how to reset safety valve on propane tank supplier

The owner of this website (www.doityourself.com) has banned the autonomous system number (ASN) your IP address is in (20473) from accessing this website.

The time has come and the epic barbecue dinner you had planned is in play as friends and family arrive. It’s time to fire up your barbecue grill and preheat it so you can begin cooking. Then you notice the flame is low, and that the grill is only heating up to 250 or 300 degrees Fahrenheit – or maybe it’s not even igniting!!! Don’t panic! There’s no need yet to call your local grill store to come out and fix it yet. This post may just save the day and some of your hard-earned money! …

* Side note about the shut down procedure. The following ignition sequences are written assuming you are turning the burners off 1st, then the Propane Tank. Therefore, each sequence starts from the “all off” positions. You can turn the burners off and leave the Propane Tank on; however, we strongly recommend you to go ahead and turn the Tank off also.

To put it simply, the key is to be sure you have your burners off before you turn on the Propane. If you turn the burners on first the gas will not be pressurized in the gas line causing the Bypass to trigger. You see, in this case the system detects there is a gas leak; hence, the bypass triggers.

* When using the improper sequence, the regulator will trip because by turning the burners on 1st, you empty the lines of any propane which causes the low line pressure.

If after having deployed this fix the issue persists, it’s time to call your local BBQ Grill Repair Company. There are numerous other more advanced issues that can occur. For instance, you may have a blockage in the Venturis Tubes. A blockage like this is caused by char/grease build-up. You can decrease the likely hood of this ever happening by being sure to have a BBQ Grill Cleaning done regularly.

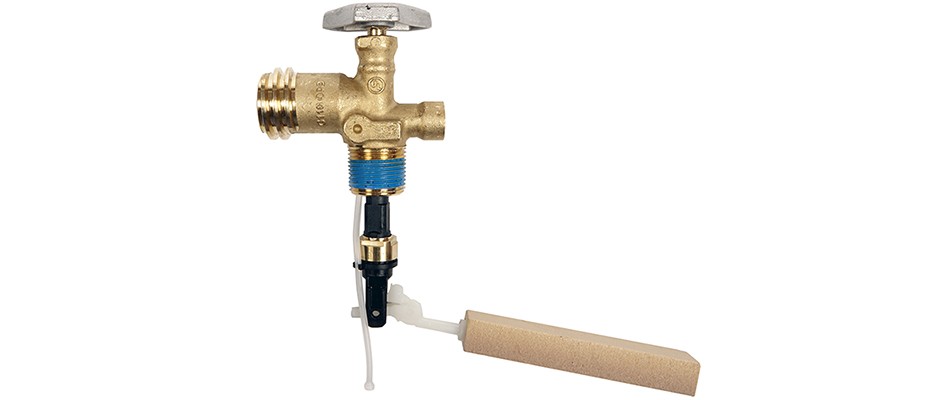

An OPD Cylinder Valve is indeed a part of your propane tanks’ inherent safety design. However, it does not have a “Bypass” as your regulator does, nor is it designed as a safety mechanism during usage. This device is required on all 4 to 40 pound DOT cylinders.

OPD stands for Overfilling Prevention Device and its first function is to do just that, prevent the user from overfilling the device. In addition, the device disallows Propane from flowing out of the cylinder if the triangular handwheel is opened and there is no gas line connected. It does this because there is no connected regulator to push open the valve’s orifice. Moreover, Propane OPD valves operate inside the bottle and are activated as the cylinders liquid propane rises in level pushing the float upward, therefore, stopping the flow of gas into the tank. This action is similar to that of a toilets float valve; once the water in the bowl rises to a certain level, the flow of water stops.

The OPD Valve is one of the main focuses regarding the fact that tanks are to be recertified 12 years after original manufacturer dates and every 5 years thereafter. Inside, there are what you can call “O-Rings” that need to be changed out at those predefined intervals. Also, the mechanism itself can be swapped out for a new one. Tampering with this device is NOT RECOMMENDED. If you suspect there’s an issue call your local propane delivery supplier and they will deal with it properly.

bottle feels heavier and obviously is filled with propane but opening the valve produces no escaping gas. OPD valves are designed so that propane will not flow from the service valve unless it is hooked up to a hose end connection.

Do you want to know how to reset the gas grill regulator? It can be because you turned the grill on to warm it up, hoping that the grill will be ready to cook by the time everyone arrives. Then you realized that the flame is weak, and the grill temperature only goes up to 250 or 300 degrees Fahrenheit. Started to panic? Read this to know the proper way to rest the gas grill regulator before calling your BBQ Grill Repair Company.

Why here? You’re right to think about why we have added a summary at the beginning of the article. The reason is, a glance will help you know that you’re at the right place to learn about regretting the propane regulators.

A gas grill regulator is a small device that is screwed onto an LPG or propane tank. It regulates the gas flow from the gas tank. It also includes a safety mechanism known as a bypass. The gas regulator consists of a ball and spring and automatically cuts off the gas supply when the hose is devoid of the back pressure.

