how to reset propane tank safety valve brands

The owner of this website (www.doityourself.com) has banned the autonomous system number (ASN) your IP address is in (20473) from accessing this website.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The time has come and the epic barbecue dinner you had planned is in play as friends and family arrive. It’s time to fire up your barbecue grill and preheat it so you can begin cooking. Then you notice the flame is low, and that the grill is only heating up to 250 or 300 degrees Fahrenheit – or maybe it’s not even igniting!!! Don’t panic! There’s no need yet to call your local grill store to come out and fix it yet. This post may just save the day and some of your hard-earned money! …

* Side note about the shut down procedure. The following ignition sequences are written assuming you are turning the burners off 1st, then the Propane Tank. Therefore, each sequence starts from the “all off” positions. You can turn the burners off and leave the Propane Tank on; however, we strongly recommend you to go ahead and turn the Tank off also.

To put it simply, the key is to be sure you have your burners off before you turn on the Propane. If you turn the burners on first the gas will not be pressurized in the gas line causing the Bypass to trigger. You see, in this case the system detects there is a gas leak; hence, the bypass triggers.

* When using the improper sequence, the regulator will trip because by turning the burners on 1st, you empty the lines of any propane which causes the low line pressure.

If after having deployed this fix the issue persists, it’s time to call your local BBQ Grill Repair Company. There are numerous other more advanced issues that can occur. For instance, you may have a blockage in the Venturis Tubes. A blockage like this is caused by char/grease build-up. You can decrease the likely hood of this ever happening by being sure to have a BBQ Grill Cleaning done regularly.

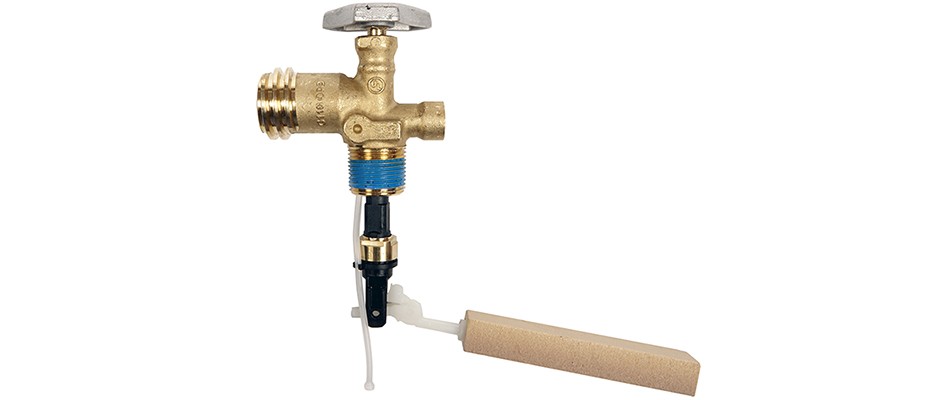

An OPD Cylinder Valve is indeed a part of your propane tanks’ inherent safety design. However, it does not have a “Bypass” as your regulator does, nor is it designed as a safety mechanism during usage. This device is required on all 4 to 40 pound DOT cylinders.

OPD stands for Overfilling Prevention Device and its first function is to do just that, prevent the user from overfilling the device. In addition, the device disallows Propane from flowing out of the cylinder if the triangular handwheel is opened and there is no gas line connected. It does this because there is no connected regulator to push open the valve’s orifice. Moreover, Propane OPD valves operate inside the bottle and are activated as the cylinders liquid propane rises in level pushing the float upward, therefore, stopping the flow of gas into the tank. This action is similar to that of a toilets float valve; once the water in the bowl rises to a certain level, the flow of water stops.

The OPD Valve is one of the main focuses regarding the fact that tanks are to be recertified 12 years after original manufacturer dates and every 5 years thereafter. Inside, there are what you can call “O-Rings” that need to be changed out at those predefined intervals. Also, the mechanism itself can be swapped out for a new one. Tampering with this device is NOT RECOMMENDED. If you suspect there’s an issue call your local propane delivery supplier and they will deal with it properly.

