how does a gas oven safety valve work made in china

Most modern appliances have safety features built in, but your gas oven safety valve is arguably the most important. If an electrical appliance malfunctions, it can cause a fire, but a misfiring gas oven could potentially blow up your house. You don"t really need to know how the safety mechanism works to use your oven, but you may find that it gives you some extra peace of mind.

Broadly speaking, there are two ways a built-in safety mechanism can work. One option is that it remains "open" by default and to shut off if certain conditions are met. That"s how fuses and circuit breakers work in an electrical circuit: Ordinarily, the electricity is free to flow, but if the current grows too large, the fuse or breaker will blow and cut off the circulation of electricity.

The other option is for your safety mechanism to be "closed" by default and allow a device to operate only when the correct conditions are met. That"s how a gas oven safety valve works. Gas ordinarily is prevented from flowing, and if the valve is working correctly, it opens only when you want to light your oven.

Many gas stoves use what"s called a "hot surface igniter," a bar or element (similar to the ones on your stovetop) that gets hot enough to ignite the gas on contact. Gas oven safety valves on stoves with this type of ignition system take a couple of different approaches.

In one approach, a bimetallic strip operates the valve. It harnesses a simple scientific principle: Metals expand and contract at different rates when they"re heated and cooled. If you bond two suitable metals together in one strip, that strip will flex to a predictable degree as the temperature goes up and down. Wall-mount thermostats often use this principle, as do analog oven thermometers and the thermometer in the lid of your gas grill.

As appliance-repair website PartSelect explains, turning on your gas oven causes electricity to flow into the heating element of your hot surface igniter. As the igniter heats up, it warms a bimetallic strip inside your gas oven safety valve. When the igniter reaches its operating temperature, the bimetallic strip opens the valve and allows the gas to flow, igniting as it crosses the heated surface.

One intriguing thing about electricity is that a change in temperature can affect how well it passes through certain materials. For example, a lot of research revolves around superconductors – materials that offer very little resistance to an electrical current – but superconductors typically must be heavily chilled to work.

According to heating-equipment vendor Anglo Nordic, gas oven safety valves use a variation of that principle to operate. In these stoves, the flow of electrical current through the hot surface igniter becomes the control mechanism. The igniter"s bar is made of a material that offers less and less resistance to electricity as it heats. When it reaches the temperature required to ignite the gas, its resistance becomes low enough to trip the safety valve and open the flow of gas.

More modern ranges use an electrical igniter. When you turn on your oven, the gas begins flowing immediately, and it sends an electrical current to a piezo electric igniter. The current makes the igniter spark (like the manual igniter on your gas grill) and lights the oven"s burner. In this case, the safety valve works in the opposite way: An electronic sensor checks for the heat caused by ignition after a few seconds, and if it"s absent, it will close the valve and shut off the flow of gas.

It"s worth pointing out that not all gas ovens have a safety valve in the conventional sense. Older stoves simply use a pilot light, a small but constant flow of gas, which, in turn, feeds a small, candle-like flame. You essentially are the safety mechanism in this system: It"s up to you to check that the pilot is lit. When you turn on the gas manually, the small pilot flame ignites the main flame. It"s a mechanically simple system, which makes it durable, and for that reason, you"ll still see it used on commercial restaurant ranges, which must stand up to decades of heavy use.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

A60 safety valve is adopted in the European type range. The flameout protection device uses the principle of magnetic attraction of the solenoid valve to ensure that the gas is automatically closed when the flame goes out unexpectedly. Widely used in Europe, Australia, Middle East, Southeast Asia and China market.

A variety of installation ways, the application is more flexibleWe can adjust and tailor-made the specifications according to the structure and functions of the cooker manufacturer. A60 safety valve has a variety of installation methods, including SPIGOT, SADDLE MOUNT, U MOUNT and FLANGE.

The A60 safety valve with CSA, CE and Australian certification meets the highest standards of air tightness, durability and working pressure and temperature in the commercial appliances industry. Cooker"s manufacturers can sell the same model to multiple markets for saving development and design costs.

The body of clamping design of on-off valve A18-X1X can be assembled with a general wrench, which is fast and convenient for assembly. Stainless steel flexible tube are produced from CSA certified raw materials with durable and reliable quality.

Manifolds and gas valves pre-assembly service to save the assembly cost of cooker"s manufacturers and increasing their production capacity. All of Alpha Brass Control"s products are high accurate and 100% air-tight tested.

Answer: No, this is not possible due to the gas being controlled by the gas safety valve. You need the igniter to be working properly before gas is allowed out of the gas safety valve.

