how does safety valve work quotation

Shipment: All products and/or services covered by the quotation are sold F.O.B. either our plant in Linden, NJ or the manufacturer"s plant for the parts and/or valves required, unless otherwise indicated. The risk of loss or damage in transit will be upon the purchaser. The products will be prepared for shipment in a manner prescribed by us or the manufacturer and shipped by any public carrier which we deem satisfactory, unless the purchaser provides other specific shipping instructions when placing orders. Any date provided by us for completion of work or for shipment is intended as an estimate only and is not to be deemed a term of the quotation. Shipping charges shall be pre-paid and billed at the time of shipment.

Warranties and Limitations: We warrant only that our products will conform to their description herein and that at the time of sale our products will be free from defects on workmanship and material. The name and reputation of Certified Valve Repair stands prudently behind every valve or piece of equipment we recondition. We are valve repair specialists, if at any time, in any way, a valve or piece of equipment that we have repaired fails to provide complete satisfaction, please bring the matter to our attention. Every repaired valve, pump, instrument, or equipment when used in accordance with the manufacturer and our recommendations is guaranteed to be free from defective workmanship and material. We will repair or replace without charge, F.O.B. our plant any repaired unit which our own examination proves to be defective within a period stated by our firm at the time of delivery. We assume no responsibility for incidental damage or expense. Authorization is required before returned articles will be accepted.

Boiler explosions have been responsible for widespread damage to companies throughout the years, and that’s why today’s boilers are equipped with safety valves and/or relief valves. Boiler safety valves are designed to prevent excess pressure, which is usually responsible for those devastating explosions. That said, to ensure that boiler safety valves are working properly and providing adequate protection, they must meet regulatory specifications and require ongoing maintenance and periodic testing. Without these precautions, malfunctioning safety valves may fail, resulting in potentially disastrous consequences.

Boiler safety valves are activated by upstream pressure. If the pressure exceeds a defined threshold, the valve activates and automatically releases pressure. Typically used for gas or vapor service, boiler safety valves pop fully open once a pressure threshold is reached and remain open until the boiler pressure reaches a pre-defined, safe lower pressure.

Boiler relief valves serve the same purpose – automatically lowering boiler pressure – but they function a bit differently than safety valves. A relief valve doesn’t open fully when pressure exceeds a defined threshold; instead, it opens gradually when the pressure threshold is exceeded and closes gradually until the lower, safe threshold is reached. Boiler relief valves are typically used for liquid service.

There are also devices known as “safety relief valves” which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service.

Nameplates must be fastened securely and permanently to the safety valve and remain readable throughout the lifespan of the valve, so durability is key.

The National Board of Boiler and Pressure Vessel Inspectors offers guidance and recommendations on boiler and pressure vessel safety rules and regulations. However, most individual states set forth their own rules and regulations, and while they may be similar across states, it’s important to ensure that your boiler safety valves meet all state and local regulatory requirements.

The National Board published NB-131, Recommended Boiler and Pressure Vessel Safety Legislation, and NB-132, Recommended Administrative Boiler and Pressure Vessel Safety Rules and Regulationsin order to provide guidance and encourage the development of crucial safety laws in jurisdictions that currently have no laws in place for the “proper construction, installation, inspection, operation, maintenance, alterations, and repairs” necessary to protect workers and the public from dangerous boiler and pressure vessel explosions that may occur without these safeguards in place.

The American Society of Mechanical Engineers (ASME) governs the code that establishes guidelines and requirements for safety valves. Note that it’s up to plant personnel to familiarize themselves with the requirements and understand which parts of the code apply to specific parts of the plant’s steam systems.

High steam capacity requirements, physical or economic constraints may make the use of a single safety valve impossible. In these cases, using multiple safety valves on the same system is considered an acceptable practice, provided that proper sizing and installation requirements are met – including an appropriately sized vent pipe that accounts for the total steam venting capacity of all valves when open at the same time.

The lowest rating (MAWP or maximum allowable working pressure) should always be used among all safety devices within a system, including boilers, pressure vessels, and equipment piping systems, to determine the safety valve set pressure.

Avoid isolating safety valves from the system, such as by installing intervening shut-off valves located between the steam component or system and the inlet.

Contact the valve supplier immediately for any safety valve with a broken wire seal, as this indicates that the valve is unsafe for use. Safety valves are sealed and certified in order to prevent tampering that can prevent proper function.

Avoid attaching vent discharge piping directly to a safety valve, which may place unnecessary weight and additional stress on the valve, altering the set pressure.

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk.

Safety valves were first developed for use on steam boilers during the Industrial Revolution. Early boilers operating without them were prone to explosion unless carefully operated.

Vacuum safety valves (or combined pressure/vacuum safety valves) are used to prevent a tank from collapsing while it is being emptied, or when cold rinse water is used after hot CIP (clean-in-place) or SIP (sterilization-in-place) procedures. When sizing a vacuum safety valve, the calculation method is not defined in any norm, particularly in the hot CIP / cold water scenario, but some manufacturers

The earliest and simplest safety valve was used on a 1679 steam digester and utilized a weight to retain the steam pressure (this design is still commonly used on pressure cookers); however, these were easily tampered with or accidentally released. On the Stockton and Darlington Railway, the safety valve tended to go off when the engine hit a bump in the track. A valve less sensitive to sudden accelerations used a spring to contain the steam pressure, but these (based on a Salter spring balance) could still be screwed down to increase the pressure beyond design limits. This dangerous practice was sometimes used to marginally increase the performance of a steam engine. In 1856, John Ramsbottom invented a tamper-proof spring safety valve that became universal on railways. The Ramsbottom valve consisted of two plug-type valves connected to each other by a spring-laden pivoting arm, with one valve element on either side of the pivot. Any adjustment made to one of valves in an attempt to increase its operating pressure would cause the other valve to be lifted off its seat, regardless of how the adjustment was attempted. The pivot point on the arm was not symmetrically between the valves, so any tightening of the spring would cause one of the valves to lift. Only by removing and disassembling the entire valve assembly could its operating pressure be adjusted, making impromptu "tying down" of the valve by locomotive crews in search of more power impossible. The pivoting arm was commonly extended into a handle shape and fed back into the locomotive cab, allowing crews to "rock" both valves off their seats to confirm they were set and operating correctly.

Safety valves also evolved to protect equipment such as pressure vessels (fired or not) and heat exchangers. The term safety valve should be limited to compressible fluid applications (gas, vapour, or steam).

