leser pressure safety valve factory

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

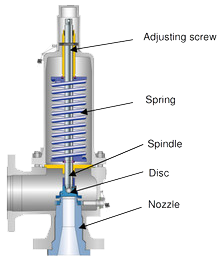

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

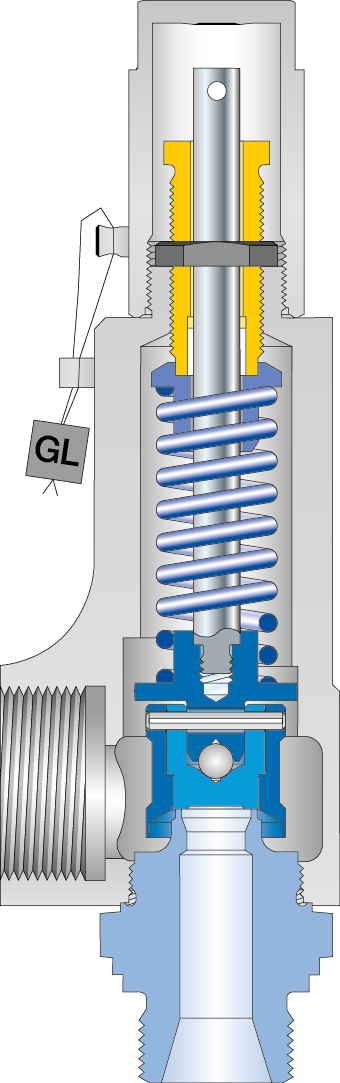

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

The primary purpose of a pressure relief valve is to protect life, property and the environment. Pressure relief valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of pressure relief valves differs depending on the main type or loading principle of the valve. The main types of pressure relief valves are spring-loaded, weight-loaded and controlled pressure relief valves.

Regardless of the type or load, pressure relief valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

