model steam engine safety valve price

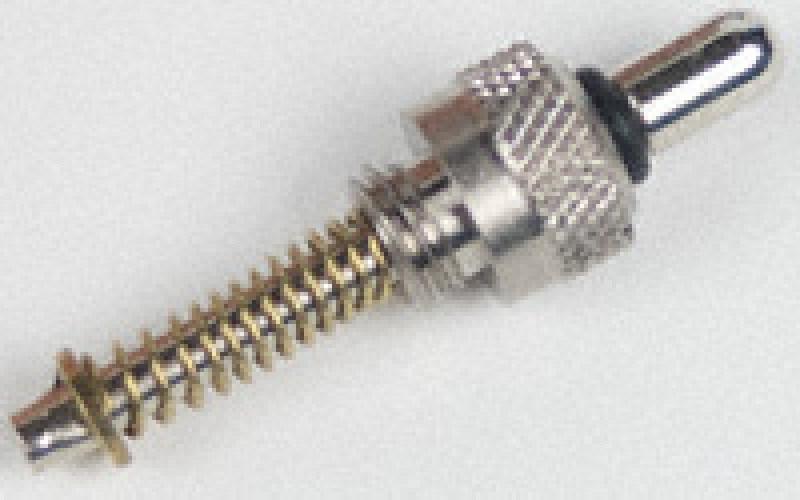

Note: these have simple adjustable spring loaded relief balls/surfaces that progressively release pressure when the setting is passed. They are not "pop"valves that trigger at a set pressure.

These safety valves use a stainless steel ball and spring in a brass body. They are set to blow at approximately 60psi. Threaded 5/16-27 Female (1/16 NPT).

After a boiler has been engineered, built and tested for a given operating pressure there is only one reliable way to prevent operation of the boiler above this design pressure. This is a safety valve. The safety valve should be sized so that a single valve can handle the maximum steam production rate of the boiler and once open prevent boiler pressure to continue to rise. Standard operating procedure for the last century has been to install two safety valves on the boiler, one set 3-5 lbs below the design pressure and one valve set at the design pressure.

The 1st valve listed below is a true adjustable differential pop valve. The differential is adjured through the differential rings lock screw hole, from 3 PSI to whatever the operator desires. The pressure of the valve can be adjusted from 40 to 200 PSI.

The other valves listed are adjustable for release pressure and have a "pop" action: The pressure differential is not adjustable on these valves. If the valves are operated above their nominal pressure, the set-reset differential increases. If operated at lower pressure, the differential decreases to the point of disappearing about 10-15% below nominal pressure.

300LPM01-L is a safety relief valve for steam service on unfired pressure vessels. It is also used on Pressure Reducing Stations, Accumulators, Cleaners, and Distillers. Meets ASME code, Section VIII.

Model 300LPM01-K is a safety relief valve for air, gas and vapors. It is used on compressors, receivers, burners, dryers and other piping systems. Meets ASME code, Section VIII.

ASME Section IV Safety Relief Valve for protection of small hot water heating boilers and hydronic heating systems. Made from proven ASTM grade Brass and Bronze materials with decorative chrome finish.

ASME Section IV capacity certified bronze safety relief valve for protection of hot water heating boilers, systems and similar equipment. It can be Pre-set to any pressure ranging between 20 to 80 psig (1.4 to 5.5 bar) at 250�F (121�C) max

ASME Section IV capacity certified bronze safety relief valve for protection of hot water heating boilers, systems and similar equipment. It can be pre-set to any pressure ranging from 15 to 160 psig (1 to 11 bar) at 250�F (121�C) max.

ASME Section VIII design certified Safety Valve to protect portable steam vessel applications such as autoclaves, sterilizers and pressure cookers against excess pressure build-up. Made from proven ASTMgrade Brass with optional decorative chrome finish.

ASME Section I & VIII air and steam capacity certified safety valve for overpressure protection of steam power boilers, deaerators, accumulators, pressure reducing stations and pressure piping systems.

Medium capacity safety valves protect ASME Section IV low pressure steam heatingboilers. Cast bronze, full nozzle design features PTFE faced elastomer soft seatingfor dependable operation.

The Apollo� 13 Series bronze low pressure steam safety valve is designed to meet ASME Section IV code requirements for protection of steam heating boilers, systems and similar equipment.

The Apollo� 13 Series bronze low pressure steam safety valve is designed to meet ASME Section IV code requirements for protection of steam heating boilers, systems and similar equipment.

The Apollo� 14 Series is a 100% American Made Bronze Safety Relief Valve for protection of steam boilers, low pressure, high volume blowers, compressors and vacuum systems.

ASME Section I and VIII capacity certified safety valve for overpressure protection of steam power boilers, systems, pressure vessels, piping and similar equipment. Suitable for steam, air and non-hazardous gases.

ASME Section I/Section VIII capacity certified safety valve for overpressure protection of steam power boilers, steam and air systems, pressure vessels, piping and similar equipment. Compact and economic design ideal for OEM applications.

ASME Section VIII capacity certified safety relief valve for overpressure protection of steam, air/gas and liquid systems, pressure vessels, piping and similar equipment.

Drip Pan Elbows connect to the safety valveoutlet and direct steam discharge into the discharge piping, allowing condensate to drain away. Isolates the valve from piping stresses.Highly recommended in steam service.

ASME Section I & VIII air and steam capacity certified safety valve for overpressure protection of steam power boilers, deaerators, accumulators, pressure reducing stations and pressure piping systems.

High volume air relief valves designed for low pressure air and gas service. Ruggedbronze construction features elastomer soft seating and TFE coated discs fordependable operation.

ASME Section VIII capacity certified relief valve foroverpressure protection of compressors, intercoolers,dryers, receivers, control and instrument air lines andsimilar equipment.

ASME Section I and VIII capacity certified safety valve for overpressure protection of steam power boilers, systems, pressure vessels, piping and similar equipment. Suitable for steam, air and non-hazardous gases.

ASME Section I/Section VIII capacity certified safety valve for overpressure protection of steam power boilers, steam and air systems, pressure vessels, piping and similar equipment. Compact and economic design ideal for OEM applications.

ASME Section VIII capacity certified safety relief valve for overpressure protection of steam, air/gas and liquid systems, pressure vessels, piping and similar equipment.

High flow vacuum relief valves feature one piece cast bronze bodies, Teflon coated discs and elastomer soft seating provide accurate and dependable operation. Ideal for use with high volume vacuum systems, bulk hauling tanks and trailers, powdered solids/bulk handling and pneumatic conveying equipment.

The Apollo� Model VR Vacuum Relief valve is designed to automatically vent a system should avacuum occur. It prevents siphoning of water from the system and/or tank collapse.

Choose these valves for small steam-heating boilers requiring pressure relief between 5 psi and 12 psi. They spring fully open at the set pressure and remain open until the system pressure is restored below the set pressure. All have a bronze body for durability and a long service life.

8613371530291

8613371530291