For liquid-packed vessels, thermal relief valves are generally characterized by the relatively small size of the valve necessary to provide protection from excess pressure caused by thermal expansion. In this case a small valve is adequate because most liquids are nearly incompressible, and so a relatively small amount of fluid discharged through the relief valve will produce a substantial reduction in pressure.

Flow protection is characterized by safety valves that are considerably larger than those mounted for thermal protection. They are generally sized for use in situations where significant quantities of gas or high volumes of liquid must be quickly discharged in order to protect the integrity of the vessel or pipeline. This protection can alternatively be achieved by installing a high integrity pressure protection system (HIPPS).

In the petroleum refining, petrochemical, chemical manufacturing, natural gas processing, power generation, food, drinks, cosmetics and pharmaceuticals industries, the term safety valve is associated with the terms pressure relief valve (PRV), pressure safety valve (PSV) and relief valve.

The generic term is Pressure relief valve (PRV) or pressure safety valve (PSV). PRVs and PSVs are not the same thing, despite what many people think; the difference is that PSVs have a manual lever to open the valve in case of emergency.

Relief valve (RV): an automatic system that is actuated by the static pressure in a liquid-filled vessel. It specifically opens proportionally with increasing pressure

Pilot-operated safety relief valve (POSRV): an automatic system that relieves on remote command from a pilot, to which the static pressure (from equipment to protect) is connected

Low pressure safety valve (LPSV): an automatic system that relieves static pressure on a gas. Used when the difference between the vessel pressure and the ambient atmospheric pressure is small.

Vacuum pressure safety valve (VPSV): an automatic system that relieves static pressure on a gas. Used when the pressure difference between the vessel pressure and the ambient pressure is small, negative and near to atmospheric pressure.

Low and vacuum pressure safety valve (LVPSV): an automatic system that relieves static pressure on a gas. Used when the pressure difference is small, negative or positive and near to atmospheric pressure.

In most countries, industries are legally required to protect pressure vessels and other equipment by using relief valves. Also, in most countries, equipment design codes such as those provided by the ASME, API and other organizations like ISO (ISO 4126) must be complied with. These codes include design standards for relief valves and schedules for periodic inspection and testing after valves have been removed by the company engineer.

Today, the food, drinks, cosmetics, pharmaceuticals and fine chemicals industries call for hygienic safety valves, fully drainable and Cleanable-In-Place. Most are made of stainless steel; the hygienic norms are mainly 3A in the USA and EHEDG in Europe.

The first safety valve was invented by Denis Papin for his steam digester, an early pressure cooker rather than an engine.steelyard" lever a smaller weight was required, also the pressure could easily be regulated by sliding the same weight back and forth along the lever arm. Papin retained the same design for his 1707 steam pump.Greenwich in 1803, one of Trevithick"s high-pressure stationary engines exploded when the boy trained to operate the engine left it to catch eels in the river, without first releasing the safety valve from its working load.

Although the lever safety valve was convenient, it was too sensitive to the motion of a steam locomotive. Early steam locomotives therefore used a simpler arrangement of weights stacked directly upon the valve. This required a smaller valve area, so as to keep the weight manageable, which sometimes proved inadequate to vent the pressure of an unattended boiler, leading to explosions. An even greater hazard was the ease with which such a valve could be tied down, so as to increase the pressure and thus power of the engine, at further risk of explosion.

Although deadweight safety valves had a short lifetime on steam locomotives, they remained in use on stationary boilers for as long as steam power remained.

Weighted valves were sensitive to bouncing from the rough riding of early locomotives. One solution was to use a lightweight spring rather than a weight. This was the invention of Timothy Hackworth on his leaf springs.

These direct-acting spring valves could be adjusted by tightening the nuts retaining the spring. To avoid tampering, they were often shrouded in tall brass casings which also vented the steam away from the locomotive crew.

The Salter coil spring spring balance for weighing, was first made in Britain by around 1770.spring steels to make a powerful but compact spring in one piece. Once again by using the lever mechanism, such a spring balance could be applied to the considerable force of a boiler safety valve.

The spring balance valve also acted as a pressure gauge. This was useful as previous pressure gauges were unwieldy mercury manometers and the Bourdon gauge had yet to be invented.

Paired valves were often adjusted to slightly different pressures too, a small valve as a control measure and the lockable valve made larger and permanently set to a higher pressure, as a safeguard.Sinclair for the Eastern Counties Railway in 1859, had the valve spring with pressure scale behind the dome, facing the cab, and the locked valve ahead of the dome, out of reach of interference.

In 1855, John Ramsbottom, later locomotive superintendent of the LNWR, described a new form of safety valve intended to improve reliability and especially to be tamper-resistant. A pair of plug valves were used, held down by a common spring-loaded lever between them with a single central spring. This lever was characteristically extended rearwards, often reaching into the cab on early locomotives. Rather than discouraging the use of the spring lever by the fireman, Ramsbottom"s valve encouraged this. Rocking the lever freed up the valves alternately and checked that neither was sticking in its seat.

A drawback to the Ramsbottom type was its complexity. Poor maintenance or mis-assembly of the linkage between the spring and the valves could lead to a valve that no longer opened correctly under pressure. The valves could be held against their seats and fail to open or, even worse, to allow the valve to open but insufficiently to vent steam at an adequate rate and so not being an obvious and noticeable fault.Rhymney Railway, even though the boiler was almost new, at only eight months old.

Naylor valves were introduced around 1866. A bellcrank arrangement reduced the strain (percentage extension) of the spring, thus maintaining a more constant force.L&Y & NER.

All of the preceding safety valve designs opened gradually and had a tendency to leak a "feather" of steam as they approached "blowing-off", even though this was below the pressure. When they opened they also did so partially at first and didn"t vent steam quickly until the boiler was well over pressure.