Has your propane tank valve gotten stuck yet again? This can put a serious damper if you’ve planned a BBQ, or literally anything that requires your propane tank. But here’s some good news: this article will tell you exactly how to unstick a propane tank valve.

Before we move onto the meat of the matter, you need to understand how your propane tank works. This applies to anything that runs on propane: fireplaces, water heaters, stoves, gas grills, and even RVs. Knowing how your tank operates will make it easier to troubleshoot minor issues.

A basic tank is filled with propane liquid and uses a special machine that forces the propane gas into the tank under pressure, turning it into its liquid form. It remains pressurized in the tank until the valve is released. When the valve is turned, the pressure decreases and the gas converts to vapor and escapes through the opening.

The propane gas is allowed to escape the canister under a certain pressure determined by the size of the valve. Large commercial propane tanks have multiple valves and gauges.

The main valves are the fill valves to refill the tank, a service valve to release the propane, and a relief valve. The relief valve prevents too much pressure from building up in the tank and exploding.

Tanks also have gauges that measure the level of liquid in the tanks called a float gauge, as well as a vapor recovery valve that can be used to release excess vapor in the tanks when getting it serviced.

The tanks are often closed very tightly to prevent leaks. If your propane tank won’t open after you bring it home the first time, try using a wrench or a pair of pliers. You can also unhook the tank from your stove and apply a bit of oil to the valve, before trying to yank it open with pliers.

Before you try to fix a propane safety valve (or any other tank valve), you need to identify the cause of the blockage. This will determine what you need to do to correct the issue.

The most important thing to bear in mind is that propane is highly combustible. When correcting a faulty tank valve, make sure you don’t puncture the tank and cause more damage. Safety is always a priority, so work in a ventilated area and do not light matches or lighters near your tank.

Set the propane tank on a steady, level surface. Make sure you are in a dry and cool area. Carefully check the tank for any signs of obvious damage and try to find the source of any possible leaks.

Wrap the rubber band around the outer edges of the valve to get a better grip on the blocked valve. Once you get a firm grip, twist firmly to loosen and dislodge the valve with your hand.

If this doesn’t work, spray a bit of oil or lubricant on the valve. Shake the valve back and forth to loosen it up, and then try to twist it open once again.

If the valve is still stuck, use a pair of pliers or a wrench to force it open. Grasp the edge of the valve with your pliers firmly and twist counterclockwise to open the valve. Try not to use too much pressure or as this can break the valve instead.

If your valves have rust or water damage, assess the situation. If it is still in the early stages, you can use baking soda and vinegar to get rid of the rust. However, if it is too far gone, you will need to replace the valve.

To avoid the fuss of a propane tank valve that needs to be dislodged, you can follow a few simple steps to prevent it from happening in the first place.

Don’t twist the valve closed too tightly. This might sound obvious, but people tend to close the valve really tightly, especially after a refill. Shut it tight, but don’t overdo it.

After buying a new tank or refilling your old one, smack the bottom of the tank on the ground once or twice. This will loosen the valve so you can open it more easily.

Don’t open the valve of a new cylinder rapidly as this can make it get jammed the next time. Instead, test the water and work it slowly and carefully.

If your propane tank leaks when connected, you most likely need a new valve. Check for the site of the leak by spraying soapy water at the valve, connection point, and pipes. If you see bubbles at the valve or connection, the gasket is broken and the valve requires replacing.

Soak the hose for a few minutes in warm soapy water to clean it. Use grease-cutting dish soap or something similar to break down accumulated oil and debris. Rinse the hose thoroughly under running water and allow it to dry.

The propane tank shut-off valve is your best bet during leaks if the hose or valve isn’t the one behind the leaks. The service or shut-off valve is the metallic spigot-like dial located under the tank cover and hooked to the top of the tank.