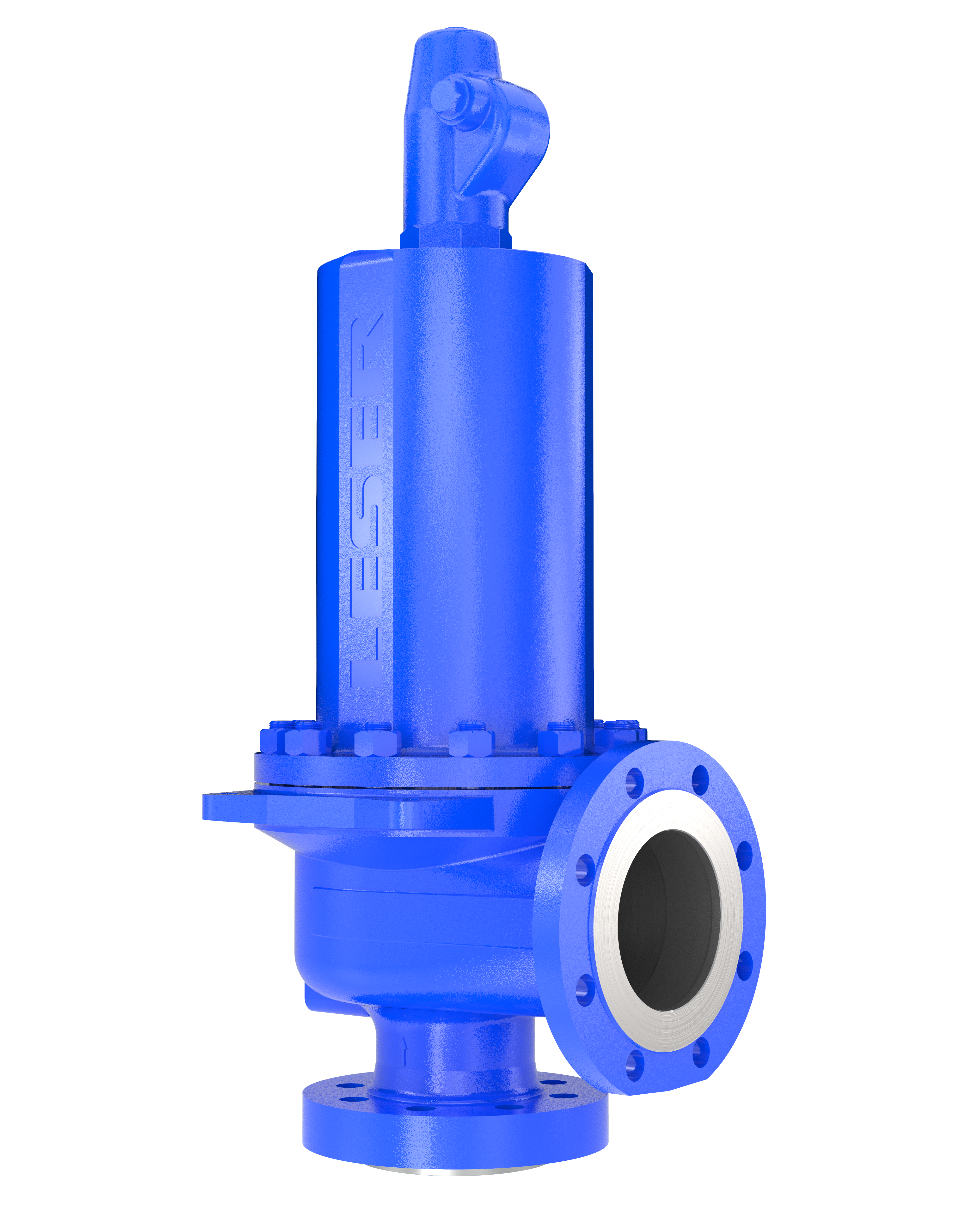

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME VIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Twelve subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

LESER US supplies representatives, distributors, and end customers in North America. This subsidiary provides on-site manufacturer expertise for all your commercial and technical needs. LESER US stocks 7 million USD worth of safety valves and spare parts at its location in Charlotte, North Carolina. This allows LESER US to deliver safety valves and spare parts from the regional warehouse within one week or, in emergencies, on the same day.

Loyalty by transformation. With almost 200 years of experience, LESER ranks among the pioneers of mechanical engineering in Germany. The company started in Germany in 1818 as a brass foundry and developed a product portfolio of components of mechanical equipment and machines during the "industrial revolution".

In 1885 the company developed its first safety valve for the protection of steam boilers. Even at that early date, LESER products were working for the safety of man and the environment. Since the 1970"s LESER has specialized only in safety valves.

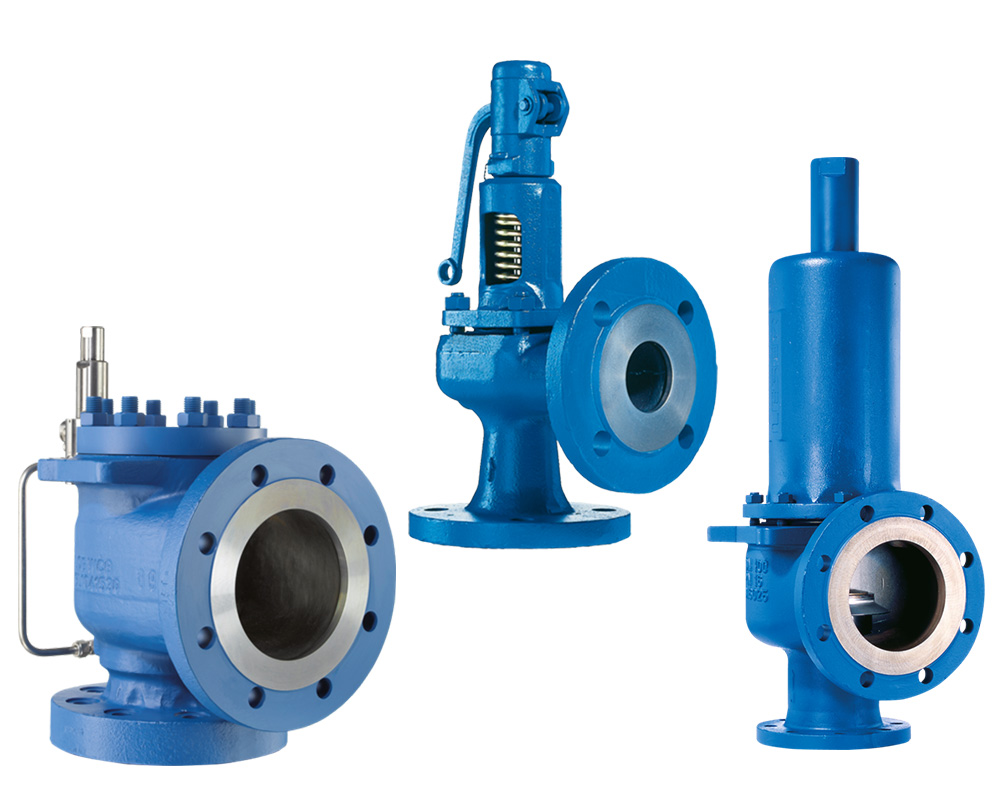

Safety valves from the API product group meet all the requirements of API 526 such as standardized capacity, nominal diameter, and center to face dimensions which offers 100% compatibility. Because of their robust construction, they are especially suitable for being constructed from special materials such as Duplex, Monel, and Hastelloy.

