herose safety valve factory

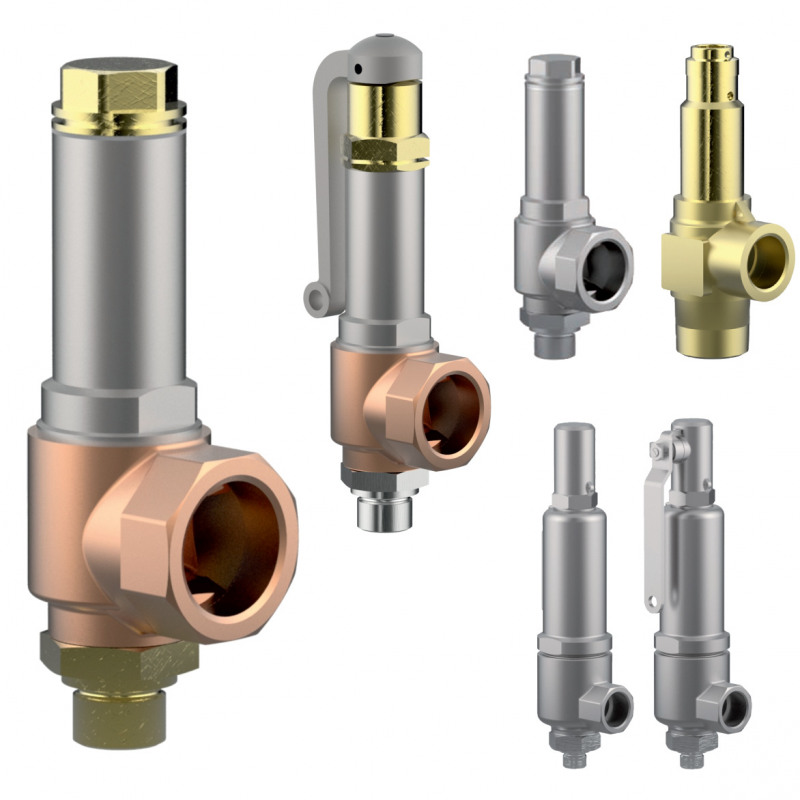

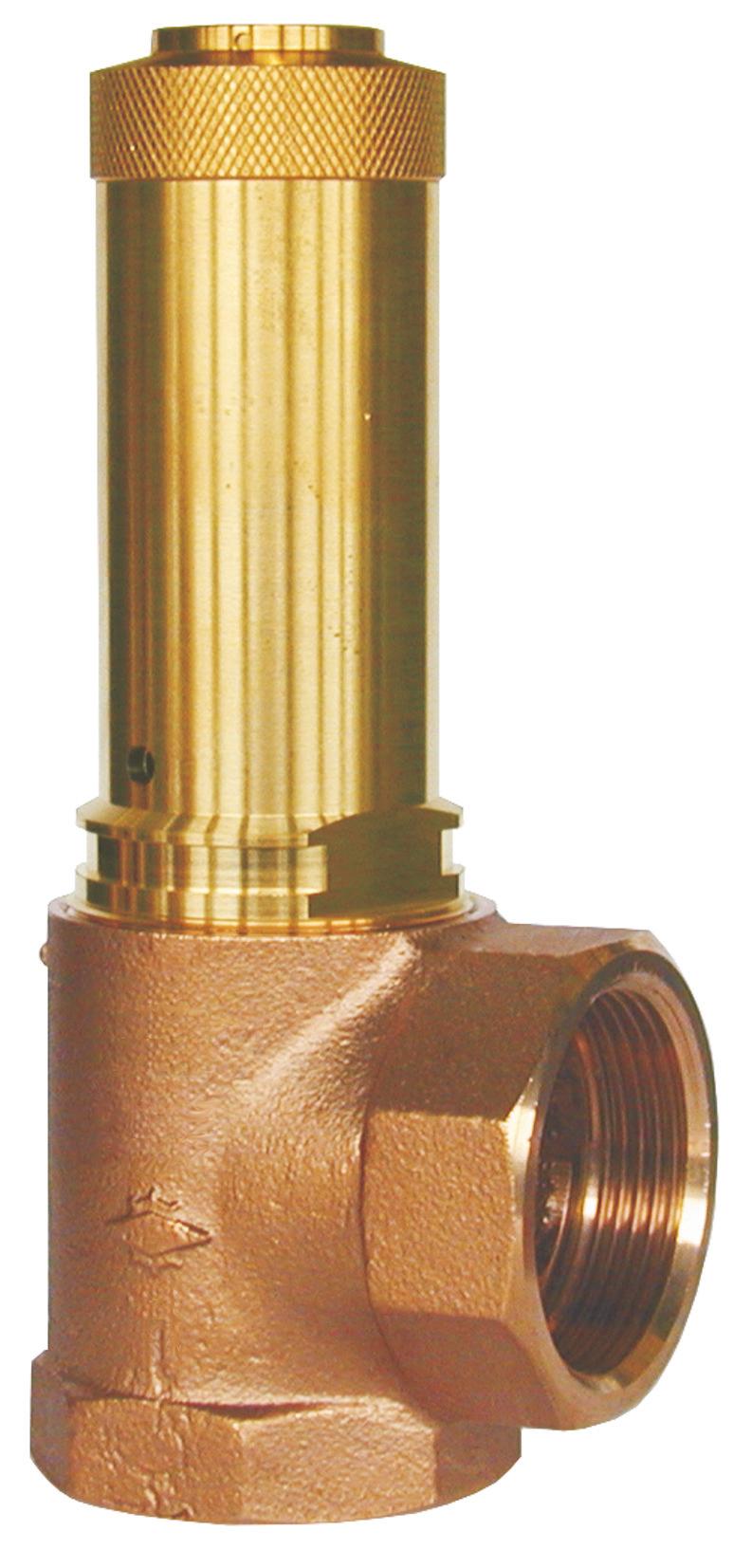

Valves for industrial applicationsIn order to prevent the uncontrolled rise in pressure in pressure vessels or pressurized pipelines, a safety valve is inserted. The safety valve is designed so that it opens at a given maximum pressure, thereby relieving the line or the container. Safety valves find their use in almost all areas of the pressure vessel and pipeline construction. In cryogenics as a spring-loaded safety valve for example.

Safety with superiorityHEROSE provides safety around the world for the handling of technical gases, steams and liquids. With 140 years experience in the development, manufacture and sale of valves with a high level of innovation and modern production with certified quality management, our company is one of the world"s leading manufacturers and suppliers of

We specialise in developing and manufacturing individual solutions required by the market right up to the production stage. We have developed, e.g. an innovative valve generation for use in extreme temperatures between -270° C and +400° C, special valves for air separation and valves for the liquefaction of natural gas (LNG).

Foundry master Theodor Rose set up the valve factory Th. Rose KG in Altona. He started production of valves for ship construction and building technology

Construction of the new production facilities in Bad Oldesloe covering 3500 square meters. Continuing more than 130 years of tradition, quality valves are still manufactured here

