hot water safety valve shower quotation

There"s something especially invigorating about taking a refreshing shower just after you wake up or at the end of a long day. When your shower isn"t producing enough pressure, however, that spa-like experience can turn into a rather disappointing one.

If you"ve tried all the standard fixes and they haven"t restored your shower to its former glory, replacing the shower valve could be the best solution. Shower valve replacement costs are usually far lower than buying an entirely new shower, yet this simple job can make your existing unit feel and perform as if it"s brand new.

Replacing a shower valve is a relatively simple job. According to data from Porch, you can expect to pay around $310 for a valve and stem replacement, or slightly more if you replace the whole unit.

Fees for replacing the whole shower valve can be as high as $540, with this price including the cost of the unit and labor. The cost of the valve itself is usually around $160, so if you"re a skilled DIYer, you may find it worth your time to complete the replacement yourself.

It takes around two hours to install a shower valve, assuming there’s already a shower installed. Upgraded Home says the average fees for installing a shower valve are between $375 and $575, depending on the type of valve and the cost of living in your zip code.

It"s worth getting quotes from several plumbers to get an idea of the hourly rates in your area so you know how much you can expect to pay. While it"s possible to do the job yourself, installing the valve is a moderately skilled job, so it"s worth hiring a plumber if you don"t have a lot of experience.

The shower valve assembly is a simple part that controls water pressure. Shower valves themselves don"t really have a lot of moving parts. How long your valve will last depends on the type of shower you have, how hard your water is and whether the valve is a brass one or one with a cartridge.

The job of the shower valve is to control the water pressure. If the shower valve is installed incorrectly or the cartridge is worn, you may notice water coming out of your tub faucet at the same time as the shower is running. The water pressure out of the showerhead may not be as powerful as you’d expect.

A properly installed shower valve should serve you well for a long time. Even if you live in an area with hard water that causes limescale build-up in your appliances, you can expect to have a shower valve work well for about four or five years.

Replacing a shower valve can be a simple job for someone who is confident in their plumbing skills. Check out our full replacement guide, or follow the steps below.

If there"s no water stop for your shower, or you can"t find that specific stop tap, you can turn off the supply using the main stop tap. Be aware, however, that this will turn off the water supply to the whole house.

Model 9201EFE (patent pending) is a thermostatic mixing valve that mixes hot and cold water to supply tempered water of up to 12 gpm (45.4 L) for emergency eyewash fixtures. Unit employs a paraffin filled thermostatic mixing element. Lowest internal pressure drop where supply pressure is low, and a high Cold Water Bypass flow rate of 10 gpm (37.8 L). The improved brass design with a one piece casting uses internal check stops, over-sized valve seats, a shuttle design that eliminates valve binding, and a funnel design to improve temperature control with better mixing at low flow rates. Lime and calcium resistant components are used throughout. The outlet temperature factory setting is 85° F (29° C). Maximum operating pressure: 125 psi (8.62 Bar). Temperature adjustment range 60 - 90° F (16 - 35° C). Min/max inlet hot water temperature: 120°/180° F (49°/82° C), with recommended inlet temperature: 140° F (60° C). Min/max inlet cold water temperature: 40°/70° (4.4°/21.1° C). Inlet 1/2" NPT(F). Outlet 3/4" NPT(F).

DURA-trol solid bimetal thermostat directly linked to valve porting to control the intake of hot and cold water and compensate for supply temperature and pressure fluctuations. DURA-trol is highly responsive and cannot be damaged by extremes in temperature

ECO-MIX DURA-trol solid bimetal thermostat directly linked to valve porting to control the intake of hot and cold water and compensate for supply temperature and pressure fluctuations. DURA-trol® is highly responsive and cannot be damaged by extremes in temperature. Thermostatic Mixing Valve can be set to the correct temperature for the application. Locking temperature regulator to prevent accidental movement set for 85°F (29°C), Recommended Hot Inlet Temperature 140°F. Mixing valve will close down on failure of cold water supply. Mixing valve with special internal cold water bypass capable of 40 GPM (151 l/min) @ 30 PSI (2.1 Bar) upon failure of hot water supply. Adjustable high temperature limit stop * set for 90°F, (32°C)Integral wall support, Full 1 1/4” bottom or top inlets and 1 1/2” top outlet, Integral wall support, Dial thermometer (range 0 to 140°F, -10 to 60°C), Rough bronze finish, Exposed stainless steel cabinet with hinged door and cylinder lock, Union Angle checkstops on inlets To determine the amount of Hot Water needed to maintain a steady outlet temperature for 15 minutes, click Hot Water Requirements. This guide is not meant to be used as a means to size the hot water heaters but rather to illustrate consumption. This product provides tepid water per the requirements of ANSI Z358.1 This product is certified to meet Low Lead requirements of wetted surface area containing less than 0.25% lead by weight.

This 3 Way Brass Thermostatic Shower Mixing Valve for Solar Hot Water provides accurate and stable water temperature. It has a built-in bypass that allows cold water to flow through in a system failure, ensuring your family’s safety. This valve is ideal for solar hot water systems with durable brass construction. Order today and enjoy years of reliable service!

This Thermostatic Shower Mixing Valve for Solar Hot Water is a 3-way mixing valve for solar hot water systems. This is a brass thermostatic shower mixing valve with a temperature range of 60°C to 110°C. The valves are manufactured in Taiwan and are guaranteed to be made with high-quality materials. It is supplied complete with full instructions and can be installed by a competent plumber or heating engineer without difficulty.

The 3-Way Brass Thermostatic Shower Mixing Valve for Solar Hot Water is easy to install and use. The valve controls the flow of hot water from your solar heater, ensuring that no energy or money is wasted by unused heating water. You can also use this thermostatic valve with a regular boiler system. This product has various finishes, including brass, chrome, white, black, and gold.

This article describes key safety inspection points that should be examined when inspecting building hot water supply anti-scald protection and tempering valve or mixing valve or temperature compensating valve installations.

We discuss temperature or scalding safety, valve adjustment, and leak concerns at mixing valves, and we include manufacturer"s instructions & warnings about mixing valve installation, safety, and periodic inspection & maintenance.

Watch Out: are there temperature control devices installed on the building hot water supply system? In most jurisdiction scald protection is required for residential properties but it may not be specified by local codes for commercial properties.

Check the temperature control settings on the device and where appropriate, actually measure hot water output temperature at the fixtures closest to hot water supply in order to assure that the mixing valve has been set to protect the building occupants from scalding.

