leser pressure safety valve for sale

The primary purpose of a pressure relief valve is to protect life, property and the environment. Pressure relief valves are designed to open and release excess pressure from vessels or equipment and then close again.

The function of pressure relief valves differs depending on the main type or loading principle of the valve. The main types of pressure relief valves are spring-loaded, weight-loaded and controlled pressure relief valves.

Regardless of the type or load, pressure relief valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

Well-known companies worldwide rely on LESER safety valves. With its sole focus on overpressure protection, the safety valve specialist LESER is one of the international market leaders.

The primary purpose of a safety valve is to protect life, property and the environment. Safety valves are designed to open and release excess pressure from vessels or equipment and then close again.

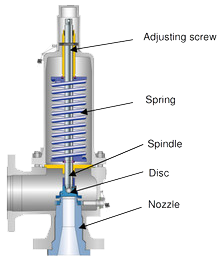

The function of safety valves differs depending on the load or main type of the valve. The main types of safety valves are spring-loaded, weight-loaded and controlled safety valves.

Regardless of the type or load, safety valves are set to a specific set pressure at which the medium is discharged in a controlled manner, thus preventing overpressure of the equipment. In dependence of several parameters such as the contained medium, the set pressure is individual for each safety application.

In addition to the small installation space of the above-mentioned compressors, they should be completely covered by an acoustic enclosure to reduce noise emissions. In order to reduce the size of the very cost-intensive sound enclosure, AERZEN requires special valves that are adapted to the available small installation space. Compressors are discontinuous machines for pressure generation.

In order to ensure that occurring pulsations do not impair the function of the safety valve, the set pressure of the valve is adjusted accordingly and an appropriate distance to the pressure line is ensured by design.

The LESER solutionAs a renowned manufacturer of safety valves, it is advantageous to be able to react flexibly to the above-mentioned concerns, primarily to the small installation space, with its portfolio. Being able to change the installation position of safety valves is a clear advantage for the compressor designer. They are much more variable in their design and construction options and can also respond more flexibly to special customer specifications. If the progressive modularization of compressors requires more compact designs, safety valves in different mounting positions, for example, can be an answer to the problem, unlike the classic upright position. In addition, the spindle guide plays a special role here. The friction at the guiding points must be reduced as much as possible so that the spindle runs smoothly. Otherwise, a safety valve can only be installed vertically.

Why LESER safety valves?For a global acting OEM like AERZEN, a specialist like LESER, who has not only the knowledge but also the necessary approvals, is an important component for success. LESER offers a global approval concept that allows safety valves to be used regardless of location. When ordering safety valves, only the applicable regulations must be specified in order to ensure appropriate labeling and material selection. In addition, LESER has tested and approved further installation positions in addition to the conventional installation situation, standing on the inlet pipeline. For example, some types of valves may be installed with a horizontal stem or even upside down, e.g. Types 526 and 441. For horizontal installation, care must be taken to align the outlet. Liquids, e.g. in the form of condensate, should be able to drain off downwards to avoid back pressures and even corrosion. When installed upside down, the inverted weight forces are corrected by correction factors. LESER offers not only safety valves with basic documentation and accessories but also other special documentation and options. From the “Fugitive Emission Test” with helium up to 3.2 ship class castings and from back pressures up to more than 200 bar-g to high pressure heating jackets for up to 30 bar-g, LESER sales engineers develop solutions for customer specific applications as described above for AERZEN.

Loyalty by transformation. With almost 200 years of experience, LESER ranks among the pioneers of mechanical engineering in Germany. The company started in Germany in 1818 as a brass foundry and developed a product portfolio of components of mechanical equipment and machines during the "industrial revolution".

In 1885 the company developed its first safety valve for the protection of steam boilers. Even at that early date, LESER products were working for the safety of man and the environment. Since the 1970"s LESER has specialized only in safety valves.

Since the 1980"s LESER has been the number one supplier for safety valves in the world and strengthens this position each year. LESER currently has 7 different locations worldwide and continiues to expand its international presence in an effort to supports its growing customer base.

High performance relief valves, compact relief valves, high efficiency relief valves, modulate action relief valves, clean service relief valves, critical service relief valves.

The Leser safety valve is a product safety valve. This safety valve product line is manufactured by the manufacturer Leser, a very famous safety valve manufacturer in Germany. The manufacturer of Leser, specializes in only one product, which is a safety valve.

German Leser safety valves are widely used in a variety of industries. This Leser safety valve product is applied to a number of industries such as: in the petroleum, chemical, pharmaceutical, energy, food production, shipbuilding, heating industries...

Leser full valves are produced in a variety of lines and models, with each type, each line will have separate applications. Each line, model will have a different design and structure, and different materials.

Safety valve company Leser is a German manufacturer of safety valves Leser. Safety valve company Leser is the largest safety valve manufacturer in Germany, the largest in Europe, in addition to being one of the world"s leading safety valve manufacturers.

Leser products are manufactured according to different standards, depending on the local supply, Leser"s products will be produced according to different standards. , China for these two markets.

First of all, let"s find out what is a safety valve? Safety valve is a safety device used as a safety device for the working system. The safety valve is not responsible for regulating pressure, it only has the function of releasing pressure in an overpressure situation.

Safety valves are used to ensure the safety of the system, people and the environment. The safety valve is designed to release excess pressure from the system until the pressure returns to normal and in the normal state the safety valve is closed.

Why is there a safety valve symbol? When installing a system, it is necessary to first create a drawing to build up the overall diagram of the system. In the system will install many different equipment, machines, valves. Therefore, each device will be designated with a unique symbol to identify the correct equipment and installation. So what is the symbol of the safety valve, you can observe through the image

The Leser API safety valve product has the ability to work in extreme temperature and pressure conditions, the ability to work in high and low temperatures is very good, the temperature range of this product line it is -268 degrees Celsius to 538 degrees Celsius and the working pressure of the valve can be up to 0,12 bar to 413bar.

This product line is a series of pilot valve operated safety valves. This series of products are used with high capacity applications, this safety valve has the highest discharge capacity in its class.

This valve is as its name suggests, highest discharge capacity, operating pressure up to 96% of set pressure, back pressure up to 90% of set pressure.

Designed with sizes from DN25 to DN200, made from alloy steel materials, WCB, CF8M, SA 352 LCB, etc. The working conditions of this pressure relief valve line are from -48 degrees Celsius to -200 degrees Celsius. 2,5 degrees Celsius, pressure from 426bar to XNUMXbar.

This safety valve product line features a compact design, this safety valve product is often applied to compact applications, with sizes from DN15 to DN40 and a variety of connections, flanges and threads.

Low pressure safety valve products are applied to low pressure dynamic applications, the working pressure level of this product line can only work to the highest pressure of 160bar.

Microbiological safety valve is a pressure reducing valve product line that is applied from the microbiological stainless steel material line with a smooth surface to ensure food safety and hygiene, this safety valve product is often applied to various applications. food, beverages and pharmaceuticals.

Microbiological safety valve products have the following types: 481, 483, 484, 485, 488. Different types with different designs, sizes and capacities, so the application with each type will be different.

This safety valve is manufactured with PTFE liner, PTFE liner design, as known PTFE material has good high temperature working ability, plus good corrosion resistance, thus helping to produce This safety valve product can perfectly be installed in the system with corrosive nature.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

LESER offer spring loaded and pilot operated safety valves for all industrial applications according to the European Pressure Equipment Directive 2014/68/EU (CE-mark) and ASME VIII Division 1 (UV-Stamp).

Major global companies in chemicals, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding as well as heating and air conditioning industries use LESER safety valves.

8613371530291

8613371530291