The igniter is a small round or rectangular (flat oven igniter and the round oven igniter) device located near the burner and is wired in series with the gas safety valve. When the igniter is cold, it has a lot of resistance, meaning it gets most of the electricity in the circuit. As the igniter heats up, its resistance drops allowing the heat to pass to the bi-metal strip in the gas safety valve, which then allows gas to be released to the burner assembly. The gas then gets ignited by the glow-bar igniter. The igniter glows the whole time the burner is on, keeping the gas safety valve open. The thermostat senses when the desired temperature is reached, and cuts off electricity to the gas safety valve and igniter.

Appliance medic has an help line on “Gas Oven Glow bar Igniters” along with and some helpful tips if you plan on making this repair yourself. He also offers some helpful suggestions on the two different types of igniters: the flat oven igniter and the round oven igniter and how to tell which shape your gas oven takes.

Appliance medic also offers a helpful support on How Gas Ovens Work which might help you troubleshoot any problems.Examples of a Flat Oven Igniter and a Round Oven Igniter for your gas oven:Flat Oven Igniter Part NumberFlat oven igniter that is commonly used on viking gas stoves and ranges

As soon as mankind was able to boil water to create steam, the necessity of the safety device became evident. As long as 2000 years ago, the Chinese were using cauldrons with hinged lids to allow (relatively) safer production of steam. At the beginning of the 14th century, chemists used conical plugs and later, compressed springs to act as safety devices on pressurised vessels.

Early in the 19th century, boiler explosions on ships and locomotives frequently resulted from faulty safety devices, which led to the development of the first safety relief valves.

In 1848, Charles Retchie invented the accumulation chamber, which increases the compression surface within the safety valve allowing it to open rapidly within a narrow overpressure margin.

Today, most steam users are compelled by local health and safety regulations to ensure that their plant and processes incorporate safety devices and precautions, which ensure that dangerous conditions are prevented.

The principle type of device used to prevent overpressure in plant is the safety or safety relief valve. The safety valve operates by releasing a volume of fluid from within the plant when a predetermined maximum pressure is reached, thereby reducing the excess pressure in a safe manner. As the safety valve may be the only remaining device to prevent catastrophic failure under overpressure conditions, it is important that any such device is capable of operating at all times and under all possible conditions.

Safety valves should be installed wherever the maximum allowable working pressure (MAWP) of a system or pressure-containing vessel is likely to be exceeded. In steam systems, safety valves are typically used for boiler overpressure protection and other applications such as downstream of pressure reducing controls. Although their primary role is for safety, safety valves are also used in process operations to prevent product damage due to excess pressure. Pressure excess can be generated in a number of different situations, including:

The terms ‘safety valve’ and ‘safety relief valve’ are generic terms to describe many varieties of pressure relief devices that are designed to prevent excessive internal fluid pressure build-up. A wide range of different valves is available for many different applications and performance criteria.

In most national standards, specific definitions are given for the terms associated with safety and safety relief valves. There are several notable differences between the terminology used in the USA and Europe. One of the most important differences is that a valve referred to as a ‘safety valve’ in Europe is referred to as a ‘safety relief valve’ or ‘pressure relief valve’ in the USA. In addition, the term ‘safety valve’ in the USA generally refers specifically to the full-lift type of safety valve used in Europe.

Pressure relief valve- A spring-loaded pressure relief valve which is designed to open to relieve excess pressure and to reclose and prevent the further flow of fluid after normal conditions have been restored. It is characterised by a rapid-opening ‘pop’ action or by opening in a manner generally proportional to the increase in pressure over the opening pressure. It may be used for either compressible or incompressible fluids, depending on design, adjustment, or application.

Safety valves are primarily used with compressible gases and in particular for steam and air services. However, they can also be used for process type applications where they may be needed to protect the plant or to prevent spoilage of the product being processed.

Relief valve - A pressure relief device actuated by inlet static pressure having a gradual lift generally proportional to the increase in pressure over opening pressure.

Relief valves are commonly used in liquid systems, especially for lower capacities and thermal expansion duty. They can also be used on pumped systems as pressure overspill devices.

Safety relief valve - A pressure relief valve characterised by rapid opening or pop action, or by opening in proportion to the increase in pressure over the opening pressure, depending on the application, and which may be used either for liquid or compressible fluid.

In general, the safety relief valve will perform as a safety valve when used in a compressible gas system, but it will open in proportion to the overpressure when used in liquid systems, as would a relief valve.

Safety valve- A valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored.

With the strengthening of China’s environmental awareness and the change of energy structure, China’s urban gas industry has made great progress. The types of gas have developed from simple coal system to multiple gas sources. In the late 1990s, the continuous development, construction and utilization of China’s natural gas resources have promoted the development of China’s urban natural gas into a new era.