Generally, it happens when there’s a leak. It can also be activated if the gas tank and one of the burners are turned on. You should turn off the gas tank and wait for a while before turning on the burners.

The grill regulators (or propane gas regulators) are a component of the gas grills that controls the gas flow from the fuel canister to the heating element. It also acts as a safety barrier between the high-pressure propane tank and the heating appliance.

In short, it brings the pressure of the propane down to a safe level. If the pressure is too low, the grill may not heat up. If it is too high, it may cause a flameout (or worse).

The regulator is bound to a propane tank to manage the gas flow to the burner of your grill. The higher the gas flow, the larger the flame, and thus the more heat. If the gas flow is low, the flame will be small, and the amount of heat will be low.

In addition, the regulator has what is called a bypass, which is a plastic mechanism that cuts off the gas supply when there is no pressure in the hose extending from the grill. This can be caused by a gas leak or by leaving the burners on for a long time.

All BBQ gas grills have a regulator, which, as the name implies, regulates the flow of propane gas. The regulator has a built-in safety mechanism called a bypass valve. This bypass valve system sits between the regulator and the propane tank.

Usually the system is in a locked state. This is the activated or tripped state of the safety mechanism. In some cases, this is caused by gas leakage, but in most cases, it is due to the user using an improper ignition method.

The safety device of gas regulators consists of a ball and a spring. The pressure from the propane tank pushes the ball against the spring. When it happens, a gas flow is established. If there’s a leakage or burners are left open, the reverse flow of the air pressure doesn’t let the ball displace from its position inside the regulator. As a result, propane from the LPG canister can’t pass through the safety device.

If you don’t light the grill in a certain way, the safety device will mistake it for a leak and reduce gas flow from the canister to less than 10% of normal. This condition is called “bypass.” When the gas supply is reduced, the grill cannot be brought up to its normal temperature, and in some cases, the grill will not light.

Wait a few seconds for the hose to build up pressure before doing anything else. This pressure will push the equipment in and give you the “all clear” to operate normally. It should be noted that allowing the pressure to build-up is the most significant part of the entire process.

After a short wait, turn the appropriate burner to start/high and press the igniter button to ignite, just as you would with a normal grill. The actual ignition method will vary depending on your particular model. Please refer to your owner’s manual for details.

Light all main burners, turn the temperature to high, and close the lid. After about 10-15 minutes, if the temperature reaches 500-550℃, the liquid propane grill is working properly.

Basically, the key is to always turn off the burner before you turn on the liquid propane tank valve. If you turn on the burner first, the gas won’t be pressurized in the gas line, and the bypass will be activated.

To the system, it looks like there is a leak, so the bypass is activated or triggered. (Even if there is no gas leak, the system will think there is a leak because of the low back pressure.)

Side note:If used in the wrong order, the regulator will trip. Turning the burner on first will empty the propane line, resulting in low line pressure.

In most cases, performing a propane regulator reset will get the job done for you. However, sometimes, especially if there’s a severe issue with the propane regulator, resetting the regulator isn’t the option, and you’ll have to replace it.

It’s not necessary the failure to ignition can indicate that you need to reset the regulator. In fact, low temperature can also be the reason for propane regulators in need of a reset.

Also, please note that the flame should always be blue. If it’s not and you’re constantly getting the yellow flame, it’s problematic, and you can go ahead either clean your burner tubes or reset the gas regulator.

If the gas regulators continuously trip, there may be a leak in the hose. Close the valve on the gas tank and disconnect the regulator and gas line from the propane tank. Immerse the regulator in a solution of soap and water, then attach the regulator and hose back to the gas container.

Make sure the burners on the grill are “off,” and the valve on the tank is turned on. Soap bubbles will indicate the location of any leakage in the regulator or hoses. Replace the regulator or hose as necessary.

Now that we know what the problem is with the propane regulator, let’s try to come up with a solution. Of course, this assumes that you have checked your gas container to see if it simply needs to be replaced with a new propane tank.

Slowly turn on the supply from the fuel container by rotating the valve counterclockwise.Make sure you do it veryslowlyto avoid tripping the regulator. It should take 20-30 seconds.

When it’s about cooking on your grill, a tip-top gas regulator can guarantee the constant flow of heat for your BBQ and save you from distress. The regulator reset call, however, needs the right identification of the problem first. It might be your grill regulator demands to be replaced, and working on the valves can be of no help. You can take the right steps by following this quick guide. Hence, if your grills fail to serve your outdoor cooking with sufficient temperature, follow this expert guide on how to reset the gas grill regulator.

If your Mosquito Magnet® fails to start, it may be the result of poor gas flow from the propane tank through the regulator to the trap. The Reset Tool has been designed to reset the internal mechanisms of the propane regulator and release any back pressure from your tank.

It is recommended that you do this procedure every time you connect the regulator to the propane tank to avoid any difficulty in the start up process.

My understanding is the safety is in the regulator, if there is to large of a flow of gas it trips and restricts it. That is why you need to turn the tank on with the burners off. If you can"t get the appliance to work shut the tank off while the burners are on then turn them off and the regulator should reset.