Remember that while these valves may show a target temperature on the valve setting knob, the actual water temperature that comes out of a building faucet or tap will vary and may be hotter or cooler than the actual temperature set.

This is not precise lab-grade equipment capable of controlling water temperature precisely, and more, the length of pipe run between the hot water source and the building faucet or fixture will affect the temperature of water received there. A long run of un-insulated hot water pipe will deliver cooler water than a well-insulated water supply pipe of any length.

See TANKLESS COIL / HOT WATER COIL LEAKS for a detailed discussion of how to recognize, evaluate, and repair leaks at tankless coils on heating boilers

At above left we illustrate the typical piping arrangement into and out of a tankless coil water heating system. Cold water is piped to an inlet marked "COLD" and building hot water supply piping is connected to the tankless coil outlet marked "HOT".

This tankless coil piping example from Crown Boilers indicates the use of a mixing valve or anti-scald valve right at the heating boiler. The company includes an interesting warning reading as follows [Quoting - Crown BDS Installation Manual]

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Using the modern Watts Regulator Co. Series LF1170 / LFL1170 Hot Water Temperature Control Valve instructions as an example, these valves control water temperature in the following ranges:

Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves INSTALLATION INSTRUCTIONS[PDF] Installation, operating, and adjustment instructions for the LF1170 and LFL1170 mixing valves.

Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves SPECIFICATIONS[PDF] (2019), Watts Regulator Co. (2013), USA Tel: (978) 688-1811, Fax: (978) 794-1848,

Excerpt: This 1 inch lead free hot water control valve is designed for installation on water heating equipment to provide tempered water to point-of-use fixtures and is ideal for radiant heat applications.

It consists of a lead free brass body, solder union connections, solid wax hydraulic principle thermostat, integral filter washers and check valves, virtual shutoff upon loss of cold water supply, and a locking mechanism for the temperature setting.

Carson Dunlop Associates, THE IMPORTANCE OF THERMOSTATIC MIXING VALVES TO PROTECT AGAINST SCALDING: Part ONE [PDF] Carson Dunlop Associates, School of Home Inspection, retrieved 2022/08/14, original source: https://www.carsondunlop.com/training/resources/the-importance-of-thermostatic-mixing-valves-to-protect-against-scalding-part-one/

Excerpt: Anyone that has been scalded knows how painful it can be. When water is hot, it doesn’t take long for flesh to burn, and children’s skin burns more quickly. Also, at higher risk areolder people who react more slowly, and are more susceptible to burns as a result.[See details at TABLE OF SCALDING TEMPERATURES & TIMES]

Carson Dunlop Associates, THE IMPORTANCE OF THERMOSTATIC MIXING VALVES TO PROTECT AGAINST SCALDING: Part TWO [PDF] Carson Dunlop Associates, School of Home Inspection, retrieved 2022/08/14, original source: https://www.carsondunlop.com/training/resources/the-importance-of-thermostatic-mixing-valves-to-protect-against-scalding-part-two/

Due to the safety importance of this issue, ensure that the home inspector training program you select includes training on thermostatic mixing valves, so that you can provide the necessary advice for your clients.

Illustration: The Watts LF1170 or LFL1170 temperature control valve. Temperature an be adjusted by loosening a hex screw in the valve cap and rotating the cap - as described above.

At the plumbing fixture outlet hot water temperature must be at or below the highest temperature allowed by local building codes. These temperature specifications vary by U.S. state and in Canada.

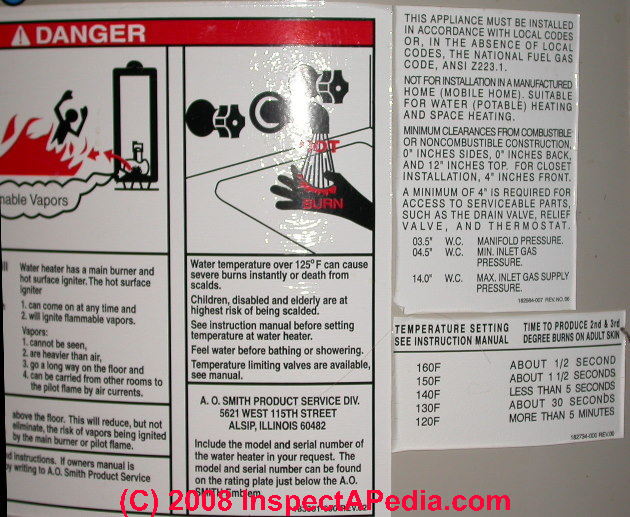

See TABLE OF SCALDING TEMPERATURES & TIMES - where we explain how long it takes for hot water to cause a burn and where we cite regulations about water temperature control and anti-scalding requirements.

Watch out: it can be confusing listening to plumbers, home inspectors, and building supply sales staff who toss around terms like "mixing valve", "tempering valve", and "pressure-balancing valve" a bit loosely, all referring to ways to avoid scalding burns at plumbing fixtures, but not all working the same way.

A point of supply pressure balancing valve or automatic mixing valve (or a manual mixing valve) can be installed at or near the water heater, or at the tankless coil or other hot water source so that scald protection is provided even if the water heater is set to a high temperature.

An temperature-sensing thermostatic mixing valve or anti-scald device can be installed at or near the water heating device so that even if the water heater is set to a high temperature (to obtain more total hot water as we discuss

MIX VALVE SCALD PROTECTION, Best Practices, includes excerpts or adaptations from Chapter 6 of Best Practices Guide to Residential Construction (found at page bottom, Click to Show or Hide), adapted courtesy of Wiley & Sons and written by Steven Bliss.

The other type of thermostatic valve is built into some high-end showers (Figure 6-54) courtesy of Steven Bliss, Best Construction Practices author. These devices allow the user to set the temperature on a dial when showering.

The unit will compensate for changes in either pressure or temperature to maintain a constant delivery temperature and flow rate. If the cold water fails or the tempered water is still too hot for any reason, the unit will shut off the flow.

Watch out: read the installation instructions from the manufacturer of the product you are installing, both to make sure it"s installed properly and thus will work as expected, and also so that you understand what to expect by way of hot water temperature control the product handles.