You need to use this valve to turn the gas off at the tank in the event of an emergency or leak. Always turn this valve to the right (clockwise), completely to shut off the gas.

This kind of valve is required on all large 4-to-40-pound commercial cylinders in vapor service. The OPD valve is a protective device and is exactly what it sounds like. It prevents the tank from overfilling.

Place the open jaws of the crescent wrench over the large bolt of the tank’s gas regulator. This is located at the meeting point of the propane tank and the gas regulator. Use the thumbscrew to grip the jaws around the large nut.

Then, loosen the nut with the wrench. Continue to remove the nut by hand until you can pull the neck of the regulator from the propane tank connection. You may catch a small whiff of gas as the regulator’s neck is pulled from the propane tank, but this is nothing to be worried about.

Remove the tank from the grill’s cart. In some models, you might have to loosen a safety strap. Store the empty tank in a safe and dry location, outdoors and well away from any flames.

It is perfectly normal to smell a little propane as tiny amounts can leak when the tank is in use. You can also smell the gas when the tank is nearly empty.

It is common for a propane tank to hiss. Hearing this sound is an indication that your tank is leaking so shut off all the valves and check for the location of the leak.

It is always a little scary when dealing with gas tanks, as we are well aware of the risks. However, knowing how to handle any kind of malfunctioning will make it much easier to deal with.

Once you know how to unstick a propane tank valve, you can loosen the valve or spigot without any trouble. And this will make the process of grilling much easier. Happy cooking!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Gauges, regulators, valves … welcome to your propane tank! If you’ve only used propane to power a gas grill in the past, the larger tanks may be intimidating. It can seem like a whole new world at first, especially if you’re used to powering your home using other fuel sources like natural gas, whose components may not be as visible. And while your propane supplier often handles a lot of the periodic propane tank maintenance and refilling, it’s a great idea to know the basics — especially if you own your own tank. No worries — we’ll make it easy for you. So you can feel confident and secure managing the day-to-day operations of living with propane.

Here’s a quick glossary ofpropane tank parts along with their functions — plus a few tips for making sure your propane tank stays in good working order.

PropaneFill Valve: When your propane is delivered, this is the valve that the technician attaches to the fuel hose. The hose from the truck connects to this valve. The hose end coupling screws into the valve with a gasket to create a reliable seal that prevents gas from escaping.

Service (Shut Off) Valve: Essentially the master switch to the propane supply, the service valve is the point at which propane gas enters the piping system to supply all the appliances that connect to it.

Float Gauge Assembly:The float gauge shows the volume of propane in the tank. Sometimes called a dial gauge, the float gauge is made of several parts: a mechanical float that lives inside the tank (much like the float you’d see if you lift the lid off your toilet’s water tank) connected to a reader on the outside of the tank that displays the liquid level (this may be a numeric gauge or a visual one color coding for safe, under-, and over-fill levels). It doesn’t show the exact amount of liquid in the tank, but it is reliable for everyday monitoring of your tank’s propane level.

To check the approximate propane level in your tank, look at the float gauge. It will be a round (or roundish) device on the tank (see image above) with a needle over a range of numbers or graphic indicators. The numbers will range from 5 to 95—indicating a percentage of volume, not the number of gallons remaining. If you see a level below 30, it means that your tank is getting low and needs to be refilled.

If you’re an AmeriGas customer, you may also have a remote tank monitor that automatically transmits the tank’s percentage to us every day. You can check your tank’s current status—without looking at your tank—by logging into your AmeriGas account.Learn more about our online services.

Relief Valve: This is the safety relief mechanism designed to vent propane in the event that pressure builds — for example, if the heat rises very suddenly to an extreme temperature (as might happen in a forest fire or other emergency situation). A spring inside the valve is designed to release if the pressure inside the tank builds to a certain level, at which point the valve will open slightly and start to hiss. If pressure rises excessively, the valve will open completely. The relief valve allows pressure to be released quickly and safely. All propane tanks are required by law to have a relief valve. You may also hear it called a pop-off valve or a pressure-venting valve.