The pressure of natural gas transmission and distribution is higher than that of man-made gas, so it is very important to store and transport natural gas safely in densely populated cities and towns. If the leakage and shutdown accidents caused by improper selection or poor quality of

In order to have enough “strength” and “rigidity” — “strength” means that the valve should be able to bear the Zui high pressure of gas transmission and distribution in the pipeline, and more importantly, it must have enough “rigidity”, that is, it can keep the valve from deformation even under various external forces of the underground pipe network, which can guarantee the sealing performance of the valve:

1. Reduce the structural height of the valve as much as possible (referring to the height from the center line of the valve flow section to the valve top) to reduce the buried pipe depth;

2. The top of the valve shall be equipped with a fully closed opening and closing indicator, so that the operator can see the status of the valve at any time, which is an important condition for safe operation;

3. Full diameter design, reduce the flow resistance, facilitate to pass through the pipeline cleaner or pipeline detector, and also meet the requirements of non-stop transmission of closed hole opener to open holes on the pipeline;

4. Reliable sealing performance, cj3055-95 “test and inspection of urban gas valves” standard stipulates that: under 1.1 times of nominal rated service pressure, soft sealing valve is not allowed to have any perceived internal leakage, and under 1.1 times of nominal rated service pressure, hard sealing valve is allowed to have internal leakage less than 0.3dnmm3/s, which is relatively strict, such as: 500mm nominal diameter gas valve The internal leakage per minute shall not be more than 9 ml (the capacity of ordinary drinking cup is 200 ml) and the external leakage is not allowed;

5. The shell of the gas valve used in the underground pipe network shall be corrosion-resistant. It is recommended to use different shell materials according to the transmission medium and service pressure of the pipeline;

6. For the design of valve parts, the structure of less maintenance and no maintenance shall be considered, so as to reduce the workload of maintenance as much as possible, reduce the road closure due to valve maintenance and affect the traffic;

7. Most of the underground pipeline valves are manually opened and closed. It is required that the opening and closing torque of the valve is small, and the number of turns in the whole process should not be too many, and the air source can be cut off as soon as possible after the accident;

8. Various underground pipelines of urban roads in China are crowded and complex, so it is not suitable to excavate basement inspection wells, so direct buried valves are recommended.

1. For the transmission and distribution pipeline under medium pressure class B (0.2MPa), it is recommended to use gray cast iron valve, which has the advantages of good corrosion resistance and low price, so it is very suitable for underground pipeline;

2. For medium pressure class A (0.4MPa) or below, or even high pressure class B (0.8MPa), it is recommended to use ductile iron or cast steel for manufacturing, with emphasis on the selection of ductile iron. For example, compared with cast steel brand WCB, the mechanical property of the former is no less than that of the latter, while the corrosion resistance and casting process are better than that of the cast steel, and the price is also lower than that of the cast steel (generally about 70% of the cast steel). Therefore, the overall performance and price of the ductile iron valve are better than that of the cast steel valve. In the above pressure range, the ductile iron valve can be selected as much as possible, but especially Do not pay attention to the quality control of nodular cast iron;

3. In places with high-pressure class A (1.6Mpa) or higher, it is recommended to select cast steel valves, and WCB brand is generally used to manufacture valves below 4MPa;

PE ball valve has also come out. This series of ball valves can be directly buried and have good sealing performance. However, at present, the price of PE ball valve is relatively high, especially for ball valve larger than 100mm.

In the 1980s, China’s gas is mainly made of artificial coal. There are more impurities and “gas glue” in the artificial coal gas. The traditional single ram wedge type sluice valve can not meet the needs of the gas working condition more and more. This kind of valve generally has the problems of “not tightly closed” and the valve rod is blocked. The gas oil sealed plug valve solves the problems of not tightly closed and the valve rod is blocked. Its main technical features: hard sealing structure is adopted to make it have the function of scraping rubber; the sealing surface does not contact with gas impurities, there is no valve rod in the cavity, and there is no problem of valve rod seizing; the sealing grease and O-ring that are specially developed to resist the erosion of gas medium improve the performance of plug valve.

1. It is not the same diameter as the pipeline, but about 75% of the pipeline flow area, which increases the flow resistance and eddy current, and can not pass through the pig;

With the development of gas industry and the establishment of gas plants, special gas valves with large or even extra large nominal diameter are needed. The problem of artificial gas formation is solved one by one by using parallel double gate valve for gas, and the diameter of Zui is 1600mm.

1. In the process of opening and closing, the parallel double gate valve can scrape off the “gas glue” on the sealing surface, which solves the big problem that the gas impurities adhere to the sealing surface and affect the valve sealing;

V. the valve body adopts the specially designed “squirrel cage frame stiffener” to reduce the overall weight of the valve and enhance the strength and rigidity of the shell;

7. The gate valve of this series is equipped with a fully closed opening and closing indicator, so that the operator can clearly understand the status of the valve.

Compared with the above valves, butterfly valves are lighter, larger in diameter and lower in price. In the early 1980s, some gas companies once used butterfly valves. After about ten years of use, it is generally considered that the effect is not good.

