how to calculate cdtp in safety valve brands

Built-up back pressure is the backpressure generated due to pressure losses at the outlet of an open relief valve when it is discharging. This pressure depends on the pressure of the vent header downstream to the relief valve and the relieving flowrate which is being discharged. The built-up backpressure is the pressure in the vent header plus pressure drop in the line from relief valve to vent header, when the valve is discharging at full capacity.

For certain relief valve designs, the backpressure on the valve acts as a closing force and can affect the opening pressure for the valve. ‘Conventional’ valves are highly susceptible to this effect and hence not used in applications where high backpressure is expected. ‘Balanced Bellows’ and ‘Pilot Operated’ relief valves relatively shielded from effects of high backpressure.

For some relief valves (especially conventional type relief valves), the opening of the valve is affected by backpressure seen by the valve. If the backpressure seen by such relief valves is higher than atmospheric, then it has to be designed to open at a lower differential pressure value than the relief valve set pressure minus atmospheric pressure. However when the relief valve is tested before installation, it only sees atmospheric pressure as backpressure. Hence to open this relief valve at same differential pressure value, the set point pressure for opening the valve has to be lower than original design set point pressure. This set point value is known as cold differential test pressure (CDTP).

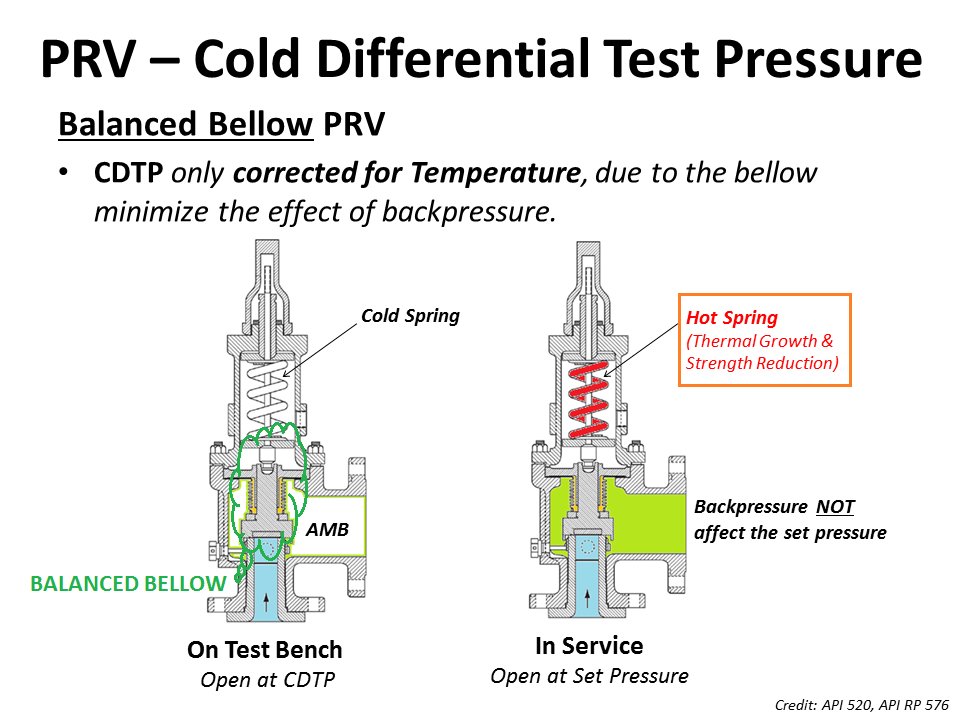

For pilot operated and balanced bellows type relief valves, effect of backpressure on valve opening characteristics is very low and hence CDTP is the same as the original design set point pressure value.

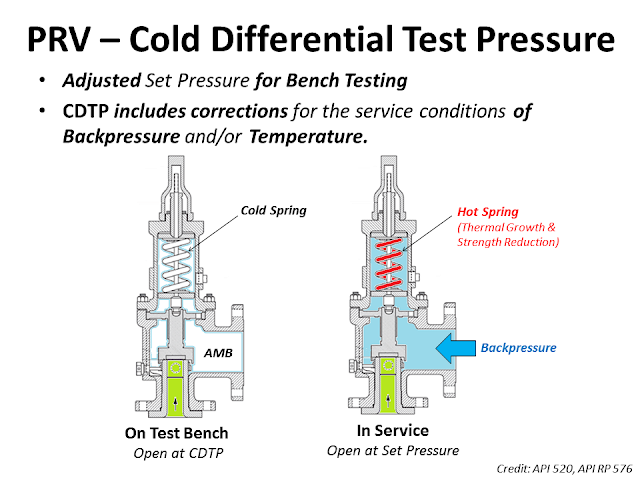

The conditions at which PRV is set to operate on a test stand could be different from the actual service conditions under which a PRV is required to open in the plant.