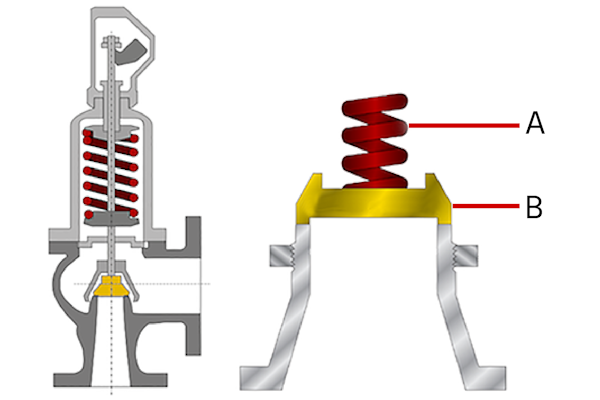

The quick-opening "pop" valve was a solution to this. Their construction was simple: the existing circular plug valve was changed to an inverted "top hat" shape, with an enlarged upper diameter. They fitted into a stepped seat of two matching diameters. When closed, the steam pressure acted only on the crown of the top hat, and was balanced by the spring force. Once the valve opened a little, steam could pass the lower seat and began to act on the larger brim. This greater area overwhelmed the spring force and the valve flew completely open with a "pop". Escaping steam on this larger diameter also held the valve open until pressure had dropped below that at which it originally opened, providing hysteresis.

These valves coincided with a change in firing behaviour. Rather than demonstrating their virility by always showing a feather at the valve, firemen now tried to avoid noisy blowing off, especially around stations or under the large roof of a major station. This was mostly at the behest of stationmasters, but firemen also realised that any blowing off through a pop valve wasted several pounds of boiler pressure; estimated at 20 psi lost and 16 lbs or more of shovelled coal.

Pop valves derived from Adams"s patent design of 1873, with an extended lip. R. L. Ross"s valves were patented in 1902 and 1904. They were more popular in America at first, but widespread from the 1920s on.

Although showy polished brass covers over safety valves had been a feature of steam locomotives since Stephenson"s day, the only railway to maintain this tradition into the era of pop valves was the GWR, with their distinctive tapered brass safety valve bonnets and copper-capped chimneys.

Developments in high-pressure water-tube boilers for marine use placed more demands on safety valves. Valves of greater capacity were required, to vent safely the high steam-generating capacity of these large boilers.Naylor valve) became more critical.distilled feedwater and also a scouring of the valve seats, leading to wear.

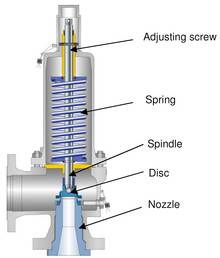

High-lift safety valves are direct-loaded spring types, although the spring does not bear directly on the valve, but on a guide-rod valve stem. The valve is beneath the base of the stem, the spring rests on a flange some height above this. The increased space between the valve itself and the spring seat allows the valve to lift higher, further clear of the seat. This gives a steam flow through the valve equivalent to a valve one and a half or twice as large (depending on detail design).

The Cockburn Improved High Lift design has similar features to the Ross pop type. The exhaust steam is partially trapped on its way out and acts on the base of the spring seat, increasing the lift force on the valve and holding the valve further open.

To optimise the flow through a given diameter of valve, the full-bore design is used. This has a servo action, where steam through a narrow control passage is allowed through if it passes a small control valve. This steam is then not exhausted, but is passed to a piston that is used to open the main valve.

There are safety valves known as PSV"s and can be connected to pressure gauges (usually with a 1/2" BSP fitting). These allow a resistance of pressure to be applied to limit the pressure forced on the gauge tube, resulting in prevention of over pressurisation. the matter that has been injected into the gauge, if over pressurised, will be diverted through a pipe in the safety valve, and shall be driven away from the gauge.

There is a wide range of safety valves having many different applications and performance criteria in different areas. In addition, national standards are set for many kinds of safety valves.

Safety valves are required on water heaters, where they prevent disaster in certain configurations in the event that a thermostat should fail. Such a valve is sometimes referred to as a "T&P valve" (Temperature and Pressure valve). There are still occasional, spectacular failures of older water heaters that lack this equipment. Houses can be leveled by the force of the blast.

Pressure cookers usually have two safety valves to prevent explosions. On older designs, one is a nozzle upon which a weight sits. The other is a sealed rubber grommet which is ejected in a controlled explosion if the first valve gets blocked. On newer generation pressure cookers, if the steam vent gets blocked, a safety spring will eject excess pressure and if that fails, the gasket will expand and release excess pressure downwards between the lid and the pan. Also, newer generation pressure cookers have a safety interlock which locks the lid when internal pressure exceeds atmospheric pressure, to prevent accidents from a sudden release of very hot steam, food and liquid, which would happen if the lid were to be removed when the pan is still slightly pressurised inside (however, the lid will be very hard or impossible to open when the pot is still pressurised).

In the process industry, both terms refer to safety devices, which generally come in the form of valves, cylinders, and other cylinders that protect people, property, and the environment. Safety valves and relief valves are integral components of process safety. However, they are used for almost identical purposes. Their main difference lies in their operating mechanisms.

In the event of an overpressure, a safety valve or pressure relief valve (PRV) protects pressure-sensitive equipment. It is recommended to strip down relief valves regularly and prevent serious damage due to backpressure. Pressure relief valves are a crucial part of any pressurized system. In order to prevent system failures, you can set the pressure to open at predetermined levels. A setpoint, also known as a predetermined design limit, is set for all pressure systems. When the setpoint is exceeded, an overpressure valve opens.

There are various types of safety valves used in several types of industries, including power plants, petrochemical plants, boilers, oil and gas, pharmaceuticals, and more. Using safety valves helps to prevent accidents and injuries that can harm people, property, and processes. Pressure builds up in vessels and systems automatically when the device is activated above a preset level. Safety valves must be configured so that their prescribed pressure is exceeded in order for them to function (i.e., relieve pressure). Ideally, excess pressure should be released either to the atmosphere or back into the pneumatic system to prevent damage to the vessel. In addition, excess pressure should be released to keep pressure within a certain range. As soon as a slight increase in pressure above the desired limit has lifted the safety valve, it opens.

Valve relief removes excessive pressure from a system by limiting its pressure level to a safe level. Often referred to as pressure relief valves (PRVs) or safety relief valves, these valves provide relief from pressure. The purpose of a relief valve is, for example, to adjust the pressure within a vessel or a system so that a specific level is maintained. The goal of a relief valve, unlike a safety valve, is not to prevent damage to the vessel; rather, it is to control the pressure limit of a system dynamically depending on the requirements. Conversely, safety valves have a maximum allowable pressure set at a certain level, which allows escaping liquid or gas whenever the pressure exceeds it, eliminating damage to the system. It is imperative that safety valves are installed in a control system to prevent the development of pressure fluctuations that can cause property damage, life loss, and environmental pollution.