1. The isolation width of the sealing pair of butterfly valve is too narrow, which is easy to cause the valve disc to close excessively or not in place, affecting the sealing;

3. Because the middle part of the seal fitting is rubber or polytetrafluoroethylene, it is easy to be damaged or fall off during gas flushing, and the service life is short. It is proved that butterfly valve is not suitable for gas pipeline except for special position.

Flat gate valve is a general valve which has been used in gas pipeline in recent years. Its flow resistance is small when the valve is full bore, and the seal on both sides is formed by pressing PTFE or rubber O-ring on the gate. This kind of valve can’t be completely closed or fully opened without gas in the middle cavity, which is not convenient for users to judge whether the valve is closed tightly in emergency repair. If the valve is to be completely closed without gas in the middle cavity, the opening and closing torque will increase rapidly; some factories Home made reducer, such as DN200 caliber, with an inner diameter of only 150 mm. Users should pay special attention to it. Therefore, the flat gate valve is suitable for the occasion of lower pressure level system and smaller nominal diameter.

Elastic seal gas gate valve is different from flat gate valve. The features of the valve are similar to the elastic seat structure of the fixed ball valve. The sealing seat rings on both sides of the ram are of the elastic floating structure. The sealing faces are always close together during the opening and closing process, and can compensate the wear of the sealing pair, which is suitable for the occasion of high pressure system. When the valve is fully open and fully closed, there is no gas in the valve cavity, even if the remaining gas in the valve cavity is released There is still no pressure in the cavity, so users can safely construct the pipeline downstream of the valve, which greatly reduces the working time for gas stop preparation before construction.

There are two connection forms of elastic seal gas gate valve: flange type and welding type. Flange type is the traditional connection way. The welding type can directly weld the valve and the pipeline, saving the pipe laying cost; the two kinds of valves can be directly buried, avoiding unnecessary inspection wells, and bringing convenience to the construction.

When the elastic seal gas gate valve is fully opened, it looks like a section of pipeline with the same diameter of the pipeline, with minimal flow resistance; all sealing surfaces are hidden and do not contact with the medium. For the artificial coal to gas, the “gas glue” cannot adhere to the sealing surface, and for the natural gas, the dust and gravel can not wash the parts.

In a word, the elastic sealing gas gate valve is suitable for gas pipeline, especially for underground gas pipeline. From the situation of foreign investigation, many countries use the elastic flat gate valve on the natural gas pipeline. Compared with the nominal diameter elastic flat gate valve and the ball valve, they have the function of fire prevention, and the price is about 30% lower than the ball valve, so the use effect is the same. The disadvantage of Trz series elastic seal gas gate valve is that its structure height is large, and it has 4 nominal diameters. Because it is buried underground, the height above the central axis of the pipeline is the same as that of the common gate valve, and its disadvantage is not obvious, mainly that the height of the lower half is larger than that of the common gate valve, and the buried depth is larger during construction, but generally does not affect the pipeline laying;

The emergency cut-off valve for pressure regulator is an important safety protection device in gas transmission and distribution system. The emergency cut-off valve is to install the emergency trip mechanism on the upper or side position of the stop valve. It is also connected with the regulator body as a whole, and with the filter as a whole. Its function is to shut down the air source in an emergency after the regulator fails, causing overpressure or loss of pressure, so as to ensure safety. The large use of natural gas in the city has improved the pressure level system of the pipe network. The failure of the pressure regulator will bring disastrous consequences to the city. The domestic gas industry has paid more and more attention to this. The products selected in China have not formed a certain trend. Imported, joint venture and domestic products are hard to distinguish between the good and the bad, so the selection should be cautious. RAQ series gas emergency shut-off valve is connected with the filter as a whole, with novel and compact structure and high sensitivity. It can quickly cut off the gas source of the pressure regulator at the set overpressure (300 mm / H2O) and pressure loss (180 mm / H2O) to ensure the safety of users;

In case of gas leakage or other disasters of gas boiler, gas air conditioner and gas equipment, the emergency shut-off valve shall cut off the gas source quickly to prevent the expansion of the disaster. At present, the gas emergency shut-off valve has not been popularized in China. With the strengthening of environmental protection awareness and safety awareness, as well as the development of gas industry, the gas emergency shut-off valve will certainly get people’s attention. The gas emergency shut-off valve is a valve to ensure safety. It is connected with the automatic monitoring equipment to execute the valve closing instruction. Therefore, the gas emergency shut-off valves are all electric valves. According to the existing data, there are two types of such valves, one is solenoid valve, the other is electric valve. Due to the high requirements of gas emergency shut-off valve, such as fast speed, sealing, small flow resistance, caliber specification, etc., the existing solenoid valve and electric valve have certain defects, which can not meet all the requirements. These valves are analyzed one by one as follows:

