improved high lift safety valve pricelist

The Nabic Fig 500ST High Lift Safety Valve is ideal for installations where the media / service fluid being used would normally necessitate a stainless steel valve, but where the working environment does not. It is suitable for use with hot water, steam, air, plus other media - please contact us for more information on which fluids are suitable. The valve comes supplied as a sealed dome unit or with a test lever, this high-quality valve is designed and tested to BS EN ISO 4126-1 standard.

To ensure quality and accuracy of set pressure, all Nabic 500ST valves are shell and seal tested before dispatch, and are fitted with a tamper-proof seal.

As standard, the superb Nabic 500ST features a tough and durable PTFE design with high seat tightness, along with stainless steel wetted parts with PTFE to metal seating. It incorporates diaphragm protected working parts and offers the user easy inspection and cleaning. The 500ST offers a range of additional features, including padlocks (compliant with M&E3), Viton seat design, and more.

NABIC have long been recognised as the industry standard for commercial and industrial safety and relief valves for hot water applications. NABIC products are all UK made with castings from the UK and Europe. NABIC products do not have castings from the far east as with many of its competitors.

Flowstar (UK) Limited (Company Number: 01384915, VAT Number: GB 475 448 317) is the largest worldwide stockist of NABIC safety valves and NABIC relief valves. Our NABIC prices are genuine discounts off the official NABIC list price. We have not increased our prices before discounting as on some websites. If you buy NABIC valves on a regular basis we can offer further discount and will price match were possible.

Returns: You need to tell us if you wish to return un-used goods within 14 days of purchase either by phone or email. You then have a further 14 days to return the goods back to us. We aim to process the refund within a few days of receiving them. Please note we charge a 20% restocking fee. This is to cover the work originally carried out setting and testing the valve and also the work we will need to do on its return to get it ready for resale.

NABIC have long been recognised as the industry standard for commercial and industrial safety and relief valves for hot water applications. NABIC products are all UK made with castings from the UK and Europe. NABIC products do not have castings from the far east as with many of its competitors.

Flowstar (UK) Limited (Company Number: 01384915, VAT Number: GB 475 448 317) is the largest worldwide stockist of NABIC safety valves and NABIC relief valves. Our NABIC prices are genuine discounts off the official NABIC list price. We have not increased our prices before discounting as on some websites. If you buy NABIC valves on a regular basis we can offer further discount and will price match were possible.

Returns: You need to tell us if you wish to return un-used goods within 14 days of purchase either by phone or email. You then have a further 14 days to return the goods back to us. We aim to process the refund within a few days of receiving them. Please note we charge a 20% restocking fee. This is to cover the work originally carried out setting and testing the valve and also the work we will need to do on its return to get it ready for resale.

Four types of commonly used Boiler Safety Valves are: Dead weight safety valve, Spring loaded safety valve, Lever safety valve and High steam and low water safety valve. The choice of a particular type of safety valve for a boiler depends on the type of the boiler and its safe working pressure.Learn More

Choose from our selection of boiler safety valves, including over 60 products in a wide range of styles and sizes. In stock and ready to ship.Learn More

5/5 · Boiler systems have safety valves to protect them from over pressure operation due to any reason. These safety valves are provided in drum, superheater and reheater inlet andLearn More

For steam boilers, a small overpressure is required, usually 3% or 5%. For most other applications, 10% overpressure is required, but according to API 520, for special applications such as fire protection, larger valves with overpressures of 20% are allowed. For most types of safety valve, air or gas setting is permissible. A speciallyLearn More

1. Safety valve pressure setting can be done from high to low pressure or vice-versa. 2. Take necessary personal safety valve precaution and arrange tools i.e. gagging tool and master gauge. 3. Slowly raise the boiler pressure and blow off the safety valve manually few times for thermal expansion and to reduce the thermal stress on the valves. 4.Learn More

A second type of pressure relief valve which offers advantages in selected applications is the valves on boiler external piping, safety relief valves on.Learn More