The hydraulic system relies on a pressure relief system in order to regulate the running pressure. By allowing excess pressure to escape from the pressurized zone, pressure relief valves and safety valves prevent overpressure when the pressure in the system reaches a predefined limit. By venting excess pressure through a relief port, or returning it through a return line, a pneumatic system can enable the excess pressure to escape into the atmosphere. Pump-driven pressure generators and control media that cannot be vented into the atmosphere are typical examples of this type of application.

Excess pressure may be relieved from the system using relief valves and safety valves. The valve opening increases proportionally as the vessel pressure increases with the relief valve. Gradually opening the valve rather than abruptly releases only a prescribed amount of fluid. As pressure is reduced, the release proceeds at this rate until the pressure drops. By contrast, an emergency safety valve operates automatically when a predetermined pressure is reached in the system, preventing a catastrophic system failure. When the system is under excessive stress, the safety valve regulates the pressure within the system and prevents overpressure.

Defining a “setpoint” is the process of defining a pressure level which triggers the device to vent excess pressure. Setpoint is different from pressure. Overpressure is prevented by setting these devices lower than the highest pressure the system can handle before overpressure occurs. Setting the device below this pressure prevents overpressure. The valve opens when pressure rises above the setpoint. A setpoint also known as the maximum allowable working pressure (MAWP) cannot be exceeded when deciding the pressure in pounds per square inch (PSIG). The adjustment points for safety valves are generally 3 percent above working pressures, while adjustment points for relief valves are 10% above working pressures.

Pressure in an auxiliary passage can be controlled by a safety valve as well as a relief valve by releasing excess pressure. Safety valves of this type are pressure-sensitive and reliable. Safety valves can be categorized according to their capacity and setpoint, although both terms often refer to safety valves. Self-opening devices open automatically when maximum allowable pressure has been reached rather than being manually activated to prevent over-pressurizing. Contrary to relief valves, safety valves are typically used for venting steam or vapor into the atmosphere. Relief valves regulate fluid flow and compressed air pressure and gases, whereas safety valves typically regulate steam and vapor venting. Put simply, relief valves are used for more gradual pressure control requiring accurate, dynamic systems, whereas safety valves are used for one set to prevent damage to a system.

For pressure control applications that require dynamic setpoints and therefore varying pressure limits, our Electronic Relief Valve is the appropriate solution. This device accepts a control voltage to dynamically set the relief pressure setpoint. Traditional relief valves are set manually, so that a technician must adjust the relief valve and have a pressure gauge to find the accurate setpoint. The Kelly Pneumatic Electronic Relief Valve allows an electronic control system to quickly and safely command a dynamic maximum pressure based on feedback from current system specifications. The Kelly Electronic Relief Valve also has an optional feedback signal representing the current pressure in the system. This allows the control system to dynamically respond to changing conditions.

The improper installation of pressure relief devices can have dire consequences, causing unnecessary safety risks, and delaying operations while they are replaced or repaired. PRVs are typically one of the last lines of defense in an upset condition. To ensure that PRVs relieve and flow properly, the ASME and the National Board certify all PRV assembly programs, testing facilities, and even technicians. When you see marks and symbols on your pressure relief devices, it means that your device is certified safe because it came from a National Board and/or ASME certified organization.

The simple answer? Safety. However, there’s a bit more to safety than you might think. In order to ensure safe operation, organizations like the ASME and National Board set firm standards and require the completion of specific programs to attain certification. These programs are rigorous, and the UV Assembly Program is no exception. It’s designed to be very stringent, as it ensures consistency in the capabilities and functionality of all components in the PRV assembly process. Ideally, a PRV should be procured from a certified assembler that is also able to test and repair the device if necessary. Unfortunately, this is a tall order that not all suppliers are able to.

Vinson Process Controls has the capabilities and credentials required to assemble, test and repair pressure relief devices. In order to better serve our customers, we earned the certifications for the UV (assembly program), VR (valve repair) and T/O (testing only) certifications from the ASME and the National Board. We take the guesswork out of PRV procuring and maintenance so that our customers can relax and reap the benefits.

As a UV-certified assembler, Vinson has invested in stocking Anderson Greenwood™ and Crosby™ relief valves for faster lead times. We have a wide range of options for our customers, including same-day service, when required. The vast majority of Vinson’s relief valve inventory is in the portable 81P valves and pilot operated valves. Apart from the combined inventory we share with Emerson, we also have access to shared inventory across all 21 of Emerson’s Impact Partners. We are proud to say that all valves assembled in our Carrolton Valve Center have met or exceeded expected shipping dates.

In addition to faster lead times, our customers can maintain confidence that the products shipping from Vinson are of the samequality as those shipping directly from Emerson’s factory. The ASME, the National Board and Emerson audit all shops, quality control processes, techniques, and valves, before and after awarding certifications. Vinson will continue to receive audits to ensure that we are meeting or exceeding expectations over time. Our adhesion to our quality control manual means that all valves assembled by Vinson have the same factory warranty as if they were assembled in Emerson’s production line.

As a part of the Emerson Impact Partner Network, Vinson is one of the primary points of contact for direct sales of Anderson Greenwood™ and Crosby™. We are a certified UV assembler, also offering valve repair and testing services. We can offer you quotes for both repair and replacement options. Because of this unique status, Vinson can offer competitive pricing.

Vinson is proud to be an ASME and National Board UV and VR certified supplier. We are excited about our ability to offer our customers flexible delivery and quality products, all at a competitive rate. Our partnership with Emerson™ and the Emerson Impact Partner network enables us to provide continued support for our clients, no matter the complexity of their application needs. Contact us for assistance with your next project. We’re here to help and we’d love to hear from you!

Industrial equipment often uses either safety or relief valves to prevent damaging pressure levels from building up. Though they perform similar functions, there are some critical differences between safety and relief valves. Understanding these two valves’ differences is essential for proper pressure system operation. So here we discuss the pressure safety valve vs pressure relief valve.

A pressure relief valve is a device that releases pressure from a system. The relief valve is generally immune to the effects of back pressure and must be periodically stripped down. Pressure relief valves are one the essential parts of a pressure system to prevent system failures. They are set to open at a predetermined pressure level. Each pressure system has a setpoint that is a predetermined limit. The setpoint determines when the valve will open and prevents overpressure.

