goetze safety valve brands

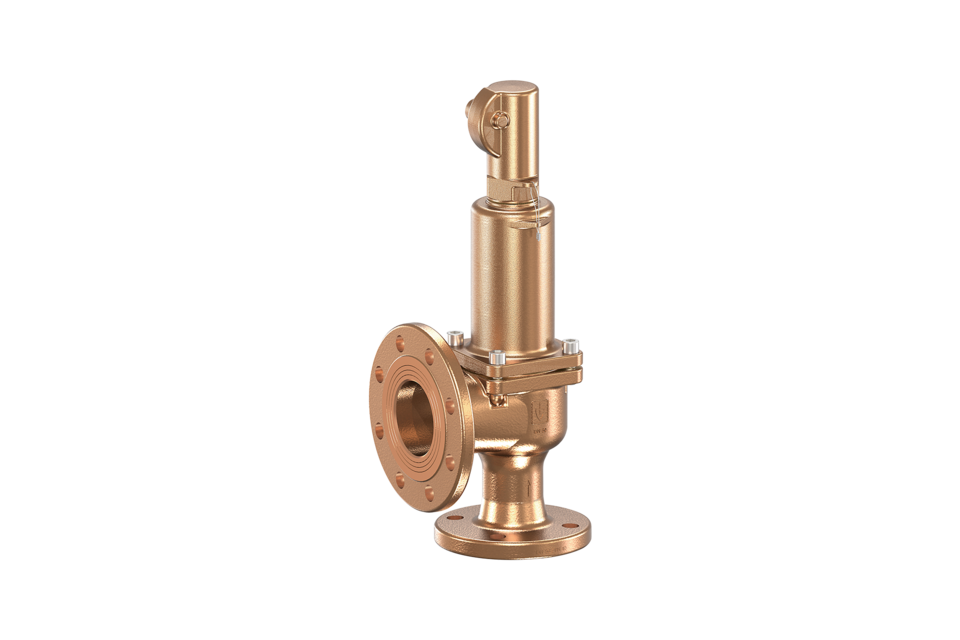

These valves are European design and are available in BSP or NPT process connections. We have direct crossover valves for Atlas Copco, Ingersoll Rand, Compair, Kaeser and Boge. All valves are CRN approved and are available with test certificates.

"description": "Goetze Safety Relief Valve. CRN Registered, NPT or BSP. Atlas Copco, Ingersoll Rand, Compair, Kaeser and Boge. ASME . National Board. Test certificate. Brass. Stainless Steel.",

"twitter:description": "Goetze Safety Relief Valve. CRN Registered, NPT or BSP. Atlas Copco, Ingersoll Rand, Compair, Kaeser and Boge. ASME . National Board. Test certificate. Brass. Stainless Steel.",

"og:description": "Goetze Safety Relief Valve. CRN Registered, NPT or BSP. Atlas Copco, Ingersoll Rand, Compair, Kaeser and Boge. ASME . National Board. Test certificate. Brass. Stainless Steel.",

A proven all-around valve with proportional operating characteristics and an extremely compact design. In addition to the basic version, these valves are also available for the most varied customer requirements as a gastight version or with a lifting lever.

In addition, due to its relatively large setting range per spring, it is ideally suited in cases where either a stock valve for various applications and set pressures is required or if the customer is looking for an adjustable pressure relief valve.

Pressure Relief Valves, commonly known as pressure safety valves, protects the equipment / line from over-pressure by opening when the pressure exceeds a certain set value to relief the fluid at its outlet. This serves as a safety device to prevent the equipment from a critical failure.

Safety valves made of stainless steel, angle-type with threaded connections. The benefits and applications of this series made of high-alloyed stainless steel begin, where versions made of gunmetal are at their limits. The flexibility of the various versions offer the optimal configuration for every application. In addition to the basic version the numerous sealing possibilities and materials, back-pressure compensating metal bellows and / or a gastight cap offer the necessary optional extras required to fulfill the highest safety requirements.

The competence of Goetze KG is in demand worldwide. For 70 years. Our wealth of experience is as diverse as the areas of application for our high-performance fittings. Our well thought-out product families cover all industrial applications: liquids of all types, gases, technical vapors and water vapor. Goetze valves are used from -270 ° C to + 400 ° C and the greatest possible safety is always in the foreground. We have the right solution for you: take our word for it. We have been designing and manufacturing safety fittings for a wide range of applications for over 70 years. With over 300,000 valves a year - made in Germany - we are your competent partner for pressure.

The competence of Goetze KG Armaturen has been in demand for more than 65 years. Our wealth of experience is as broad and varied as our areas of application for our high-performance fittings. Our well thought-out family of products covers every industrial application: Liquids of all kinds, gases, technical vapours and steam. Goetze valves are used with temperatures ranging from -270°C up to 400°C and the greatest possible safety is a priority. We have the right solution for you: Take us at our word!

We have been designing and manufacturing safety valves for a highly diversified range of applications for over 65 years. With over 200.000 valves per year "Made in Germany", we are your competent partner for all matters relating to the handling of pressure.

The "work station": manageable units, short set-up times and employees with the necessary know-how, skill and experience. Not any anonymous assembly line production. We are always proud to hear when the Goetze KG is referred to as a "manufactory".

Intelligent minds and skilled hands are the one thing - however for the manfacturing process at Goetze KG nothing can beat the highest level of precision achieved through the use of high-tech production equipment: Computer controlled CNC machines.

In order to fit all the necessary information onto the valve, we use precision laser marking technology. This means that we are also able to take individual customized marking requirements of customers into consideration.

You can rely on this: Every single valve is tested in our factory. This is not only a random spot check: Each valve is subjected to an ISO-certifed quality control test, before it is allowed to leave the factory.

A development of the existing series 492, the valve features a compact design claimed by Goetze to be half as heavy and half the size of comparable valves.

The new DN6 also utilises rotatable outlet housing, allowing the outlet direction to be adjusted following installation, simplifying the valve installation in an existing line environment.

8613371530291

8613371530291