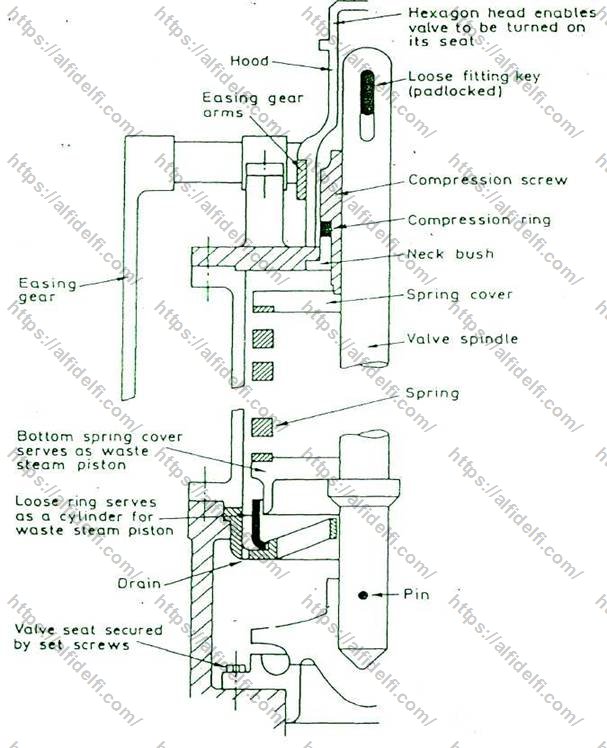

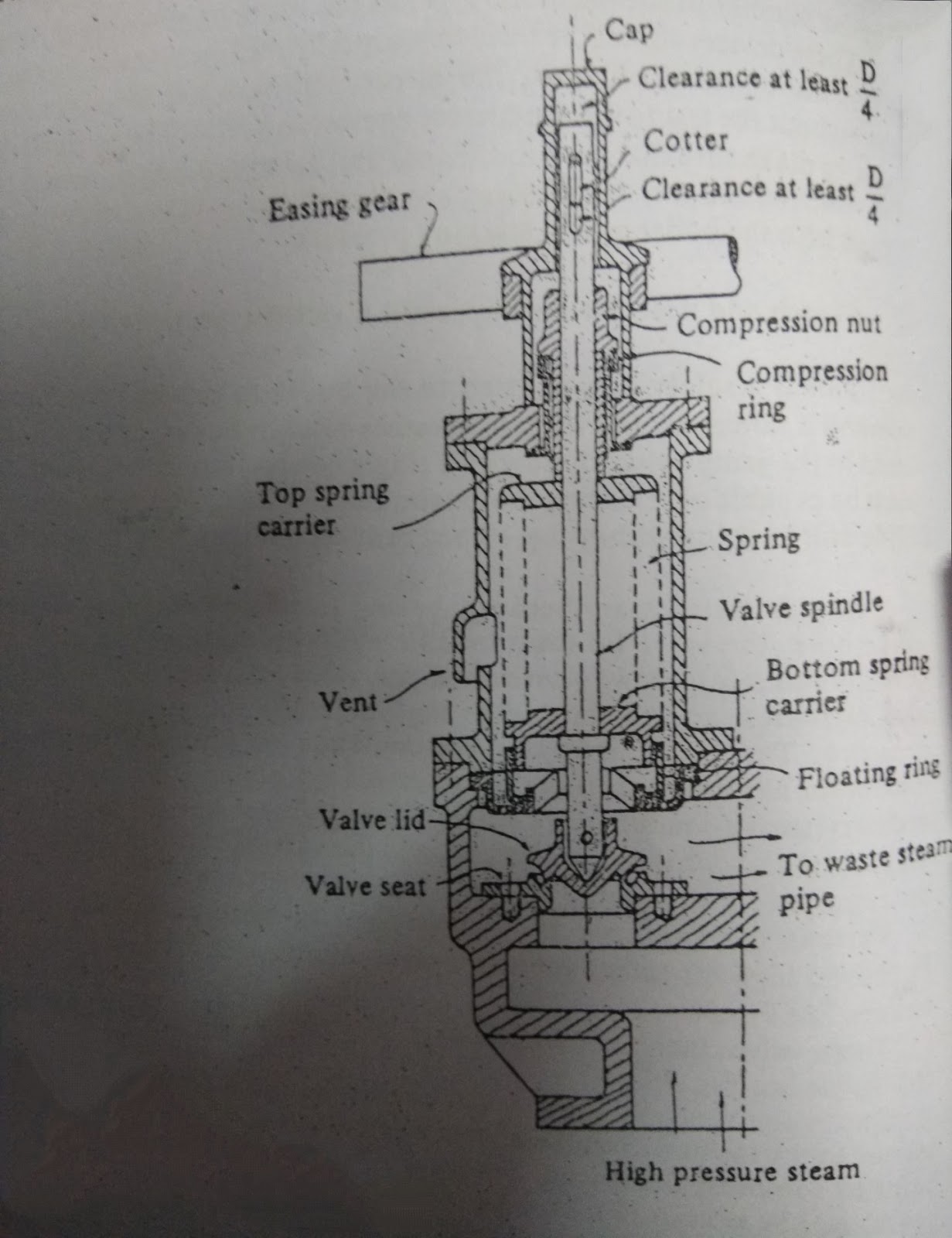

Safety valve can be classified according to the amount that the valve will lift against the spring pressure. · Ordinary Spring Loaded · High Lift · Improved High Lift · Full Lift · Full Bore Relay The area of the bore of the valve governs the theoretical maximum amount of steam that can pass through a valve of any design.Learn More

There are three main components of a safety valve: disc, nozzle, and spring. The total capacity of the safety valve must be more than the maximum flow capacity (MFC) of the safety valve in case steam valves fail to open. Most steam boilers connect two safety valves in it, but it may require a third safety valve if it does not exceed the MFC.Learn More

By increasing the operating pressure of the system beyond the specified, the safety valve (safety valve) stabilizes the pressure by discharging a volume of fluid out of the system. It is important that the safety valves perform their function under any circumstances and prevent Increase system pressure. Category: Boiler accessories. Description.Learn More

The safety valve for the boiler compensates for the expansion. arising when heating water. Thus, the work of the indirect water heater and the boiler are closely related. For this type of water heaters, it is required to choose a suitable safety valve. All the characteristics we need are listed in the technical data sheet of the device, soLearn More

The most commonly used safety valve is spring loaded safety valve. Below shows the constructions and working principle of a spring loaded safety valve.Learn More

2022/9/8 · FBC operation. Engineering of FBC boilers. Caustic gouging. Boiler water management. Boiler inspection -shut down. Alkali boil out. A coverage on safety valve. Student Portal. Behavioural Training Modules.Learn More

Safety valves are generally located on the steam drum of the boiler and open automatically when the inlet-side pressure of the valves exceedsLearn More

Safety Valve Which Automatically Discharges Steam and Safety Valves Fast Response 100% Customer Satisfaction at best prices in India. HP Valve Offers Types Of Air Safety Valve,Learn More

Safety Valves - A safety valve is a valve that acts as a fail-safe in a thermal-hydraulics plant. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. | PowerPoint PPT presentation | free to viewLearn More

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded andLearn More

How There are three main parts to the safety valve: nozzle, disc, and spring. Pressurized steam enters the valve through the nozzle and is then threaded to the boiler. The disc is the lid to the nozzle, which opens or closes depending on the pressure coming from the boiler. The spring is the pressure controller.Learn More