I thought that is why they went to the outside threads, because the old tanks with the internal threads you could turn on and gas would flow. I was always taught to open it and close it fast to make sure any dirt got blown out. when they went to the external thread the tank won"t flow unless it is hooked up. I never investigated what is in there that the new hook up triggers to allow the gas to flow.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

(1) Unless covered elsewhere in these Orders, every natural gas tank shall be provided with one or more spring-loaded safety relief valves set to open as follows with relation to the maximum allowable working pressure:Type of Vessel

All safety relief valves required by this Order shall be ASME labeled except for safety relief devices on DOT cylinders and safety relief valves as required in 537(c)(3), which may be ASME or Underwriters" Laboratories rated and stamped.

(2) Each safety relief valve shall be plainly marked by the manufacturer of the valve with the pressure in pounds per square inch at which the valve is set to start to discharge and the discharge capacity in cubic feet per minute (cfm) air.

(3) No shutoff valves shall be installed between the safety relief valves and the tank without written permission from the Division except that a shutoff valve may be used on multiple valve installations where the arrangement of the valves will provide full required flow through the safety relief valves at all times. The opening or connection between the tank and safety relief valve or valves shall have at least the combined areas of all connected safety relief valve inlets.

(4) Safety relief valves shall be so arranged that they will have an unobstructed full size discharge to a to a safe place, and shall be so arranged that escaping gas will not impinge on the vessel, valves or fittings.

(5) Except for safety valves that are integral with service valves, safety relief valves on tanks and cylinders shall be installed in a vertical position and shall be fitted with suitable raincaps.

(6) Safety relief valves for natural gas service shall not be fitted with lifting devices. The adjustment if external shall be provided with means for sealing the adjustment to prevent tampering by unauthorized persons. If at any time it is necessary to break such seal, the valve shall be removed from service until it has been reset and sealed. Any adjustments necessary to natural gas safety relief valves shall be made by the manufacturer or other companies having competent personnel and adequate facilities for the repair, adjustment and testing of such valves. The organization making such adjustment shall attach a permanent tag with the setting, capacity and date. All safety relief devices shall be tested at least annually and maintained in proper operating condition.

(7) If pressure regulators are used, a safety relief device shall be provided on the low-pressure side of each final stage regulator and on the low-pressure side of all other regulators unless the piping and/or fittings from the low-pressure side of such regulators to the high-pressure side of the next stage regulation are suitable for full tank pressure.

(8) Safety relief valves for surge tanks containing vapor only shall have a relieving capacity of not less than the maximum input from the system, vaporizer or reducing valves.

(10) On underground installations, the discharge from safety relief valves shall be vertically upward and shall be piped to a point at least 10 feet aboveground, and shall meet the requirements for the location of tanks as specified in Order 531(a)(1), (2) and (3).

(1) The minimum required rate of discharge of the safety relief valves for aboveground CNG tanks shall be at least equal to any input from the system, whether stored or being compressed.

(2) Safety relief valves located on stationary tanks of over 166,000 cubic feet capacity, shall be fitted with ferrous standpipes which will discharge at least 2 feet above the top of the tank, but not less than 10 feet above ground level. These standpipes shall not be threaded at the open end, and shall be fitted with suitable drain openings. Return bends and pipe fittings at the upper ends of safety relief valve discharge pipes are prohibited. Standpipes shall be adequately braced or otherwise supported if over 4 feet in length.

(1) The minimum relieving capacity of the safety relief valves for LNG tanks shall be at least equal to the capacity marking on the vessel nameplate required in 523(c)(4).

(2) Safety relief capacity shall be determined for exposure to external fire and shall be sufficient to prevent pressure in the tank from exceeding 120 percent of the allowable working pressure for tanks built with a factor of safety of less than 5 and 150 percent for tanks built with a factor of safety of 5 or more. For calculating, the applicable formula in Appendix A shall be used to determine minimum relieving capacity.

(3) Safety relief valves for underground LNG tanks shall have a relieving capacity at least equal to the relief valve capacity markings on the vessel nameplate. When the capacity is not based on exposure of the vessel to fire, such underground tanks shall not be uncovered until they are free of liquid.

(5) Safety relief valves located on stationary tanks over 2,000 gallons capacity shall be fitted with ferrous or suitable copper alloy standpipes which will discharge at least 2 feet above the top of the tank but not less than 10 feet above ground level. These standpipes shall not be threaded at the open end, and shall be fitted with suitable raincaps and shall be provided with a drain opening at their lower end unless the safety relief valves discharging into the standpipes are fitted with suitable drain openings. Return bends and pipe fittings at the upper ends of safety relief valve discharge pipes shall be prohibited. Standpipes shall be adequately braced or otherwise supported if over 4 feet in length.

(6) The outer tank of LNG vessels shall be provided with one or more relief devices set to open at not more than the maximum design working pressure of the outer tank. The discharge area shall be not less than .00024 square inch per pound of water capacity of the inner tank.

8613371530291

8613371530291