As we had discussed the backpressure that relief valve faces in a closed system would not be present during testing in the shop and this needs to be compensated for conventional relief valves.

However as discussed above the parameter of Temperature correction factor would still be applicable to Bellows and pilot-operated relief valve if the PRV temperature is significantly different from that of ambient temperature.

Project Scenario : A Relief valve of Dresser 1900 Series (Conventional relief valve) valve is required to open at 800 Psig where the service temperature is 400°F and backpressure is 100 Psig.

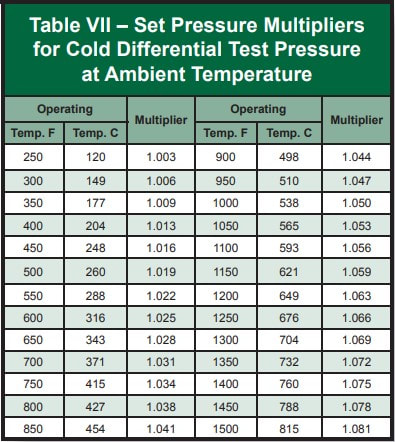

nasim123. Where are you getting the 120F figure from ? As previously, the method differs between manufacturers and their design. Manufacturers aCCDTP is based on their design, experience, testing and reports from the field. CDTP temperature correction continues to be argued. You really need to look at it case by case. What if an operating pressure is say 10C and the relief temp say 300C ? do you set the SRV higher with a correction factor of say 2% (CDTP = Set P x 1.02) or leave it for 10C operating temp ? How critical is opening point ?, has valve been set within tolerance ? You must apply good engineering practice with manufacturers advice to ascertain best CDTP setting. Per my earlier opening statement, base CDTP on the spring temperature at the moment of relief and against the manufacturers temperature correction multiplier. That"s the closest optimum CDPT you can get.

Further for Convetional Valve API-521 paragraph 4.2.3.3 A convetional PRV Operating with a constant superimposed back pressure normally required a correction factor to compensate for the back pressure. In this case the required set pressure minus superimposed back pressure is equal to CDTP. This change account for the addtional closing force exerted on the valve disk by back pressure.

Now, we have to add this pressure for back pressure consideration or valve is tested based on CDTP, But if we tested based on CDTP than this is less that the set pressure as CDTP is Set Pressure - Superimposed back pressure.

(100Mbs) Over 2000 Questions and Answers. Full API document, codes, questions on each applicable Code/Section (1-2 months) prior to participate in Prometric examination. Full Training presentations for self learning. Bonus: API 510, 571 Flash Cards, PSV notes – excel files.

The Cold Differential Test Pressure (CDTP)of thePressure Relief Valve (PRV) is a set pressure that is adjusted to be used for the PRV (Bench Testing). Because in actual use conditions, the PRV may be affected by the Backpressure. And the operating temperature. Therefore, when testing at room temperature and without backpressure, it is necessary to adjust the set pressure to compensate for these factors. In other words, the shop test pressure = CDTP.