There are many Different Types of valves used in the industry like Gate Valve Globe Valve Y - Type Globe Valve Ball Valve Plug Valve Diaphragm Valves Reducing Valves Pinch Valve Butterfly Valve Needle Valve Check Valve Relief & safety valve Solenoid Valve Globe ValvesLearn More

Types of Safety Valves: · Dead weight safety valve. · Spring loaded safety valve · Lever loaded safety valve · High steam and low water safety valve · Spring loadedLearn More

Four types of safety valve that we can deal with are; Deadweight safety valve (i.e. Weight lies on top of pressure cooker) Lever-type safety valve Spring-loaded safety valve High steam and low water safety valve Steam Stop Valve Function A Steam stop valve has the function to regulate the flow of steam from the boiler to the steam pipe.Learn More

The spring type safety valve must have a device to prevent the screws and nuts from being turned randomly. The static weight safety valve must have a device to prevent the heavy piece from flying off. The globe valve on the inlet pipe of impulse type safety valves must be fully opened, locked or sealed. Reliable air and power sources should beLearn More

Spring loaded mechanically operating safety valve valves are used in boiler drum and super heater outlet. In addition to spring loaded safety valve ElectromaticLearn More

High performance safety valve for the protection of large boilers and The nozzle uses an austenitic stainless steel stabilised with Niobium,Learn More

ENTRADE Boiler Valves: We are valve specialists and have a wide range of valve types in particular Crown valves and Boiler Water level gauges. Safety valve - Wikipedia, the free encyclopedia. The two general types of protection encountered in industry are thermal such a spring balance could be applied to the considerable force of a boilerLearn More

There are also devices known as "safety relief valves" which have the characteristics of both types discussed above. Safety relief valves can be used for either liquid or gas or vapor service. Boiler Safety Valve Nameplate Requirements Safety valves require nameplates that contain important information about the device, including: CapacityLearn More

Dead weight safety valve,; Spring loaded safety valve,; Lever safety valve and; High steam and low water safety valve. The choice of a particular type of safetyLearn More

Marine Boiler [Part-1], Safety Valve. Safety valve are fitted to protect the boiler from over pressure. Type of boiler safety valve, marine auxiliary boiler and exhaust gas boiler setting of safety valve, accumulation pressure test, boiler safety valve set pressure, boiler safety valve working pressure , material used in construction of safetyLearn More

A safety valve is a valve mechanism for the automatic release of steam from the boiler of a steam locomotive, which helps prevent from a steam locomotive from exploding. Safety valves were first used on steam locomotives during the industrial revolution in the late-1800"s. Early boilers without them were prone to accidental explosion. They are equipped on just aboutLearn More

Safety Valve - This device is typically used for steam or vapor service. It operates automatically with a full-opening pop action and recloses when the pressure drops to a value consistent with the blowdown requirements prescribed by the applicable governing code or standard. Relief Valve - This device is typically used for liquid service.Learn More

Relief and safety Valves are used in high pressure systems to control the pressure and keep balance of the system. The different between safety valves and relief valves is that the safety valves fully open or close under a certain pressure while the relief valves can open in proportion to the pressure in front of them. The safety and pressure relief valves are used automatically. They both operate under similar conditions. When the pressure builds up in a system, it has to be managed by releasing the material to flow through. These valves have a threshold pressure at which they open. The consolidated safety and safety relief valves comprise of a bonnet vent and bellow with springs.

The springs are set up for the threshold pressure and when the pressure exceeds the threshold, the spring is pushed into the bonnet vent and the bellow opens the valve. The Safety Relief Valves can be open and shut valves. They either open or shut off at any given pressure. This is mostly for the safety of an application not to explode under high pressure. The Pressure Relief Valve on the other hand releases the material after the threshold pressure, but not fully. If the pressure is slightly higher the threshold, then the valve opens slightly. If the pressure is very high above the threshold, it opens wider. It also functions in the same manner when the pressure drops down. The valve closes in proportion to the pressure. The safety valve shuts down at once only when the pressure is below the threshold.

Ready Stock of ASTM A351 CF8M Spring Loaded Safety Valve in wide range of Sizes, Stainless Steel Air Compressor Pressure Relief Valve Manufacturers In India

Relief Valves are designed to control pressure in a system While Safety Valves are used for controlling the pressure in a system they release pressure immediately in the event of an emergency or system failure

The Setpoint of relief valve is usually set at 10 Percent above working pressure limit while safety valve is usually set at 3% above working pressure limit.

If you are operating systems that can only be off for short periods of time, it is sensible to keep a spare valve to swap over and then the removed valve can be inspected and recertified.

Safety valves or pressure relief valves are pressure regulating devices that are responsible for expelling excess pressure from the system when the maximum pressure levels for which they have been designed are exceeded, usually due to a

Safety valves perform their function when the pressure of the system where the fluid is contained, becomes higher than the maximum set pressure of the valve previously adjusted. When the system pressure is higher than the valve’s set

pressure, this opens, releasing the excess pressure to the atmosphere or to containment tanks, depending on the toxicity of the fluid. After releasing the excess, the valve closes again and the system pressure returns to normal.

To ensure total safety of personnel and installation, make sure that the valves have passed all safety tests and meet the requirements of the system where they are to be installed. All our valves are supplied with certificates of materials, cas-

What is the difference between the instantaneous full opening safety valve AIT (PSV) and the normal opening relief valve AN or progressive opening relief valve AP (PRV)?

The Pressure Safety Valve (PSV) opens instantaneously and fully upon reaching the set pressure for which it is designed, expelling the excess pressure from the system immediately. They are optimised for use with steam or gases.