API 526 is a purchase specification in which the nominal diameters, flange pressure ratings, center to face dimensions, flow areas, body and spring materials and their service limits are stipulated for "API safety valves" API safety valves are used worldwide in the petrochemical industry, both on- and off-shore. These applications are characterised by standardised plants, blow-down systems and long pipework sections. The LESER type 526 combines the requirements of the API standards and the ASME Code with the tried and tested service reliability of the LESER range.

Safety valves from the Clean Service product group were specially developed for the food, beverage, and pharmaceutical industries and meet all the relevant standards and regulations such as DIN 11866 or ASME BPE. With a low deadspace inlet area, the unique LESER HyTight assembly, and the optional pneumatic lifting device you have very good cleanability (CIP, SIP). With a large selection of aseptic connections (threaded, flanged, or clamped) the valve can be optimally fitted to different requirements.

The safety valves of the 48x series can be fitted with manually lockable lifting devices H4 to hold open at a small lift, and with pneumatic lifting devices H8 for automated systems (CIP process).

Safety valves from the High Performance product group offer especially high capacity for their size. With a large quantity of nominal diameters (DN), pressure ranges and product options, they have proven themselves as a universal safety valve for many applications.

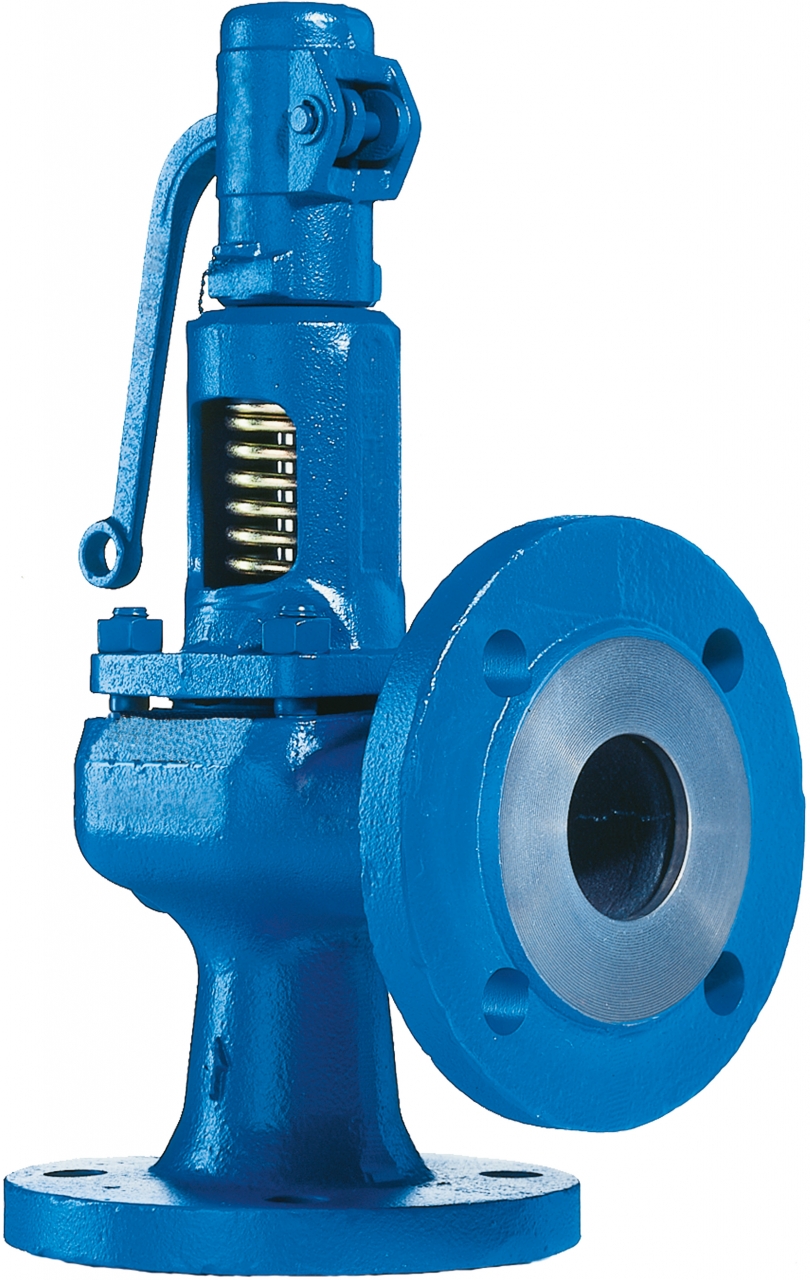

Full Flanged Safety Valves with Flanged Connections open rapidly to the full design lift.They are used in particular for vapours and gases, in applications where the maximum mass flow has to be discharged rapidly. LESER type 441 is suitable for almost any industrial application, and are worldwide one of the best selling spring-loaded flange type safety valves.

Type 441 ANSI: Cast steel construction with ANSI flanges. Two body materials: stainless steel and cast steel. Center to face length in accordance with API 526, greater discharge capacity than standard API valves.

PTFE-lined safety valves from the Critical Service product group are utilized for highly corrosive media such as chlorine, acids, and lyes. With their highly resistant lining they offer a safe solution for corrosive media.

The product group Compact Performance includes threaded and flanged safety valves with compact dimensions for economical protection of small and midsized capacites. Due to its many orifice diameters, seals, and connections this product group offers a very wide area of application.

Type 437:Safety relief valve spring loaded for small mass flows (e.g. thermal expansion and overflow). Body material: stainless steel, 430 chrome steel.

Type 459/462Full lift safety valve spring loaded for the medium mass flow range (e.g. small scale or pilot plant). Two body materials: stainless steel or steel.