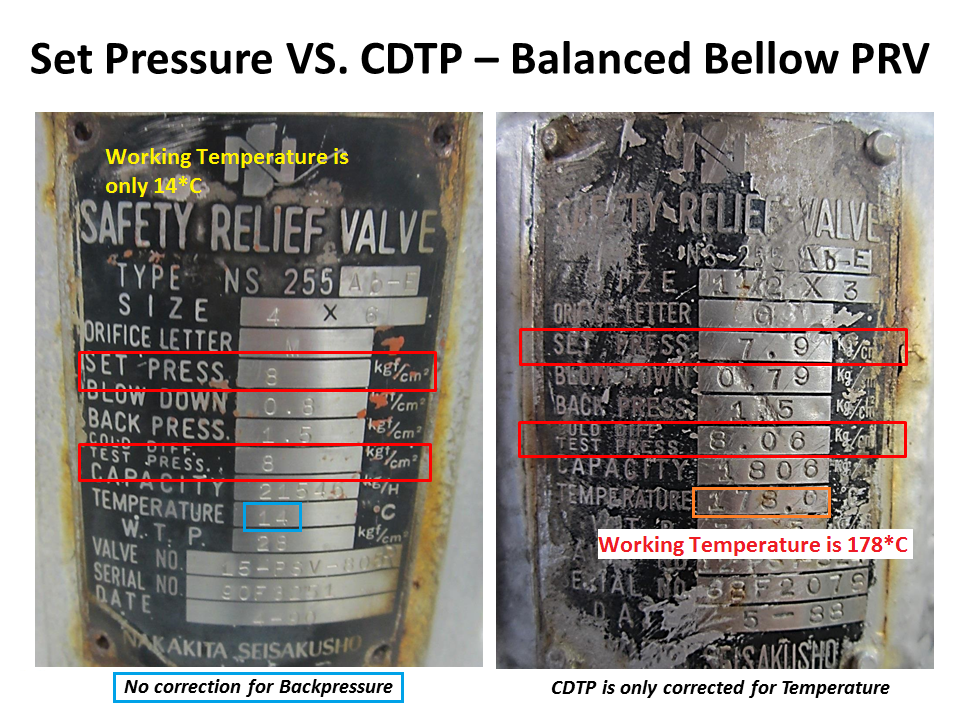

An example of aCold Differential Test Pressure (CDTP)with abackpressure (superimposed)effect. In this case, CDTP is equal to Set Pressure minus Backpressure.

An example of aCold Differential Test Pressure (CDTP)with different temperature compensations for use and testing. And an example ofCDTP that has been adjusted to compensate for both Backpressure (Superimposed) and temperatureeffects.

Test Stand or Test Bench is a set of equipment used for Pressure Relief Valve (PRV) in Pop Test (Set Pressure Test), Blowdown and Seat Tightness Test (Leakage Test)

As for theBalanced Bellow Pressure Relief Valve, which has a bellowfor reducing the impact of theBackpressure, the Cold Differential Test Pressure (CDTP) of the Balanced Bellow Type PRV will compensate only for the impact of different temperatures between the Shop Test and In-service.

The National Board strives to keep information in the hands of website users. Provided here are more than 70 Technical Articles previously published in the National Board BULLETINand/or from the proceedings of past General Meetings.

NATIONAL BOARD tells how to calculate the CDTP for a PRD taking into account a temperature differential and a back pressure, CDTP is not more than the difference of the SET PRESSURE minus the superpositions exerted by the effect of the temperature and the back pressure of a valve of conventional design (without bellows). By the way, the temperature correction is given by a multiplying factor that will depend on the quality of the internals of each valve and this is supplied by the manufacturer"s brand. For example DRESSER has its own tables of multiplying factors

www.controlglobal.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 49aa4de84ffe7587c78dee4984bc4222 63.210.148.230 01/26/2023 01:17 PM UTC

Did you know, under certain circumstances, you need to verify if the Cold Differential Test Pressure (CDTP) is properly compensated for the superimposed backpressure from the flare header?

Have you come across a conventional pressure relief valve relieving to a flare header? Did you know that, under certain circumstances, you need to verify if the Cold Differential Test Pressure (CDTP) is properly compensated for the superimposed backpressure from the flare header?

API 520 Part I, Ninth Edition, Section 5.3.2.1 says, "Superimposed backpressure at the outlet of a conventional spring-loaded PRV acts to hold the valve disc closed with a force additive to the spring force. The actual spring setting can be reduced by an amount equal to the superimposed backpressure to compensate for this."

It further goes on to say in Sections 5.3.2.2 & 5.3.2.3, "Balanced spring-loaded or pilot-operated PRVs should be considered if the superimposed backpressure is variable. However, if the amount of variable superimposed backpressure is small, a conventional valve could be used provided:

For example, conventional valves are often used when the outlet is piped into a relief header without compensating the set pressures for the superimposed backpressure caused by other relieving devices. This approach can be used provided the allowable accumulation is not exceeded during the release.

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

8613371530291

8613371530291