In contrast, the normally or progressively opening Pressure Relief Valve (PRV) opens gradually as the system pressure rises above the set pressure of the valve above its setting. They are optimised to work with liquids.

At VYC Industrial we are specialists in the design and manufacture of all types of safety valves. We have a wide range of safety valves to cover all the needs of the sector.

The Mod. 496 EN safety valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The Mod. 495 EN pressure relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The relief valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open, at the fi rst proportional to the pressure increase, and after instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open proportional to the pressure increase.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

The valve works as an automatic pressure releasing regulator activated by the static pressure existing at the entrance to the valve and is characterized by its ability to open instantly and totally.

They are used in places such as power, chemical and petrochemical plants to discharge safety valves, control valves, etc. in pressure lines and equipment that convey compressible substances such as steam, air, carbon dioxide, helium, methane, nitrogen, oxygen and other gases.

Test bench for regular inspections and setting and resetting safety valves. Ideal for distributors, maintenance companies or with in-house maintenance. It allows safety valves to be adjusted, tested and/or checked to the test pressure (setting) Pe wile cold (simulating service conditions), matching the opening pressure Ps and the closing pressure Pc, in accordance with the standard regulations.

Controlled safety pressure relief system CSPRS valves are mainly used where conventional direct-loaded spring action valves cannot guarantee the opening and closing margins that certain specifi c conditions of service demand.

The objective is to help the closure by means of pressure so that the valve remains completely watertight until reaching the set pressure and/or to activate the opening with pressure.

Increase the operating pressure of the system up to 99.9% of the set pressure.The control safety pressure relief system CSPRS device can be used with any safety valve available in the market and in particular, with models VYC Mod. 485, 486, 494, 495 and 496.

There is a wide range of safety valves available to meet the many different applications and performance criteria demanded by different industries. Furthermore, national standards define many varying types of safety valve.

The ASME standard I and ASME standard VIII for boiler and pressure vessel applications and the ASME/ANSI PTC 25.3 standard for safety valves and relief valves provide the following definition. These standards set performance characteristics as well as defining the different types of safety valves that are used:

ASME I valve - A safety relief valve conforming to the requirements of Section I of the ASME pressure vessel code for boiler applications which will open within 3% overpressure and close within 4%. It will usually feature two blowdown rings, and is identified by a National Board ‘V’ stamp.

ASME VIII valve- A safety relief valve conforming to the requirements of Section VIII of the ASME pressure vessel code for pressure vessel applications which will open within 10% overpressure and close within 7%. Identified by a National Board ‘UV’ stamp.

Full bore safety valve - A safety valve having no protrusions in the bore, and wherein the valve lifts to an extent sufficient for the minimum area at any section, at or below the seat, to become the controlling orifice.

Conventional safety relief valve -The spring housing is vented to the discharge side, hence operational characteristics are directly affected by changes in the backpressure to the valve.

Balanced safety relief valve -A balanced valve incorporates a means of minimising the effect of backpressure on the operational characteristics of the valve.

Pilot operated pressure relief valve -The major relieving device is combined with, and is controlled by, a self-actuated auxiliary pressure relief device.

Power-actuated safety relief valve - A pressure relief valve in which the major pressure relieving device is combined with, and controlled by, a device requiring an external source of energy.

Standard safety valve - A valve which, following opening, reaches the degree of lift necessary for the mass flowrate to be discharged within a pressure rise of not more than 10%. (The valve is characterised by a pop type action and is sometimes known as high lift).

Full lift (Vollhub) safety valve -A safety valve which, after commencement of lift, opens rapidly within a 5% pressure rise up to the full lift as limited by the design. The amount of lift up to the rapid opening (proportional range) shall not be more than 20%.

Direct loaded safety valve -A safety valve in which the opening force underneath the valve disc is opposed by a closing force such as a spring or a weight.

Proportional safety valve - A safety valve which opens more or less steadily in relation to the increase in pressure. Sudden opening within a 10% lift range will not occur without pressure increase. Following opening within a pressure of not more than 10%, these safety valves achieve the lift necessary for the mass flow to be discharged.

Diaphragm safety valve -A direct loaded safety valve wherein linear moving and rotating elements and springs are protected against the effects of the fluid by a diaphragm

Bellows safety valve - A direct loaded safety valve wherein sliding and (partially or fully) rotating elements and springs are protected against the effects of the fluids by a bellows. The bellows may be of such a design that it compensates for influences of backpressure.

Controlled safety valve - Consists of a main valve and a control device. It also includes direct acting safety valves with supplementary loading in which, until the set pressure is reached, an additional force increases the closing force.

Safety valve - A safety valve which automatically, without the assistance of any energy other than that of the fluid concerned, discharges a quantity of the fluid so as to prevent a predetermined safe pressure being exceeded, and which is designed to re-close and prevent further flow of fluid after normal pressure conditions of service have been restored. Note; the valve can be characterised either by pop action (rapid opening) or by opening in proportion (not necessarily linear) to the increase in pressure over the set pressure.

Direct loaded safety valve -A safety valve in which the loading due to the fluid pressure underneath the valve disc is opposed only by a direct mechanical loading device such as a weight, lever and weight, or a spring.

Assisted safety valve -A safety valve which by means of a powered assistance mechanism, may additionally be lifted at a pressure lower than the set pressure and will, even in the event of a failure of the assistance mechanism, comply with all the requirements for safety valves given in the standard.

Supplementary loaded safety valve - A safety valve that has, until the pressure at the inlet to the safety valve reaches the set pressure, an additional force, which increases the sealing force.