Pressure relief valves are typically used in gas or liquid systems where there is a need to prevent excessive pressure from building up. When the pressure in the system reaches a certain level, the valve will open and release the pressure. Pressure relief valves are an essential safety feature in many designs and can help to prevent damage to the system or components.

PRVs are generally considered to be safe and reliable devices. However, before installing a PRV in a system, some potential disadvantages should be considered. Here are five pros and cons of pressure relief valves:

Pros: Pressure relief valves are anessential safety feature in many systems. They protect against over-pressurization by relieving excess pressure from the system. This can help to prevent severe damage or even explosions.

Pressure relief valves can help to improve the efficiency of a system. The system can operate at lower overall pressure by relieving excess pressure and saving energy.

Pressure relief valves can be used as a safety device in systems that are susceptible to overpressurization. By relieving pressure before it builds up to a dangerous level, they can help to prevent accidents and injuries.

Cons: Pressure relief valves can be a potential source of leaks. If not properly maintained, the valve may not seat properly and can allow fluids or gasses to escape.

Pressure relief valves can sometimes cause problems if they do not open or close properly. This can lead to process disruptions and may cause safety issues.

A pressure safety valve is a device used to release pressure from a system that has exceeded its design limit. This safety valve is a fail-safe device. This type of valve is typically used in systems that contain fluids or gasses under high pressure. Pressure safety valves are designed to open and release pressure when the system has exceeded its maximum pressure limit. This helps to prevent the system from rupturing or exploding.

Pressure safety valves are an essential part of many different types of systems and can help keep both people and property safe. If anyone is ever in a situation where they need to release pressure from a system, it is essential to know how to use a pressure safety valve correctly.

A pressure safety valve (PSV) is a type used to relieve a system’s pressure. PSVs are commonly used in chemical and process industries, as well as in some kinds of pressure vessels. There are both advantages and disadvantages to using a PSV. Some of the pros of using a PSV include: PSVs can help to prevent overpressurization, which can be dangerous.

A safety valve is a pressure relief device used to prevent the over-pressurization of a system. On the other hand, a relief valve is a device used to relieve pressure from a system that is already overpressurized. Function Of Pressure Relief Valve Vs Safety Valve

The function of a pressure relief valve is to protect a system or component from excess pressure. A safety valve, on the other hand, is designed to protect from overpressurization. Both types of valves are used in various industries, but each has unique benefits and drawbacks.

Pressure relief valves are typically used in systems where a small amount of overpressure can cause damage. On the other hand, safety valves are designed for systems where overpressurization could be catastrophic. Both valves have advantages and disadvantages, so choosing the right type of valve for the specific application is essential.

Relief valves are usually set to open at a specific pressure and will close once the pressure has been relieved. Safety valves are similar in that they are also used to protect equipment from excessive pressure. However, safety valves are designed to stay open until they are manually closed. This is because safety valves are typically used in applications where it is not safe to have a closed valve, such as in a gas line. Operation Of Safety Relief Valve Vs Pressure Relief Valve

Two types of valves are commonly used in industrial settings: relief valves and safety valves. Both of these valves serve essential functions, but they operate in different ways.

Relief valves are designed to relieve pressure build-up in a system. They open when the system pressure reaches a certain point, which allows excess pressure to be released. On the other hand, safety valves are designed to prevent accidents by preventing system pressure from getting too high. They open when the system pressure reaches a certain point, which allows excess pressure to be released before an accident can occur.

So, which valve is better? That depends on the situation. A relief valve is the better option to protect the system from pressure build-up. If anyone need to protect the system from accidents, then a safety valve is the better option Setpoint Of Pressure Relief Valve Vs Safety Relief Valve

The relief valve is made to open when it reaches a specific pressure, commonly described as a “setpoint”. Setpoints shouldn’t be misinterpreted as the pressure set. A setpoint on a relief valve is set to the lowest possible pressure rating, which means it is set to the lowest system pressure before an overpressure situation is observed. The valve will open as the pressure increases to a point higher than the setpoint. The setting point is determined as pounds per square inch (PSIG) and should be within the maximum allowed operating pressure (MAWP) limits. In safety valves, the setpoint is typically placed at about 3 percent over the working pressure level, whereas relief valves are determined at 10 percent.

No, the safety valve and relief valve can not be used interchangeably. Though both valves are seal butterfly valve and used for safety purposes, they serve different functions. A safety valve relieves excess pressure that builds up in a system, while a relief valve regulates the pressure in a system.

Knowing the difference between these two types of valves is essential, as using the wrong valve for the intended purpose can potentially be dangerous. If unsure which type of valve to use, it is always best to consult with a professional.

A few key points help us understand the safety valve vs pressure relief valve. Safety valves are designed to relieve pressure in a system when it gets too high, while relief valves are designed to relieve pressure when it gets too low. Safety valves are usually set to open at a specific pressure, while relief valves are generally open at a particular vacuum. Safety valves are typically intended for one-time use, while relief valves can be used multiple times. Choose the trusted valve manufactureraccording to the specific business needs.

“I don’t believe in life after death. But I do believe in some grinding destiny that watches over us on earth. If I didn’t, the safety valve would give and the boiler would explode.” ~ Hedy Lamarr

“Every one’s got it in him, if he’ll only make up his mind and stick at it. None of us is born with a stop-valve on his powers or with a set limit to his capacities, There’s no limit possible to the expansion of each one of us.” ~ Charles M. Schwab

“About half the people at Valve have run their own companies, so they always have the option not just to take a job at another game company, but to go start their own company. The question you always have to answer is, ‘How are we making these people more valuable than they would be elsewhere?"” ~ Gabe Newell

“I wanted to destroy everything beautiful I’d never have. Burn the Amazon rain forests. Pump chlorofluorocarbons straight up to gobble the ozone. Open the dump valves on supertankers and uncap offshore oil wells. I wanted to kill all the fish I couldn’t afford to eat, and smother the French beaches I’d never see. I wanted the whole world to hit bottom.” ~ Chuck Palahniuk

“Occasionally, I go off the rails. I once nearly killed somebody once – it wasn’t funny. I am a lunatic. The pressure of work, the pressure – everyone has a stop valve, and I don’t have one.” ~ Ozzy Osbourne

“My father had a phase of having jukeboxes all over the house. He was a music lover but he was also into musical machinery. Not instruments, he was never interested in playing particularly but there would be these odd objects, like valve amplifiers being dismantled on the kitchen table. My mum wasn’t massively keen on that, but it was part of the environment.” ~ Squarepusher