FixedLiquid Level Gauge: Also known simply as a fixed liquid level gauge or the bleeder valve, this is the only tank component that gives a precise measure of how much liquid propane is in the tank. It’s used only by certified propane service providers when filling the tank — and even then, it’s used only to monitor, not to refill (propane goes into the tank through the fill valve).

Vapor Return Valve: Also known as the vapor equalizing connection or vapor equalization valve, this feature is required on all ASME propane tanks. They are usually deployed in the event that the liquid in the container becomes very overheated and must be evacuated from the container.

Liquid Withdrawal Valve: Used by technicians to withdraw liquid propane from the tank so it can be moved or disposed of. Note: Never attempt to remove liquid propane from a tank on your own. This should only be done by a professional using specialized equipment.

PropaneRegulator:Though they come in many shapes and sizes, the function of all propane regulators is the same — they maintain a safe and effective level of pressure on propane within the tank. This helps keep the flow steady and usable. These components make a persistent humming noise when operating — don’t worry, it’s normal.

You’re aware of what your tank should look like when it’s “all systems go” — as well as some important warning signs that will tell you it’s time to contact a professional. Armed with these basic terms and tips, you’re set up for propane success.

Safety Note: We do not recommend attempting any propane system adjustments, repairs, or maintenance on your own. Only certified propane professionals are equipped with the gear and knowledge to properly assess and address propane systems safely.Please contact us for more information and service.

We all know what time it is! It’s grilling season and that means lots of great food and family fun. Summer is a season full of fun activities, the great outdoors, and of course, BBQs. July is the peak month for grilling and according to the National Fire Protection Association’s (NFPA) “Home Grill Fires” report, “10,200 home fires are started by grills each year on average.” Something as simple as operating a grill can be disastrous if not handled safely and not paying attention to potential warning signs.

As we kick off summer, we want to make sure everyone has a good time and is safe when handling propane tanks. That’s why it’s important to be knowledgeable about proper propane safety standards for a fun and safe environment. Get your grill ready as we walk you through various potential safety hazards, how to check your propane tanks for leaks and how to properly store your propane tanks.

Overheated propane tank – overheated gas cylinders can be dangerous because the gas inside quickly expands when it’s heated, which causes extra pressure inside the cylinder. Propane tanks are very sturdy and it would take extreme heat for them to burst, so ideally, you want to store them outdoors and out of the direct sunlight.

Outdated recertification – Making sure your tank is within its certification date is important. It’s against the law to fill expired propane cylinders. Propane cylinders must be recertified after 12 years from the original date of manufacture and recertified cylinders are good for 5 years before re-inspection. Using outdated tanks are dangerous as they can contain leaks, rust, punctures or other hazards.

Leaking tank – Leaking propane tanks can be a huge hazard if it goes unnoticed. Gas leaks and oxygen mixed together are 2 of the 3 elements that can cause an explosion if combined. All it would take is a spark to ignite and cause combustion. If you do find a leak in your tank, immediately turn off the valve and call your propane supplier.

When checking for leaks you’ll need to spray a soapy solution onto all threaded connections and the valve stem. In addition, any area of the tank that has an oily stain is an area to check since leaking propane can cause an oily stain. If you see bubbles appear, whether or not the valve is open, you have a problem that needs to be addressed. If the bubbles are on the cylinder or valve our team can service it, otherwise replacement parts for the grill need to be obtained.

An additional signal that there is a leak in your tank is the smell of rotten eggs. A solution is added to propane tanks in case of leakage so that people could easily be made aware of the issue. Make sure your tank is turned off and unplugged from the hose and call your propane supplier to get your tank serviced.

