gas for over 17 years.

The internal fusible device is located in the gas line connected to the gas appliance. Due to their low cost, the internal fusible device can be used economically at each gas appliance. External fusible devices are significantly more expensive and they are normally used for liquid fuels or used with remote sensing devices. The external fusible devices normally have a manual override or resettable feature.

In Europe, as in the United States, inside gas lines are maintained by licensed plumbers hired by the home owner. In the US, the NFPA standards require gas appliances to be equipped with manual gas shut-off valves. These manual shut-off valves are not considered emergency valves, and are not required to be easily accessible. Few home cooks are knowledgeable about the location of these valves, and would not be inclined to search for the valve when a gas fire does occur. For these reasons, European lines feeding gas appliances throughout the home are protected with passive fire safety devices, such as the FireBag automated thermal shut-off device which can be provided with the shut-off valve as well:

Basement gas appliances may include a furnace, water heater and dryer. In Europe the gas lines include dual-equipped shut-off valves at the appliance connection. The valve can be equipped with a safety handle for manual manipulation and the automated thermal shut-off device for passive fire safety.

Kitchen gas appliances may include ovens and ranges. The gas appliance is already equipped with a manual shut-off valve, so there is no need to install an additional valve prior to the gas appliance connection. The inexpensive FireBag passive automatic shut-off is installed in the gas line. The FireBag is manufactured in straight line versions and with elbow connections for flexible pipes.

Decorative gas fireplaces, gas logs or space heaters are equipped with passive safety devices by inserting the inexpensive thermal shut-off device in the gas line.

Outdoor patio gas appliances are also protected with automatic thermal gas shut-off devices. Gas grills are protected with extensible hoses equipped with a device such as the FireBag.

U.S. state public utility commissions and state and municipal building codes frequently reference the NFPA, and also may require safety regulations that exceed the NFPA standards. Currently the NFPA does not require passive gas safety devices, although recommendations have been made to the NFPA Technical Committee on National Fuel Gas Code.

The Technical Committee met in February 2010, to discuss revisions for the 2011 edition of the NFPA National Fuel Gas Code (NFPA 54). The committee met again in October 2010 to act on the proposed revisions. A revision for passive safety devices was requested: “for each appliance, a fusible link automatic shutoff valve shall be installed within two feet of the equipment manual shutoff valve and upstream all other components of the fuel train.”

The proposed revision was rejected for lack of data demonstrating “building fires are aggravated by the release of gas from heat damaged piping system components.”

Peter Holmes from the State of Maine’s Gas, Oil and Solid Fuel Board reports he has experienced “several fires in recent years which were greatly aggravated by the release of gas from heat damaged piping system components.”1

Although the 2010 San Bruno, CA and 1981 San Francisco pipeline ruptures and their subsequent fires were exacerbated by the lack of automatic passive thermal gas shut-off devices, current fire reporting does not track when fires could be better contained if passive thermal shut-off devices were installed.

Currently the NFPA only requires manual gas shut-off valves gas appliances in the U.S. The requirement in 9.6.4 for manual shut-off valves is intended solely to isolate an appliance for servicing, removal, or replacement without shutoff off the gas supply to other appliances. Since this valve is not an emergency shut-off valve, it is not required to be readily accessible.

Some U.S. cities, counties and states do have regulations requiring automatic gas shutoff devices. However, these regulations focus primarily on gas shutoff for excess gas flow and earthquakes. The State of California requires excess flow gas shutoff valves and earthquake actuated gas shutoff valves be installed on building gas houseline piping, (the gas pipe connecting appliances to the gas meter) after the utility gas shutoff valve, the pressure regulator (if installed), the meter(s), and the service tee. Californian homes are, therefore, protected from gas pipe breakages and earthquakes — but not from fire.

A number of regulations exist for passive, automatic safety devices that supply oil supply to and within the home. Yet, similar protection is not required for gas service in the U.S. For example, the NFPA 31 standard for the installation of oil-burning equipment requires fusible fire safety devices in residential oil heating installations. State fire codes such as those in Maine and Massachusetts, require automatic fusible valves in oil supply lines at oil tanks and burners. 2, 3

It is critical that both gas and oil supply lines are able to terminate automatically the fuel supply in the event of fire to minimize fire damage and save lives. Homes are protected by external gas shut-off valves which are accessible to fire departments. However, passive fire safety devices can provide additional protection. Internal fusible devices that automatically shut-off the flow of gas when the ambient temperature reaches a critical level can provide this protection at minimal cost.

Most people experience the benefits of fusible links through the emergency ceiling sprinkler systems commonly installed in office buildings. The sprinkler’s fusible device triggers the flow of water when fire is detected in order to rapidly extinguish the fire. Fusible links, thermal fuses, and fusible devices are all used to shutoff fuel sources in the event of fire. Recent fire safety improvements incorporate these fusible techniques.

Cost must be considered, however, in the application of safety devices. Sprinklers have become ubiquitous because they can be manufactured cheaply. Fuel shutoff devices are available in both internal fusible devices which are less expensive and external fusible devices which are more expensive.

Internal fusible devices are frequently used with natural, propane and butane gas systems because of their relative affordability. Their low cost allows them to be used with each gas appliance. External fusible devices are significantly more expensive and are more frequently used for liquid fuels or with remote sensing devices. The external fusible devices normally have a manual override or resettable feature.

Fusible fuses are safety devices typically used to control electrical current for heat producing appliances such as coffeemakers and hair dryers. A search for “thermal fuse” on the eHow.com website offers homeowners at least 506 instructional videos on replacing fusible fuses on appliances with heating elements, once the fuse has been triggered.

Fusible devices automatically shut-off fuel supply in the event of fire to meters and fuel-consuming appliances, such as heaters, boilers, ranges, varnishing booths, gas motors, and ovens. This passive safety device contains a fusible alloy which melts when the outside temperature reaches a trigger temperature, releasing the plug to completely close the flow of fuel.

The FireBag® is a thermal-activated shut-off device for propane, natural and butane gas. It automatically turns off the gas supply in a fire, preventing explosions and the spreading of fire. When the outside temperature reaches 203-212°F (95-100°C) the metal alloy that keeps the plug and cartridge together melts and the spring pressure pushes the plug against the gas opening closing it completely. No fire or heat detectors are required to automatically intercept gas flow. Once triggered, the shut-off device works up to 1,697°F (925°C) for one hour.

The FireBag is compatible with other safety devices (e.g. gas leak detectors), working even when the cause of the fire is not inside the system. Since it is a passive device, it does not require regular inspections and is virtually maintenance-free. It is not affected by external factors and works even during servicing operations.

1 NFPA 54: National Fuel Gas Code Report on Proposals (ROP), 5/17/2010, http://www.nfpa.org/Assets/files/AboutTheCodes/54/54-A2011-ROP.pdf Viewed 12/12/2010

8613371530291

8613371530291