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Similarly, the Watts Regulator Company"s instructions for the installation of the Series LF1170 & LFL 1170 Hot Water Temperature Control Valves includes this warning: [Bold font is our emphasis]

Hi, my hot water tank uses a Watts LF1170 Series Mixing Valve, I simply cannot find any videos online how to adjust that red nob to increase the temperature, it has a mini hex wrench that I have to losen the cap but I have never done this before and I don"t want to cause any leak. I would help to have a video or something showing the exact steps, thanks

No the anti-scald valve simply mixes cold in with outgoing hot to avoid scalding temperatures. But any valve can become clogged with scale or debris, as can other pipes and heating equipment.

We"re flying a bit blindly here Steve but it does not sound right for warm water to immediately re-heat the cold-in piping on the cold side of the tempering valve immediately after turning off the flowing hot-water.

If the back- flow were substantial I"d expect cold piping on the cold side of the water heater to get hot so far back into the system that warm water would come out of nearby cold faucets.

Just checked - the cold water inlet pipe is warm to touch down to and including where the cold water enters the system, also where the cold water enters the hot water cylinder. Yes the pipe cools immediately the hot water is turned on. It also appears to get warm immediately after turning of the hot water.

Keep in mind we"re only discussing water temperature, not hot water quantity - so when you say "more hot water" - more or less *quantity* of hot water is only affected indirectly by a mixing valve, in this manner:

Also keep in mind that depending on the brand and model of mixing valve, the outgoing water temperature may be affected by the incoming water temperature on both the cold and hot side. If you are out of range of the incoming hot and cold temperatures - such as those shown in the table in the article above - the outgoing water temperature may be out of spec too.

I have been told that my Mixing Valve needs to be replaced, I have a gas water heater and solar panels also for hot water, it was installed in 2009. How can I be sure this is necessary. Five years is very little time and the expense is very large.

Continue reading at ANTI SCALD VALVE PROTECTION, Best Practices or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

ANTI-SCALD VALVE INSPECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

"BDS Series Oil-Fired Hot Water Boilers, Installation Instructions, Models GS-080 -> Crown BDS-236", Crown Boiler Company, BDS 12-99, Crown Boiler Co.

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

This article describes key safety inspection points that should be examined when inspecting building hot water supply anti-scald protection and tempering valve or mixing valve or temperature compensating valve installations.

We discuss temperature or scalding safety, valve adjustment, and leak concerns at mixing valves, and we include manufacturer"s instructions & warnings about mixing valve installation, safety, and periodic inspection & maintenance.

Watch Out: are there temperature control devices installed on the building hot water supply system? In most jurisdiction scald protection is required for residential properties but it may not be specified by local codes for commercial properties.

Check the temperature control settings on the device and where appropriate, actually measure hot water output temperature at the fixtures closest to hot water supply in order to assure that the mixing valve has been set to protect the building occupants from scalding.

Remember that while these valves may show a target temperature on the valve setting knob, the actual water temperature that comes out of a building faucet or tap will vary and may be hotter or cooler than the actual temperature set.

This is not precise lab-grade equipment capable of controlling water temperature precisely, and more, the length of pipe run between the hot water source and the building faucet or fixture will affect the temperature of water received there. A long run of un-insulated hot water pipe will deliver cooler water than a well-insulated water supply pipe of any length.

See TANKLESS COIL / HOT WATER COIL LEAKS for a detailed discussion of how to recognize, evaluate, and repair leaks at tankless coils on heating boilers

At above left we illustrate the typical piping arrangement into and out of a tankless coil water heating system. Cold water is piped to an inlet marked "COLD" and building hot water supply piping is connected to the tankless coil outlet marked "HOT".

This tankless coil piping example from Crown Boilers indicates the use of a mixing valve or anti-scald valve right at the heating boiler. The company includes an interesting warning reading as follows [Quoting - Crown BDS Installation Manual]

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Using the modern Watts Regulator Co. Series LF1170 / LFL1170 Hot Water Temperature Control Valve instructions as an example, these valves control water temperature in the following ranges:

Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves INSTALLATION INSTRUCTIONS[PDF] Installation, operating, and adjustment instructions for the LF1170 and LFL1170 mixing valves.

Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves SPECIFICATIONS[PDF] (2019), Watts Regulator Co. (2013), USA Tel: (978) 688-1811, Fax: (978) 794-1848,

Excerpt: This 1 inch lead free hot water control valve is designed for installation on water heating equipment to provide tempered water to point-of-use fixtures and is ideal for radiant heat applications.

It consists of a lead free brass body, solder union connections, solid wax hydraulic principle thermostat, integral filter washers and check valves, virtual shutoff upon loss of cold water supply, and a locking mechanism for the temperature setting.

Carson Dunlop Associates, THE IMPORTANCE OF THERMOSTATIC MIXING VALVES TO PROTECT AGAINST SCALDING: Part ONE [PDF] Carson Dunlop Associates, School of Home Inspection, retrieved 2022/08/14, original source: https://www.carsondunlop.com/training/resources/the-importance-of-thermostatic-mixing-valves-to-protect-against-scalding-part-one/

Excerpt: Anyone that has been scalded knows how painful it can be. When water is hot, it doesn’t take long for flesh to burn, and children’s skin burns more quickly. Also, at higher risk areolder people who react more slowly, and are more susceptible to burns as a result.[See details at TABLE OF SCALDING TEMPERATURES & TIMES]

Carson Dunlop Associates, THE IMPORTANCE OF THERMOSTATIC MIXING VALVES TO PROTECT AGAINST SCALDING: Part TWO [PDF] Carson Dunlop Associates, School of Home Inspection, retrieved 2022/08/14, original source: https://www.carsondunlop.com/training/resources/the-importance-of-thermostatic-mixing-valves-to-protect-against-scalding-part-two/

Due to the safety importance of this issue, ensure that the home inspector training program you select includes training on thermostatic mixing valves, so that you can provide the necessary advice for your clients.

Illustration: The Watts LF1170 or LFL1170 temperature control valve. Temperature an be adjusted by loosening a hex screw in the valve cap and rotating the cap - as described above.

At the plumbing fixture outlet hot water temperature must be at or below the highest temperature allowed by local building codes. These temperature specifications vary by U.S. state and in Canada.

See TABLE OF SCALDING TEMPERATURES & TIMES - where we explain how long it takes for hot water to cause a burn and where we cite regulations about water temperature control and anti-scalding requirements.

Watch out: it can be confusing listening to plumbers, home inspectors, and building supply sales staff who toss around terms like "mixing valve", "tempering valve", and "pressure-balancing valve" a bit loosely, all referring to ways to avoid scalding burns at plumbing fixtures, but not all working the same way.

