lever safety valve for sale

Steel safety relief valves for air, gas, steam, liquid and vacuum service that meet ASME Section VIII, �UV�; Section I, �V�, are National Board certified and PED certified for non-hazardous gas

Steel safety relief valves for air, gas, steam, liquid and vacuum service that meet ASME Section VIII, �UV�; Section I, �V�, are National Board certified and PED certified for non-hazardous gas

Kunkle 900 Series valves are versatile workhorses. They’re available in different materials and have a few cap and lever options, so you can use them for numerous air, steam, liquid, or gas services. Since there’s such a wide selection of these 900 Series valves, it can be a challenge to determine which one is the best fit for your application.

When making your selection, keep in mind that certain service conditions may require you to use a specific valve. For example, Kunkle engineering specifies that only entirely stainless steel valves can be used for potable water services to ensure lead isn’t released to drinking water supplies.

Keep in mind code restrictions prevent you from using a screwed cap for some applications. ASME Section VIII Division 1, UG136(a)(3), requires that you use a lift lever for valves on water service over 140°F as well as all air and steam services. For water service, a packed lift lever is required — for air or steam, you can use an open lever.

Plain levers, or open levers, are ideal for services that are safe to vent into the atmosphere and require a manual lifting device. You can only use these valves for steam or air services, which ASME Codes require to have levers.

Packed levers are suitable for most air, steam, liquid, and gas services. They provide the benefits of the plain lever, as they allow for ASME code-mandated manual operation, as well as the threaded cap, because they guarantee that process media won’t be released into the atmosphere.

In addition, you can use packed levers for water services operating at or over 140°F. In these instances, ASME Section VIII requires safety relief valves to have a lever since it may see partial steam in a relief scenario. Plain levers aren’t suitable in these situations since they aren’t fully enclosed, so packed levers are the only viable option.

Kunkle 900 Series valves are only certified for ASME Section VIII steam service — sometimes called off-boiler service — and are well-suited for things like steam lines and heat exchangers. As such, they cannot be used directly on a boiler or any other application that would be covered by the ASME Section I codes.

If you’re looking for a valve to use for a Section I application, check out the Kunkle 6010 series. They come equipped standard with a lever and are available in a variety of sizes.

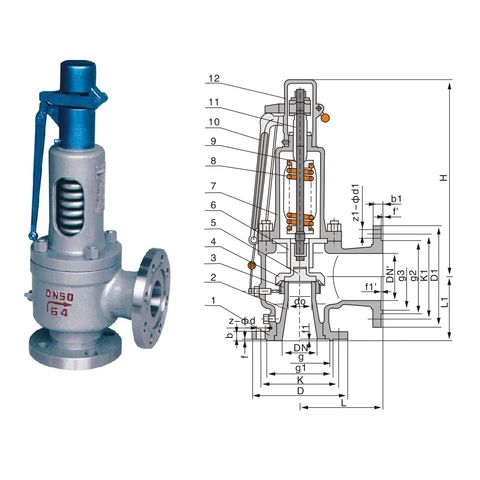

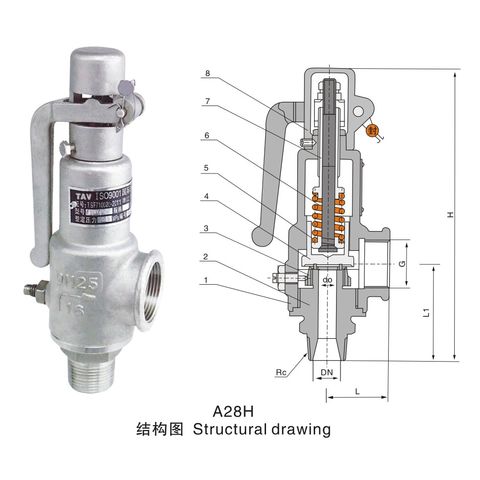

A lever safety valve consists of a valve body that has flange fixed to the steam boiler. The valve seat made of bronze is screwed to the body. The valve seat contains the valve which is also made up of bronze. Since the valve seat and valve is made up of same material, the rusting is prevented. The strut transmits the thrust on the valve. One end of the lever is fixed as fulcrum. The other end is attached to the load. A guide is also provided to move the lever vertically.

In lever safety valve, during the normal pressure inside the boiler, the valve remains in the seat. The thrust applied by the strut made the valve to stay in the seat until the steam pressure exceeds the safe working pressure.

As the steam pressure inside the boiler exceeds the safe working pressure, the valve rises above the seat and steam blows off outside the boiler. The valve returns back to its normal position when the pressure inside the boiler falls back to its normal pressure.

The valve rises in the condition when the steam pressure force becomes greater than the thrust applied by the strut on the valve. The thrust on the valve can be varied by varying the load attached at one end of the lever.

Here you have learned about lever safety valve, its main parts, working, and where it is used. If you found this piece of information useful then don’t forget to like and share.

Choose these valves for small steam-heating boilers requiring pressure relief between 5 psi and 12 psi. They spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. All have a bronze body for durability and a long service life.

8613371530291

8613371530291