I. At present, most of the solenoid valves are imported. The speed of the solenoid valve is fast, but the flow resistance is large. The flow resistance Zui in the stop valve is large, the pressure loss is large, and the caliber is small. It is difficult to manufacture the large caliber solenoid valve. Generally, it can only be below DN150, and the price is expensive. If the large caliber solenoid valve is equipped to meet the requirements of the diameter, the technical and economic ratio index is poor. Some solenoid valves are opened by electromagnetic field. Once the power is lost, the valve will be closed even if the power is lost instantaneously, which is not in line with the actual working condition. Uncoupling solenoid valve, energized uncoupling and closing valve, has high sensitivity and fast speed, because with DC low voltage, a little interference or power supply “shaking” will cause misoperation, affecting normal life and production;

2. Electric butterfly valve, with low price, is easy to be made into large caliber, and its opening and closing speed is faster than that of gate valve, and slower than that of solenoid valve; the flow anion is smaller than that of solenoid valve, and larger than that of gate valve; its sealing performance is worse than that of solenoid valve and gate valve, and because of the small sealing isolation width, the rapid opening and closing speed impact is easy to cause insufficient or excessive opening and closing;

3. Electric gate valve, with higher price, small flow resistance and good sealing performance, but its speed is too slow to meet the requirements of emergency cut-off;

4. The ball valve has small flow resistance and good sealing performance. However, the opening and closing speed of domestic or imported electric ball valve in the market is generally within 15-30 seconds, which can not meet the fast requirements. The user’s requirements for the opening and closing speed of emergency shut-off valve are generally within 10 seconds. The electric ball valve has many advantages. It can become an ideal emergency shut-off valve only by improving the opening and closing speed.

The emergency cut-off electric ball valve integrates the advantages of the ball valve, with the opening and closing speed of 3.75 seconds, which fills in the gaps at home and abroad. In addition, it has the function of anti-static and fire prevention in the structure design. The electrical equipment can be connected with the gas leakage alarm, disaster control equipment, fan and other auxiliary equipment. The overall design conforms to the price of dbj08-65-97 technical code for urban natural gas pipeline engineering It is much lower than similar imported products. Once it came out, it was accepted by gas users and received high praise.

The compressor of gas storage and distribution station often needs to be equipped with check valve to prevent gas from flowing back into the compressor. The water check valve has been eliminated in the gas industry. The main disadvantage of the general gas check valve is that the valve plate vibrates with the reciprocating motion of the compressor, which makes a great noise when colliding with the valve body and easily damages the valve plate. The second is poor sealing.

The gas valve plays an important role in the gas industry, and the Ministry of construction attaches great importance to the normative construction of the gas valve. The industry standards of the gas valve include CJ3005-1992 general technical requirements for grey cast iron valves for urban gas, CJ3055-1995 test and inspection for valves for urban gas, CJ3056-1995 general technical regulations for ductile iron and cast steel valves for urban gas In June 2002, it also passed the industry standard of domestic manual gas valve. The formulation and promulgation of these standards standardize the valve industry, promote the progress and development of gas valves, and promote the development of gas industry; provide a reference for the research, production and use units; improve the understanding of the difference between gas valves and general valves, and ensure the safety margin of gas valves; they are welcomed by the gas industry.

1. The underground pipe network is made of medium pressure class B and below, and it is recommended to use direct buried gray cast iron parallel double gate valve;

2. The underground pipe network is of medium pressure class A and below, and it is recommended to use directly buried parallel double gate valve or elastic flat gate valve;

3. For underground pipe network under high pressure class B or under high pressure class A, it is recommended to use directly buried elastic flat gate valve and fixed ball gas ball valve;

5. For storage and distribution station or ground equipment with pressure below 0.4MPa and larger than DN500 caliber, gate valve shall be used as far as possible to reduce the price.

6. In the pressure regulator or pressure regulating station, parallel double gate valve is recommended for low pressure level (below 0.4MPa), and floating type gas ball valve can be used for gas ball valve. If the pressure level system is lower than 1.6Mpa, fixed type gas ball valve and elastic flat gate valve can be used.

7. In the pressure regulating box, if the butterfly valve must be selected due to the limited space conditions, the multi eccentric butterfly valve shall be selected, and the sealing material shall be polytetrafluoroethylene or hard seal, and it must be adjusted to the closed position accurately during commissioning.

China’s gas industry, especially the rapid development and popularization of natural gas, has driven the progress and development of gas valve manufacturing industry. With the introduction of West to east gas transmission, offshore natural gas, and Russian gas sources, new gas valves will come out to meet the needs of gas users.

(Yaang Pipe Industry is a leading manufacturer and supplier of nickel alloy and stainless steel products, including Super Duplex Stainless Steel Flanges, Stainless Steel Flanges, Stainless Steel Pipe Fittings, Stainless Steel Pipe. Yaang products are widely used in Shipbuilding, Nuclear power, Marine engineering, Petroleum, Chemical, Mining, Sewage treatment, Natural gas and Pressure vessels and other industries.)