Note; this additional force (supplementary load), which may be provided by means of an extraneous power source, is reliably released when the pressure at the inlet of the safety valve reaches the set pressure. The amount of supplementary loading is so arranged that if such supplementary loading is not released, the safety valve will attain its certified discharge capacity at a pressure not greater than 1.1 times the maximum allowable pressure of the equipment to be protected.

Pilot operated safety valve -A safety valve, the operation of which is initiated and controlled by the fluid discharged from a pilot valve, which is itself, a direct loaded safety valve subject to the requirement of the standard.

The common characteristic shared between the definitions of conventional safety valves in the different standards, is that their operational characteristics are affected by any backpressure in the discharge system. It is important to note that the total backpressure is generated from two components; superimposed backpressure and the built-up backpressure:

Subsequently, in a conventional safety valve, only the superimposed backpressure will affect the opening characteristic and set value, but the combined backpressure will alter the blowdown characteristic and re-seat value.

The ASME/ANSI standard makes the further classification that conventional valves have a spring housing that is vented to the discharge side of the valve. If the spring housing is vented to the atmosphere, any superimposed backpressure will still affect the operational characteristics. Thiscan be seen from Figure 9.2.1, which shows schematic diagrams of valves whose spring housings are vented to the discharge side of the valve and to the atmosphere.

By considering the forces acting on the disc (with area AD), it can be seen that the required opening force (equivalent to the product of inlet pressure (PV) and the nozzle area (AN)) is the sum of the spring force (FS) and the force due to the backpressure (PB) acting on the top and bottom of the disc. In the case of a spring housing vented to the discharge side of the valve (an ASME conventional safety relief valve, see Figure 9.2.1 (a)), the required opening force is:

In both cases, if a significant superimposed backpressure exists, its effects on the set pressure need to be considered when designing a safety valve system.

Once the valve starts to open, the effects of built-up backpressure also have to be taken into account. For a conventional safety valve with the spring housing vented to the discharge side of the valve, see Figure 9.2.1 (a), the effect of built-up backpressure can be determined by considering Equation 9.2.1 and by noting that once the valve starts to open, the inlet pressure is the sum of the set pressure, PS, and the overpressure, PO.

In both cases, if a significant superimposed backpressure exists, its effects on the set pressure need to be considered when designing a safety valve system.

Once the valve starts to open, the effects of built-up backpressure also have to be taken into account. For a conventional safety valve with the spring housing vented to the discharge side of the valve, see Figure 9.2.1 (a), the effect of built-up backpressure can be determined by considering Equation 9.2.1 and by noting that once the valve starts to open, the inlet pressure is the sum of the set pressure, PS, and the overpressure, PO.

Balanced safety valves are those that incorporate a means of eliminating the effects of backpressure. There are two basic designs that can be used to achieve this:

Although there are several variations of the piston valve, they generally consist of a piston type disc whose movement is constrained by a vented guide. The area of the top face of the piston, AP, and the nozzle seat area, AN, are designed to be equal. This means that the effective area of both the top and bottom surfaces of the disc exposed to the backpressure are equal, and therefore any additional forces are balanced. In addition, the spring bonnet is vented such that the top face of the piston is subjected to atmospheric pressure, as shown in Figure 9.2.2.

The bellows arrangement prevents backpressure acting on the upper side of the disc within the area of the bellows. The disc area extending beyond the bellows and the opposing disc area are equal, and so the forces acting on the disc are balanced, and the backpressure has little effect on the valve opening pressure.

Bellows failure is an important concern when using a bellows balanced safety valve, as this may affect the set pressure and capacity of the valve. It is important, therefore, that there is some mechanism for detecting any uncharacteristic fluid flow through the bellows vents. In addition, some bellows balanced safety valves include an auxiliary piston that is used to overcome the effects of backpressure in the case of bellows failure. This type of safety valve is usually only used on critical applications in the oil and petrochemical industries.

Since balanced pressure relief valves are typically more expensive than their unbalanced counterparts, they are commonly only used where high pressure manifolds are unavoidable, or in critical applications where a very precise set pressure or blowdown is required.

This type of safety valve uses the flowing medium itself, through a pilot valve, to apply the closing force on the safety valve disc. The pilot valve is itself a small safety valve.

The diaphragm type is typically only available for low pressure applications and it produces a proportional type action, characteristic of relief valves used in liquid systems. They are therefore of little use in steam systems, consequently, they will not be considered in this text.

The piston type valve consists of a main valve, which uses a piston shaped closing device (or obturator), and an external pilot valve. Figure 9.2.4 shows a diagram of a typical piston type, pilot operated safety valve.

The piston and seating arrangement incorporated in the main valve is designed so that the bottom area of the piston, exposed to the inlet fluid, is less than the area of the top of the piston. As both ends of the piston are exposed to the fluid at the same pressure, this means that under normal system operating conditions, the closing force, resulting from the larger top area, is greater than the inlet force. The resultant downward force therefore holds the piston firmly on its seat.

If the inlet pressure were to rise, the net closing force on the piston also increases, ensuring that a tight shut-off is continually maintained. However, when the inlet pressure reaches the set pressure, the pilot valve will pop open to release the fluid pressure above the piston. With much less fluid pressure acting on the upper surface of the piston, the inlet pressure generates a net upwards force and the piston will leave its seat. This causes the main valve to pop open, allowing the process fluid to be discharged.

When the inlet pressure has been sufficiently reduced, the pilot valve will reclose, preventing the further release of fluid from the top of the piston, thereby re-establishing the net downward force, and causing the piston to reseat.

Pilot operated safety valves offer good overpressure and blowdown performance (a blowdown of 2% is attainable). For this reason, they are used where a narrow margin is required between the set pressure and the system operating pressure. Pilot operated valves are also available in much larger sizes, making them the preferred type of safety valve for larger capacities.