Storing and inspecting your propane tanks properly will help reduce any potential accidents during your outdoor grilling festivities. Here’s are some tips to remember when handling a propane tank:

Always make sure to keep and use propane tanks outside and away from heat sources. You never want to keep it indoors (basement, garage, etc.) in case of potential leakage and increased temperatures.

Avoid enclosed areas with excess heat, more specifically where the temperature exceeds 120 degrees Fahrenheit and keep your tank in a well-ventilated area.

Propane cylinder valves used for barbeque grills have a safety feature that slows the flow of propane if it flows too fast. However, the excess flow valve can be triggered by allowing propane to flow too quickly in normal use. In order to avoid this problem, when starting your grille first shut off all of the burner controls, then open the propane cylinder valve slowly, then open one burner valve and light the grille. After that other burner controls can be opened.

Here at Wagner Welding Supply, we can inspect and recertify your propane cylinder, allowing it to be filled again. After recertification, propane cylinders must be requalified every 5 years in order to be refilled.

The great thing about getting your propane tank filled with us is you get a full 20lb fill. Grocery stores or home improvement stores only give you 15 lbs. We have great prices and make sure you’re going home with a certified tank. We can also fill your portable propane bottles including forklift bottles and motorhome propane tanks.

We also deliver. Our propane delivery area spans the Denver Metro area. We will provide you a delivery quote and answer any questions you may have. For additional information on propane tank fills or recertification, call us at (303) 776-1491 or get a quote online.

At Smart Touch Energy, we prioritize propane tank safety. Let"s take a closer look at some of the key questions surrounding propane tank safety and how you can minimize propane tank dangers.

Propane, also referred to as liquefied gas, is a popular fuel choice for individuals and businesses. It is delivered as a liquid and pumped into a storage tank, and it will not ignite with air until the ignition source reaches at least 920°F.

Furthermore, propane is 270 times more compact as a liquid than as a gas. As such, propane is easier to transport and store as a liquid than as a gas.

According to the National Propane Gas Association (NPGA), roughly 90 percent of the U.S. propane supply is produced domestically. The NPGA points out that propane serves many purposes, including:

The U.S. Energy Information Administration reported U.S. propane and propylene inventories hit 97.7 million barrels in September 2015 — their highest level in 22 years. This indicates the demand for propane is on the rise in the United States, a trend that may continue in the foreseeable future.

On its own, propane gas is non-toxic. It produces minimal emissions and is not harmful to soil or groundwater. It also is colorless and odorless, but many propane suppliers will add a chemical compound to give propane an unpleasant smell. By doing so, propane suppliers help alert customers if a propane tank leaks — which can be a major safety hazard.

A residential propane tank that leaks may emit gas quickly. Fortunately, the following steps will ensure you are fully prepared to handle this scenario:

When it comes to propane tank safety, it is always better to err on the side of caution. Thus, if you smell gas, you"ll want to act fast to minimize this danger. Otherwise, you may put yourself and others at risk.

In addition, it is important to note that some smell sensitivities or medical conditions could make it difficult to detect propane. In these cases, a gas detector for propane may prove to be valuable, as it will provide an additional layer of security.

Another element to keep in mind when it comes to propane tank safety is odor fade, or the unintentional reduction of propane odor concentration. One reason odor fade may occur is due to water, rust or air inside a propane tank. Additionally, odor fade may happen because the odor can stick to areas such as distribution and piping systems, as well as simply to the inside of the tank. Although this problem is rare, it may affect propane tanks that have been sitting too long before being filled.

Apply a layer of soapy water or a leak detector solution to the connection between the residential propane tank"s cylinder valve and regulator outlet.

If you discover bubbles, close the cylinder valve, tighten the connection and repeat the testing process. If bubbles continue to appear, it means there is a leak in the propane tank.

Avoid Space Heating Propane Grills or Ovens: Although space heating propane grills and ovens may seem like viable options at first, they can be dangerous.