A point of supply pressure balancing valve or automatic mixing valve (or a manual mixing valve) can be installed at or near the water heater, or at the tankless coil or other hot water source so that scald protection is provided even if the water heater is set to a high temperature.

An temperature-sensing thermostatic mixing valve or anti-scald device can be installed at or near the water heating device so that even if the water heater is set to a high temperature (to obtain more total hot water as we discuss

MIX VALVE SCALD PROTECTION, Best Practices, includes excerpts or adaptations from Chapter 6 of Best Practices Guide to Residential Construction (found at page bottom, Click to Show or Hide), adapted courtesy of Wiley & Sons and written by Steven Bliss.

The other type of thermostatic valve is built into some high-end showers (Figure 6-54) courtesy of Steven Bliss, Best Construction Practices author. These devices allow the user to set the temperature on a dial when showering.

The unit will compensate for changes in either pressure or temperature to maintain a constant delivery temperature and flow rate. If the cold water fails or the tempered water is still too hot for any reason, the unit will shut off the flow.

Watch out: read the installation instructions from the manufacturer of the product you are installing, both to make sure it"s installed properly and thus will work as expected, and also so that you understand what to expect by way of hot water temperature control the product handles.

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Similarly, the Watts Regulator Company"s instructions for the installation of the Series LF1170 & LFL 1170 Hot Water Temperature Control Valves includes this warning: [Bold font is our emphasis]

Hi, my hot water tank uses a Watts LF1170 Series Mixing Valve, I simply cannot find any videos online how to adjust that red nob to increase the temperature, it has a mini hex wrench that I have to losen the cap but I have never done this before and I don"t want to cause any leak. I would help to have a video or something showing the exact steps, thanks

No the anti-scald valve simply mixes cold in with outgoing hot to avoid scalding temperatures. But any valve can become clogged with scale or debris, as can other pipes and heating equipment.

We"re flying a bit blindly here Steve but it does not sound right for warm water to immediately re-heat the cold-in piping on the cold side of the tempering valve immediately after turning off the flowing hot-water.

If the back- flow were substantial I"d expect cold piping on the cold side of the water heater to get hot so far back into the system that warm water would come out of nearby cold faucets.

Just checked - the cold water inlet pipe is warm to touch down to and including where the cold water enters the system, also where the cold water enters the hot water cylinder. Yes the pipe cools immediately the hot water is turned on. It also appears to get warm immediately after turning of the hot water.

Keep in mind we"re only discussing water temperature, not hot water quantity - so when you say "more hot water" - more or less *quantity* of hot water is only affected indirectly by a mixing valve, in this manner:

Also keep in mind that depending on the brand and model of mixing valve, the outgoing water temperature may be affected by the incoming water temperature on both the cold and hot side. If you are out of range of the incoming hot and cold temperatures - such as those shown in the table in the article above - the outgoing water temperature may be out of spec too.

I have been told that my Mixing Valve needs to be replaced, I have a gas water heater and solar panels also for hot water, it was installed in 2009. How can I be sure this is necessary. Five years is very little time and the expense is very large.

Continue reading at ANTI SCALD VALVE PROTECTION, Best Practices or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

ANTI-SCALD VALVE INSPECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

"BDS Series Oil-Fired Hot Water Boilers, Installation Instructions, Models GS-080 -> Crown BDS-236", Crown Boiler Company, BDS 12-99, Crown Boiler Co.

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

In these hot water temperature control articles, we explain how to buy, install, adjust and inspect anti-scald equipment to prevent hot water burns. We explain what a mixing valve, tempering valve, or anti-scald valve is, where and why these valves are installed on hot water systems, and how they work.

Photo: a Sparco anti-scald valve or tempering valve installed at a hydronic heating boiler. Other texts refer to these safety controls as mixing valves or compensating valves or temperature compensating valves.

Anti-scald valves used with water heaters are also called tempering valves or mixing valves. An anti-scald valve mixes cold water in with the outgoing hot water (or regulates pressure, or uses another approach) to assure that hot water exiting a building fixture is at a temperature low enough to be safe.

In the sketch shown below, courtesy of Carson Dunlop Associates (found at page bottom, Click to Show or Hide), an anti-scald valve (also referred to as a tempering valve , a compensating valve or an automatic mixing valve) is shown installed at the hot water piping and tankless coil on a heating boiler.

The drawing illustrates that hot water leaving the tankless coil has been heated to 180 °F. by the coil which is itself immersed in hot boiler water. The 180 degree F. water leaving the tankless coil is mixed with 55 °F. water inside the tempering valve. This produces outgoing hot water from the valve cooled down to 140 deg F.

In the U.S., most authorities consider hot water at or below 120 deg F to be safe from scalding. Some facilities limit water temperatures to 100 deg. F.

Anti-scald valves typically are warranted for just 12 months from the date of installation. Plumbers report a typical tempering valve life of five years. (Moley 2022)

Some plumbing faucets and valves, such as models using a ceramic cartridge, may last the lifetime of the building even if the faucet"s finish and trim do not last that long.

An anti-scald or mixing valve mixes cold water with the outgoing hot water either automatically or manually to make sure that a person using the plumbing fixture won"t be scalded.

and mixing valve manufacturers described here, all take care to refer to products like the Sparco control shown above and the Watts mixing valve shown on this page as a mixing valve or tempering valve. They are not promising that the device will prevent burns from scalding hot water.

That advice means that besides mixing valves or tempering valves that are typically installed at the water heater or tankless coil, separate anti-scald protection devices are available for and should be installed at the point of use: sink, shower, or tub etc. Those sorts of anti-scald devices are also discussed in this article.

Above, in our photograph of a more traditional single-function heating boiler limit control, the limit switch is being used on a tankless coil, serving as an upper limit on the temperature to which the boiler is to heat its water. This temperature may and usually is well above 120°F and so is a scalding burn hazard.

Really? In my experience with plumbing and heating installers, home inspectors, and consumers, these terms: automatic compensation valve, mixing valve, tempering valve, anti-scald device, automatic pressure regulating valve, pressure balancing valve, pressure compensating valve are thrown about in a blizzard of usages that treat the words as synonyms.

In the course of inspecting several thousand buildings between 1976 and 2014, I have almost never found anti-scald devices at individual plumbing fixtures in private homes. The only water temperature control we typically find are mixing valves at the hot water source. Worse, sometimes there is no hot water scald protection at all.