“The free expression of opinion, as experience has taught us, is the safety-valve of passion. The noise of the rushing steam, when it escapes, alarms the timid; but it is the sign that we are safe. The concession of reasonable privilege anticipates the growth of furious-appetite.” ~ Herbert Gladstone, 1st Viscount Gladstone

“In order for innovation to happen, a bunch of things that aren’t happening on closed platforms need to occur. Valve wouldn’t exist today without the PC, or Epic, or Zynga, or Google. They all wouldn’t have existed without the openness of the platform. There’s a strong tempation to close the platform, because they look at what they can accomplish when they limit the competitors’ access to the platform, and they say ‘That’s really exciting."” ~ Gabe Newell

“I like a big neck – thick, flat and wide. I lacquered the fingerboard with Rustin’s Plastic Coating. The tremolo is interesting in that the arm’s made from an old bicycle saddle bag carrier, the knob at the end’s off a knitting needle and the springs are valve springs from an old motorbike.” ~ Brian May

“As strenuous challenge or contemplative retreat, the parks and other units of the national lands offer welcome respite from the world, a safety valve for body and spirit.” ~ T. H. Watkins

“Many of the fights that are going on are not ones that the United States has either started or have a role in. The Shia– Sunni split, the dictatorships that have suppressed people’s aspirations, the increasing globalization without any real safety valve for people to have a better life. We saw that in Egypt. We saw a dictator overthrown, we saw Muslim Brotherhood president installed and then we saw him ousted and the army back.” ~ Hillary Clinton

“I discovered is that I have a couple of valves that were leaky and had been giving, gave me a problem then. But I hadn’t noticed anything up until then.A couple of incidents of shortness of breath and checked myself into a hospital, but that one in France really sat me down for a few minutes – a very few minutes, because seven days later I was in the studio, and eight days later, I was no the stage.” ~ Al Jarreau

“When the Vent begins, you might confuse [it] for a conversation. It’s not. It’s a Vent. It’s a mental release valve and your job is to listen for as long as it takes. Don’t problem solve. Don’t redirect. Don’t comfort. Yet. Your employee is doing mental house cleaning and interrupting this cleaning is missing the point. They don’t want a solution, they want to be heard.” ~ Rands

“People should have an escape valve for their money, their assets. If you have substantial financial assets, the government is going to confiscate the purchasing power of those assets and spend it.” ~ Peter Schiff

“You want a valve that doesn’t leak and you try everything possible to develop one. But the real world provides you with a leaky valve. You have to determine how much leakiness you can tolerate.” ~ Arthur Rudolph

“Emergency Valve Regulators,” she repeated. “So you do know what your doing? “Not really,” he said yanking another wire. ‘I made up that term to keep you happy. I’m just pulling all the red wires because they’re the pretty ones.” ~ Derek Landy

“I still preserve those relics of past sufferings and experience, like pillars of witness set up in travelling through the valve of life, to mark particular occurrences. The footsteps are obliterated now; the face of the country may be changed; but the pillar is still there, to remind me how all things were when it was reared.” ~ Anne Bronte

“It did not seem possible that Wendy Wright had been born out of blood and internal organs like other people. In proximity to her he felt himself to be a squat, oily, sweating, uneducated nurt whose stomach rattled and whose breath wheezed. Near her he became aware of the physical mechanisms which kept him alive; within him machinery, pipes and valves and gas-compressors and fan belts had to chug away at a losing task, a labor ultimately doomed. Seeing her face, he discovered that his own consisted of a garish mask; noticing her body made him feel like a low-class wind-up toy.” ~ Philip K. Dick

“What else can I do? Once you’ve gone this far you aren’t fit for anything else. Something happens to your mind. You’re overqualified, overspecialized, and everybody knows it. Nobody in any other game would be crazy enough to hire me. I wouldn’t even make a good ditch-digger, I’d start tearing apart the sewer-system, trying to pick-axe and unearth all those chthonic symbols – pipes, valves, cloacal conduits… No, no. I’ll have to be a slave in the paper-mines for all time.” ~ Margaret Atwood

“I fast every Sunday. I don’t eat anything. Just juices. […] It flushes out the system, cleans out the colon. I think that’s great. To really make it work, you have to do it properly. That’s the sewer valve of the system. You have to keep that clean like you clean the outside of your body. All these impurities come out of your system because you’re not clean inside. It comes out in pimples or disease or through big pores. Toxins trying to get out of your system. People should try to keep themselves clean.” ~ Michael Jackson

“we all have too many wheels, screws and valves to judge each other on first impressions or one or two pointers. I don’t understand you, you don’t understand me and we don’t understand ourselves.” ~ Anton Chekhov

“[Aldous Huxley] compared the brain to a ‘reducing valve’. In ordinary perception, the senses send an overwhelming flood of information to the brain, which the brain then filters down to a trickle it can manage for the purpose of survival in a highly competitive world. Man has become so rational, so utilitarian, that the trickle becomes most pale and thin. It is efficient, for mere survival, but it screens out the most wondrous part of man’s potential experience without his even knowing it. We’re shut off from our own world.” ~ Tom Wolfe

“Social Note: I have sought escape in the Prytanea on more than one occasion, pulled by the attractions of some technicolored horrors, filmed abortions that were offenses against any criteria of taste and decency, reels and reels of perversion and blasphemy that stunned my disbelieving eyes, the shocked my virginal mind, and sealed my valve.” ~ John Kennedy Toole

“If you are involved totally, sex disappears because sex is a safety valve. When you have energy unused, then sex becomes a haunting thing around you. When total energy is used, sex disappears. And that is the state of brahmacharya, of virya, of all your potential energy flowering.” ~ Rajneesh

“Every friend whom not thy fantastic will but the great and tender heart in thee craveth, shall lock thee in his embrace. And this because the heart in thee is the heart of all; not a valve, not a wall, not an intersection is there anywhere in nature, but one blood rolls uninterruptedly in endless circulation through all men, as the water of the globe is all one sea, and, truly seen, its tide is one.” ~ Ralph Waldo Emerson

“I can tell you where I was when Kennedy was shot – which was in the common room at school. I heard about it on the old valve radio. At the time of Armstrong’s landing, I was at university rehearsing a play.” ~ Sam Neill

