goetze safety valve manufacturer

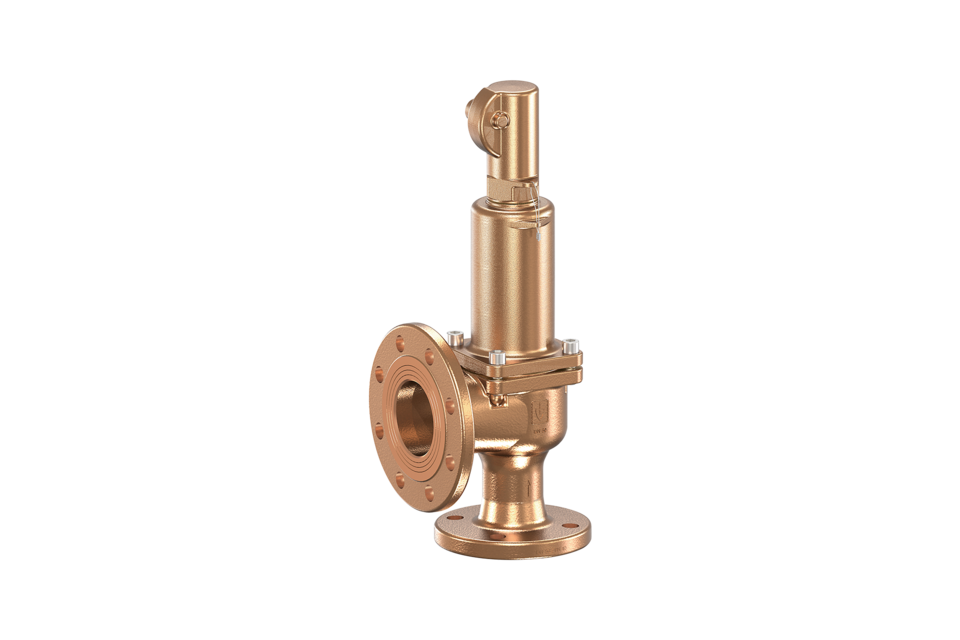

Goetze Armaturen has beendesigning and manufacturing safety valves for a highly diversified range of applications for over 65 years. Solutions are available for every industrial application, for example to handle all kinds of liquids, gases, vapours and steam. Goetze valves are suitable for use in temperatures rangingfrom -270°C up to 400°C with safety always being the top priority. The Ultravalve team is available to offer advice on all matters relating to the handling ofpressure.

Combination water meters comprises of a bulk Woltmann insert and a low-flow Volumetric insert or meter, flow is diverted between them by a by-pass valve that is set at a predetermined flow rate. This allows the combination meter to have a very large measurement range.

Whole products such as valves, boilers & showers undergo mechanical and water quality testing. This type of approval demonstrates full compliance with the requirements of the regulations and bye-laws, provided the fitting is installed according to any conditions given with the approval.

BS EN 331:2015 specifies the characteristics for the construction, performance and safety of ball valves and closed bottom taper plug valves. It also details the test methods and marking provisions. It applies to metallic valves not directly buried for domestic and commercial installations inside or outside of buildings, using gases of the first, second and third family (specified in EN 437) and working up to 0,2 × 105 Pa, 0,5 × 105 Pa, 1 × 105Pa, 5 × 105 Pa and 20 × 105Pa and with temperature limits from – 5 °C or -20 °C to + 60 °C.

Classification, verification, risk management, and technical advisory to the maritime industry on safety, enhanced performance, fuel efficiency, etc. As a classification society, DNV GL sets standards for ships and offshore structures – known as Class Rules. They comprise safety, reliability and environmental requirements that vessels and other offshore mobile structures in international waters must comply with. DNV GL is authorized by 130 maritime administrations to perform certification or verification on their behalf.

Valves have been qualified by testing to API standards 607, 4th Edition. The valve design incorporates a secondary metal seat in the body, providing the required shutoff should the primary seats be destroyed by fire.

Many of our marine valves can be pressure tested, witnessed by a classification society and supplied with 3.1 & 3.2 certifications on request, these include Lloyd’s Register of Shipping, DNV-GL (Det Norske Veritas), RINA, Bureau Veritas, Germanischer Lloyds, NK and ABS (American Bureau of Shipping). Please contact sales with your requirements.