Work With a Qualified Propane Service Technician: A qualified propane service technician can connect an appliance to a propane tank and perform the necessary assessments to ensure you can maximize the value of your appliance.

If you are ever uncertain about how to take care of a propane gas appliance, you can contact the appliance provider for extra assistance. This company will be able to address any of your concerns and questions and help you use your appliance safely.

Inspect Old Appliance Connectors:If an appliance is more than 20 years old, have a qualified service technician assess the appliance connector. If you try to do this on your own, you risk damaging the connector and causing a propane gas leak. If you work with a service technician, however, you may be able to avoid risk and bolster your appliance"s performance for years to come.

Check the Appliance Vents: Let the vents on your appliance breathe and ensure flue gases can flow easily to the outdoors. Remove any insects, bird nests or other debris from the vents. Clear the area around the appliance to ensure plenty of air can reach the burner for proper combustion.

Don"t Repair or Modify the Appliance on Your Own: If you attempt to modify, repair or replace an appliance connector, control, regulator or valve on your own, you risk causing a gas leak.

Propane tank safety extends beyond the tank itself, and those who focus on finding ways to take care of their propane gas appliances can manage risk like never before.

Of course, working with a qualified propane appliance service technician can help you keep your appliance in working order. This technician possesses the training and know-how needed to fix or upgrade an appliance safely.

A propane tank is complex, and you should never modify a propane tank on your own. If you believe your propane tank is defective, don"t try to modify or repair regulators, valves or other propane tank parts if you lack the proper training and expertise.

On the other hand, you may believe your outdoor appliance is problematic. Like propane tanks, outdoor appliances are intricate, so you may want to get expert help with appliance repairs.

Sometimes, the pilot light on an outdoor appliance may go out. If the pilot light goes out periodically, you should follow the appliance manufacturer"s instructions to reignite it correctly. Follow the instructions closely and review any safety warnings before you attempt to reignite the pilot light.

If an outdoor appliance"s pilot light goes out frequently, it likely indicates there is an issue with the appliance, and you should avoid the temptation to reignite the pilot light on your own. In this case, you should get expert help to reignite the pilot light.

If you try to reignite the pilot light on your own, you risk fire or explosion. Comparatively, a qualified propane service technician will do everything possible to fix the pilot light on your appliance and ensure the problem does not occur again.

Any time you have concerns or questions about a propane tankand/or outdoor appliance, reach out to your propane supplier and/or a qualified gas service technician for support. This will allow you to get the expert assistance you need and avoid putting yourself or others in danger.

If you find a propane tank leaks, you should never refill it. You’ll need to get the tank inspected by a qualified propane gas technician before it can be refilled.

It is against the law to refill a tank if it’s out of date. The most recent inspection date of a propane tank is printed on the side of the tank, and you should review this information before you try to have your tank refilled.

The law requires periodic inspection of propane tanks, and you should evaluate a propane tank at least once a month to identify any leaks. Remember, a diligent approach to propane tank safety can make a world of difference. If you allocate even a few minutes each month to inspect your propane tank, you can manage propane tank safety risks effectively.

You should never throw a propane tank away. Conversely, many municipal programs offer propane tank collection in cities and towns nationwide. Or, your propane supplier should be able to offer additional support so you can dispose of your propane tank properly.

How you store your residential propane tank is paramount. If you store your propane tank correctly, you will be able to reduce the risk of causing a leak.

Avoid Excess Heat: Heat builds up inside of a propane tank, and when this happens, the tank"s pressure relief valve may release propane. Therefore, you"ll want to keep your residential propane tank away from areas where temperatures reach 120°F or higher.

Disconnect the Propane Tank When Not in Use:A common scenario you might see is a propane tank connected to a barbecue. However, when the propane tank is not in use, ensure it’s disconnected from the barbecue or other appliance.