The gas valve on your boiler controls the flow of gas to the pilot light and burner. When you demand heat or hot water, the boiler works like this: The PCB first detects the fan is operational, ready to expel dangerous flue gases via the flue.

In the open position (gas is flowing) the handle (lever) will be parallel with the pipe, when it is closed (gas not flowing) the handle (lever) will be perpendicular to the pipe. This should make it easy for you to tell if the gas is on, or off.

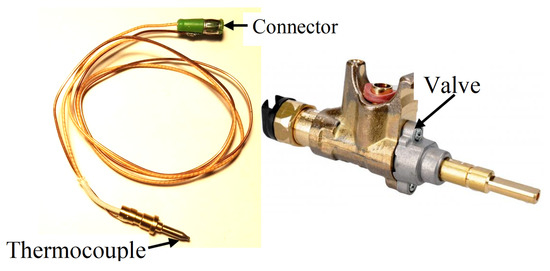

A thermocouple is a device made of two different metals which creates a small electrical charge when heated at one end by the gas pilot. This small charge causes an electromagnet inside the gas valve to open and allow gas to flow to the main burners.

A gas control valve can be found on any appliance that utilizes gas. These valves are vital for the operation and safety of any gas appliance. The valve does exactly what it sounds like, it controls the amount of gas flowing to create a steady flow without allowing any gas to leak.

Antigua and Barbuda, Aruba, Australia, Austria, Bahamas, Bahrain, Bangladesh, Barbados, Belgium, Belize, Bermuda, Bolivia, Brazil, Brunei Darussalam, Bulgaria, Cambodia, Canada, Cayman Islands, Chile, China, Colombia, Costa Rica, Cyprus, Czech Republic, Denmark, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Estonia, Finland, France, French Guiana, Germany, Gibraltar, Greece, Grenada, Guadeloupe, Guatemala, Guernsey, Honduras, Hong Kong, Hungary, Iceland, Indonesia, Ireland, Israel, Italy, Jamaica, Japan, Jersey, Jordan, Kuwait, Latvia, Liechtenstein, Lithuania, Luxembourg, Macau, Malaysia, Maldives, Malta, Martinique, Mexico, Monaco, Montserrat, Netherlands, New Zealand, Nicaragua, Norway, Oman, Pakistan, Panama, Paraguay, Peru, Philippines, Poland, Portugal, Qatar, Republic of Croatia, Reunion, Romania, Saint Kitts-Nevis, Saint Lucia, Saudi Arabia, Singapore, Slovakia, Slovenia, South Africa, South Korea, Spain, Sri Lanka, Sweden, Switzerland, Taiwan, Thailand, Trinidad and Tobago, Turks and Caicos Islands, United Arab Emirates, United Kingdom, United States, Vietnam

Disclaimer: Part Numbers are for identification purposes only. Items offered for sale are not represented as manufactured by the company that built the unit unless specified as such.

High Quality High-temperature Panel 3 Burners Table Top Gas Cooker Valve Product Number: ATM-624 Product type: build-in gas stove Panel: tempered glass or stainless steel Burner material : brass( the best material of burner) ignition type : pulse ignition with battery pulser: baiwei pulser micro switch: safety Gas Type : NG/LPG Battery Box: durable Advantage: 1. Long life aluminium burners 2. Aluminium flame distributor 3. anti high temperature 4. Fashion and perfect design Top is non sticky, easy to clean 5. Professional QC team make sure top-quality Optional: 1. Aluminum burner and brass burner 2. Bakelite knob and Metal Knob 3. Enamel trivet/Cast iron trivet 4. 220V/50HZ(110V/50HZ) power plug and Dry Battery 5. With safety device and without safety device Produce Size (mm): 590*510*115 mm Built-in(mm): 560*480 mm(R20) Packing Size(mm): 630*550*170 mm loading quantity: 20、40、40HQ = 470/930/1100 Detailed Images Packing & Delivery

A gas stove is a stove that is fuelled by combustible gas such as syngas, natural gas, propane, butane, liquefied petroleum gas or other flammable gas. Before the advent of gas, cooking stoves relied on solid fuels such as coal or wood. The first gas stoves were developed in the 1820s and a gas stove factory was established in England in 1836. This new cooking technology had the advantage of being easily adjustable and could be turned off when not in use. The gas stove, however, did not become a commercial success until the 1880s, by which time supplies of piped gas were available in cities and large towns in Britain. The stoves became widespread on the European Continent and in the United States in the early 20th century.