When a heating boiler uses a tankless coil to produce domestic hot water, a third single-function control may be installed for that purpose. In our photo, a Honeywell limit control switch is being used to monitor hot water temperature at the tankless coil which is in turn mounted on a steam boiler of an older home in Portland, Maine.

Cold water from the building is entering the tankless coil via the bottom pipe (green corrosion) and hot water, heated by the coil is leaving at the upper part of the tankless coil, where it turns downwards to enter the left side of the mixing valve.

Additional cold water is permitted to enter the bottom of the mixing valve, and tempered (non-scalding) hot water then leaves at the right side of the mixing valve in that photo,

Avoid scalding burns on someone using the plumbing appliance - generally by trying to prevent water temperature at the device from exceeding a safe limit either set by the manufacturer or adjusted by the installer or user.

Note that once a temperature limit or stop has been set, water temperature might still vary both above or below that setting, depending on the type of limiting device and on the causes of variation of water temperature entering the building or of hot water produced by and exiting the water heater itself.

Avoid or minimize variations in water temperature - generally by monitoring water pressure, flow-rate, or temperature to avoid surges of hot or cold water.

POS: Point of source: these controls are installed at the water heater or at the heating boiler that uses a tankless coil, as a tempering or mixing valve using any of several methods to control outgoing water temperature to the entire building, detailed below.

POU: Point of use: these hot water temperature controls are installed at or close to the point of use or individual plumbing fixture as we detail below.

THERMOSTATIC HOT WATER TEMPERATURE CONTROL at POINT OF USE -or POS - point of source for some devices including TAFR - Temperature Actuated Flow Reduction devices as well as others.

Watch out: as you"ll read here and in the article topics we have listed, various water temperature control devices have different purposes, and not all of them are designed to prevent scalding burns.

Watch out:Where no anti-scald valve is installed, the risk of a person being badly burned by hot water can be significant in buildings for a variety of reasons that we will explain here, including:

Use of water use efficiency improvement devices such as low-flow shower heads. When a low-flow-rate shower head is retrofitted to a home where no anti-scald valve or automatic compensation valve has been installed, even if the shower controls or tub controls have been manually adjusted to provide safe comfortable water temperature, the unexpected use of other appliances or plumbing fixtures in the building can cause the water temperature at the shower or tub to suddenly become scalding.

Watch out: it can be confusing listening to plumbers, home inspectors, and building supply sales staff who toss around terms like "mixing valve", "tempering valve", and "pressure-balancing valve" a bit loosely, all referring to ways to avoid scalding burns at plumbing fixtures, but not all working the same way.

Watch out: every anti-scald device, mixing valve, temperature control device whose instructions we reviewed includes a collection of safety warnings that explain the limitations of the device and its vulnerability to improper installation, improper adjustment, or to external causes of water temperature variation that are outside the scope of the control.

Watch out: read the installation instructions from the manufacturer of the product you are installing, both to make sure it"s installed properly and thus will work as expected, and also so that you understand what to expect by way of hot water temperature control that the product handles.

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Similarly, the Watts Regulator Company"s instructions for the installation of the Series LF1170 & LFL 1170 Hot Water Temperature Control Valves includes this warning: [Bold font is our emphasis]

The first document below lists the components and parts of the mixing valve you describe - or a model close to it. The second provides instructions for a newer Thermostatic Mixing Valve or TMV from Danfoss, the Series 30 HR/HV.

Products listed here include thermostatic mixing valves of several types including valves that are installed at the fixture or point of use (POU thermostatic mixing valves), valves that are installed at the water heating source, and other products.

Watch out: as you will read in the individual product specifications, some thermostatic mixing valve instructions take care to mention that the valve does NOT provide scald protection and should not be used where ASSE 1070 devices are required.

Apollo DUAL PURPOSE THERMOSTATIC MIXING VALVE IO MANUAL [PDF] Model MVB & MVBLF ASSE 1017 Point-of-source & ASSE 1017 Point-of-use, Conbraco Industries Inc., 1418 Pearl St., Pageland SC 29728 USA Tel: 704-841-6000

Apollo THERMOSTATIC MIXING VALVE 34ALF Series SPECIFICATIONS [PDF] Apollo, Op. Cit., this valve is a POS or Point of Source use only temperature control valve.

The Apollo “MVB” Series are designed to mix and regulate the amount of cold and hot water to produce a comfortable and safe outlet temperature at a predetermined setting, either from the “point of source” or “point of use” application for single or multiple fixtures.

ASSE 1017 model 5231 series high flow thermostatic mixing valves are designed to be installed at the hot water heater (point of distribution) and cannot be used for tempering water temperature at fixtures as a point-of- use valve.

Series 5231 thermostatic mixing valves can also be used for regulating the flow temperature in radiant panel heating systems, to which it assures a constant and accurate control with ease of installation.

Cash Acme HEATGUARD 110-D SERIES TEMPERATURE-ACTUATED MIXING VALVE [PDF] (2014) assists in scald prevention, Cash Acme Corp., 2400 7th Avenue S.W. · Cullman · Alabama 35055 · USA · www.cashacme.com

Danfoss ESBE Series 20 THERMOSTATIC MIXING VALVE TMV INSTRUCTIONS [PDF] retrieved 2017/04/03, original source: http://na.heating.danfoss.com/PCMPDF/ESBE_Series20_TMV_instructions.pdf

Danfoss THERMOSTATIC MIXING VALVE Series 30 HR/HV INSTALLATION & MAINTENANCE INSTRUCTIONS [PDF] retrieved 2017/04/03, original source: http://na.heating.danfoss.com/PCMPDF/ESBE_HRHV_TMV_instructions.pdf

Photo: a replacement Delta Scald Guard cartridge. This is a rotational stop device. Detailed instructions on how to adjust this Delta scald guard device are given just below as a PDF download from the company.

ASSE compliance: ASSE 1017 - requires installation of a check valve. An expansion tank must be installed with the check valve to accomodate thermal expansion.

The AMX300 Series DirectConnect™ Mixing Valves fit any application requiring accurate control of water temperature by mixing hot and cold water such as domestic water.