You should always store your propane tank outdoors and keep it in an upright position away from heat and direct sunlight. If you intend to use a propane tank that has been stored for a long time, be sure to look for signs of aging on the rubber tubing that links the propane tank to an appliance. If the rubber tubing is broken or cracked, you can replace it by purchasing new rubber tubing from a hardware store.

You should always move a propane tank in standing position. Ultimately, you"ll want to secure the propane tank with rope — not a metal chain. A metal chain could move around against the metal propane tank, creating sparks that could be disastrous. Meanwhile, rope is strong and sturdy and will help you keep the propane tank in place consistently.

When you travel, keep the windows of your vehicle open for added safety. You also will want to ensure the propane tank valve is locked and covered with a dust cap. And if the propane tank needs to be refilled, visit a filling station before you reach your final destination.

Believe it or not, running out of gas in your propane tank can be dangerous. Some of the most common problems that may arise due to an empty propane tank include:

Leaks:If the appliance valve or gas line of a propane tank remains open after the propane supply runs out, a leak may occur when the tank is refilled.

Rust Build-Up:Air and moisture can accumulate inside of an empty propane tank. This can result in rust build-up inside the propane tank, lowering the concentration of the odor of propane and making the gas more difficult to smell.

If the fuel level on your propane tank falls below 20 percent, you shouldcontact your fuel supplier for a refill. Setting up regular propane deliveries also may provide immediate and long-lasting benefits. The deliveries will ensure you"ll always have a full supply of propane on hand, so you"ll be able to use propane any time you choose.

An OPD prevents a propane tank from being overfilled. If a propane tank is overfilled, the tank won"t have sufficient space if liquefied gas expands in warm temperatures. As a result, a propane tank"s cylinder pressure will increase, which can create dangerous conditions.

Smart Touch Energy empowers customers with propane tank safety knowledge and insights. We also take the hassle out of ordering propane and help customers purchase energy products in an easy, convenient and cost-effective way.

Our useful FAQ is designed to be as clear as possible. If the information below does not answer your questions, please let us know by contacting us...

It is important to note that using propane gas driving is regulated country by country. Please consult with your manufacturer, a certified professional and the appropriate regulation before using gas while driving. GasStop can be used on your gas system while driving. Furthermore, GasStop can be installed alongside a crash sensor valve. A GasStop will offer protection against hose rupture/major leaks, a crash sensor valve will protect against collision. The two safety devices fulfil separate yet important functions.

GasStop offers up to 19 feet of protection against major leaks (0.31″ hose/pipe diameter) with an outlet pressure of 87 to 116 psi from your cylinder.

GasStop will completely (100%) and automatically shut off the supply of gas in the event of a major leak or catastrophic regulator failure. GasStop must be reset manually, giving the user complete control. An EFV (excess flow valve) is often a self-equalising, automatically set, flow limiter, and may not shut-off the flow of gas 100%. Many EFV’s do not have manual resets.

Always check your system for leaks before use. The GasStop pressure gauge is sensitive to minor drops in pressure, making it is a useful tool to use when performing a visual lock-up pressure test, also known as a pressure tightness test or pressure decay test. This test can only be carried outpriorto normal gas usage. During normal gas usage, GasStop will not shut off the system in the event of a minor leak. During normal gas usage GasStop will only shut off in the event of a major leak. To test your system for leaks:

Pump the pressure gauge on the GasStop up and down steadily at least 4 to 6 times. The longer the distance the gas has to travel in the pipe or hose, the more you will need to pump. If insufficient pressure has been created, the GasStop will keep shutting off the gas supply. Double check at this point that your appliance is still switched off.

The needle on the gauge should now indicate the gas pressure. If the needle is on zero, or below the red bar on the gauge, then the cylinder tap/valve is not open, GasStop has shut off, the gas has run out or you have not carried out sufficient pumping. Is the temperature around freezing? Please refer to theUseful Tipssection in your instruction booklet.

Now turn off the tap on the gas cylinder and register the exact position of the needle on the gauge. Wait 60 seconds forStandard Installationsand 5 minutes for longer gas systems (e.g RVs, caravans, motorhomes, boats and houses).