“When we can drain the Ocean into mill-ponds, and bottle up the Force of Gravity, to be sold by retail, in gas jars; then may we hope to comprehend the infinitudes of man’s soul under formulas of Profit and Loss; and rule over this too, as over a patent engine, by checks, and valves, and balances.” ~ Thomas Carlyle

“And she understood, all by herself, without reading it in a novel or hearing it on a radio program, that falling passionately in love with someone, without reservation or holding back, was good for the heart. For its valves and its arteries and that invisible shadow of the heart called the soul. Falling in love was good for the soul.” ~ Paulette Jiles

“I hope we are able to shift debate over to the Middle East and change this debate to how we help the people in their home countries rather than believing we can be their relief valve for the poverty and the grief that`s in the world by bringing people here.” ~ Steve King

“I’ve always had a flare for the dramatic. I thought about being an actor and I thought about directing, but writing truly became something I needed to do, just to stay sane. It’s my over-pressure valve.” ~ Marti Noxon

“The only big things I’ve purchased are my dad’s heart valve and a Rolls-Royce for my parents, for their anniversary. And that was only because my dad had a Lady Gaga license plate on our old car and it was making me crazy because he was getting followed everywhere, so I bought him a new car.” ~ Lady Gaga

“Usually at the core of fiction that has some element of the absurd there tends to be an examination of some societal ills that we should talk about more than we do. And it’s funny, of course, so we have that release valve with absurdism. It offers us a safe way to explore difficult subject matter.” ~ Laurie Foos

“The culture at Valve is pretty much crowdsourced. The handbook is a wiki. One of the first things we say to new hires is, ‘You have to change something in the handbook."” ~ Gabe Newell

“Unpleasant reading on the subject of anger tells us that there’s not really anything wrong with it. In limited amounts. It can even be a good thing. A pressure valve.” ~ Dick Cavett

“I use a portable pocket ultrasound device instead of a stethoscope to listen to the heart, and I share it with the patient in real time. ‘Look at your valve, look at your heart-muscle strength.’ So they’re looking at it with me. Normally a patient is tested by an ultrasonography who is not allowed to tell them anything.” ~ Eric Topol

“[The immigrant] becomes a kind of insurance policy against the effects of the recession. By blaming him, the pressure valve is regulated in times of crisis … What we have now is a public mindset of us versus them, and an overall anti-immigrant climate that is both troubling and morally reprehensible.” ~ Andrew Lam

“My parents passed away when I was a teenager, so I had to learn different survival techniques, I think, in comedy. You know, using comedy as a pressure release, as a release valve in life really kept my sanity.” ~ Jeff Ross

“If I go to the National Gallery and I look at one of the great paintings that excite me there, it’s not so much the painting that excites me as that the painting unlocks all kinds of valves of sensation within me which return me to life more violently.” ~ Francis Bacon

“To me, every kitchen appliance is useful and nothing’s overrated. When I look at my little espresso machine, I don’t see coffee. I see a steaming valve as an opportunity to make amazing creme brulee.” ~ Grant Achatz “We may exist in all universes, but ‘hear’ only one because of our limitations, the valve of our desires, our practical, physical needs. All is vibration, with nothing vibrating across no distance whatsoever. All is music. A universe, a world, is just one long difficult song. The difference between worlds is the difference between songs.” ~ Greg Bear

“You’re competing against people in a state of flow, people who are truly committed, people who care deeply about the outcome. You can’t merely wing it and expect to keep up with them. Setting aside all the safety valves and pleasant distractions is the first way to send yourself the message that you’re playing for keeps” ~ Seth Godin

“A wholesome sense of humor will be a safety valve that will enable you to apply the lighter touch to heavy problems and to learn some lessons in problem solving that “sweat and tears” often fail to dissolve.” ~ Hugh B. Brown

“There is a gesture he has, a motion, that always reminds me of a great batter leaning into a hit. He has a way of throwing one foot forward, putting his head down a bit as he silently runs the valves, and then the cheeks bloom out in the way that has mystified his dentist for years, and he hits into the solo. When that foot goes forward like that, you know that John Birks Gillespie is no longer clowning. Stand back.” ~ Gene Lees

“No matter how much restriction civilization imposes on the individual, he nevertheless finds some way to circumvent it. Wit is the best safety valve modern man has evolved; the more civilization, the more repression, the more need there is for wit.”.” ~Sigmund Freud

“Each of us is full of too many wheels, screws and valves to permit us to judge one another on a first impression or by two or three external signs.” ~ Anton Chekhov

“Sending money to Washington to have it administered and sent back is like getting a blood transfusion from your right arm to your left arm with a leaky valve.” ~ Ernest Hollings

“War is a sociological safety valve that cleverly diverts popular hatred for the ruling classes into a happy occasion to mutilate or kill foreign enemies.” ~ Ernest Becker

“This coarse and insulting way of regarding woman, as though they existed merely to be the safety-valves of men’s passions, and that the best men were above the temptation of loving them, has been the source of unnumbered evils.” ~ Annie Besant

“It’s rare that a company has an opportunity to forever transform the ways in which people interact with the world and communicate with each other, but that is exactly what we plan to do with Valve.” ~ Cher Wang

Pressure valves regulatethe flow of gas through a pipeline by opening or closing in response to changes in the pressure of the gas, air, water, or steam flowing through the pipe. Pressure valves are commonly used on natural gas systems, propane systems, and other types of gas systems.

A pressure valve regulates the flow of gas through pipelines by opening or closing in accordance with changes in the pressure of gas flowing through the pipe, thereby maintaining a constant pressure within the pipeline.

Pressure valves work by using a spring-loaded diaphragm or electrical actuator to open or close the valve in the pipeline. As the pressure inside the pipeline rises, the diaphragm moves away from the valve seat, allowing more gas to pass through. Conversely, as the pressure falls, the diaphragms move toward the valve seat, restricting the flow of gas.

Testing a pressure valve should be done before installing it into a system. If there are leaks in the pipe, the valve will not work properly. To test a pressure valve, use a leak detector to check for leaks in the pipe. Then, turn off the main supply line and connect a gauge to the valve. Turn the valve on slowly until the pressure reaches the desired level. Once the pressure has reached the desired level, turn the valve off and wait for the pressure to drop back down to normal levels.

Pressure valve control is used in many applications, but they’re mainly found in all pneumatic and hydraulic systems. Pressure valve control has a wide range of functions that can be used to maintain a set pressure level in a part of a control loop or to keep system pressures below a desired limit.

