gmsn safety valve manufacturer

PLEASE NOTE: As with all vacuum tube based designs, this module is very sensitive to noisy power supplies. Check out this forum post for more info: https://forum.gmsn.co.uk/t/safety-valve-noise-problems/355

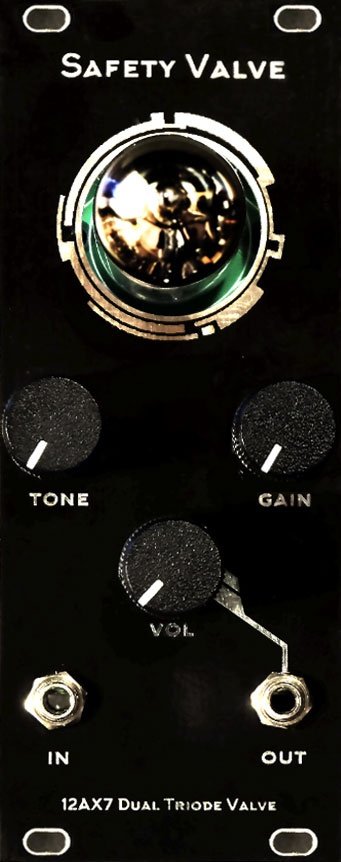

-It is designed for the 12ax7 tube to be soldered straight to the board without a socket to save excessive height. in this module provided you don’t chuck it off a balcony the valve will be fine, in this design it is also running cold so you wont have any worries of it prematurely breaking. It will last just as long if not longer than other components in the module.

-The valve also doesn’t even have to be soldered to function, if your feeling fancy look closely at the module in the above images you will notice i didn’t solder the valve in, the PCB actually holds onto the valve enough to provide sufficient contact, nearly as much as a socket would anyway! I am not sure how this will change over time, but for not it works fine. However if you want reliable and worry free use i would recommend to just solder it on down and forget about it.

-Touching the valve? This is a bit of a myth in respects to the fact that yes in some high temperature high reliability applications valves don’t want to be touched as over time the grease may indeed weaken the glass. But for general use and general purpose valves like the 12ax7 its completely negligible. in-fact this tube in this application doesn’t even get as hot as a cup of PG tips. So dont worry about it.

-Status LED! try to get a super bright 3mm LED, it will really make the tube illuminate as the heater filament in this application does not glow much if at all. In theory! a Bi Coloured LED would work too! Dont poke the LED all the way through the hole, just enough so that it is flush with the pcb, this means you can seat the valve right down to the PCB.

I don"t suppose anyone has the BOM for the thru hole version of the the Look Mum No Computer Safety Valve by GMSN, I ordered a PCB and Panel before they shuttered and now I can"t find a BOM anywhere...

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

Annulus control safety valves from Baker Hughes prevent uncontrolled flow in your well’s annular space to ensure that your gas-lift operations run smoothly and safely.

You maintain downhole safety with non-elastomeric technology and a rod piston for long-term sealing durability that withstands high pressures and temperatures. Single control lines actuate the valve while a loss-of-control pressure line provides emergency closure.

Optimize production at lower operating costs. Maximize your well productivity with annulus valves designed with a large annular flow area that minimizes pressure drops

Reduce risk. Ensure safe and reliable operation with annulus safety valves configured to your operating conditions and proven in stringent prototype testing prior to deployment

Consolidated boasts 140+ years of dedicated Pressure Relief Valve (PRV) Engineering and Manufacturing expertise. We know overpressure protection! With more than 10 major first-to-market products and features, Consolidated continues to deliver innovative technical solutions to the world"s most challenging overpressure protection applications. When combined with the expertise and full-scale service of the Green Tag Center (GTC) Network, Consolidated is able to provide a comprehensive approach to Valve Lifecycle Management (VLM) that is second to none.

Comprehensive Valve Lifecycle Management (VLM) enabled by state-of-the-art tools and delivered by the unparalleled Consolidated Green Tag Center (GTC) Network, Consolidated supports our product throughout the entire lifecycle.

Kunkle Relief Valve OverviewWhen it comes to industrial and commercial safety and relief valve products, Kunkle’s valve’s catalog is second to none in steam, air, gas, and liquid applications.

Kunkle relief valves range in size from ¼” NPT to 6” flange and are suitable in cryogenic and high temperatures up to 800°F environments at vacuum to 7,500 psig pressure. Kunkle Valve’s code certifications meet several global and national board standards, including ASME Section I, Section IV, and Section VIII, PED, CRN, TU and Chinese, as well as non-code requirements.

Relief Valves for Steam ServiceSteam supplies heat for industrial and chemical processes and also is used to heat buildings, supply mechanical energy, and drive mechanical equipment. Steam moves from the boiler to the end point, then heats by direct heating or indirect heating through a heat exchanger. Kunkle steam relief valves are critical to protecting equipment such as boilers, steam lines, and pressure valves, from being over-pressurized.

Relief Valves for Air ServiceKunkle designs valves for air service, for example for air compressors in mechanical shops and small factories where either low-pressure or high-pressure air is required. NASVI stocks Kunkle relief valves for air service in iron, steel and bronze for a variety of uses.

Relief Valves for Liquid ServiceKunkle also makes valves for liquid service, which provide bypass relief in a variety of applications and liquid types.

More About KunkleKunkle Valve is a renowned pressure relief valve manufacturer. Erastus B. Kunkle invented the safety valve to prevent overpressure in locomotive engines. Kunkle patented it in 1875. Since that time, Kunkle has earned its reputation for high-quality valves, and other equipment manufacturers ship their products with Kunkle’s valves pre-installed.

NASVI has stocked Kunkle safety relief valves since we opened in 1975, so we are confident when we call ourselves Kunkle safety valve experts. Every day we fulfill orders for our customers looking for Kunkle relief valves for steam, air, gas, and liquid applications.

Safety valve maintenance and repair ensures your industrial system will not only remain operational, but also safe for your personnel and the environment. In the event of a failure, a safety valve helps contain the challenge to a specific location or releases pressure to stop it, which also means these devices are subject to extreme duress in industrial environments.

Millennium Power Services offers expert insight into our customer’s needs, supporting the evaluation of specific concerns or mechanical issues with your safety valves. Whether you are performing preventive maintenance or reacting to a malfunction, our team of experts can spring into action and facilitate shop or on-site repairs and testing along with new safety valves.

8613371530291

8613371530291