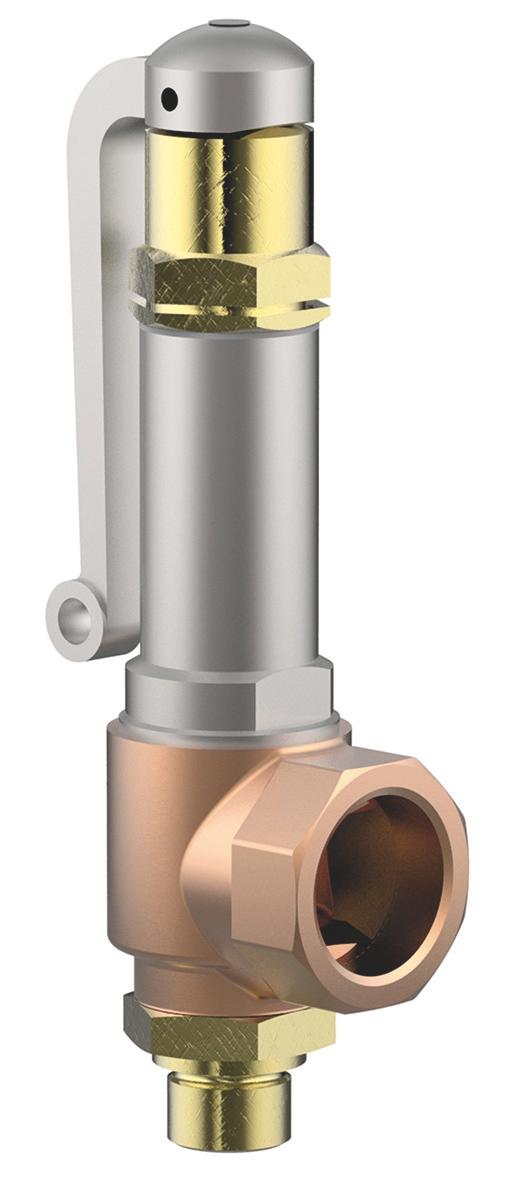

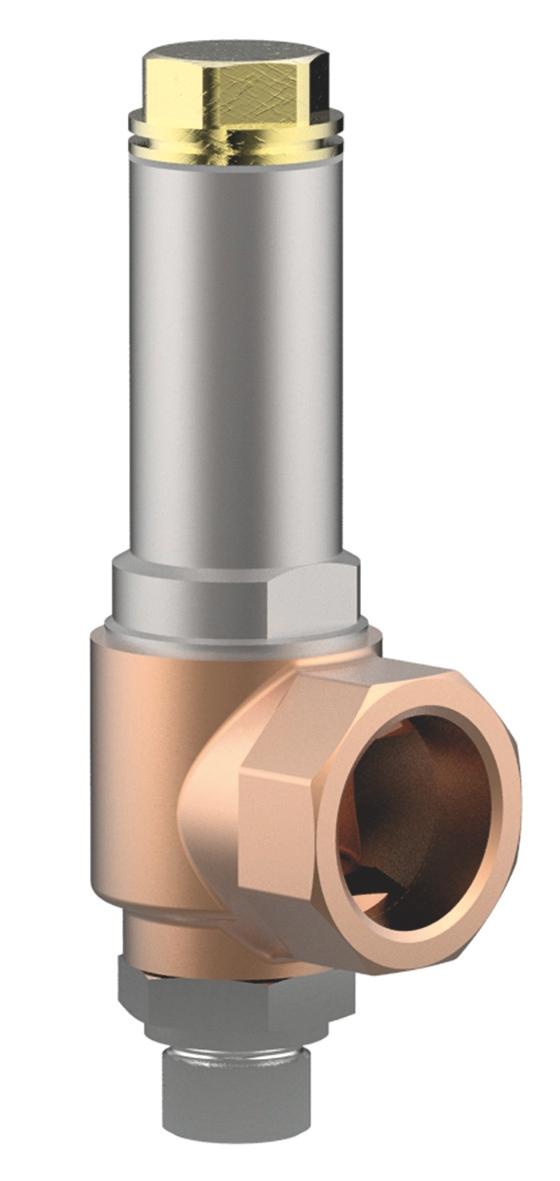

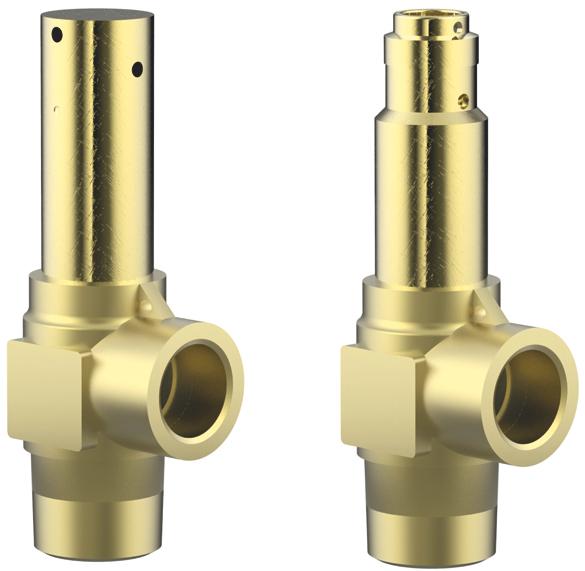

HEROSE cryogenic safety valves are certified to global certifications for CN, TR CU and ASME. Thus they can be used worldwide, regardless of where the system is installed later. Cryogenic safety valves are available in sizes from DN6 to DN50 and secure pressures up to 550 bar, at operating temperatures of -270°C to +400°C. The safety valves are manufactured primarily in stainless steel but also in bronze and brass.

Please find the cryogenic safety valves in the product choice below. You can combine different product characteristicsto find your cryogenic safety valve better.

A safety valve is a valve which automatically actuates, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to reclose and prevent further flow of fluid after normal pressure conditions of service have been restored. Ramén Valves supply safety valves from the German brand Herose.

HEROSE is the leading manufacturer worldwide of valves for cryogenic applications and services. Based on 140 years of experience in the development and manufacture of valves, we strive to provide customers with technical solutions over and above industry standards.

Our cryogenic safety valves are installed for protection against overpressure in tank containers and pipelines used for the storage, distribution and transport of liquefied gases — such as oxygen, nitrogen, argon, carbon dioxide, helium, hydrogen, etc. — at temperatures as low as -270°C (-454°F). A bellow-sealed option is available.