One of the main concerns with pilot operated safety valves is that the small bore, pilot connecting pipes are susceptible to blockage by foreign matter, or due to the collection of condensate in these pipes. This can lead to the failure of the valve, either in the open or closed position, depending on where the blockage occurs.

The terms full lift, high lift and low lift refer to the amount of travel the disc undergoes as it moves from its closed position to the position required to produce the certified discharge capacity, and how this affects the discharge capacity of the valve.

A full lift safety valve is one in which the disc lifts sufficiently, so that the curtain area no longer influences the discharge area. The discharge area, and therefore the capacity of the valve are subsequently determined by the bore area. This occurs when the disc lifts a distance of at least a quarter of the bore diameter. A full lift conventional safety valve is often the best choice for general steam applications.

The disc of a high lift safety valve lifts a distance of at least 1/12th of the bore diameter. This means that the curtain area, and ultimately the position of the disc, determines the discharge area. The discharge capacities of high lift valves tend to be significantly lower than those of full lift valves, and for a given discharge capacity, it is usually possible to select a full lift valve that has a nominal size several times smaller than a corresponding high lift valve, which usually incurs cost advantages.Furthermore, high lift valves tend to be used on compressible fluids where their action is more proportional.

In low lift valves, the disc only lifts a distance of 1/24th of the bore diameter. The discharge area is determined entirely by the position of the disc, and since the disc only lifts a small amount, the capacities tend to be much lower than those of full or high lift valves.

Except when safety valves are discharging, the only parts that are wetted by the process fluid are the inlet tract (nozzle) and the disc. Since safety valves operate infrequently under normal conditions, all other components can be manufactured from standard materials for most applications. There are however several exceptions, in which case, special materials have to be used, these include:

Cast steel -Commonly used on higher pressure valves (up to 40 bar g). Process type valves are usually made from a cast steel body with an austenitic full nozzle type construction.

For all safety valves, it is important that moving parts, particularly the spindle and guides are made from materials that will not easily degrade or corrode. As seats and discs are constantly in contact with the process fluid, they must be able to resist the effects of erosion and corrosion.

The spring is a critical element of the safety valve and must provide reliable performance within the required parameters. Standard safety valves will typically use carbon steel for moderate temperatures. Tungsten steel is used for higher temperature, non-corrosive applications, and stainless steel is used for corrosive or clean steam duty. For sour gas and high temperature applications, often special materials such as monel, hastelloy and ‘inconel’ are used.

A key option is the type of seating material used. Metal-to-metal seats, commonly made from stainless steel, are normally used for high temperature applications such as steam. Alternatively, resilient discs can be fixed to either or both of the seating surfaces where tighter shut-off is required, typically for gas or liquid applications. These inserts can be made from a number of different materials, but Viton, nitrile or EPDM are the most common. Soft seal inserts are not generally recommended for steam use.

Standard safety valves are generally fitted with an easing lever, which enables the valve to be lifted manually in order to ensure that it is operational at pressures in excess of 75% of set pressure. This is usually done as part of routine safety checks, or during maintenance to prevent seizing. The fitting of a lever is usually a requirement of national standards and insurance companies for steam and hot water applications. For example, the ASME Boiler and Pressure Vessel Code states that pressure relief valves must be fitted with a lever if they are to be used on air, water over 60°C, and steam.

A test gag (Figure 9.2.7) may be used to prevent the valve from opening at the set pressure during hydraulic testing when commissioning a system. Once tested, the gag screw is removed and replaced with a short blanking plug before the valve is placed in service.

The amount of fluid depends on the particular design of safety valve. If emission of this fluid into the atmosphere is acceptable, the spring housing may be vented to the atmosphere – an open bonnet. This is usually advantageous when the safety valve is used on high temperature fluids or for boiler applications as, otherwise, high temperatures can relax the spring, altering the set pressure of the valve. However, using an open bonnet exposes the valve spring and internals to environmental conditions, which can lead to damage and corrosion of the spring.

When the fluid must be completely contained by the safety valve (and the discharge system), it is necessary to use a closed bonnet, which is not vented to the atmosphere. This type of spring enclosure is almost universally used for small screwed valves and, it is becoming increasingly common on many valve ranges since, particularly on steam, discharge of the fluid could be hazardous to personnel.

Some safety valves, most commonly those used for water applications, incorporate a flexible diaphragm or bellows to isolate the safety valve spring and upper chamber from the process fluid, (see Figure 9.2.9).

... -start valve with Series MX2 air treatment units without the need for additional connection interfaces. The soft-start valve is positioned upstream of the safety valves, ...

Two hands safety valve, which allows a safety use of two hands pneumatic controls (for example two push-button 3/2 N.C. to a certain distance) excluding false signals in case of push-button ...

The SI2 safety valve prevents the allowed operating pressure from being exceeded by more than 10%. If, after opening, the adjusted response pressure falls ...

... stainless steel full-lift clean service safety valve designed to AD Merkblatt A2 and TRD 421 standards and suitable for pure steam, vapour and inert gases.

Insert style flow control valves are comprised of a precision orifice in parallel with a check valve, combined into a single component. Each is designed for easy installation into metal housings using ...

Press-in style flow control valves are comprised of a precision flow orifice in parallel with a check valve, combined into a single component. Each part is designed for easy installation into plastic ...

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for you. With a pe of ...

... have been type tested as well. These pressure regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, or even biologically produced methane. It has AISi ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses and/or injured ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

Excavator pipe-rupture valves prevent uncontrolled cylinder movement in the event that a pipe or hose bursts. The ESV valve fulfills all of the requirements of the ISO 8643 and EN 474-5 standards for ...

