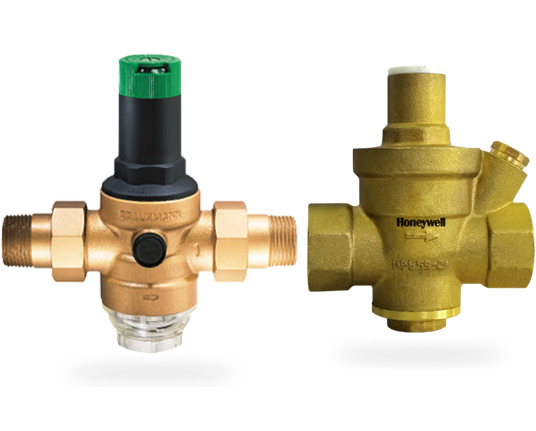

honeywell safety valve brands

Distributor of hydraulic press safety, quick opening safety, rotary and safety valves. Amerigear®, Boston Gear®, Carlisle®, DeMag®, Desch® and IMI Norgren®, pneumatic, double action, quick release and flow control valves also provided. Repair and preventative maintenance services are offered. Value added services such as custom barcoding, CAD capabilities, OEM assembly, plant surveys and third party logistics are also available. Serves the metal processing, metal service center, paper mill and paper converting, canning, grinding, commercial laundry, marine, oil and gas and material handling industries. Vendor managed inventory (VMI) programs available. Kanban delivery.

Of all the challenges you face keeping your customers’ plants operating at full capacity, safety and relief valves shouldn’t be one of them. NASVI’s job is to give you the confidence that your valve supply chain is rock solid regardless the pressure it’s under.

... -start valve with Series MX2 air treatment units without the need for additional connection interfaces. The soft-start valve is positioned upstream of the safety valves, ...

Two hands safety valve, which allows a safety use of two hands pneumatic controls (for example two push-button 3/2 N.C. to a certain distance) excluding false signals in case of push-button ...

The SI2 safety valve prevents the allowed operating pressure from being exceeded by more than 10%. If, after opening, the adjusted response pressure falls ...

... stainless steel full-lift clean service safety valve designed to AD Merkblatt A2 and TRD 421 standards and suitable for pure steam, vapour and inert gases.

Insert style flow control valves are comprised of a precision orifice in parallel with a check valve, combined into a single component. Each is designed for easy installation into metal housings using ...

Press-in style flow control valves are comprised of a precision flow orifice in parallel with a check valve, combined into a single component. Each part is designed for easy installation into plastic ...

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for you. With a pe of ...

... have been type tested as well. These pressure regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, or even biologically produced methane. It has AISi ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for ...

Material: Body- CF8M; Valve Seat- CF8M Métal Seat, PTFE Soft Seat available Orifice Size: fc"(15mm), 3/4M(20mm), l"(25mm), l1/4,’(32mm)I ltë”(40mm), ...

The Safety valves from ATOS are designed to guarantee protection for application on various devices, especially those that monitor spool position. They are also recommended for hydraulic ...

The Resideo Braukmann SV300 Pilot Operated Safety Valve is controlled by the medium flowing through it via a pilot valve. It is preferably installed in branches of supply pipework and protects downstream parts of a system which are at risk from unacceptable excess pressure which can, for example, be caused by pumps. If the inlet pressure to the valve rises up to the set opening pressure, then the valve opens immediately to the maximum flow position. If the pressure falls to the set pressure, then the valve closes slowly to prevent pressure shock loads.

D22 pressure reducing valves protect installations against excessive pressure from the supply. They can be used for industrial or commercial applications within the range of their specification. Because pressure reducing valves are subject to wear, they cannot be used as the only means of protection and if the downstream system needs to be protected against excessive pressure to prevent leakage, then a suitable safety valve must be fitted.

Emergency situations are not the only times relief valves are active; once installed they continuously regulate the flow of substance. They can also be pre-set to open when the pressure or temperature gets to a certain point that may be dangerous. Generally valves are placed on or near the pump head of the hose, pipe or tube. A wide variety of relief valve designs exist, although most resemble ball-check valves, swing check valves or diaphragm valves.

This last is particularly useful when controlling a flow of fluids that contains suspended solids. Most relief valves are spring operated, as are the majority of check valves. One specialized type of relief valve is known as a vacuum relief valve. As opposed to a normal relief valve, which relieves high pressure, a vacuum relief valve is used to relieve dangerously low pressures, or vacuums, by inserting air or an inert gas.

Like every other type of check valve, relief valves may be constructed from a variety of materials, including PVC, brass, ductile iron, copper, polyethylene, polypropylene, aluminum, steel, stainless steel and rubber. Which raw substance is used to produce each relief valve depends on the environment said relief valve will be in. The wrong product could result in erosion or contamination of the process stream. However, as long as research is done, finding the appropriate type of relief valve is possible. Every plumbing or fluid transfer application in the industrial, commercial and domestic arenas employ or will employ check valves. In fact, check valves of all kinds are an essential part of every day life. Because they need not be supervised to function and prevent product malfunction, check valves are not only desirable but often required by law to ensure the safety of water, gas and pressure applications.

The RV10 safety relief valve is well-suited for overpressure protection of production equipment, including compressors, scrubbers, separators, pipelines or anywhere overpressure protection may be required.

Honeywell Maxon electromechanical safety valves shut off gas lines in less than one second. All shut-off valves come equipped with Maxon"s long-lasting metal-to-metal seating. A variety of optional body materials and body connections provide reliable operation even for highly corrosive fuels and for oxygen.

Replaces Maxon 5000 (5000, 5000-NI, 5000-CP, 5000-NI-CP), STO (STO-A, STO-M, STO-A-NI, STO-M-NI, STO-A-CP, STO-A-NI-CP, STO-M-NI-CP) and 808 (808, 808-NI, 808-CP, 808-NI-CP) series valves

We hold thousands of new and obsolete Honeywell spares in several of our locations including Safety Automation , S245B-1ZA11.0, contact us for pricing and availability. At NRwell our mission is to keep your business moving and to offer a superior level of service from people you can trust.

The TS131 temperature relief valve for heating systems according to EN 12828 is a self-acting valve which is activated by the flow temperature of the heat generator. It opens and discharges water from the heat generator or condensing coil at a flow temperature of 95 °C and thereby prevents a significant temperature rise in the heat generator.

Materials: Valve body, spring cover and brass temperature sensor well; double copper temperature sensor with capillary tube; copper capillary; valve piston made of brass; valve seat gasket of heat-resistant elastomer.

Admiral Valve provides safety valves for a diversified customer base including ethanol, chemical, food processing, manufacturing and petroleum industries. We are certified in accordance with both the American Society of Mechanical Engineers (A.S.M.E.) and the National Board of Boiler and Pressure Vessel Inspectors (NBIC). Being in business for more than 50 years, we take pride in our ability to ensure customer satisfaction that each valve is certified to the highest standards for performance, safety and reliability. In addition to supplying customers with high quality safety valves, we also repair several different types of valves from a variety of manufacturers. Holding National Board Stamp #23, we are among the oldest certified repair facilities in the world.

8613371530291

8613371530291