A major global gas company successfully subjected our cryogenic safety valves to an endurance test of 144,000 opening and closing cycles, and have subsequently been using our valves with trouble-free operation in over 35,000 installations for almost ten years.

Our diverter valves have been tested by a well-known cryogenic bulk vessel manufacturer. These tests reported a valve life expectancy of over 150 years.

HEROSE’s product range of LNG valves included bronze valves which are TUV-certified according to EN 12567, as well as stainless-steel valves which are additionally fire-safe approved according to EN ISO 10497.

This approval ensures that our fire-safe LNG valves remain tightly shut off, protecting plant and personnel when fires occur. HEROSE’s fire-safe LNG valves have been installed in critical applications worldwide.

Our product range of industrial safety valves covers the fields of gases, vapours, fluids and refrigerants. A special development is the industrial safety valve for pneumatically drained silo vehicles. Like other valves in the HEROSE range, this industrial safety valve is resistant to extreme vibration and environmental conditions.

As an environmentally aware company, we strive to ensure excellent sealing characteristics in all our industrial safety valves, minimising emissions to the atmosphere.

HEROSE offers the full package of cryogenic globe valves, control valves, check valves and emergency-closure valves, as well as diverter ball valves and change-over valves. All types are available in bronze or stainless steel, either for manual operation or as an actuated design.

More recently, we have introduced a complete range of stainless-steel gate valves, which takes HEROSE’s quality and design capabilities into new applications, such as cryogenic road tankers.

HEROSE is extending its range of products for cryogenic technology with ball valves. Especially for CO2 tanks and ISO containers for offshore use, or any other application where a rapid opening and closing of the valve is required, these cryogenic ball valves are an optimum supplement to the HEROSE product range.

HEROSE offers a range of pneumatic actuated cryogenic control valves. These valves are working with a linear or equal percentage control characteristic and are approved for air gases, vapours and cryogenic liquefied gases including LNG.

HEROSE’s success is ensured by our highly qualified staff. Our engineers are committed to the ongoing development of our valves to find tailor-made solutions for our customer base when existing products fail to meet their application requirements.

Our customers benefit from our TÜV approved quality systems according to the latest editions of DIN EN ISO 9001, PED 97 / 23 / EG, AD 2000 and TPED 99 / 36 / EG. The high-quality design of the HEROSE range is verified by the fact product complaints have only been made against less than 0.03% of the total valves we have manufactured. The company’s primary target is customer satisfaction.

Welcome, and Thank You for visiting the leading supplier of cryogenic valves and industrial gas valves. We sell cryogenic and high pressure valves from only the highest quality manufacturers, like Herose valves. At Ratermann Manufacturing, we pride ourselves at not only shipping your valve products fast and at the most competitive price, but being the information authority in the industry. Our support staff will assist you in ordering exactly what you need to match the specifications of your gas applications.

HEROSE is one of Europe’s leading manufacturers of valves for industrial applications, providing safety for the handling of technical gases, steams and liquids.

For over 145 years HEROSE has developed valves for cryogenic technology and pressure vessel construction. Producing more than 400,000 valves per year, they are one of the most experienced suppliers in the sector with products being used throughout the world.

Infections represent by far the greatest threat to our health. The healthy body can easily avert minor infectious diseases. However, if the person is weakened or pathogenic agents are present in greater concentration, each infection is an extreme burden for the person and the organism. In order to prevent this threat, the Münchener Medizin Mechanik GmbH, or in a short form, MMM is engaged in the development and implementation of treatment systems which help people to become and remain healthy by the creation of sterile environments. For many years, HEROSE has been supplying safety valves to this enterprise, which counts among the leading suppliers in this field worldwide with its 900 coworkers.

A tour through production. A steam sterilizer consists of four main assembly groups the steam generator, the pressure vessel – the actual sterilization chamber – the control and the so-called piping. In addition a safety valve is always installed in this area, which discharges the extremely high steam pressure in the case of emergencies. The HEROSE safety valves 06380 and 06395 are applied here. Sales Manager Volker Maass: “MMM belongs to our most important customers in this areas.”

Thomas Beutlhauser, Manager of Materials Management of the MMM Group knows how to appreciate the quality of HEROSE products as well as the dependability of delivery and the service. Last but not least: “Even the innovation capability of HEROSE is convincing for us. We are discussing new valves of stainless steel at the moment.”