Change-over valves from the Best Availability product group increase plant availability.Change-over Valves are used when a plant shutdown is impossible or undesirable for process engineering or commercial reasons. With change-over valves, it is possible to switch over between parallel safety valves without interrupting operation, so as, for example, to perform maintenance work. The design of the change-over valves ensures: low pressure losses on discharge flow (3% criterion) adequate open passage in any position during the change-over process stable operation of the downstream safety valves The combination of LESER change-over and safety valves has been comprehensively tested on full flow test labs.

Safety valves from the Modulate Action product group feature a standard or proportional opening characteristic. They minimize medium loss when opening and are used for protection from pressure peaks, thermal relief, and liquids.

Relief and Safety Relief Valves with Flanged Connections are ideal relief valves for medium mass flows. Their large proportional range leads to consistent functioning and relief of pressure peaks, particularly with liquids. Both proportional and safety relief valves are characterized by particularly stable operation.

Since the 1980"s LESER has been the number one supplier for safety valves in the world and strengthens this position each year. LESER currently has 7 different locations worldwide and continiues to expand its international presence in an effort to supports its growing customer base.

High performance relief valves, compact relief valves, high efficiency relief valves, modulate action relief valves, clean service relief valves, critical service relief valves.

LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide, backed by more than 200 years of tradition. LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the API, PED and ASME VIII. Major companies in the oil and gas, petrochemical, chemical, energy, technical gases, LNG/LPG etc use LESER safety valves. LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany.

LESER safety valves are used by leading petrochemical, industrial gas, machine building, oil and gas production, chemical, food and pharmaceutical companies. LESER offers spring-loaded and pilot-operated safety valves for all industrial applications according to PED and ASME VIII as well as application-based solutions for special requirements. The LESER product range offers the right product for almost every application.

LESER safety valves are developed and manufactured in Germany. The LESER product range offers the right product for almost every application. Multiple options and special materials complete the range as a well as client-specific solutions.

Attractive Pricing - As the largest safety relief valve manufacturer in Europe (and #3 worldwide), LESER has the ability to produce high-quality products in a cost-efficient manner through large batch sizes and full automation of production; this allows LESER to pass on cost savings to the customer.

LESER Authorized Repair Centre (LARC) Network - More than 30 LARCs in North America provide the end-user with access to authorized, reliable, and convenient local support for the repair of their installed base.

LESER offer spring loaded and pilot operated safety valves for all industrial applications according to the European Pressure Equipment Directive 2014/68/EU (CE-mark) and ASME VIII Division 1 (UV-Stamp).

Major global companies in chemicals, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding as well as heating and air conditioning industries use LESER safety valves.

8613371530291

8613371530291