If installed correctly GasStop will only shut off if there is a major problem with your system e.g. a major leak or catastrophic regulator/system failure. If no major leak is present it may be that an inappropriate appliance or regulator is being used. If you are ever in doubt, contact a gas specialist before using your gas.

GasStop is made from high quality, surface treated brass and can withstand being left outdoors. Our gauge face is made from reinforced polycarbonate. As with any brass device, weathering will happen over the course of many years. To slow this process we highly recommend covering your GasStop when not in use.

Yes, GasStop is UL listed. Furthermore each and every GasStop is rigorously tested. All of our testing is evidenced via a global third-party test auditor.

Yes. GasStop is designed to be used with regulators rated at 1.5 kg/h and up to 20″ W.C. Please note GasStop will not work with some EFV (excess flow valve) regulators/connectors.

GasStop can be installed across a wide range of systems. Note that GasStop can only be used and installed as specified in the instructions. GasStop cannot be used on high pressure/high capacity appliances. GasStop is only to be used on a pressure regulated system rated at 1.5 kg/h and up to 20″ W.C.

The gas pressure gauge is a very useful, multipurpose tool.– The gauge indicates when the gas cylinder is almost empty (a decline in the vapour pressure curve). The gauge does not indicate the exact amount of LPG left in the cylinder. – A steady pressure reading only indicates that LPG is left in the cylinder. -If the needle is pointing to:

HIGH: Increased gas pressure GAS: Sufficient gas (steady pressure) LOW: Almost empty (approximately 30 minutes left of gas use) -As GasStop is directly installed into the bottle there are a few variables that can affect unregulated pressure, namely: temperature, amount of liquified gas vs rate of vaporisation, gas type and gas purity. There may also be other irregularities which affect the pressure reading. -As per the instructions, it is advised to run the gas for a small period of time to have a better indication of gas level. This allows the LPG/pressure to reach something called “phase equilibrium”. Further to this point there is a “vapour pressure curve”, this is why it is recommended to run the bottle for a short while to allow for this process.

Yes. GasStop can be used with an automatic or manual changeover gas pressure regulator, rated at 1.5 kg/h and up to 20″ W.C. A GasStop will need to be installed on each bottle attached to the changeover device.

GasStop will only shut-off in the event of a major leak. A major leak is defined as a sudden and dramatic change in the gas flow rate. GasStop is calibrated to shut-off at ≥125% of the guaranteed flow rate (UL requirement). If GasStop were to be calibrated to shut-off in the event of a minor leak, this would interfere with the ‘normal’ usage/consumption of your gas appliance(s) – GasStop would shut-off every time you use your appliance(s). We have therefore calibrated the device to shut-off for major leaks only. UL standards state that an LPG shut-off device must be calibrated as described above. GasStop will therefore not shut-off the supply of gas in the event of a minor leak.

You may notice that in colder temperatures (below 0oC/32oF), an EFV (GasStop) may shut-off more readily when used with higher demand appliances and/or on longer length pipework. For optimum results try where possible to use your LPG system above 0oC/32oF.

Always open the propane valves SLOWLY. As was mentioned above, there are safety devices built in to limit high flows in the event of a major leak. If the valve is opened quickly the rush of propane can trigger the flow limiters.

I have even found the above to be true on some newer propane grills. My SIL has a grill that never seemed to get really hot. It would heat, but not great. I"m rarely assigned as grill master. I sometimes lose focus = burnt offerings. As an experiment I opened the propane valve slowly and then lit the grill. The burner flames were noticeably better. I closed the lid for warm up. In a short time the resulting smoke and fire was impressive. The burners had never really been hot enough to burn off the accumulating grease... at least until the valve slowly opened experiment. Anyway, the grill masters have been opening the valve slowly ever since with good results.

8613371530291

8613371530291