HEROSE provides safety around the world for the handling of technical gases, steams and liquids. With 140 years experience in the development, manufacture and sale of valves with a high level of innovation and modern production with certified quality management

For more than 90 years, CPV Manufacturing has been at the forefront of engineering innovation in valves and fittings. CPV pioneered the O-Seal system concept and many other revolutionary designs. Other manufacturers may try to imitate, but CPV"s technology, quality integrity and experience are the real thing. At CPV, research and development are always centered on how well a new product will solve a specific challenge. This means new designs always start with customer needs and are never isolated from the job they will be doing in the field.

This philosophy began with CPV��s founder, Isaiah Engle. Back in 1915, this enterprising farmer, who loved repairing his neighbors" machinery, left Abilene, Kansas for Philadelphia and opened a machine shop. Soon after, he began making pump valves for large steam operating reciprocating pumps. To fix the problem of leakage, Isaiah designed a revolutionary soft seat that increased operating efficiency and durability.

HEROSE cryogenic globe valves are available with a wide range of connections and material combinations. They can be equipped with additional functions, such as bellows seals for increased tightness requirements, or with a non-return function. With this combination, use of a separate valve can be eliminated. Cryogenic globe valves are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -255°C to +120°C.

HEROSE cryogenic angle valves are available with weld connections in stainless steel. They can be equipped with additional functions, such as bellows seals for increased tightness requirements, or with a non-return function. With this combination, use of a separate valve can be eliminated. Cryogenic angle valves are available in sizes from DN15 to DN50 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C.

With HEROSE cryogenic gate valves, the flow rate is three to five times higher than with globe valves of comparable size. This speeds up the filling of tanks and trailers and saves valuable time for the delivery of cryogenic liquefied gases.

The cryogenic gate valves are available in sizes from DN25 to DN100 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The gate valves are manufactured in stainless steel.

A combination of individual HEROSE valves with different functions will be pre-assembled at the factory to form a system. This reduces the joining and welding work on site and saves time and costs for installation on vacuum insulated vessels. Cryogenic fill cluster are available in sizes DN25 and DN40 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The fill clusters are manufactured in stainless steel and bronze.

HEROSE cryogenic ball valves have a larger flow diameter than comparable shut-off valves. They provide faster opening and closing times and are suitable for tank applications, as well as for cryogenic pumps, pipelines or low pressure trailers.

Cryogenic ball valves are available in sizes from DN8 to DN150 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The cryogenic ball valves are manufactured in stainless steel.

If required, HEROSE pneumatically actuated globe valves can be equipped with an additional hand wheel, with which the valve can be opened or closed manually in case of loss of pressure. Optional seawater-resistant materials are available, which are ideally suitable for offshore use. The actuated valves are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The actuated valves are manufactured in stainless steel and bronze.

The HEROSE pressure regulator combines three functions: pressure build-up, economiser and safety function. Fewer valves and piping are required, which also saves costs. With combined pressure regulators, cryogenic liquefied technical gases such as nitrogen, oxygen or argon can be economically stored at constant pressure during operation.

A check valve is used to secure against undesired return flows in pipelines, as it allows the flow of gases or liquids only in one direction. In the cryogenic area specially designed check valves are required, which are up to the requirements of temperatures well below freezing point. Cryogenic check valves are available in sizes from DN10 to DN200 and secure pressures up to 50 bar, at operating temperatures of -196°C to +120°C. The check valves are manufactured in stainless steel and bronze.

HEROSE cryogenic safety valves are certified to global certifications for CN, TR CU and ASME. Thus they can be used worldwide, regardless of where the system is installed later. Cryogenic safety valves are available in sizes from DN6 to DN50 and secure pressures up to 550 bar, at operating temperatures of -270°C to +400°C. The safety valves are manufactured primarily in stainless steel but also in bronze and brass.

The cryogenic overflow valves secure pressures up to 36 bar, at operating temperatures of -196°C to +185°C. The overflow valves are manufactured in stainless steel and bronce.

In contrast to a standard ball valve on a changeover valve at least two safety valves are designed to protect the application (for example, a liquid gas tank) against impermissible overpressure.

A changeover valve has usually two outputs but one input only and serves to connect two safety valves with a pressure device. Changeover valves can be found in the area of air gases, vapours and in cryogenics at cryogenic liquefied gases such as Nitrogen. Cange-over valves are available in sizes from DN6 to DN50 and secure pressures up to 250 bar, at operating temperatures of -270°C to +400°C. The changeover valves are manufactured primarily in stainless steel but also in bronze and brass.

8613371530291

8613371530291