KOHLER THERMOSTATIC MIXING VALVE INSTALLATION & CARE GUIDE [PDF] (2015) describing a POU point-of-use hot water temperature control from Kohler, Models K-2972, K2975, K2973, K2976.This valve meets or exceeds ASME A112.18.1/CSA B125.1 and ASSE

TUB AND SHOWER VALVES INSTALLATION INSTRUCTIONS [PDF] (2002) Moen, retrieved 2022/06/12, original source: https://assets.moen.com/shared/docs/instruction-sheets/mt692c.pdf

Moen, ONE HANDLE TUB/SHOWER VALVE TRIM INSTALLATION INSTRUCTIONS (2014) Moen, retrieved 2022/06/12, original source: https://assets.moen.com/shared/docs/instruction-sheets/ins2153c.pdf

Moley, Hot Water Tempering Valve, Maintaining & Servicing, [Website] Moley Plumbing & Gasfitting, retrieved 2022/06/12, original source: https://www.moyleplumbing.com.au/blog/hot-water-tempering-valve-maintenance-service#:~:text=A tempering valve should last approximately five (5) years.

Resideo (Honeywell) Braukmann PROPORTIONAL THERMOSTATIC MIXING VALVE [PDF] (2020) AM-1 1070 Series Proportional Thermostatic Mixing Valve, Resideo Technologies, Inc., 1985 Douglas Drive North, Golden Valley, MN 55422 1-800-468-1502

Symmons TEMPCONTROL 700-Series MIXING VALVE INSTALLATION MANUAL [PDF] [Shown above] Symmons Industries, Inc., 31 Brooks Drive, Braintree, MA 02184 USA, Tel: (800) 796-6667 Web: symmons.com Email: gethelp@symmons.com

left. Install retaining nut back onto valve body.[Note the requirement t torque the retaining nut to 132 inch pounds. - Ed.]5) Refer to "Setting Valve Temperature" section (pg.4)

Tempress PRESSURE BALANCING VALVE I-595 INSTALLATION INSTRUCTIONS [PDF] (2020) for use with Tub and Shower Fittings, Newport Brass, 2001 Carnegie Ave, Santa Ana CA 92705 USA Tel: (949) 417-5207

Watts, SERIES LF1170 AND LFL1170 HOT WATER TEMPERATURE CONTROL VALVE INSTRUCTIONS [PDF] (2013) Watts Regulator Co., USA Tel: (978) 688-1811, Fax: (978) 794-1848,

I can but guess because there is other information about your plumbing system that I don"t know, but it"s possible that you are anti scald device is installed at the water heater and that there is too much distance between that point and the nearest hot water Plumbing fixture.

A solution would be to install the anti scald device right at your plumbing fixtures. It"s more expensive in the landlord may not want to do that. OR the mixing valve output temperature is simply set lower than necessary. Temperature can be set as high as 120F. but no higher at the fixture or there"d be a scalding burn hazard.

A mixing or equalizer valve was just installed on my hit water tank by the landlord. I am finding that the water isn"t hot enough for us. We were told the temperature would be set for 110°F and would not be allowed to be higher.

We also pay for our own hot water usage through the gas company and it isn"t being paid for by the landlord. We are not using any cold water for showers or for anything other than drinking at this point. I would like to know if there is a way to increase the amount of hot water.

There is no risk of scalding in this house as we are adults who know how to live responsibly while using the water without harm to ourselves and others within the home.

If we are talking about a domestic water heater that produces hot water for washing and bathing, there will be a thermostat (or two of them) on the water heater; the thermostat controls vary depending on whether the heater is fueled by oil or gas or electricity.

Continue reading at ANTI-SCALD WATER TEMPERATURE CONTROL TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

ANTI SCALD VALVES / MIXING VALVES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Thanks to Bruce Jones, Renewable Energy Solutions Manager, for suggesting clarifications about which way to turn the mixing valve to make water supply hotter or colder. email August 2010.

Thanks to reader Chris Martino for pointing out inconsistent text about which way to turn the hot water mixing valve or tempering valve. December 2010.

[5] "Water Saving Tips: For Residential Water Use, Indoors and Out",Alliance for Water Efficiency, 300 W Adams Street, Suite 601 Chicago, Illinois 60606, Tel: 773-360-5100, 866-730-A4WE, Email: jeffrey@a4we.org, web search 12/14/11, original source: plumbingefficiencyresearchcoalition.org/

[6] "Danger in the Shower: 2008 Forum Looks at Hot Water", John Koeller, Home Energy, Jan/Feb 2009, Home Energy Magazine, 1250 Addison Street Suite 211B, Berkeley, Ca. 94702, Tel: (510) 524-5405 Email: contact@homeenergy.org

TECHNICAL REFERENCE GUIDE to manufacturer"s model and serial number information for heating and cooling equipment, useful for determining the age of heating boilers, furnaces, water heaters is provided by Carson Dunlop Weldon & Associates

:max_bytes(150000):strip_icc()/increase-low-shower-pressure-4052359_FINAL-e06ed996ea4e4b30836d24a86f45c003.png)

Shower mixing valves automatically mix hot and cold water to deliver blended water within a specified range for showers and baths in residential and institutional settings. We offer a range of products with various features and configurations, including models that quickly compensate for temperature fluctuations induced by water temperature and pressure changes.

One way to provide an extra measure of protection for all family members – not just seniors – is with an anti-scald shower valve. Here are just a few good reasons to make the switch:

Safety and comfort. An anti-scald valve prevents burn injuries in the shower or bathtub while the constant water temperature provides comfort and peace of mind.

Long-term savings. Anti-scald valves that control both water pressure and temperature fluctuation will end up saving you money because you won’t spend as much time trying to get the temperature just right. You’ll also save money and keep the valve working longer by routinely removing calcium deposits from the aerator with a vinegar solution.

At Best Choice Plumbers, we offer numerous ways to help protect your family – while providing added convenience – in the bathroom. Other solutions include motion sensitive faucets, comfort height toilets, grab bars, shower bench seats, and more. For a free in-home comfort and safety analysis, contact Best Choice Plumbers today.

At this time of year, hot showers are valued and many homeowners change the temperature of their hot water heater to reflect their desire for warmth. Still, some homeowners find it difficult to find the perfect equilibrium in their hot water heater, and the result is a shower or bath that runs too hot or too cold. Other baths and showers simply run too hot or cold, regardless of the hot water heater temperature. There are several options for solving this problem.

It’s possible your shower runs hot or cold because you just haven’t found the right temperature setting for your hot water heater. In general, 120 degrees Fahrenheit is considered to be the magic number for hot water heaters. This temperature is warm enough to stem the growth of bacteria in the hot water heater, and also warm enough to reach a perfect hot temperature in your shower.

In homes with young children or elderly occupants, 120 degrees may be too hot. Homeowners living with young children or elderly relatives should consult with a physician before changing the temperature on the water heater.