Manufacturing high-performance fittings and a well thought-out family of products covering every industrial application: Liquids of all kinds, gases, technical vapours and steam. Goetze KG valves are used with temperatures ranging from -270°C up to 400°C and the greatest possible safety is a priority.

For over 70 years, Goetze KG Armaturen has been manufacturing sophisticated high-performance valves and fittings for media under pressure: liquids, air, gases and vapours. The family-owned company, which is based in Ludwigsburg, has made themselves a reputation worldwide with their high level of quality "Made in Germany". Goetze is your partner regarding safety (valves). We assure the handling of hydrogen from the retrieval to the application – either in the electric part of the process or at the hydrogen filling station for vehicles. We protect filling processes, which are under high pressure or the storage of liquid hydrogen in tanks.

The competence of Goetze KG is in demand worldwide. For 70 years. Our wealth of experience is as diverse as the areas of application for our high-performance fittings. Our well thought-out product families cover all industrial applications: liquids of all types, gases, technical vapors and water vapor. Goetze valves are used from -270 ° C to + 400 ° C and the greatest possible safety is always in the foreground. We have the right solution for you: take our word for it. We have been designing and manufacturing safety fittings for a wide range of applications for over 70 years. With over 300,000 valves a year - made in Germany - we are your competent partner for pressure.

The competence of Goetze KG Armaturen has been in demand for more than 65 years. Our wealth of experience is as broad and varied as our areas of application for our high-performance fittings. Our well thought-out family of products covers every industrial application: Liquids of all kinds, gases, technical vapours and steam. Goetze valves are used with temperatures ranging from -270°C up to 400°C and the greatest possible safety is a priority. We have the right solution for you: Take us at our word!

We have been designing and manufacturing safety valves for a highly diversified range of applications for over 65 years. With over 200.000 valves per year "Made in Germany", we are your competent partner for all matters relating to the handling of pressure.

The "work station": manageable units, short set-up times and employees with the necessary know-how, skill and experience. Not any anonymous assembly line production. We are always proud to hear when the Goetze KG is referred to as a "manufactory".

Intelligent minds and skilled hands are the one thing - however for the manfacturing process at Goetze KG nothing can beat the highest level of precision achieved through the use of high-tech production equipment: Computer controlled CNC machines.

In order to fit all the necessary information onto the valve, we use precision laser marking technology. This means that we are also able to take individual customized marking requirements of customers into consideration.

You can rely on this: Every single valve is tested in our factory. This is not only a random spot check: Each valve is subjected to an ISO-certifed quality control test, before it is allowed to leave the factory.

Diverter ball valve for the installation of for example two safety valves in combination with bursting discs for the protection of containers designed for the storage of cryogenic gases. The requirements of the PED relating to redundant or diverse safety devices are fulfilled by this fitting in combination with safety valves of the 2400 / 2480 series. On each side two additional connections for bursting discs are available. In case the safety valves need to be maintained or the bursting discs replaced, the side requiring maintenance can be shut off. The ball-valves are oil- and grease-free as standard.

A proven all-around valve with proportional operating characteristics and an extremely compact design. In addition to the basic version, these valves are also available for the most varied customer requirements as a gastight version or with a lifting lever.

In addition, due to its relatively large setting range per spring, it is ideally suited in cases where either a stock valve for various applications and set pressures is required or if the customer is looking for an adjustable pressure relief valve.

Safety valves made of stainless steel, angle-type with threaded connections. The benefits and applications of this series made of high-alloyed stainless steel begin, where versions made of gunmetal are at their limits. The flexibility of the various versions offer the optimal configuration for every application. In addition to the basic version the numerous sealing possibilities and materials, back-pressure compensating metal bellows and / or a gastight cap offer the necessary optional extras required to fulfill the highest safety requirements.

A development of the existing series 492, the valve features a compact design claimed by Goetze to be half as heavy and half the size of comparable valves.

The new DN6 also utilises rotatable outlet housing, allowing the outlet direction to be adjusted following installation, simplifying the valve installation in an existing line environment.

8613371530291

8613371530291