Gas stoves became more common when the oven was integrated into the base and the size was reduced to better fit in with the rest of the kitchen furniture. By the 1910s, producers started to enamel their gas stoves for easier cleaning. Ignition of the gas was originally by match and this was followed by the more convenient pilot light. This had the disadvantage of continually consuming gas. The oven still needed to be lit by match and accidentally turning on the gas without igniting it could lead to an explosion. To prevent these types of accidents, oven manufacturers developed and installed a safety valve called a flame failure device for gas hobs (cooktops) and ovens. Most modern gas stoves have electronic ignition, automatic timers for the oven and extractor hoods to remove fumes.

Gas stoves are a significant source of indoor air pollution,methane emissions from gas stoves in the United States were equivalent to the greenhouse gas emissions of 500,000 cars.gas venting and unintended fugitive emissions throughout the supply chain results in natural gas having a similar carbon footprint to other fossil fuels overall.

The first gas stove was developed in 1802 by Zachäus Winzler (de), but this along with other attempts remained isolated experiments.Northampton, England in 1826 and opened a gas stove factory in 1836. His invention was marketed by the firm Smith & Philips from 1828. An important figure in the early acceptance of this new technology, was Alexis Soyer, the renowned chef at the Reform Club in London. From 1841, he converted his kitchen to consume piped gas, arguing that gas was cheaper overall because the supply could be turned off when the stove was not in use.

A gas stove was shown at the Great Exhibition in London in 1851, but it was only in the 1880s that the technology became a commercial success in England. By that stage a large and reliable network for gas pipeline transport had spread over much of the country, making gas relatively cheap and efficient for domestic use. Gas stoves only became widespread on the European Continent and in the United States in the early 20th century.

Early gas stoves were rather unwieldy, but soon the oven was integrated into the base and the size was reduced to fit in better with the rest of the kitchen furniture.

Gas stoves today use two basic types of ignition sources, standing pilot and electric.pilot light) under the cooktop.flame failure device for gas hobs (cooktops) and ovens. The safety valve depends on a thermocouple that sends a signal to the valve to stay open. Although most modern gas stoves have electronic ignition, many households have gas cooking ranges and ovens that need to be lit with a flame. Electric ignition stoves use electric sparks to ignite the surface burners.Auto reignition is an elegant refinement: the user need not know or understand the wait-then-turn sequence. They simply turn the burner knob to the desired flame size and the sparking is turned off automatically when the flame lights. Auto reignition also provides a safety feature: the flame will be automatically reignited if the flame goes out while the gas is still on—for example by a gust of wind. If the power fails, surface burners must be manually match-lit.

Also stoves with electric ignition must be connected with gas protection mechanisms such as gas control breaker. Because of this many manufacturers supply stoves without electricity plug.

One of the important properties of a gas stove is the heat emitted by the burners. Burner heat is typically specified in terms of kilowatts or British Thermal Units per hour and is directly based on the gas consumption rather than heat absorbed by pans.

Often, a gas stove will have burners with different heat output ratings. For example, a gas cooktop may have a high output burner, often in the range 3 to 6 kilowatts (10,000 to 20,000 BTU/h), and a mixture of medium output burners, 1.5 to 3 kW, and low output burners, 1 kW or less. The high output burner is suitable for boiling a large pot of water quickly, sautéing and searing, while the low output burners are good for simmering.

Some high-end cooktop models provide higher range of heat and heavy-duty burners that can go up to 6 kilowatts (20,000 BTU/h) or even more. These may be desired for preparing large quantities or special types of food and enable certain advanced cooking techniques. However, these burners produce greater emissions and necessitate better ventilation for safe operation.

In the last few years, appliance manufacturers have been making innovative changes to the design and layout of gas stoves. Most of the modern cooktops have come with lattice structure which usually covers the complete range of the top, enabling sliding of cookware from one burner to another without lifting the containers over the gaps of cooktop. Some modern gas stoves also have central fifth burner or an integrated griddle in between the outer burners.

Usually, there isn"t much of a style difference in between them. Slide-in come with lips on their either side and controls over the front along with burner controls. Freestanding gas range cooktops have solid slides and controls placed behind the cooktop.

Many stoves have integrated ovens. Modern ovens often include a convection fan inside the oven to provide even air circulation and let the food cook evenly. Some modern ovens come with temperature sensors which allows close control of baking, automatically shut off after reaching certain temperature, or hold on to particular temperature through the cooking process. Ovens may also have two separate oven bays which allows cooking of two different dishes at the same time.

Many gas stoves come with at least few modern programmable controls to make the handling easier. LCD displays and some other complex cooking routines are some of the standard features present in most of the basic and high-end manufacturing models. Some of the other programmable controls include precise pre-heating, automatic pizza, cook timers and others.

A built-in Japanese three burner gas stove with a fish grill. Note the thermistor buttons protruding from the gas burners, which cut off the flame if the temperature exceeds 250°C.