On some hot water heaters, adjusting the temperature is as easy as turning a dial. However, on other hot water heaters the temperature setting is hidden behind a panel. Follow these steps to remove the panel and adjust the temperature in your hot water heater to a toasty 120 degrees.

Use the phillips head screwdriver to remove the panel covering the temperature dial on the water heater. This panel cover will likely be marked to indicate that it covers the temperature dial.

The mixture of hot water and cold water available in a shower or tub can be adjusted at the shower valve stem, the part found under the faucet. The exact process for adjusting the hot and cold water will depend on the type of faucet in your shower or tub, but the general idea is as follows:

Take off the metal cover beneath the handle, exposing the valve stem. You’ll see a plastic part around the valve stem. This plastic part is known as the “rotational stop limit,” (RSL). This is the part of the shower that controls the mixture of hot and cold water coming out of the faucets. The directional controls will probably be noted on the RSL, but in general a counter-clockwise turn will release more hot water, and a clockwise turn will release less hot water. To turn the RSL, you may have to pull out the RSL cover to reveal the teeth that hold the RSL in place.

In addition to the YouTube videos above, there are several online resources that may help you adjust the hot and cold water in your shower or tub. Here are a few:

Handyman How To: This online resource includes a very useful step-by-step tutorial with a helpful picture and an informative section about water temperatures as they relate to bacteria and scalding danger.

Apartment Therapy: This website has a very lengthy explanation about the best temperature for water heaters and how to prevent children from being scalded.

When in doubt, you can always contact a plumber to help you adjust your shower’s hot and cold settings. Residents of the Pittsburgh area can call Terry’s Plumbing. We’re happy to make any necessary adjustments to your faucets or water heater.

So how much will water heater repair cost? The exact amount varies depending on the issues you’re facing, the time it takes to repair, and even the technician you hire.

The dip tube carries cold water to the bottom of the tank for heating. If the dip tube is corroded, blocked, or leaking, water heating won’t occur as efficiently.

The pressure relief valve makes sure your water tank pressure remains at safe levels. If pressure builds up too much, this valve opens to relieve some of that pressure.

If you notice that the valve is consistently leaking, it may mean that the tank’s pressure is too high, or you might simply have a faulty/clogged valve.

The function of the anode rod in your water tank is to prevent corrosion. It does this by taking on corrosion first—as long as the anode rod is corroding, your water tank and heating element won’t.

The thermostat regulates the temperature in your water heater. If there is more heat needed, it will turn on the heating elements. Once water is warm enough, the elements are turned off.

Electric heaters use a conductive metal element to heat the water. Therefore, if the element is corroded or stops functioning, you don’t get hot water.

Tankless water heatersare a relatively new technology that helps save you on water heating costs. Since they function quite differently from conventional water heaters, they will have their own unique issues.

Tankless water heaters require periodic flushing to keep mineral and sediment from building up inside the unit. Cleaning this buildup out will allow the unit to run more efficiently, so it’s recommended that you get your water heater tank flushed about once per year.

If you write the codes or comply with the codes as an engineer, contractor or owner, pay attention to how the codes are argued and interpreted to protect the health and safety of people.

I recently concluded a domestic hot water scald burn case involving a student in a university dormitory tub-shower. The tub-shower valves installed throughout the dormitory were code-compliant valves when manufactured; the manufacturer confirmed that the valves were third-party certified to ASSE 1016 in 2001.

The university maintenance personnel admitted to removing the maximum-temperature limit stops, which is a safety device, from the tub-shower valves. With no temperature control devices downstream of the gas-fired, storage-type water heaters serving the multistory building, the likelihood that scalding hot water would flow from a showerhead while a student was showering was an omnipresent threat.

Yet, the university argued that it had no reason to suspect that anyone would ever be scalded in a shower because they were unaware of any student having complained of the water being “too hot” in the previous five years (an arbitrary look-back period, which is not relevant to the issue of whether a plumbing system is safe). However, a closer look at the records did show complaints of water too hot and numerous complaints of leaks followed by complaints of no hot water.

I was surprised when I read the university’s expert report defending the removal of the maximum-temperature limit stops from the tub-shower valves by the owner’s in-house maintenance personnel. The defense was based upon a university maintenance employee’s belief that the valves may have been installed before the university even purchased the building. At that time, the code did not require the installation of valves conforming to ASSE 1016, with the maximum-temperature limit stop adjusted to a temperature of no greater than 120 F.

The university’s expert further surmised that perhaps the valves were installed before the ASSE 1016 standard even had a provision for a maximum-temperature limit stop, which provision became part of the ASSE 1016 standard in 1988. The valve manufacturer, in this case, was ahead of the curve, having introduced its valve with a maximum-temperature limit stop in 1986.

Therefore, the defense argued that removing the limit stops violated no code as tub-shower valves with maximum-temperature limit stops weren’t even required to have been installed in the first instance. The defense further argued that with the limit stops removed, the tub-shower valve met the previous ASSE 1016 standard — the one introduced in 1973 did not contain a provision for maximum-temperature limit stops.

Note that the foreword of the 1973 ASSE 1016 standard admonishes any claim that a product meets the standard without third-party testing and certification. There is no evidence that this tub-shower valve with its maximum-temperature limit stop was ever tested and certified to this 1973 standard, even though the removal of the limit stop should not affect the other functionalities of the valve.

Although no record of the installation dates existed in the university’s records, the university was able to identify the model number of the valve and provide a photocopy of a specification sheet for the subject tub-shower valve, which showed evidence of being retrieved from a three-ring binder.

The specification sheet bore a date of 06/02; the valve manufacturer confirmed that there was no earlier specification sheet for that model of tub-shower valve. The valve manufacturer identified the model number for the subject tub-shower valve as included in the 2001 third-party testing and certification of its valves to the ASSE 1016 standard.

The defense concluded that the university maintenance personnel’s relatively recent removal of the safety device violated no code because maximum-temperature limit stops were not required by code some 30-plus years ago when the valve was alleged to have been installed.

However, for many years, including the most recent effective version of the International Plumbing Code (IPC), there was a provision requiring that: “[a]ll plumbing systems, materials and appurtenances, both existing and new, and all parts thereof, shall be maintained in proper operating condition in accordance with the original design in a safe and sanitary condition.” I’d be curious to hear from others how they would interpret the later removal of a product’s safety device, although not required by the code in effect at the time of installation.