There are many different types of pressure valve control in the industry, such as pressure relief valves, pressure reducing valves, pressure safety valves, counterbalance valves, unloading valves, and sequencing valves. Most of these pressure valves are typically closed valves, but pressure reducing valves are commonly open valves. It’s important for most of these valves to have restrictions so that the required pressure control can be achieved.

The flow must be consistent at all times in certain applications. Injuries or deaths can be caused by variations in the flow of gases. That’s why pressure control valves are so important in the processing loop.

Pressure relief valves are used to keep the pneumatic and hydraulic systems under the desired pressure value. Based on the different installation positions, pressure relief valves have different functions as below. The downstream pressure should be reduced to a constant level whenever it goes over a threshold.

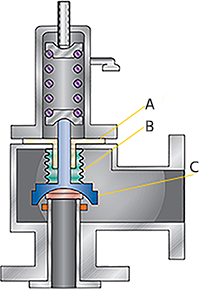

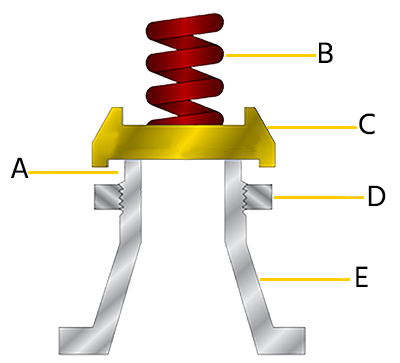

A pressure relief valve is usually made of three parts: a ball/diaphragm, a spring-loaded mechanism, and a valve nozzle. A spring-loaded mechanism is placed in the valve’s housing, which is used to close the orifice. The pressure relief valve’s spring-loaded mechanism can be adjusted to change the pressure on the spring mechanism. If you want to increase the set pressure limit, just simply increase the pressure on the valve spring-load mechanism directly. If you want to decrease the set pressure limit, only decrease the pressure on the spring-load mechanism directly. A relief valve set-pressure can be specified by the manufacturer if there is no adjustability. When the set pressure is reached, the pressure overcomes the spring pressure and pushes the ball or diaphragm back opening the orifice and releasing the excess pressure. Depending on the media, it is either released into the atmosphere or discharged into it. It is possible to return to a tank or pumping circuit with compressed air.

There are two types of PRVs used in industry, one is the direct-acting pressure reducing valves, and the other type is pilot operated pressure reducing valves. The pressure reducing valves use globe type or angle type valve bodies. Most of the time, the main type of valve used in water systems is the direct acting valve, which consists of a globe-type body with a spring-loaded, heat-resistant diaphragm connected to the outlet of the valve that acts upon a spring. This spring holds a pre-set tension on the PRVs seat that’s installed with a pressure equalizing mechanism for precise water pressure control.

Pressure reducing valves are widely used in water conditions, such as in buildings, industrial plants, water treatment plants, homes, and so on. It will automatically reduce the water pressure from the main supply, in case to lower the water pressure to the destination and more sensible pressure for equipment.

Sequence valves are widely used in hydraulic systems, and are a type of pressure valve. Sequence valves are similar to pressure relief valves, but are used to control a set of pressure-related operating sequences. The main function of a sequence valve is to divert the flow in a predetermined sequence, and its construction is very similar to a pressure relief valve, which is a pressure actuated valve, usually a closed valve.

The sequence valve works on the principle that the valve plug will be moved when the main system pressure exceeds the spring setting. As a result, the outlet of the sequence valve will remain closed until the upstream pressure rises to a predetermined value, and then the valve will open, allowing air to transfer from the inlet to the outlet. Sequence valves are primarily used to force two actuators to operate in sequence. One nice feature of the sequence valve is that the valve has a separate drain connection to the spring chamber, under normal operating conditions, high pressures may occur at the output port. When the pressure rises above its limit, the pressure sequence valve will allow flow to occur in another part of the system. The pressure sequence valve is installed in a pneumatic control and its switching operation requires a specific pressure.

Counterbalance valves are used to handle loads that are over-limited and to safely suspend loads, these valves commonly work with hydraulic cylinders. This type of valve can also be used with hydraulic motors and is then commonly referred to as a brake valve. Both counterbalance valves and pilot-operated check valves can be used to lock the fluid in the cylinder to prevent drift. However, pilot-operated check valves cannot control over-running loads. A counterbalance valve should be used when uncontrolled motion may occur with an overrunning load.

The pressure safety valve is one of the most critical automatic safety devices in a pressure system, and in many cases is the last line of defense for safety. The important function of a pressure safety valve is overpressure protection, so ensure that the pressure safety valve can operate properly in any situation. Pressure safety valves are mainly used in pressurized vessels or equipment to protect the environment, property safety, and life safety in the event of an overpressure event. A pressure safety valve opens and releases excess pressure in a vessel or equipment, and closes again when normal conditions are restored and prevents the further release of fluid.

A “safety valve” is an exception to mandatory minimum sentencing laws. A safety valve allows a judge to sentence a person below the mandatory minimum term if certain conditions are met. Safety valves can be broad or narrow, applying to many or few crimes (e.g., drug crimes only) or types of offenders (e.g., nonviolent offenders). They do not repeal or eliminate mandatory minimum sentences. However, safety valves save taxpayers money because they allow courts to give shorter, more appropriate prison sentences to offenders who pose less of a public safety threat. This saves our scarce taxpayer dollars and prison beds for those who are most deserving of the mandatory minimum term and present the biggest danger to society.

The Problem:Under current federal law, there is only one safety valve, and it applies only to first-time, nonviolent drug offenders whose cases did not involve guns. FAMM was instrumental in the passage of this safety valve, in 1994. Since then, more than 95,000 nonviolent drug offenders have received fairer sentences because of it, saving taxpayers billions. But it is a very narrow exception: in FY 2015, only 13 percent of all drug offenders qualified for the exception.

Mere presence of even a lawfully purchased and registered gun in a person’s home or car is enough to disqualify a nonviolent drug offender from the safety valve,

Even very minor prior infractions (e.g., careless driving) that resulted in no prison time can disqualify an otherwise worthy low-level drug offender from the safety valve, and

The Solution:Create a broader safety valve that applies to all mandatory minimum sentences, and expand the existing drug safety valve to cover more low-level offenders.

8613371530291

8613371530291