Material: Body- CF8M; Valve Seat- CF8M Métal Seat, PTFE Soft Seat available Orifice Size: fc"(15mm), 3/4M(20mm), l"(25mm), l1/4,’(32mm)I ltë”(40mm), ...

The Safety valves from ATOS are designed to guarantee protection for application on various devices, especially those that monitor spool position. They are also recommended for hydraulic ...

safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India

safety valve, safety relief valve, pressure relief valves, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve

safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

We provide superior quality valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are specially designed to offer high durability and optimum performance. Using materials like pure aluminum, cast iron and stainless steel trim these valves are made to high resistance to temperature and corrosion. Functionally different valves like Safety Valve, Safety Relief Valve, Pressure Reducing Valves, Breather Valves, Globe & Ball Valves, Pipeline Specialty Valves, Flush Bottom Valves and Float Valves are available with us.

Fluidyne carried out an extensive market research to manufature durable and effective safety relief valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves that are highly suitable for most chemical, petrochemical, oil, pharmaceutical, phartilizer, power industries and more. These industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves have high reliability and are approved by factory inspectors, inspectors under Indian Boiler Regulation (IBR), B.V., Lloyds and Chief Controller of Explosives. Citizen Metal safety and relief valves are in used in above industries for over 50 years.Flanged Safety Relief Valves

Our range of small bore safety valves, industrial safety relief valves, flanged safety relief valves, industrial safety valves, flanged safety valves offer superior performance and maximum functionality. They are available in Screwed, Socket weld, Flanged Construction type or flanged-inlet, Screwed-outlet connection type. Their simplicity in construction makes them pretty cost effective and easy to use.

For Storage Tank, complete range of sizes :- 15 NB to 600 NB Flame and Detonation Arresters, Spark Arresters Free-Emergency-Conservation Vents Dip Gauges and Gauge HatchsVent nuts/Caps, Syphon bush, Fill caps, Lightning Arresters etc. Tyrus Valve, Vacuum Relief, Pressure Relief Valves. Available in : CS, CI, SS304, 316, AI etc. For more details on Tank Fittings, Flame / Spark Aresstors plz refer our section on "Safety Fittings"

Model PV - 1230 is one of our specially designed range of relief valves that has got connection flanged pallets of Al or Stainless Steel. This model comes with a tank accessory that is suitable for storage of chemicals and hydrocarbons. Model Pv 1230 is most suitable for low pressure and low vacuum operations.

Designed mostly like model PV 1220 our PV - 1240 range of vauts also offer high performance & durability. These efficient valves are commonly suitable for vacuum service. The disc available with these vaults is either weight loaded or spring loaded.

Safety Valves are designed and manufactured to meet the requirement of all a variety of applications as per API 526 and API 520. They also conforms to Standard VIII and the design requirement of Indian Boiler Regulations, they are of Full Lift type direct spring loaded, with a top guide, The full nozzle has the eliminating distortion of the seating surface, as body strain is not transmitted The Nozzle is made from a corrosion resistance stainless Steel material, When closed position, the fluid does not come in contact with the valve Body an therefore only subject to the outlet pressure which is very much lower pressure.

Similar to FTVC-520, but with closed bonnet & closed cap. Also available with same sizes and rating as FTVC - 520.Close Bonnet Safety Valve For Steam Application

Full lift safety relief valve, offers the combination of top guiding and unobstructed seat bore, producing a valve with maximum discharge capacity. Supplied with certificate confirming set lift pressure.

Tag : safety valves, Safety Relief Valve, Industrial Safety Relief Valve, Safety Relief Valve Dealers, Safety Relief Valve Distributors, Safety Relief Valve Exporters, Safety Relief Valve Suppliers, Safety Relief Valve Manufacturers in india, Safety Relief Valve Price in India, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

Safety Relief Valves, Stainless Steel Forged Steel 304 Valve, Stainless Steel F321 Safety Relief Valves, F347 Safety Relief Valves, SS High Pressure Safety Relief Valves, Class 150, 300, 600, 900, 1/2 inch stainless steel Safety Relief Valves, 1/2" stainless steel Safety Relief Valves, 3/4 Size Safety Relief Valves, 4 inch stainless steel Safety Relief Valves, Industrial Safety Relief Valves, Stainless Steel 316 Safety Relief Valves Suppliers in India...Read more

Alloy Steel Safety Relief Valves, Chrome Moly Alloy A217 / SA217 Cast Valves, WC9 Alloy Steel Globe Valve, 4 Inch, 2500#, A350 LF3, A352 LC3, A182 F5A/F5, A217 C5, A182 F9, A217 C12, A182 F11, A217 WC6, A182 F22, A217 WC9, A182 F91, A217 C12A, 10 Inch, RF, WC9 Gate Valve, PSB, 12 Inch, 2500 LB, Alloy Steel Valves Dealers & Distributors in India.. Read more

Safety Relief Valves, Carbon Steel Safety Relief Valves, Carbon Steel Valve Material, ASTM A350 LF2 Safety Relief Valves, Carbon Steel ASTM A106 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34 ASTM A105N Safety Relief Valves, Cast Carbon Steel Safety Relief Valves, API 600 Cast Steel Safety Relief Valves, Forged Carbon Steel Safety Relief Valves Exporters & Suppliers In India.. Read more

Hastelloy Safety Relief Valves, Hastelloy C276 Safety Relief Valves, Hastelloy C22 Safety Relief Valves, Hastelloy B2 Safety Relief Valves, Hastelloy C276/C22 Valves, ASTM B 435 Hastelloy X Safety Relief Valves, Hastelloy B2 Safety Relief Valves, ASME B16.34 Safety Relief Valves, UNS N10665 Hastelloy B2 Safety Relief Valves, UNS N10276 Hastelloy C276/C22 Manufacturer / Suppliers in Mumbai India. Read more