The defense had yet to contend whether any post-installation code required the university to install ASSE 1016 valves with maximum-temperature limit stops, both integral to the valve and field adjusted, per the manufacturer’s instructions, to limit the maximum setting of the valve to 120 F. The defense report concluded that no such code required any update to tub-shower valves, citing various code provisions regarding the lawfulness of existing installations (i.e., grandfather clauses).

In my opinion, having been involved for decades in writing, analyzing, interpreting and applying the various building codes, there should be no room to argue that any tub-shower valve installation without a maximum-temperature limit stop is “grandfathered” into a long-ago code. In nearly every building in America, tub-shower valves with integral maximum-temperature limit stops, field-adjusted to limit the maximum setting of the valve to 120 F, are code-required to have been or to be installed by now.

The reason is simple: With every installation of a water heater, either in new construction or as a replacement in an existing structure, tub-shower valves must be installed, re-adjusted or replaced with new, ASSE 1016-compliant valves. In this multistory dormitory building, several separate instances of gas water heater replacement were recorded.

All were performed when the local code in effect required the installation of tub-shower valves conforming to ASSE 1016 (that is, requiring integral maximum-temperature limit stops) and field-adjusted to limit the maximum setting of the valve to 120 F or less.

In existing structures, installing a new water heater is an alteration to a plumbing system; it can cause an existing plumbing system to become unsafe if the proper precautions are not performed. The installation of a new water heater affects the entire domestic hot water distribution system’s temperatures. The removal and replacement of a water heater require alterations to the fuel gas piping, the fuel gas vent piping and the water piping connections.

Installing a new water heater requires an assessment of the number and use of the fixtures to determine if the replacement water heater is of adequate size and fuel input capacity to meet the hot water needs of the consumers. Therefore, when a new or replacement water heater is installed, the existing plumbing fixtures, including shower and tub-shower valves, should be brought up to the current code to make the plumbing system safe. The applicable IPC provision is:

Additionally, with respect to gas water heaters, the International Fuel Gas Code (IFGC) specifically requires the scald protections of the IPC to be followed when installing a water heater. The applicable IFGC provision is:

“Water heaters shall be tested in accordance with ANSI Z21.10.1 and ANSI Z21.10.3 and shall be installed in accordance with the manufacturer’s instructions.

“The requirements for water heaters relative to sizing, relief valves, drain pans and scald protection shall be in accordance with the International Plumbing Code.” (Emphasis added.)

I have always interpreted this provision in the IFGC to refer to the IPC’s requirement for anti-scald valves in showers, combination bathtub-showers, bathtubs and whirlpool bathtubs (i.e., both ASSE 1016 and ASSE 1070 valves). The applicable IPC provisions are:

“Individual shower and tub-shower combination valves shall be balanced-pressure, thermostatic or combination balanced-pressure/thermostatic valves that conform to the requirements of ASSE 1016 or ASME A112.18.1/CSA B125.1 and shall be installed at the point of use.

“Shower and tub-shower combination valves required by this section shall be equipped with a means to limit the maximum setting of the valve to 120 F (49 C), which shall be field-adjusted in accordance with the manufacturer’s instructions. In-line thermostatic valves shall not be utilized for compliance with this section.

“The hot water supplied to bathtubs and whirlpool bathtubs shall be limited to a maximum temperature of 120 F (49 C) by a water-temperature limiting device that conforms to ASSE 1070 or CSA B125.3, except where such protection is otherwise provided by a combination tub/shower valve in accordance with Section 424.3.”

The university interpreted this provision of the IFGC to refer to the IPC’s requirement for a tempering valve to limit the temperature of the hot water supplied to the potable hot water distribution system to 140 F for a combination potable water-heating and space-heating system.

A similar requirement for a tempering valve for combined systems where water greater than 140 F is required for space heating is contained in the International Mechanical Code (IMC); unfortunately, for many years, the IMC titled this provision as “scald protection.” I was present when the title of this provision was changed because this provision is not for scald protection. The title is now “temperature limitation.”

An ASSE 1017 valve is not an acceptable means for scald protection, and a hot water temperature of 140 F is not for purposes of scald protection. According to the Moritz & Henriques burn studies, at 140 F, it takes only three seconds for a serious, blistering, irreversible burn that will cause scar tissue in an adult male.

Rather, the requirements of a hot water distribution temperature of 140 F for combination potable water-heating and space-heating systems are based on other plumbing system design principles to ensure adequate hot water capacity and for the proper function of a water heater.

Regardless of any debate over the obligations of a property owner to install and field-adjust ASSE 1016-compliant valves when installing a water heater, either in new construction or as a replacement in an existing structure, there is one code that repudiates any notion of “grandfathering” of noncompliant structures or premises — the International Property Maintenance Code (IPMC).

Based upon the language of the IPMC, the installation of code-compliant ASSE 1016 valves, field-adjusted to limit the maximum temperature of mixed hot water flowing from bathtubs and showers to 120 F, is required of property owners regardless of whether any other alterations, additions or repairs to the domestic hot water (plumbing) system are made, and regardless of any other percentages of construction.

“The provisions of this code shall apply to all existing residential and nonresidential structures and all existing premises and constitute minimum requirements and standards for premises, structures, equipment and facilities for light, ventilation, space, heating, sanitation, protection from the elements, life safety, safety from fire and other hazards, and for safe and sanitary maintenance[.]” (Emphasis added.)

“This code shall be construed to secure its expressed intent, which is to ensure public health, safety and welfare insofar as they are affected by the continued occupancy and maintenance of structures and premises. Existing structures and premises that do not comply with these provisions shall be altered or repaired to provide a minimum level of health and safety as required herein.” (Emphasis added.)

Chapter 5 also requires that the hot or tempered water supplied to bathtubs and showers (as well as other plumbing fixtures) be in accordance with the IPC:

“Every sink, lavatory, bathtub, or shower, drinking fountain, water closet or other plumbing fixture shall be properly connected to either a public water system or to an approved private water system. All kitchen sinks, lavatories, laundry facilities, bathtubs and showers shall be supplied with hot or tempered and cold running water in accordance with the International Plumbing Code.” (Emphasis added.)

IPC’s Chapter 6, Water Supply and Distribution, discusses the materials design and installation of water supply systems, both hot and cold, in Section 601.1 (2009 International Plumbing Code), Section 607 and Section 607.1. They specifically defer to Section 424.3, Individual Shower Valves.

“In residential occu

8613371530291

8613371530291