Modern gas stove ranges are safer than older models. Two of the major safety concerns with gas stoves are child-safe controls and accidental ignition. Some gas cooktops have knobs which can be accidentally switched on even with a gentle bump.

Gas stoves are at risk of overheating when frying oil, raising the oil temperature to the auto-ignition point and creating an oil fire on the stove. Japan, South Korea and China have regulated the addition of electronic safety devices to prevent pan overheating. The devices use a thermistor to monitor the temperature close to the pan, and cut off the gas supply if the heat is too high.

The U.S. Department of Energy (DOE) ran tests in 2014 of cooktop energy transfer efficiency, simulating cooking while testing what percentage of a cooktop"s energy is transferred to a test block. Gas had an efficiency of 43.9%, with ±0.5% repeatability in the measurement. This level of efficiency is only possible if the pan is big enough for the burner.

Japanese gas flames are angled upwards towards the pot to increase efficiency.heatsink-like fins.Jetboil manufactures pots for portable stoves that use a corrugated ribbon to increase efficiency.

Carbon monoxide, formaldehyde, and nitrogen dioxide from gas stoves contribute to indoor air pollution.asthma.The Lancet Respiratory Medicine found "no evidence of an association between the use of gas as a cooking fuel and either asthma symptoms or asthma diagnosis".

Cooking, especially high heat frying, releases smoke (measured as fine particulate matter), acrolein and polycyclic aromatic hydrocarbons.air purifier.U.S. Consumer Product Safety Commission is investigating reducing the health effects of gas stoves, including emissions and ventilation standards.

Gas stoves are often run on natural gas. The extraction and consumption of natural gas is a major and growing contributor to climate change.methane) and carbon dioxide, which is released when natural gas is burned, are greenhouse gases.methane emissions from gas stoves in the United States were equivalent to the greenhouse gas emissions of 500,000 cars.

Some places, such as the Australian Capital Territory, have curtailed installation of gas stoves and appliances in new construction, for reasons of health, indoor air quality, and climate protection.

Valves for industrial applicationsIn order to prevent the uncontrolled rise in pressure in pressure vessels or pressurized pipelines, a safety valve is inserted. The safety valve is designed so that it opens at a given maximum pressure, thereby relieving the line or the container. Safety valves find their use in almost all areas of the pressure vessel and pipeline construction. In cryogenics as a spring-loaded safety valve for example.

"TRS is an exciting opportunity for an Offshore Safety Valve Technician to carry out Maintenance / Commissioning / Testing of Safety and Control Valves experience within the Oil and Gas industry to join our International Client"s Offshore project team based in Soyo, Angola.".

Because of different of drive source, SSV can dividedinto Hydraulic safety valve and pneumatic valve ; With thermal and high voltage explosion-proof device ; Actuators and prepare two parts of the valve, standard interface, easy replacement and maintenance .

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to prevent the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

(1)The pressure of the disc is balanced through the lever and heavy hammer and the valve is ensured seal by moving the for ton of heavy hammer and changing the weight of heavy hammer to reach the required set pressure.

(2)The sealed surface is made of Fe base stainless steel by overlaying welding. Through thermal treatment, the wear resistance and anti-erosion of disc is improved.

(3)At the top of valve is equipped an electromagnet to open and another to close the valve. The actions of the mechanism and the electric appliance are separate and will not affect each other.

(2)Impulse safety valve shall be installed vertically and the lever shall be kept level. The clearance from the lever to both sides of guide fork shall be even.

(4)A long distance between the leading pipe of the impulse safety valve and the inlet pipe of the main safety valve shall be kept. And the distance between the electric contact pressure meter and the inlet pipe of the main safety valve shall be no less than 5 times of the diameter of the inlet pipe, for feat that the validity of the mater and the impulse safety valve may be affected by the steam releasing process of the main safety valve.

This valve is used for power plant boilers, pressure containers, pressure and temperature reducing device and other facilities. It serves to present the pressure exceeding the highest allowable pres-sure value and ensure the safety of the device when working.

1,When the medium pressure rises to the set pressure, the in-pulse safety valve opens, and the medium in the impulse pipe enters into the piston chamber of the main safety valve from impulse pipe, forcing the piston to descend, and then the valve automatically open-s; when the impulse safety valve closes, the disc will slash automatically close.

2,The sealed surface is made of Fe base stainless steel by over-laying welding. Through thermal treatment, the wear resistance and anti-erosion of disc so improved.

2,The main safety valve shall be fastened upon the gallows, which sustains the back-seat force produced in the steam discharging process of the main safety valve.

3,The exhaust pipe shall contain a special gallows to prevent the force of its weight directly applying on the main safety valve. The connecting Lange At the lowest point of the exhaust pipe, water drainage shall be taken into consideration to avoid producing water hammer while discharging set between the main safety valve and exhaust pipe shall eliminate any extra stress.

8613371530291

8613371530291