Wholesale Various High Quality Industrial Safety Relief Valves Products from Citizen Metals, Largest Suppliers of Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Dealers, Alloy 20 Check Valve, UNS N08020 Alloy 20 Safety Relief Valves, Alloy 20 Safety Relief Valves Suppliers, Alloy 20 Safety Relief Valves Manufacturer, Alloy 20 Safety Relief Valves Manufacturers in India. Read more

We supply broad range of Nickel 200/201 Safety Relief Valves, Leading Suppliers of Nickel 200/201 Valves, Ni-200 Safety Relief Valves, Ni-201 Safety Relief Valves, Uns N02200 Safety Relief Valves, Uns N02201 Safety Relief Valves, Nickel 200/201 Safety Relief Valves Dealers, Safety Relief Valves Suppliers, Nickel 200/201 Safety Relief Valves Manufacturer, Nickel 200/201 Safety Relief Valves Manufacturers in India. Read more

we supply Monel 400 Valves with high quality and best affordable rate., Monel 400 Safety Relief Valves, Monel DIN 2.4360, 2.4375 Safety Relief Valves, Monel UNS N04400 Safety Relief Valves, Monel UNS N05500 Safety Relief Valves, Monel Safety Relief Valves, Monel K500 Safety Relief Valves, Monel 400 Safety Relief Valves Distributors in India... Read more

We specialize in the oil & gas industries and offer specialty Duplex Steel Safety Relief Valves, UNS S31803 Safety Relief Valves Suppliers in India, DIN 1.4410 Super Duplex Steel Safety Relief Valves, ASME B 16.10 UNS S32760 Safety Relief Valves, ASTM A351 Duplex Steel UNS S31803, ASME SA494 Duplex Steel UNS S31803, Duplex Steel UNS S31803 Class 900 Safety Relief Valves Exporters in India. Read more

Safety Relief Valves, 254 Smo Safety Relief Valves, Cryogenic 254 SMO gate valve, ASME B16.34 SS 254 SMO Safety Relief Valves, Stainless Steel 254 SMO Safety Relief Valves, ASTM A351 SS SMO 254 Safety Relief Valves, ASME B 16.10, ASME B 16.5, ASME B 16.25, ASME B 16.34, 254 SMO Industrial Valves, Stainless Steel 254SMO Safety Relief Valves Suppliers in India.. Read more

Safety Relief Valves, 904l Stainless Steel Safety Relief Valves, 904l Stainless Steel Industrial Safety Relief Valves, SS 904L ASTM A351 Safety Relief Valves, ASME B 16.10 Safety Relief Valves, ASME B 16.5, ASME B 16.25, ASME B 16.34, UNS N08904, 1.4539, BS 904S13, JIS SUS 890L Safety Relief Valves

Safety Relief Valves, Inconel Safety Relief Valves, Inconel 600 Safety Relief Valves, INCONEL WERKSTOFF NR. 2.4816 Safety Relief Valves, Inconel 600N06600 Safety Relief Valves, Inconel 2.4816 Safety Relief Valves, UNS N06600 Safety Relief Valves, Inconel 600 Safety Relief Valves, API 600/ BS1414, ALLOY 600 Safety Relief Valves, ASME B 16.5 Safety Relief Valves Dealers in India.. Read more

We are the one of the top most manufacturers of different types of Industrial Safety Relief Valves, We have a large inventory of Safety Relief Valves in a variety of options., Largest Suppliers of Titanium Gr2(B367 Gr C2) Safety Relief Valves, Titanium Gr3(B367 Gr C3) Safety Relief Valves, Titanium TA1, TA2, Titanium Gr.5, Gr6 Safety Relief Valves,Gr7 ,Gr12, Titanium TC4,TA9,TA10 Dealers in India.. Read more

Brass Safety Relief Valves, brass Safety Relief Valves price list in India, brass Safety Relief Valves 1/2, 1 inch brass Safety Relief Valves, brass Safety Relief Valves 3/4, brass Safety Relief Valves price list india, 3 inch brass check valve, brass Safety Relief Valves price list, 1/2 inch Safety Relief Valves, 4 brass Safety Relief Valves, 3/4 brass Safety Relief Valves, 4 inch brass Safety Relief Valves, 2 inch brass Safety Relief Valves Read more

Experience Of 50 Years In Copper Knife Gate Valve, We have a large inventory of Copper Safety Relief Valves, Copper 90/10 Safety Relief Valves, Copper 70/30 Safety Relief Valves, Copper Cu-Ni 70/30 Safety Relief Valves, Copper 90/10 Safety Relief Valves Dealers, Copper 70/30 Safety Relief Valves Suppliers, Copper Cu-Ni 70/30 Safety Relief Valves Manufacturer, Copper Cu-Ni 90/10 Safety Relief Valves Manufacturers in India. Read more

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch Dealers, Distributors, Exporters, Suppliers india, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions,

Tags : safety valve, safety relief valve, pressure relief valve, spring loaded safety valve, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, safety relief valve 10 psi, safety relief valve 5 psi, safety relief valve 15 psi, 1/4 inch safety relief valve, pressure relief valve 1 inch, pressure relief valve 2 inch, pressure relief valve 6 inch, pressure safety valve manufacturers, spring loaded safety valve manufacturers, flanged pressure relief valve, water heater pressure relief valve, boiler pressure relief valve, vacuum relief valve, pressure relief valve weight, pressure safety valve sizing, safety valve dimensions, pressure safety valve dimensions

8613371530291

8613371530291